Diaphragm for micro-speaker and method of manufacturing the diaphragm

A manufacturing method and technology of diaphragm, applied in the direction of diaphragm structure, flat diaphragm, polymer material diaphragm, etc., can solve the problems of time waiting, deviation of bonding position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Reference will now be made to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

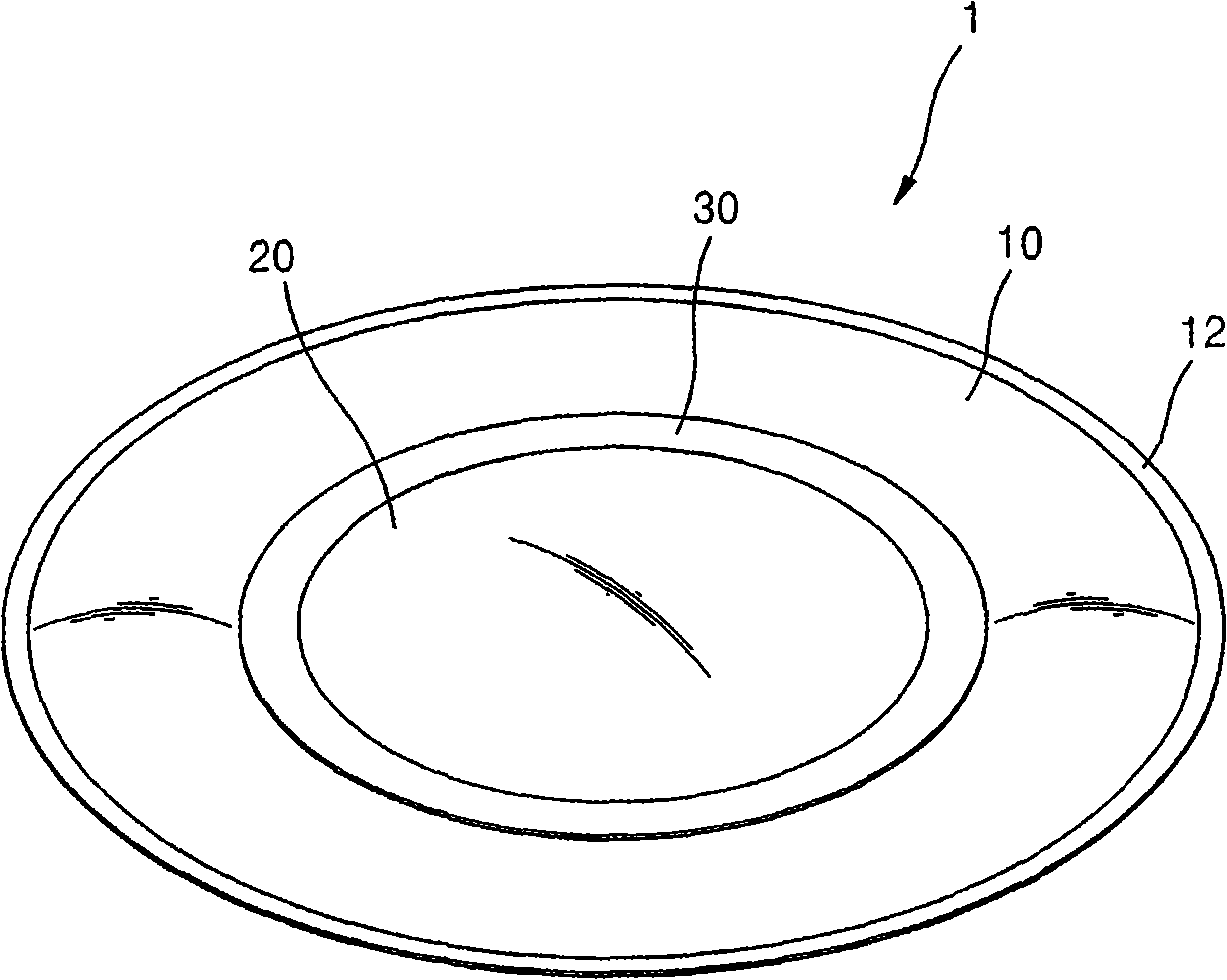

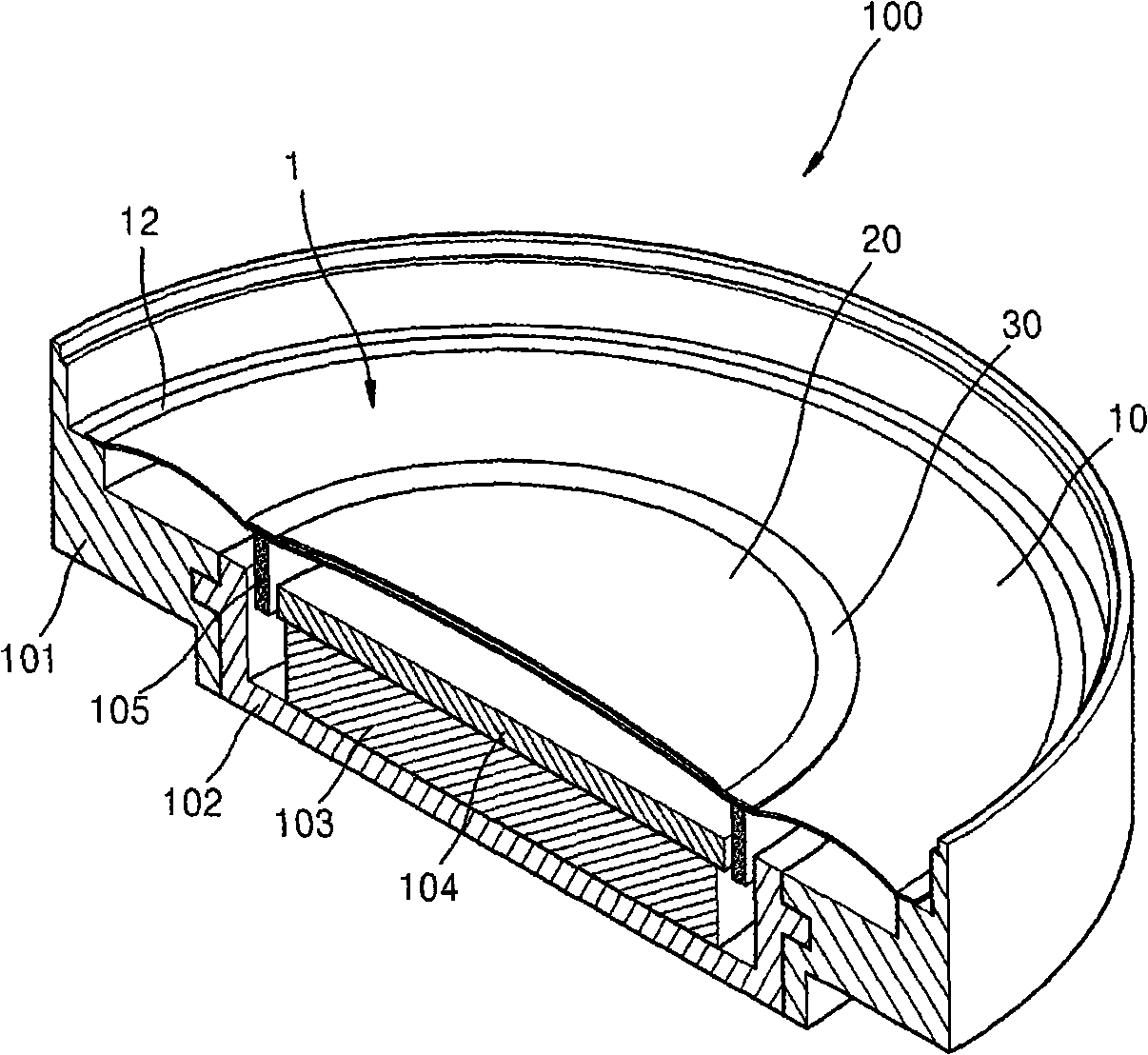

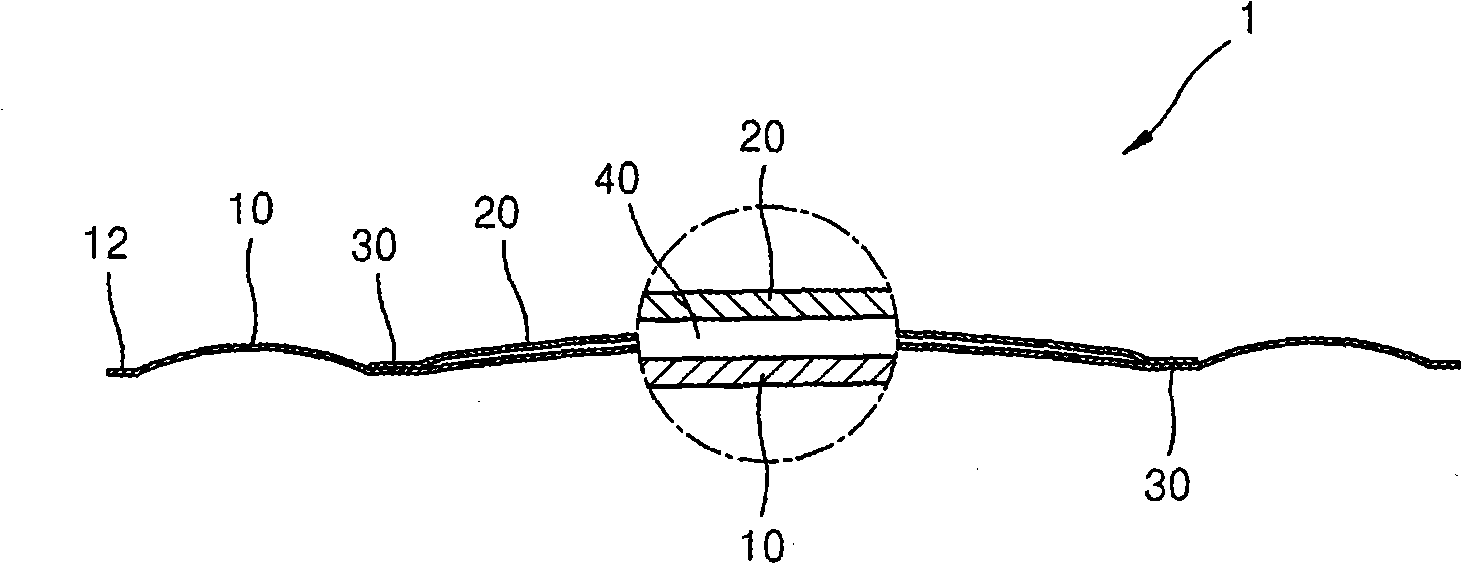

[0030] figure 1 is a perspective view of a diaphragm of a micro horn according to an embodiment of the present invention, figure 2 for adoption figure 1 Cutaway view of the microhorn of the diaphragm, and image 3 for figure 1 A cross-sectional view of the diaphragm.

[0031] Diaphragm 1 is a micro-speaker device for a small audio device, such as a mobile phone, a notebook computer, an MP3 player, an earphone, and the like. The diaphragm 1 includes several thin films formed of a polymer compound and stacked on top of each other.

[0032] Due to the predominantly small size of the diaphragm 1 of the microhorn, the membranes have different shapes and are formed from different materials in order to achieve the desired sound characteristics. Although the diaphragm may be formed of a single thin film. In this embodiment, however,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com