Multilayer coil component and method for manufacturing the same

A technology of stacking coils and manufacturing methods, applied in coil manufacturing, transformer/inductor components, inductor/transformer/magnet manufacturing, etc., can solve the discontinuous gap between the magnetic ceramic layer and the inner conductor layer, and cannot achieve DC resistance, It is difficult to obtain problems such as DC resistance, and achieve the effect of small variation in characteristics, prevention of migration, and suppression of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

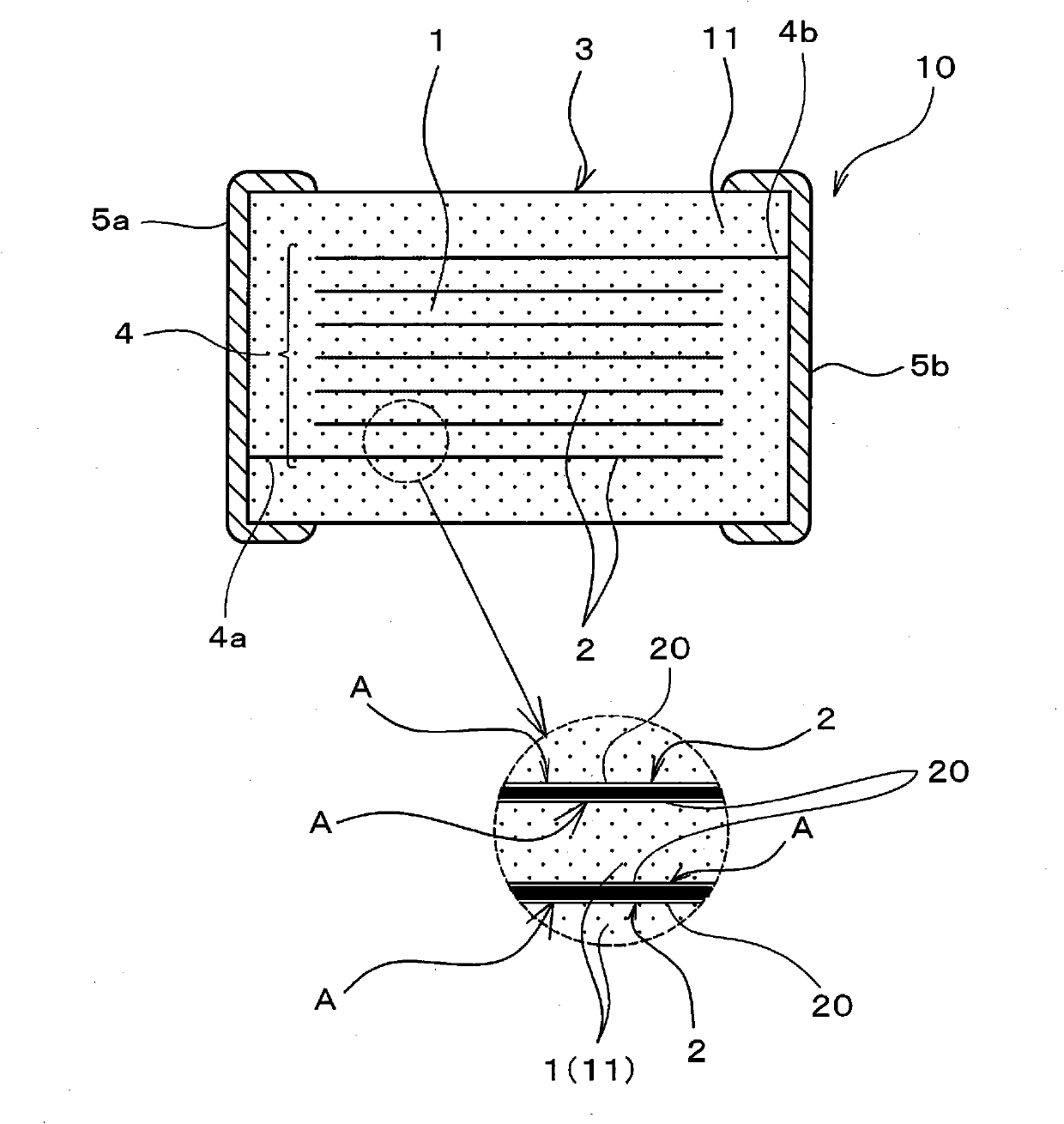

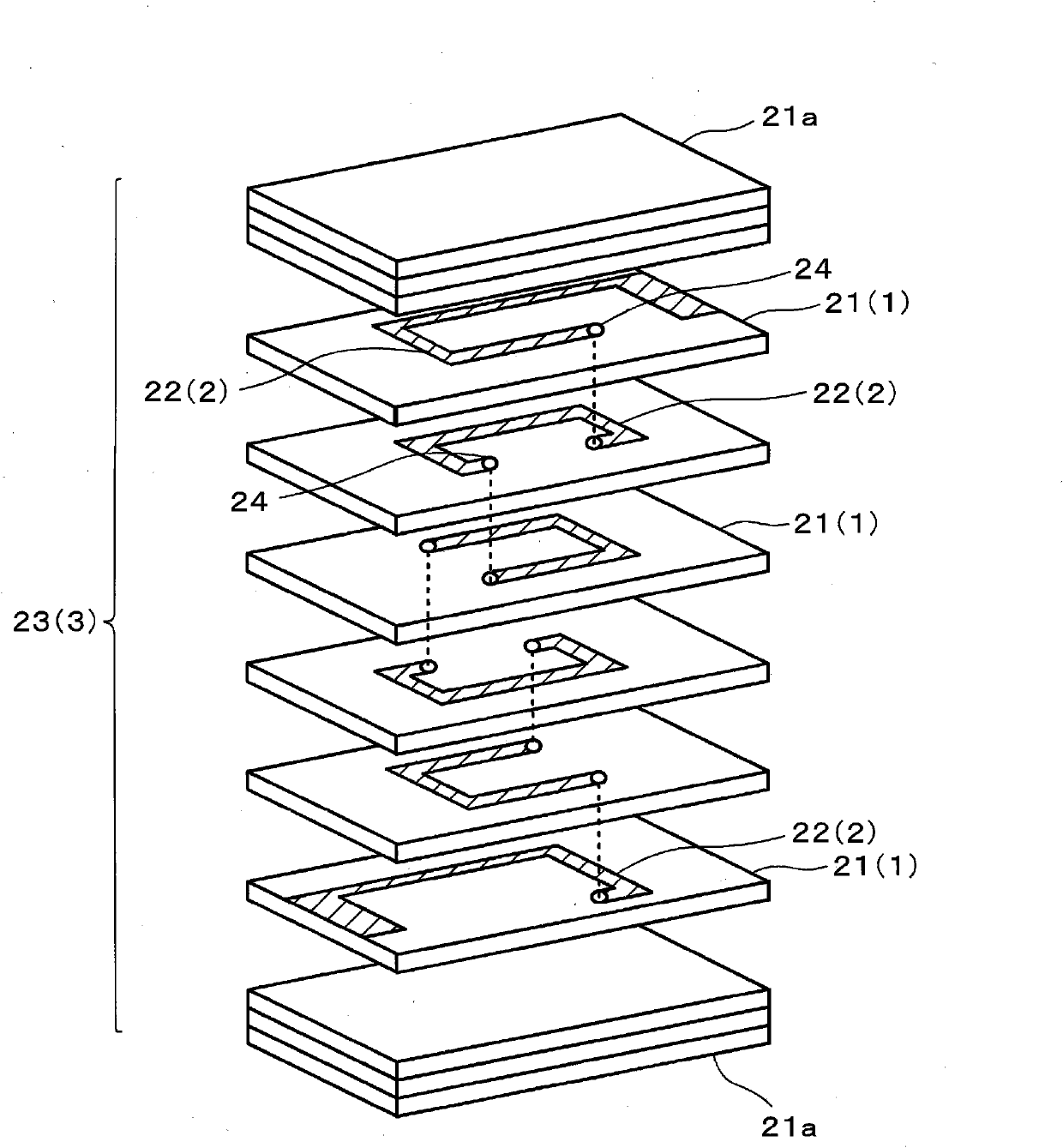

[0056] figure 1 is a laminated coil component (in this embodiment, a layer

[0057] A cross-sectional view of the structure of the stacked impedance element), figure 2 It is an exploded perspective view showing the main part.

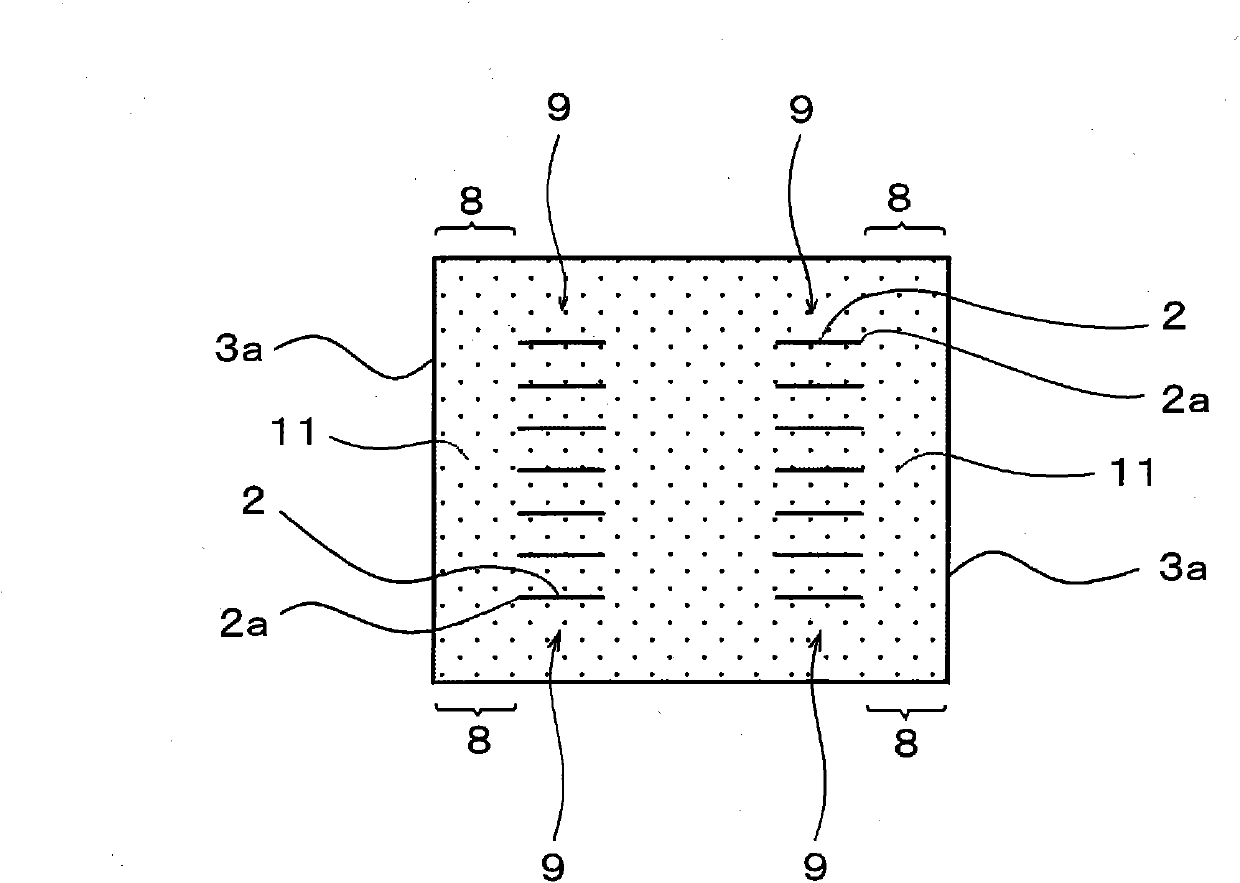

[0058] This laminated coil component 10 is provided with a helical coil 4 inside a magnetic ceramic element 3, and the helical coil 4 is made of Ag, which is arranged with a magnetic ceramic layer (a NiCuZn ferrite layer in this embodiment) 1 interposed therebetween. It is formed by connecting two layers of the inner conductor which is the main component.

[0059] In addition, a pair of external electrodes 5 a and 5 b which are electrically connected to both ends 4 a and 4 b of the helical coil 4 are arranged at both ends of the magnetic ceramic element 3 .

[0060] like figure 1 As schematically shown, in this laminated coil component 10, a metal film (Ni film in this embodiment) 20 is distributed on the surface of the inner conductor 2, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com