Disc type permasyn motor for electric car hub

A technology for electric vehicles and permanent magnet synchronization, applied to synchronous motors with stationary armatures and rotating magnets, electric vehicles, motors, etc., can solve problems such as energy loss, reduce losses, reduce back magnetic density, and air gap The effect of magnetic density enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

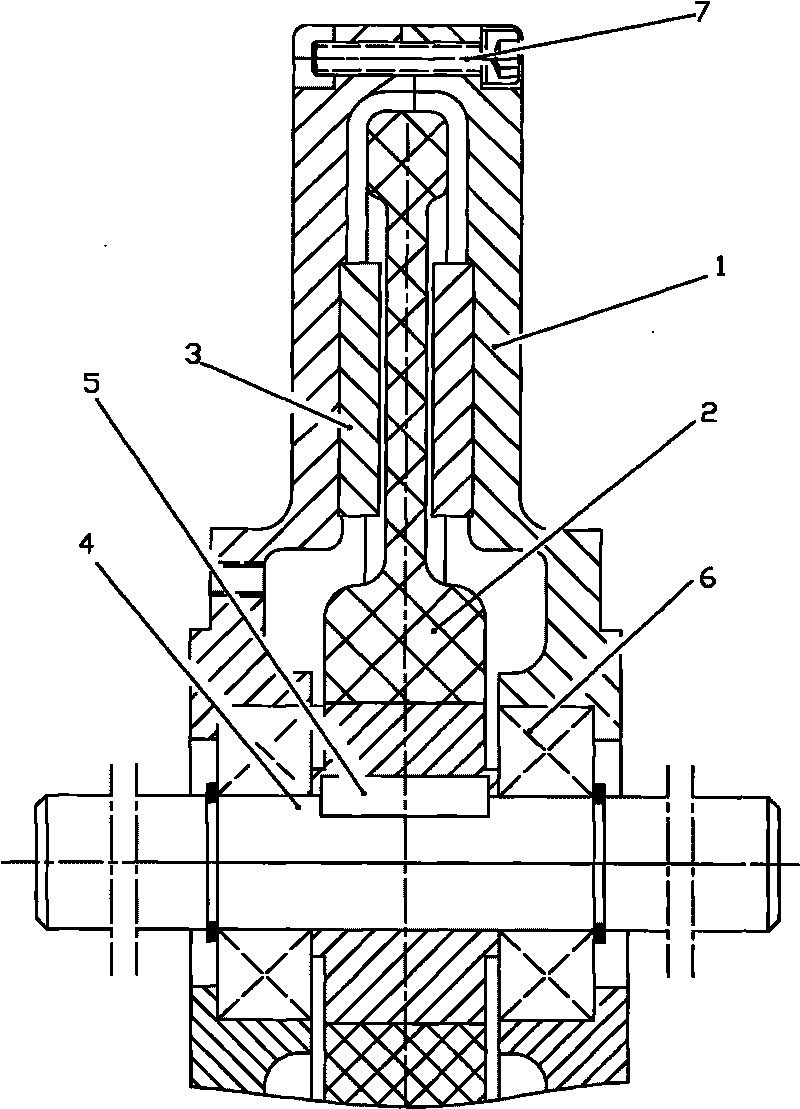

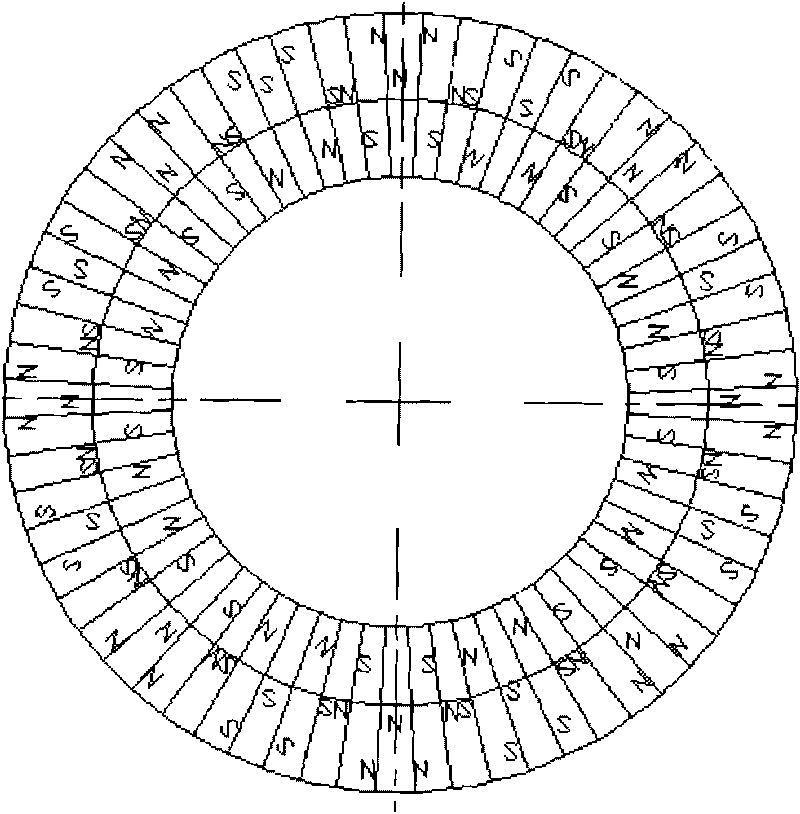

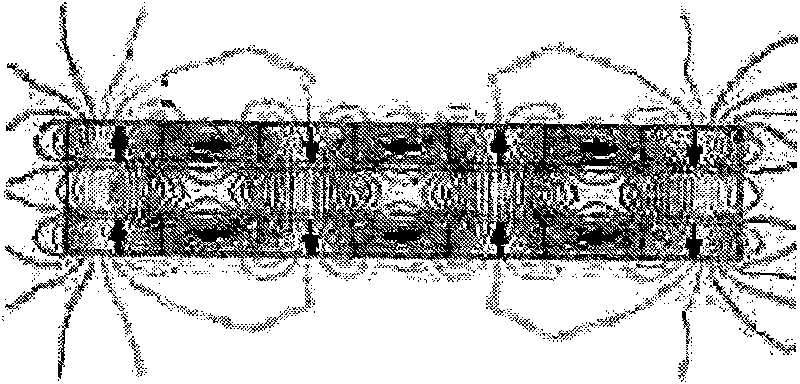

[0021] like figure 1 As shown, a hub disc type coreless permanent magnet synchronous motor of the present invention includes a rotor shell 1, a stator armature disc 2, a magnetic steel disc 3, a fixed mandrel 4, a key 5, a bearing 6, and an inner hexagonal screw 7. The motor has an outer rotor structure. The rotor casing 1 includes two parts fixedly connected by hexagon socket screws 7. Each part of the rotor casing 1 is supported on the fixed mandrel 4 through a bearing 6. Two magnetic steel discs 3 parallel to each other are symmetrically arranged. It is fixed on the inner wall of the rotor shell 1, and an annular air gap with a rectangular cross section is formed between the two magnetic steel discs 3 . Two magnetic steel discs 3 generate an axial magnetic field. The stator armature 2 adopts a coreless structure and is directly formed by injection molding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com