Soft magnetic material, powder magnetic core and method for manufacturing the same

A soft magnetic material, powder magnetic core technology, applied in inductance/transformer/magnet manufacturing, magnetic core/yoke, inorganic material magnetism, etc., to achieve high magnetic permeability, improved productivity and economy, and low loss of core resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

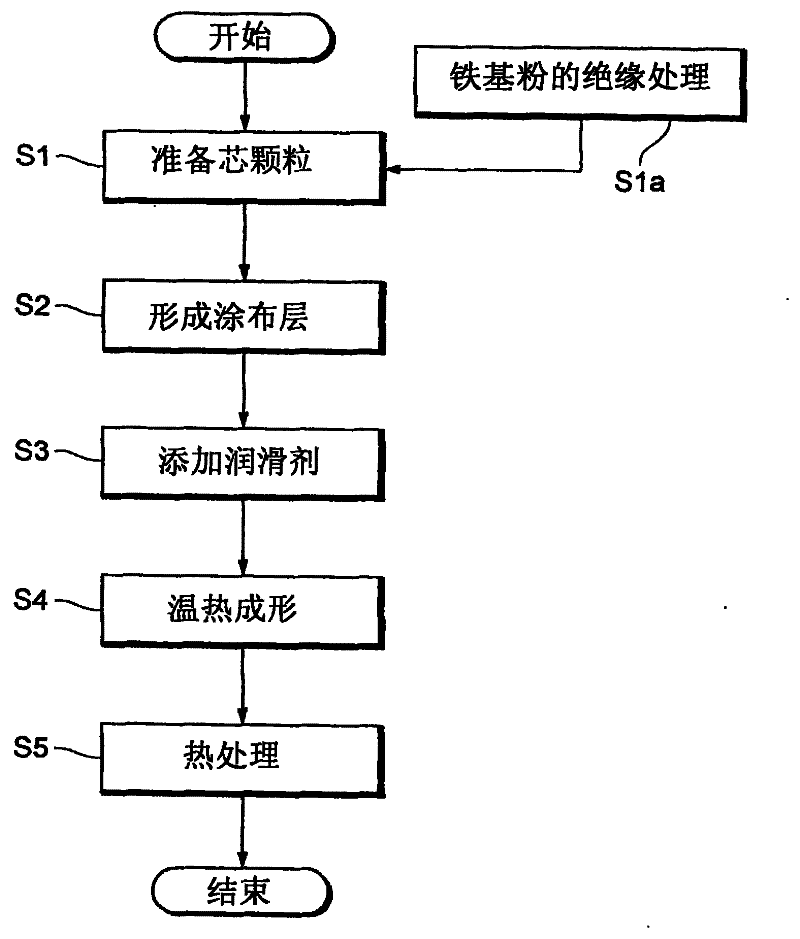

Method used

Image

Examples

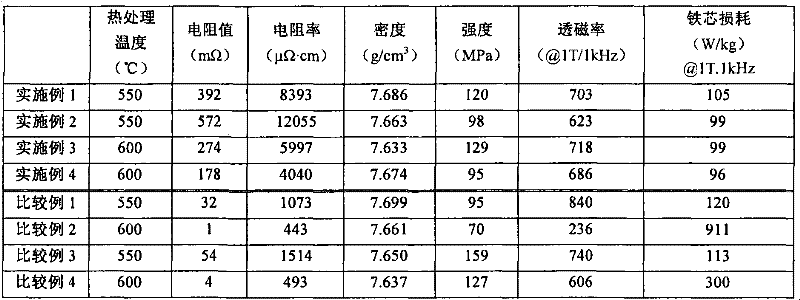

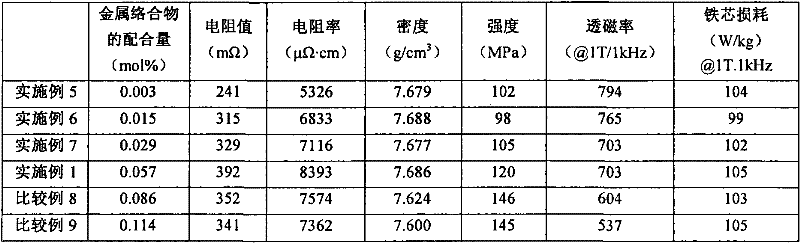

Embodiment 1

[0064] First, pure iron with an insulating film (manufactured by Hoganas AB, trade name: Somaloy 700, average particle diameter 200 μm) was prepared as a core particle having soft magnetic particles mainly composed of iron and a layer of iron in the soft magnetic layer. An insulating film formed on the surface of a particle. Next, zirconium tetraacetylacetonate (zirconium tetraacetylacetonate), which is a metal complex, was put into toluene to prepare a coating liquid containing the metal complex. A coating solution containing a metal complex was coated on pure iron with an insulating film, and dried to form a coating layer, thereby producing the soft magnetic material of Example 1. In addition, the compounding quantity of the metal complex was 0.057 mol% at the ratio of zirconium to the iron contained in the pure iron with insulating film.

[0065] Thereafter, 0.1% by weight of zinc stearate was added as a lubricant to the soft magnetic material of Example 1, and the mixture...

Embodiment 2

[0068] Except that aluminum acetylacetonate was used instead of zirconium tetraacetylacetonate, the same treatment as in Example 1 was performed to produce the soft magnetic material of Example 2 and the powder magnetic core of Example 2. In addition, the compounding quantity of the metal complex was 0.285 mol% at the ratio of aluminum to the iron contained in the pure iron with insulating film.

Embodiment 3

[0070] The soft magnetic material of Example 3 and the powder magnetic core of Example 3 were produced by performing the same treatment as in Example 1 except that the temperature was raised to 600° C. during the heat treatment, and then kept at 600° C. for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com