Quadrature-direct axis inductance variable permanent magnet brushless motor and wide-area efficient optimization design method thereof

A technology of permanent magnet brushless motor and AC/D axis inductance, which is applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of narrow speed regulation range, limit the load capacity, and restrict the large-scale application of permanent magnet motors, and achieve The effect of high overall efficiency and high torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Step 1, obtain the ratio of the inductance of the AC-direction axis through the magnetic circuit diagram of the permanent magnet motor with multiple working conditions;

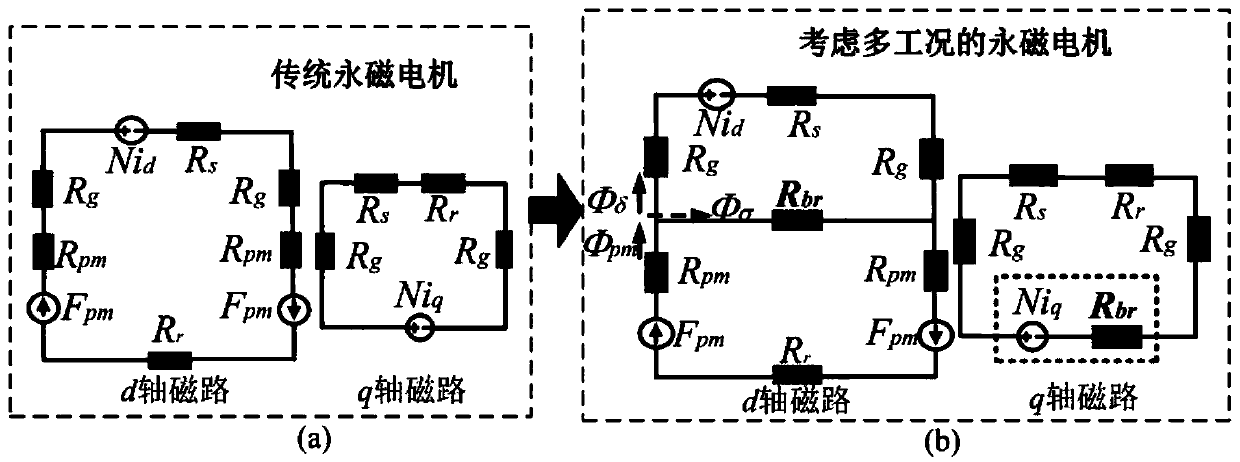

[0041] see figure 1 , the simplified d- and q-axis equivalent flux paths of conventional PM motors and PM motors incorporating variable reluctance are given, where the d- and q-axis flux paths are shown at different rotor positions. according to figure 1 (b), the quadrature axis inductance L d , L q and leakage flux Ф σ (i d , i q ) can be expressed as follows:

[0042]

[0043] where: N is the number of winding turns, R br (i d , i q ) is the introduced variable reluctance, R pm is the permanent magnet reluctance, R r is the rotor reluctance, R s is the stator reluctance, R g is the air-gap reluctance; i d , i q are the d and q axis armature currents, respectively;

[0044] then L q / L d It can be expressed as:

[0045]

[0046] Step 2, when the automobile is in different work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com