A Capacitive Impedance Epoxy Resin Casting Insulated Electromagnetic Voltage Transformer

A technology of voltage transformer and epoxy resin, which is applied in the direction of inductors, transformers/inductor coils/windings/connections, transformers, etc., can solve problems such as fuse blown, voltage transformer burnt, etc., to increase ground capacitance, The effect of increasing the number of winding layers and increasing the limit output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

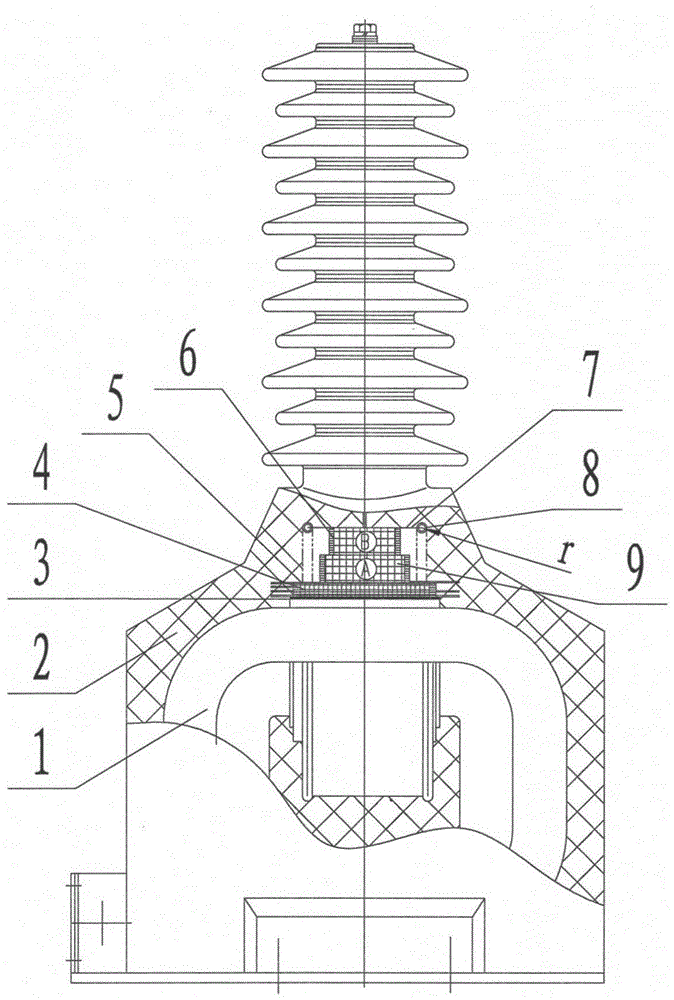

[0026] Such as figure 1 As shown, it is a schematic structural diagram of a capacitive impedance epoxy resin cast insulated electromagnetic voltage transformer. The capacitive impedance epoxy resin cast insulated electromagnetic voltage transformer includes an iron core 1, a winding skeleton 3, a secondary winding 4, Inner electrostatic screen 5, interlayer insulation 6, outer electrostatic screen 7, voltage equalizing ring 8 and primary winding 9, the middle part of the window of core 1 is provided with winding frame 3, and winding frame 3 is wound with secondary coils from inside to outside in turn. The winding 4 and the primary winding 9, the primary winding 9 adopts a hierarchical pagoda structure. An inner electrostatic screen 5 is provided on the inner side of the primary winding 9 , and an outer electrostatic screen 7 is provided on the outer side of the primary winding 9 , and voltage equalizing rings 8 are provided at both ends of the outer electrostatic screen 7 . I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com