Stator core, winding type stator, concentrated winding motor and production method

A stator core and wire-wound technology, which is applied in the field of stator core, concentrated winding motor, and wire-wound stator, can solve the problems of high production cost of stator core, high motor iron loss, and reduced motor performance, and achieve reduction The effect of reducing the amount of scrap, reducing production costs, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

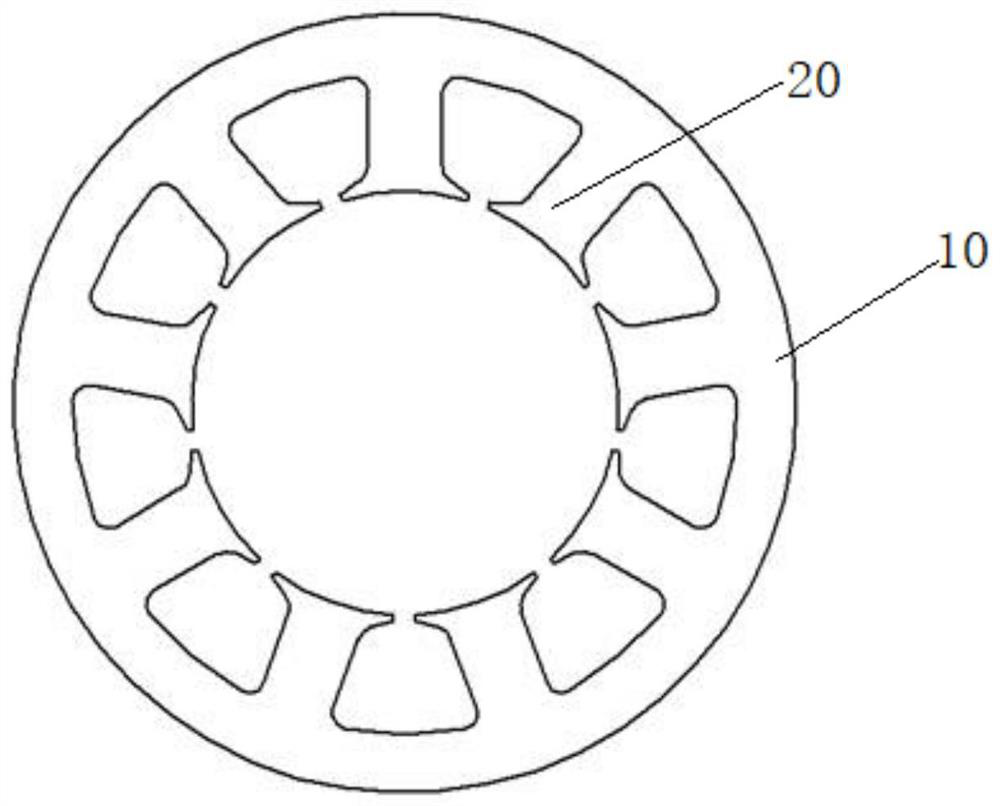

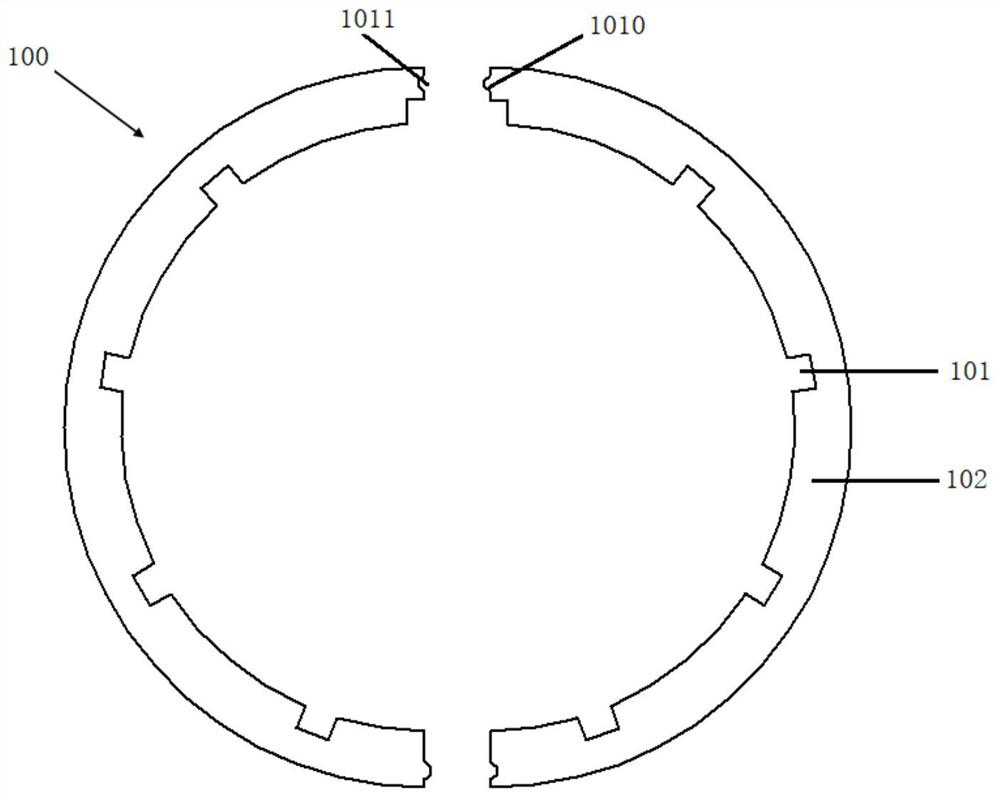

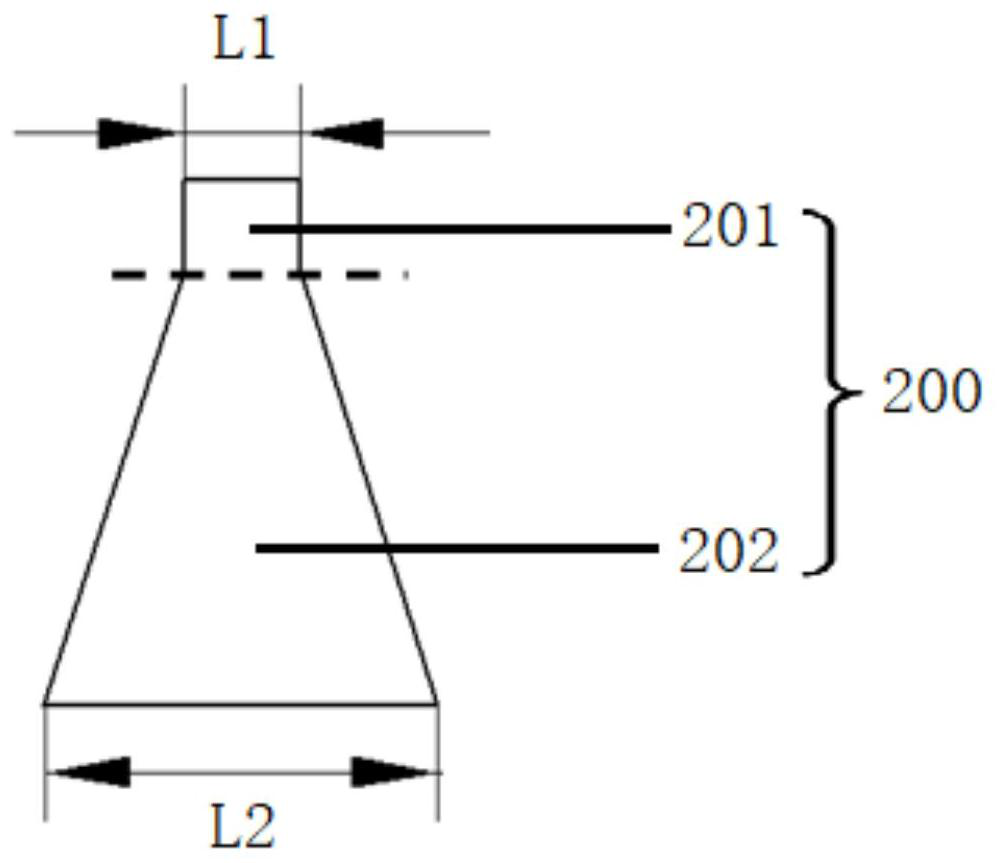

[0057] combine Figure 2 ~ Figure 4 As shown, this embodiment provides a stator core, including: a yoke structure 100 and several tooth structures 200, the yoke structure 100 is divided into several yoke structure segments 102, and several yoke structures The structural segments 102 are sequentially connected end to end, and the tooth structure 200 is matched and connected to the side of the yoke structure 100 facing the center of the yoke structure 100 , and each of the yoke structural segments 102 is connected by a mortise and tenon joint. Several tooth structures 200 are connected.

[0058] Several yoke structure sections 102 are connected end to end, so that the yoke structure is in the shape of a ring; several grooves 101 are opened on each yoke structure section 102, and the number of the tooth structures 200 is the same as that of the yoke structure sections 102. The number of the grooves 101 is the same, and each of the tooth structures 200 is correspondingly embedded...

Embodiment 2

[0063] combine Figure 5 ~ Figure 7As shown, this embodiment provides a stator core, including: a yoke structure 100 and several tooth structures 200, the yoke structure 100 is divided into several yoke structure segments 102, and several yoke structures The structural segments 102 are sequentially connected end to end, and the tooth structure 200 is matched and connected to the side of the yoke structure 100 facing the center of the yoke structure 100 , and each of the yoke structural segments 102 is connected by a mortise and tenon joint. Several tooth structures 200 are connected.

[0064] Several yoke structure sections 102 are connected end to end, so that the yoke structure is in the shape of a ring; several grooves 101 are opened on each yoke structure section 102, and the number of the tooth structures 200 is the same as that of the yoke structure sections 102. The number of the grooves 101 is the same, and each of the tooth structures 200 is correspondingly embedded ...

Embodiment 3

[0070] combine Figure 8-10 As shown, this embodiment provides a stator core, including: a yoke structure 100 and several tooth structures 200, the yoke structure 100 is divided into several yoke structure segments 102, and several yoke structures The structural segments 102 are sequentially connected end to end, and the tooth structure 200 is matched and connected to the side of the yoke structure 100 facing the center of the yoke structure 100 , and each of the yoke structural segments 102 is connected by a mortise and tenon joint. Several tooth structures 200 are connected.

[0071] Several yoke structure sections 102 are connected end to end, so that the yoke structure is in the shape of a ring; several grooves 101 are opened on each yoke structure section 102, and the number of the tooth structures 200 is the same as that of the yoke structure sections 102. The number of the grooves 101 is the same, and each of the tooth structures 200 is correspondingly embedded in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com