Novel stator and rotor structure of switched reluctance motor

A switched reluctance motor, stator and rotor technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, AC motor control, etc., can solve the problem of temperature rise, affect the life of the motor, reduce the safety of the motor, etc. , to achieve the effects of reducing torque ripple, reducing the magnetic density at the pole-to-pole endpoints, and improving the effect of excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The present invention will be further described below with reference to the accompanying drawings.

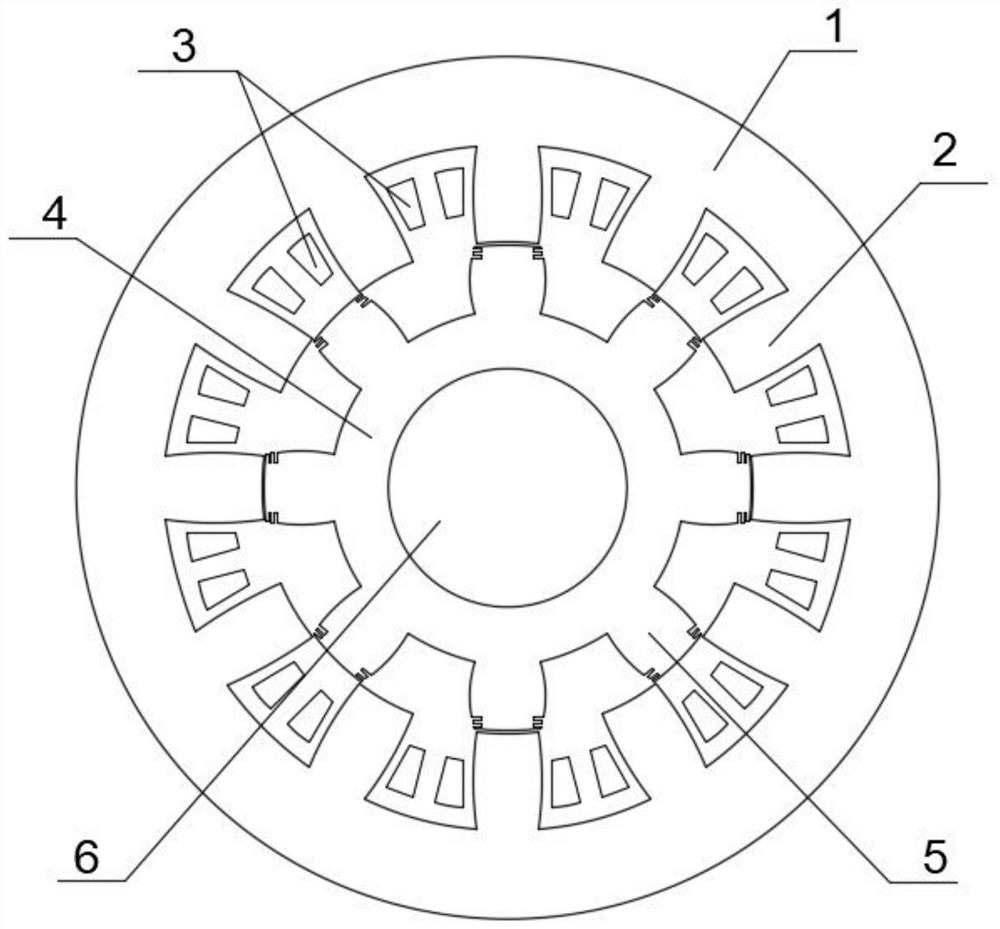

[0014]Referfigure 1 As shown, the three-phase 12 / 8 pole switching magnetic blocking motor is designed, the motor structure is a double male polar structure, the stator is outside, the rotor, the windings are centralized windings, mounted on the stator teeth.

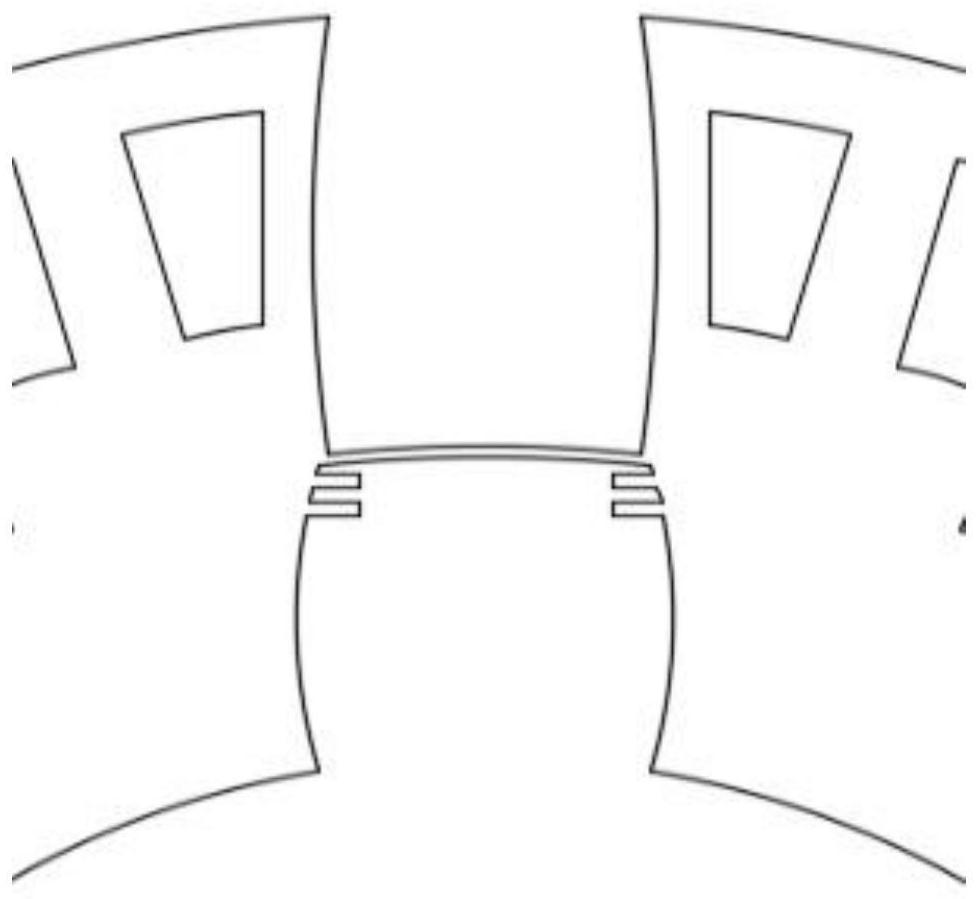

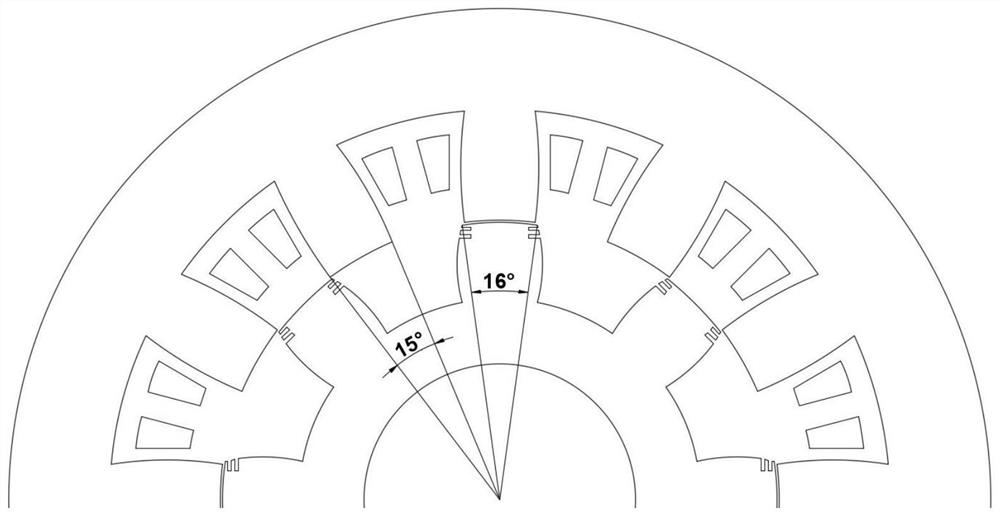

[0015]Referfigure 2 As shown, for the stator: the curved teeth of the motor stator compresses the stator groove space, which can increase the tank manifest, enhance the heat dissipation function of the motor;, due to the widening of the magnetic passage, the magnetic magnetic can be reduced. Military waveform.

[0016]Referfigure 2 As shown, for the rotor: Since the edge magnetic flux is an important reason that causes the motor torque pulsation, the edge magnetic flux will be generated before the rotor is coincident, so two rectangular grooves are opened on both sides of the rotor tooth. This structure can reduce the edge magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com