Magnetic conducting pot and manufacturing method thereof

A technology of magnetic conduction and magnetic conduction layer, which is applied in the field of materials, can solve the problems of complex production process, high cost, and the inability of aluminum materials to conduct magnetism, and achieve the effect of improving comprehensive quality and magnetic conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

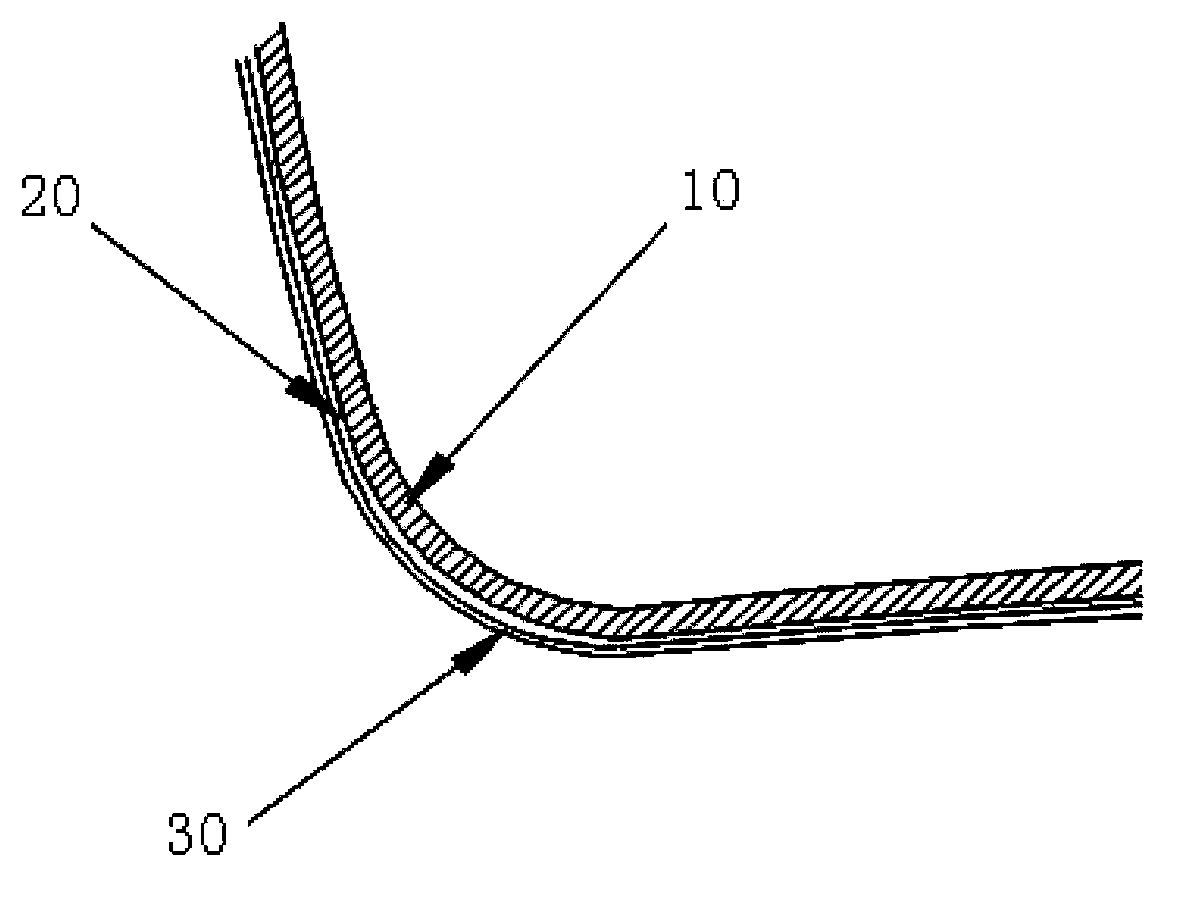

[0036] Production Method:

[0037] 1. First stamp the aluminum material with a thickness of 1.5~1.8mm into the pot body through the mold, then sandblast the outer surface of the pot body to make the surface roughness Ra 2.0~6.0μm, and then carry out oxidation treatment on the surface .

[0038] 2. Spray the magnetic material with strong magnetic permeability on the outside of the pot body, and the spraying atomization pressure is 0.2-0.3MPa. Secondly, it is baked for 15 minutes at a temperature of 80-90 degrees Celsius to form a magnetically permeable layer with a film thickness of 40-200 μm.

[0039] The components of the magnetically permeable material are: 20-30 parts by weight of resin, 30-65 parts by weight of magnetically conductive metal pigment, and 1-5 parts by weight of additive organic matter. Among them, the magnetic metal pigments are mainly iron-aluminum alloys, nickel-iron alloys, silver alloys or amorphous soft magnetic alloys and other magnetic metal pigment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com