Patents

Literature

45results about How to "Strong resistance to demagnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

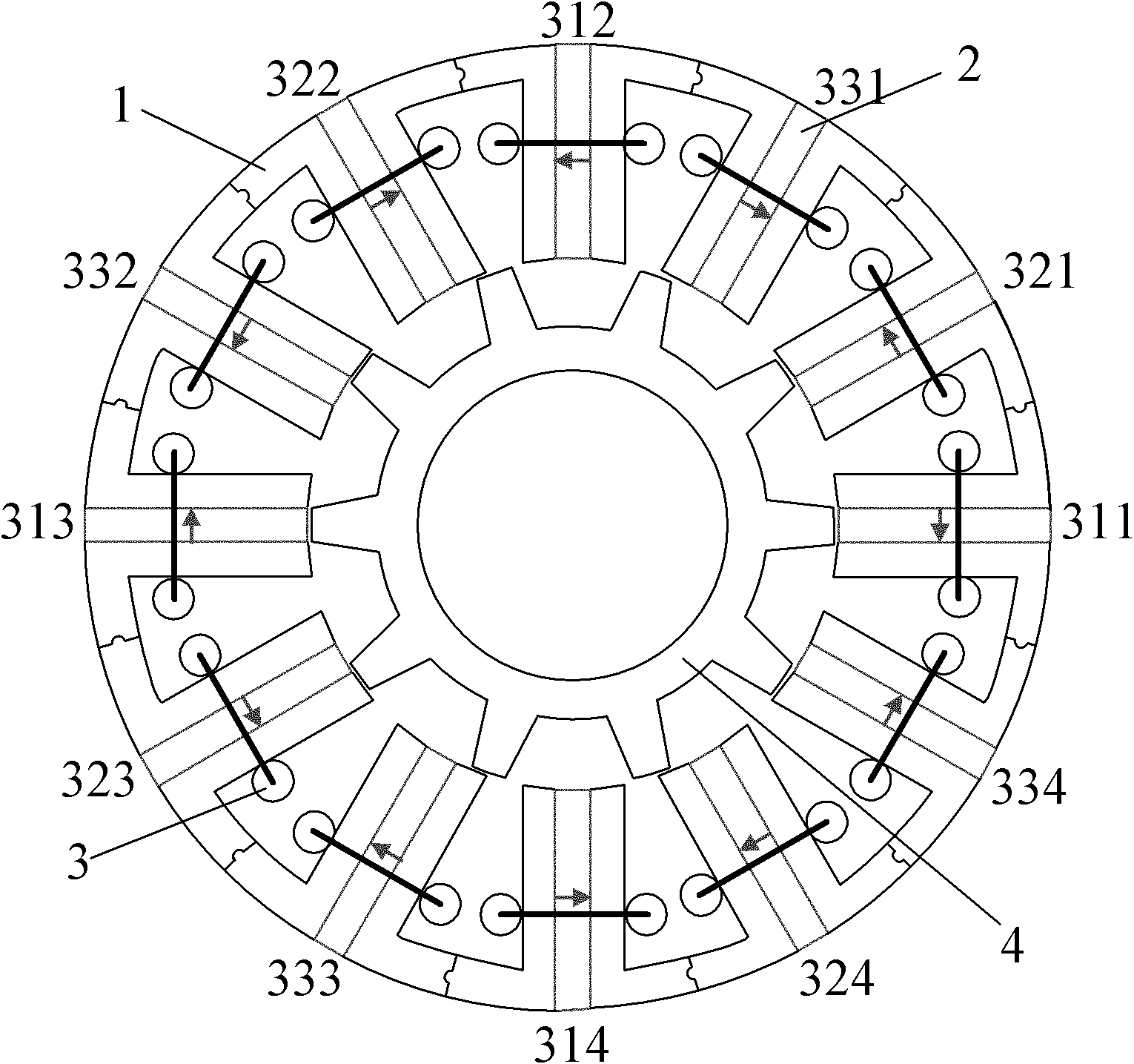

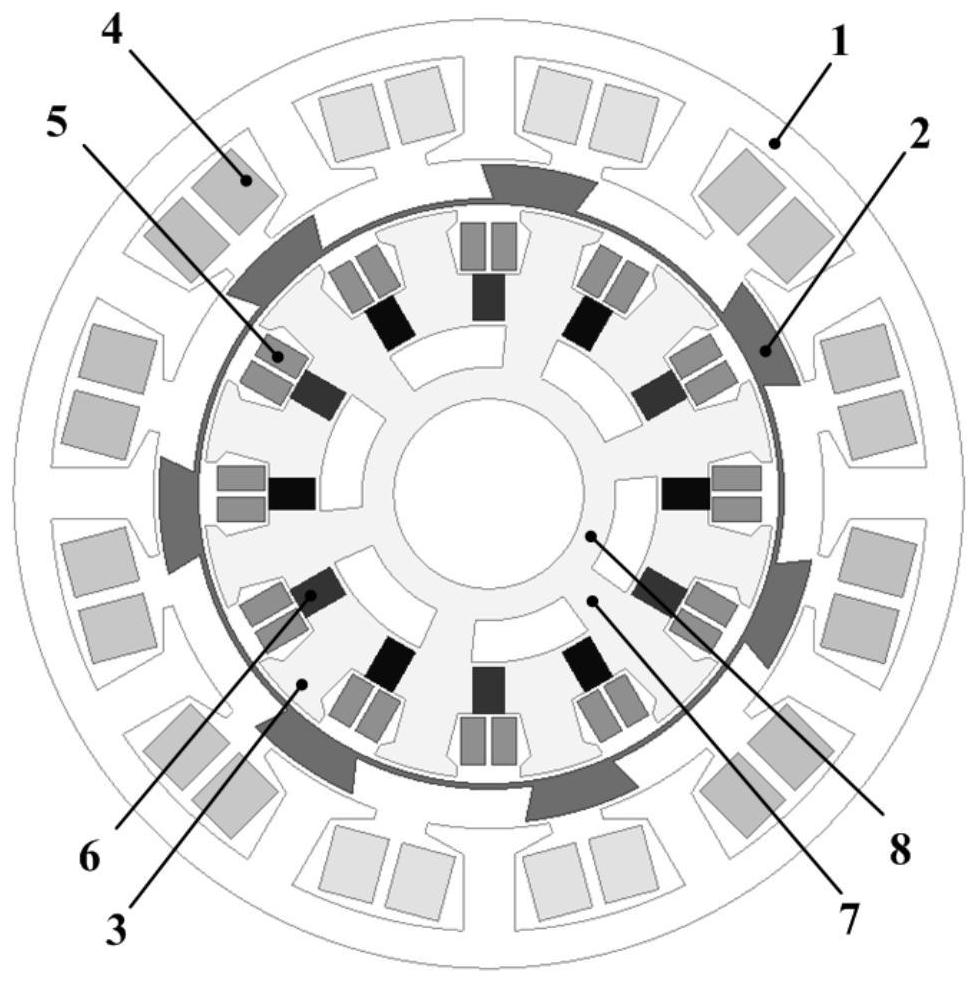

Six-phase flux switching type permanent magnet motor

InactiveCN103248158ASmall positioning torqueStable output torqueMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnetic core

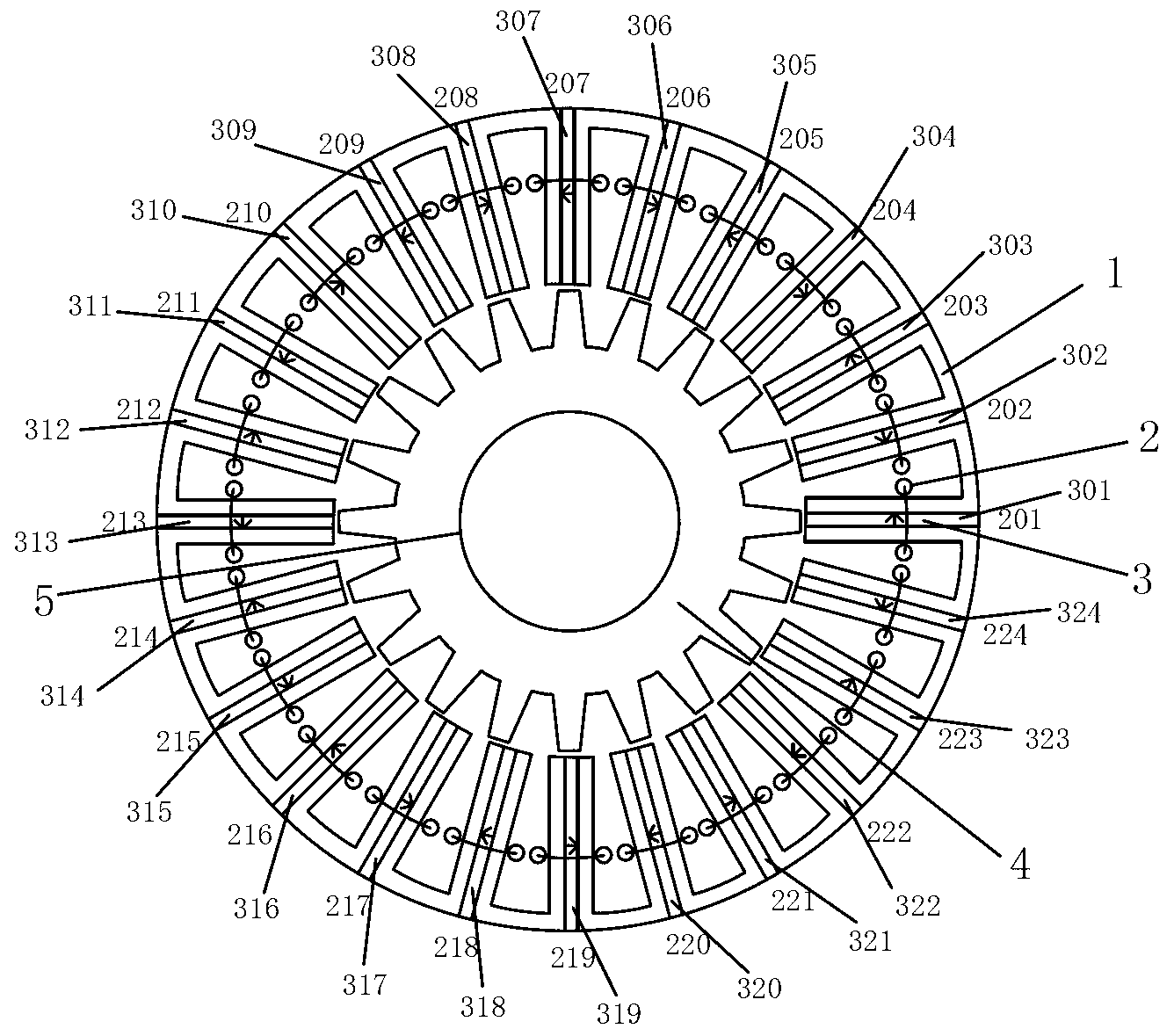

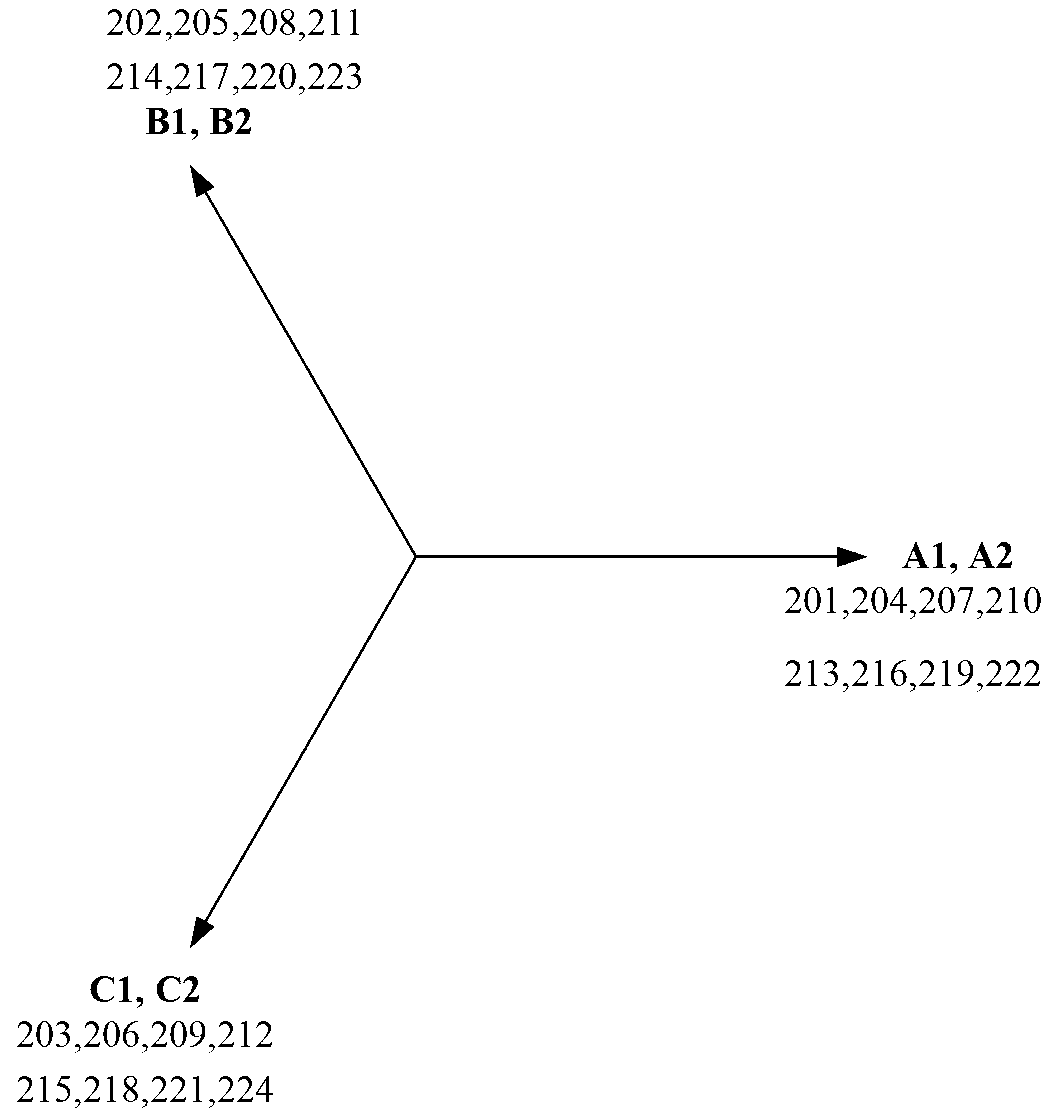

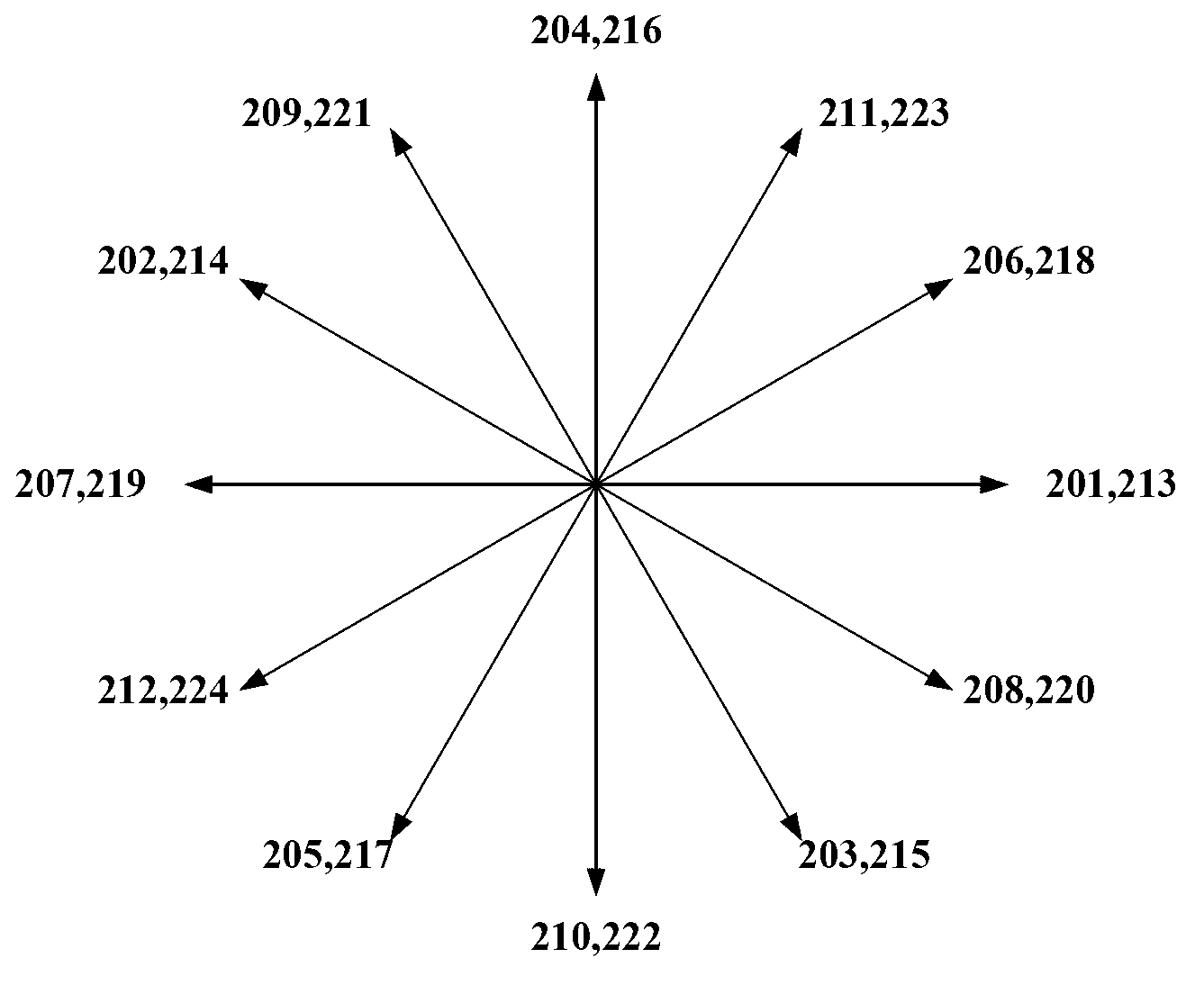

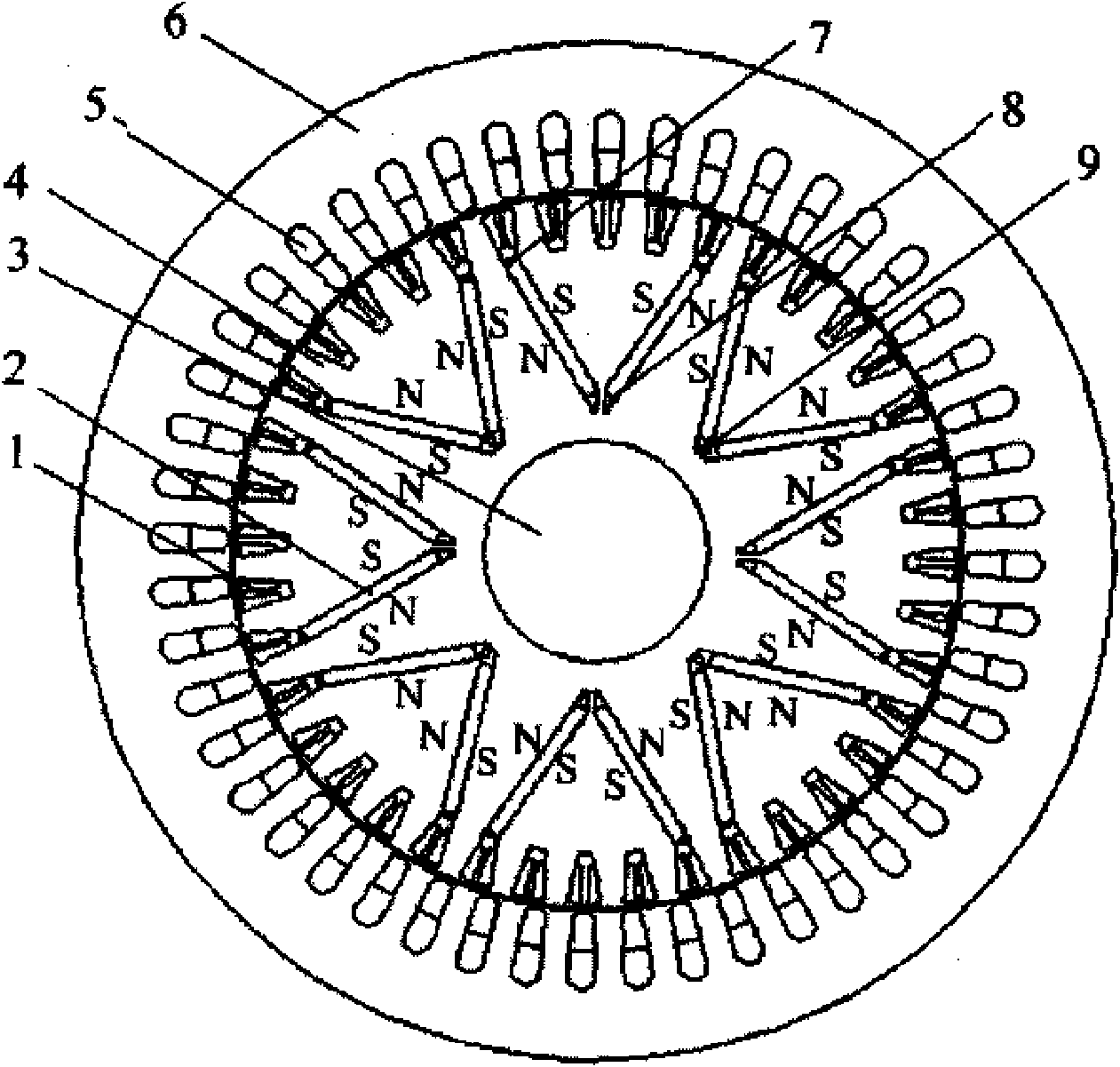

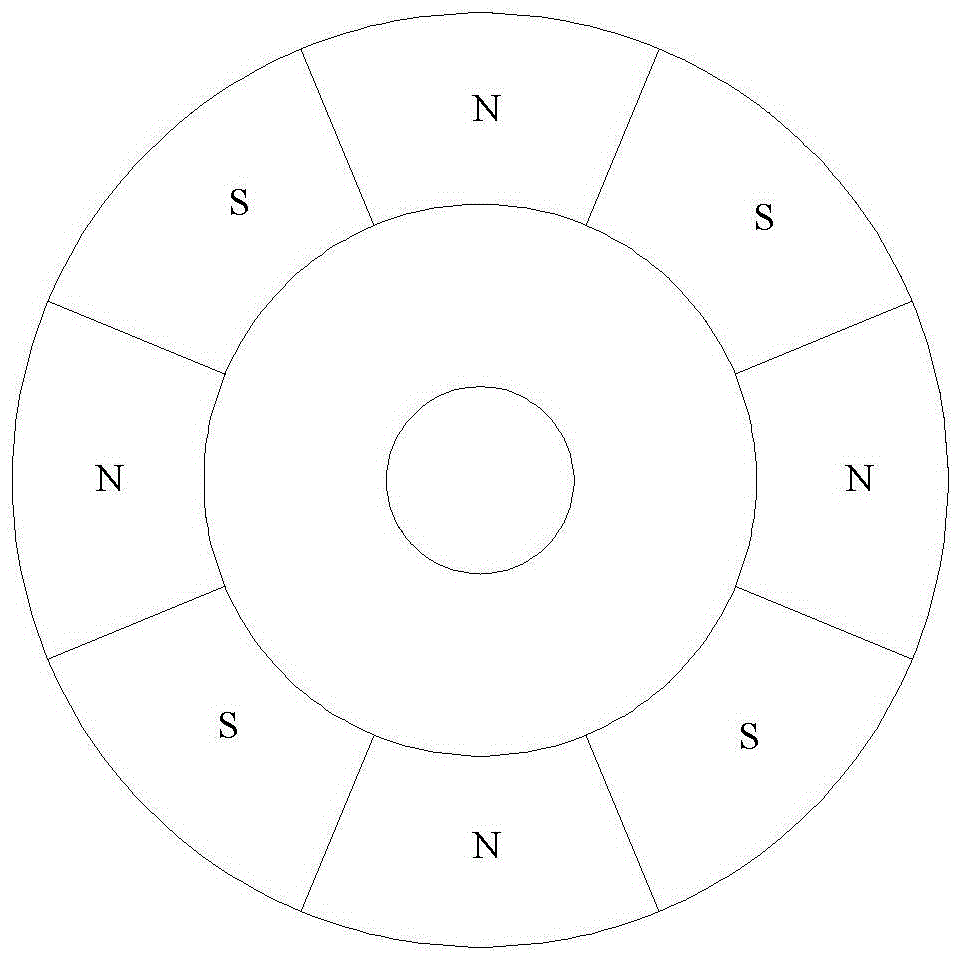

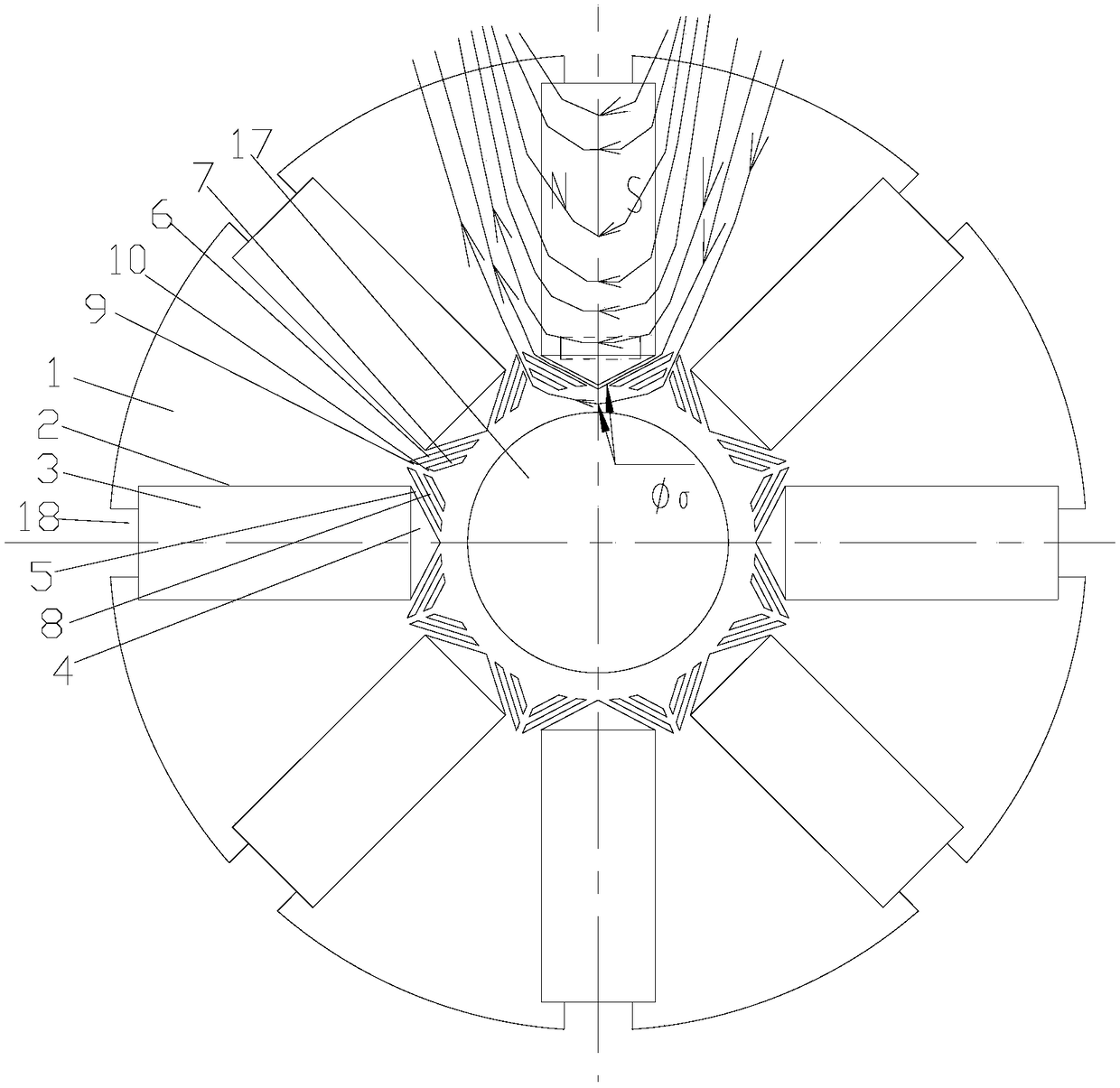

The invention provides a six-phase flux switching type permanent magnet motor which comprises stators, rotors and a rotating shaft, wherein each stator adopts a permanent magnet double salient structure, that is, the permanent magnet, the stator core and the armature winding are arranged on each stator, the stator core is assembled by an U-magnetic core and each permanent magnet embedded in the magnetic core, and the permanent magnets are of tangential alternate magnetization; the armature winding is of six-phase armature winding arranged on the stator, the six-phase armature winding adopts centralization coils, and the rotors are made of permeability magnetic material; the magnetizing directions of the permanent magnets are of the tangential of the stator circle, and the magnetizing directions of two adjacent permanent magnets are opposite to each other; the number of the armature coil and the stator groove is even number times of the phase number; and each phase 2n coils winding, and n coils are distributed at the two ends of the diameter of the stator circle respectively. And two three-phrase winding can conduct independent power supplying and generating.

Owner:SOUTHEAST UNIV

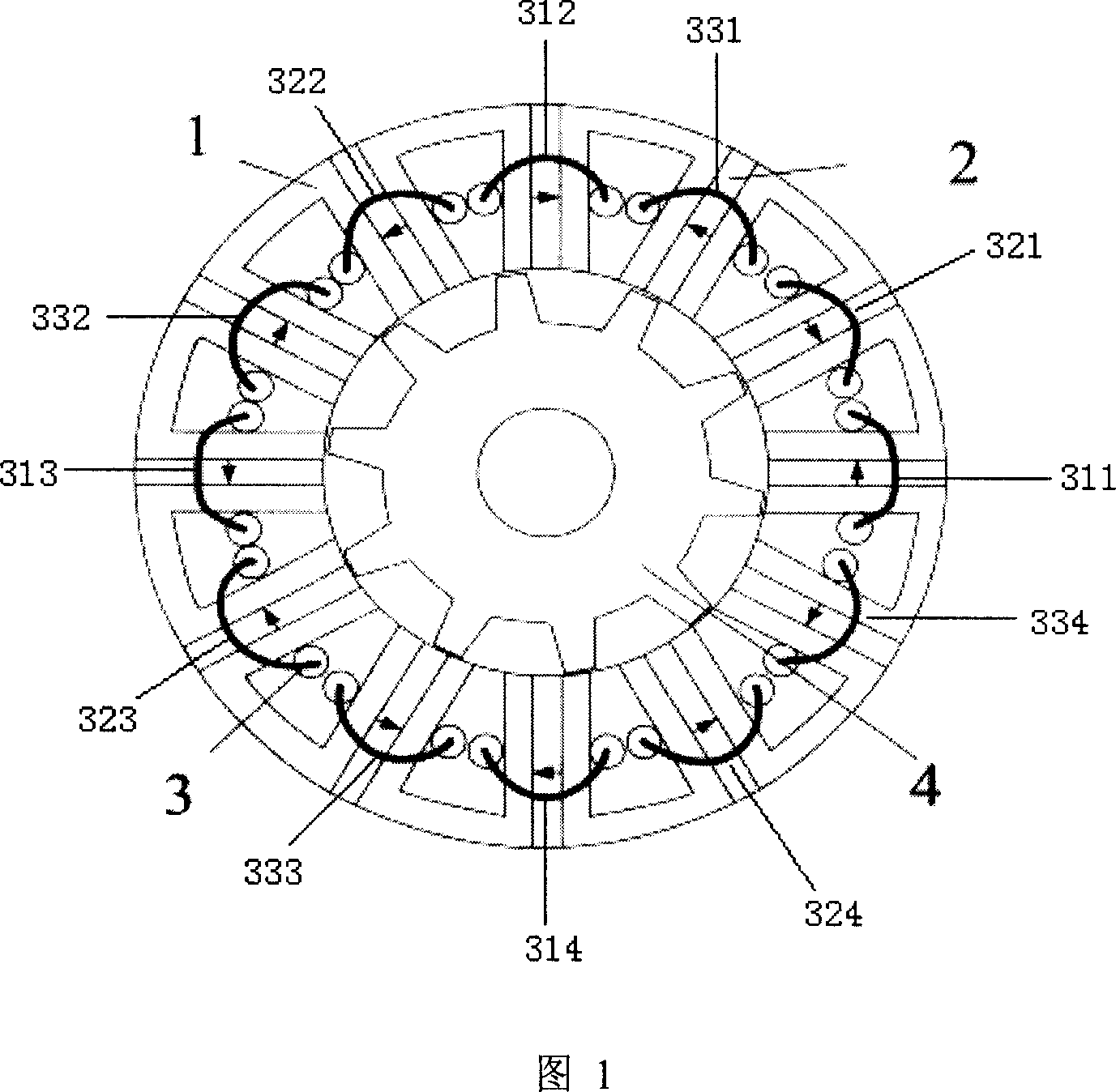

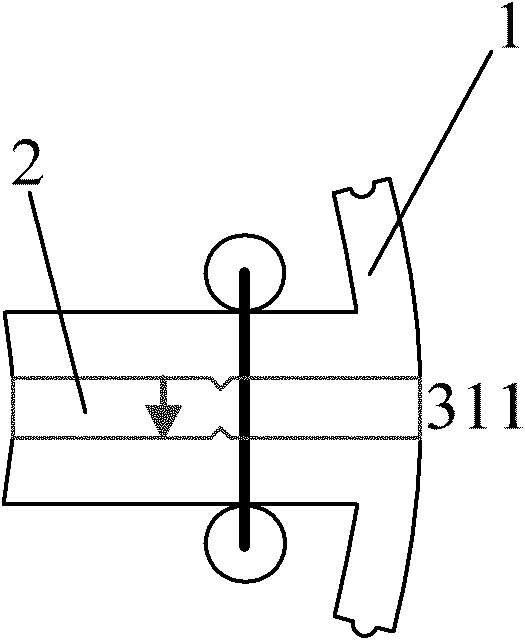

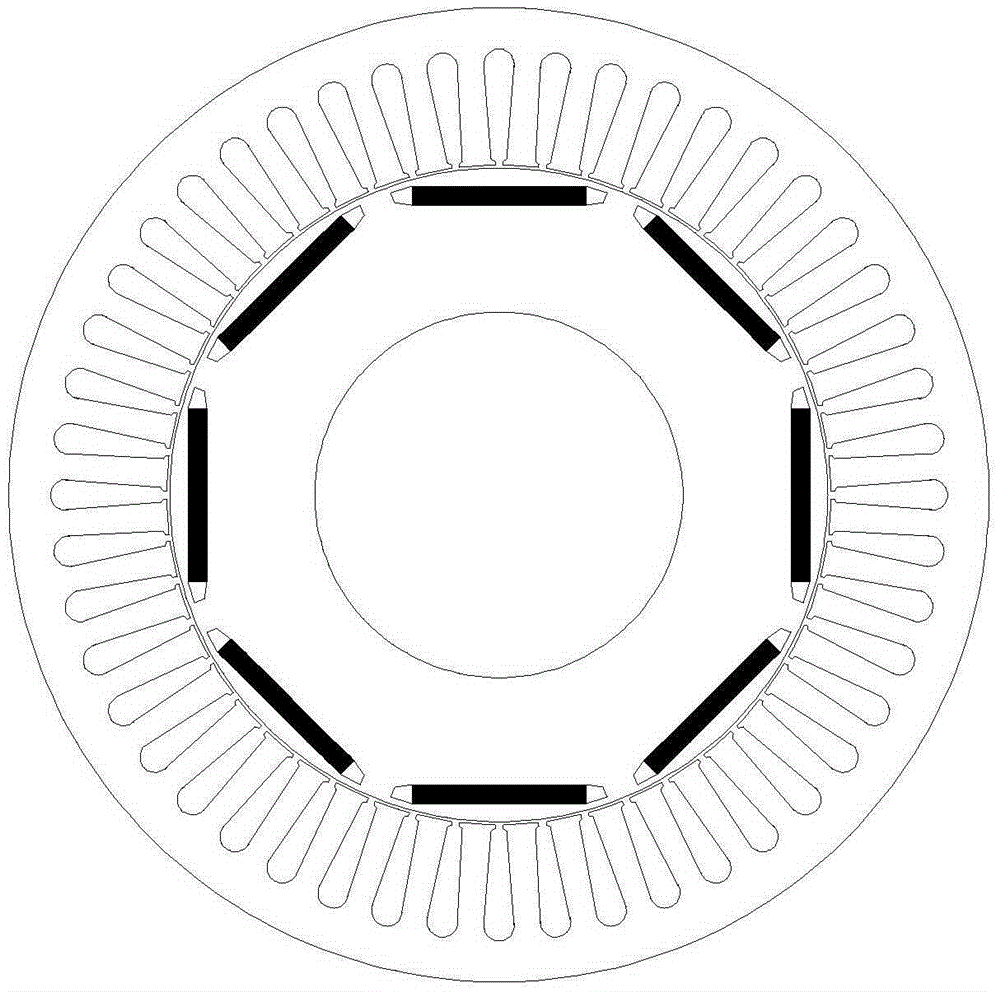

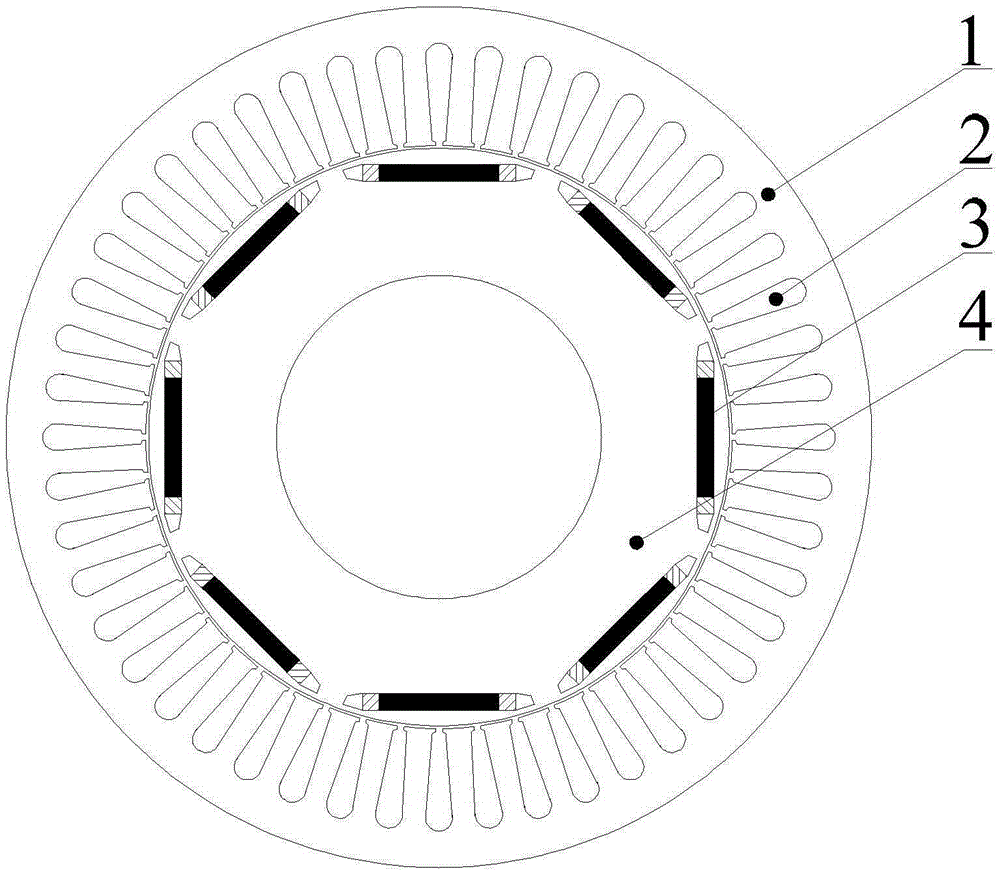

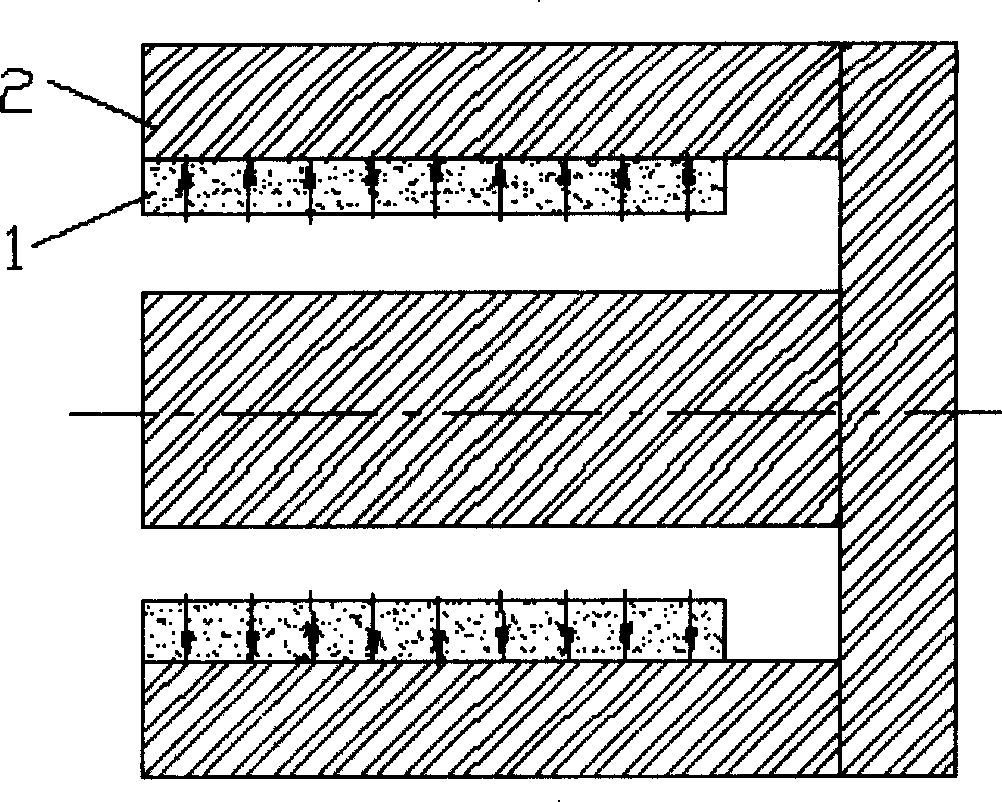

Coil mutual-supplementary magnetic pass switching biconvex permanent magnetic motor

InactiveCN101079557AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsHigh power densityConductor Coil

The invention discloses a motor with stronger torque output ability and higher power density, which consists of stator (1) and rotor (4), wherein the rotor (4) lies in the interior or exterior of the stator (1); the stator (1) and rotor (4) are double-salient pole structures with the gathered winding (3) and permanent magnet (2) on the stator (1); the radial of second and fourth winding coils are faced with each gathered winding coil in the U-shaped magnetic iron groove of two adjacent stators (1); four winding coils connect front head to end sequently; the permanent magnet (2) is set between two adjacent U-shaped magnetic iron core.

Owner:SOUTHEAST UNIV

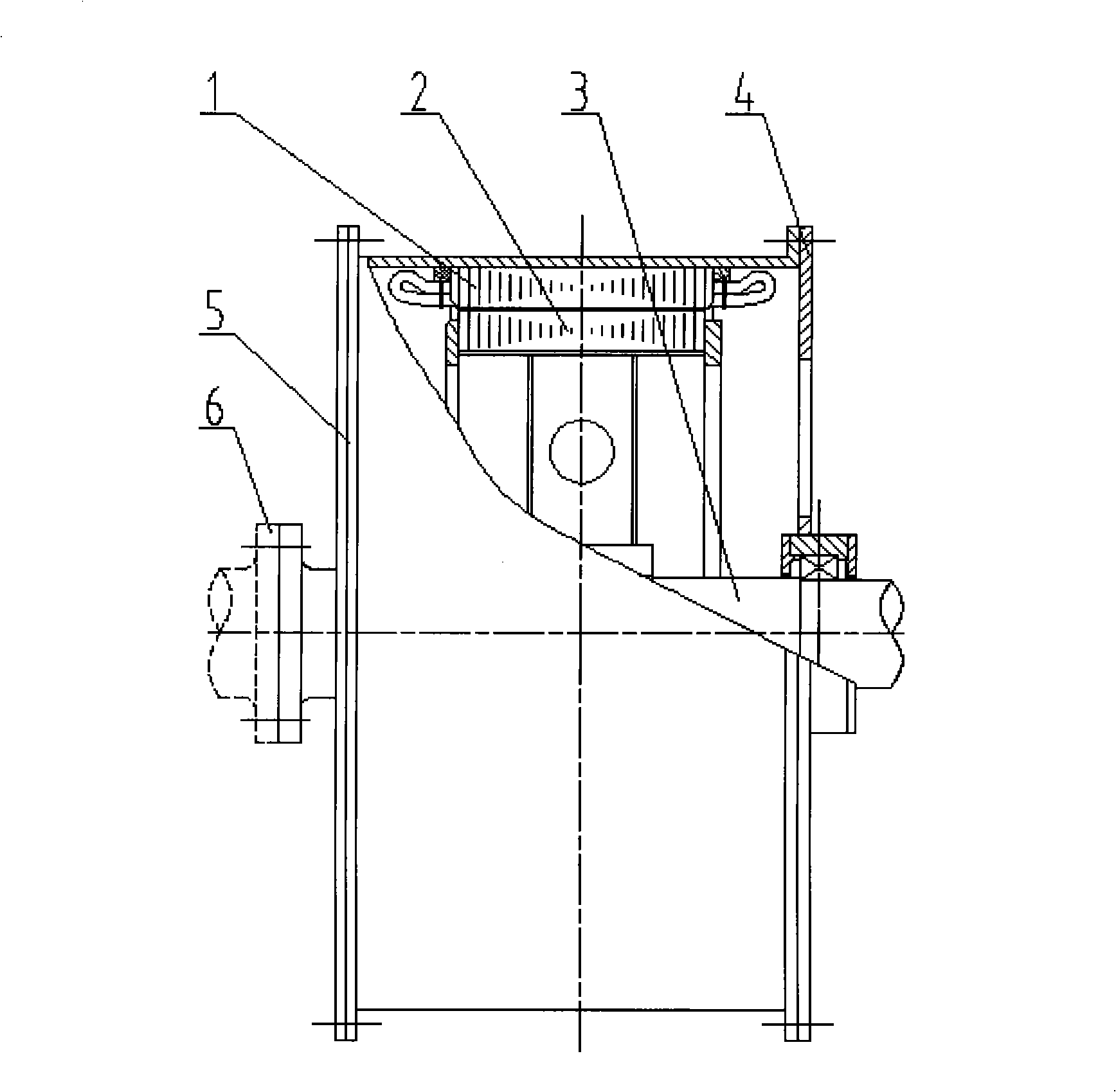

Self-starting permanent magnet motor provided with composite material starting conducting bars

InactiveCN102111051ASmall starting currentStrong resistance to demagnetizationMagnetic circuit rotating partsSynchronous machinesPhysicsPower flow

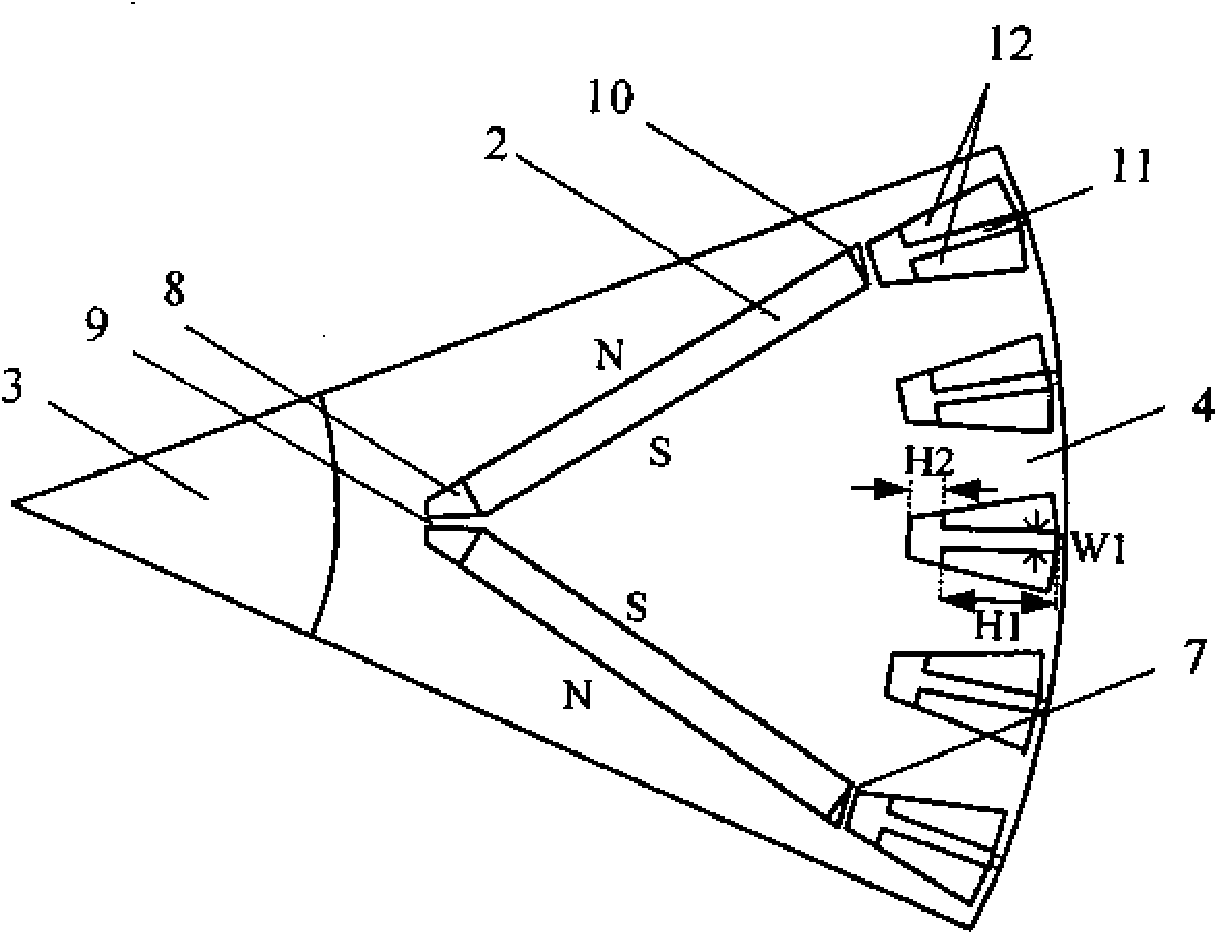

The invention discloses a self-starting permanent magnet motor provided with composite material starting conducting bars, which belongs to the technical field of permanent magnet motors. A rotor of the permanent magnet motor has a stamping type structure; a permanent magnet is arranged on the inner side of a rotor core, N and S magnetic poles are arranged alternately; a permanent magnet rotor adopts a magnetic pole structure of a U type, V type or mixed type magnetic circuit; composite material rat cage starting conducting bars are uniformly distributed close to the surface of the rotor core; and the composite material rat cage starting conducting bars is made of two types of materials including brass and copper-iron alloy. The brass is positioned on a middle part between the bottom part of a rotor groove and the upper part of the rotor groove; two side parts of the upper part of the rotor groove are made of the copper-iron alloy; or the middle part of the rotor groove is made of the brass, while the two sides of the rotor groove are made of the copper-iron alloy. Two ends of each composite material starting conducting bar are shorted out outside the rotor core through a welded brass end ring. Through the adjustment of the structure sizes of the brass and the copper-iron alloy materials, the obtained permanent magnet motor has a small starting current multiple and strong demagnetization resistance, can be started smoothly, and is suitable for workplaces requiring long-time continuous operation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

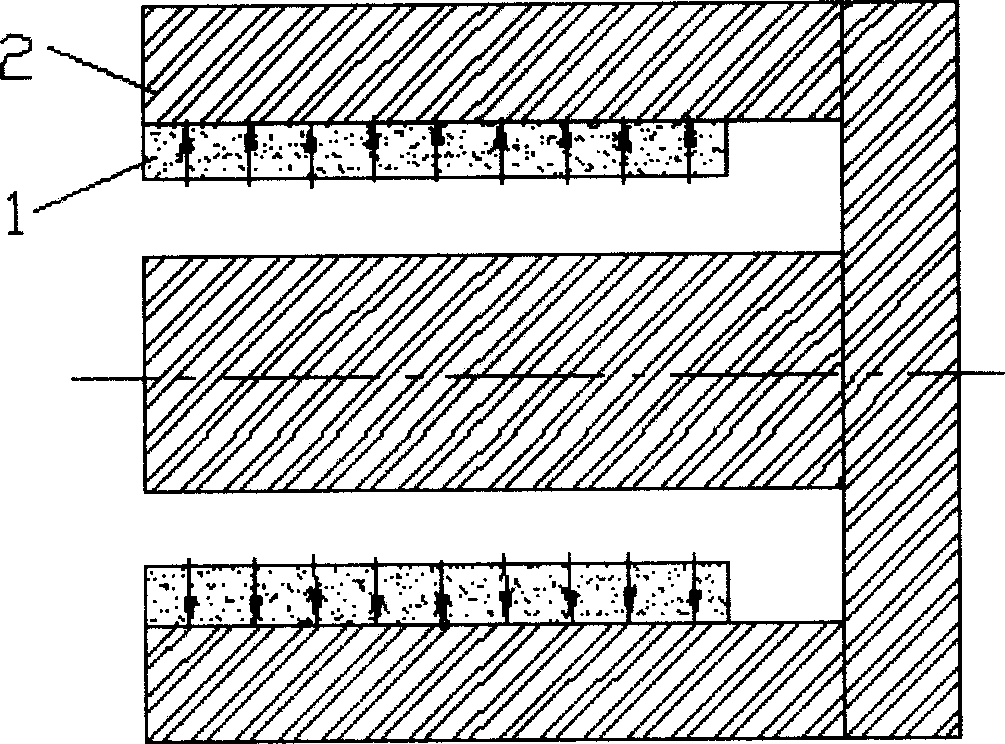

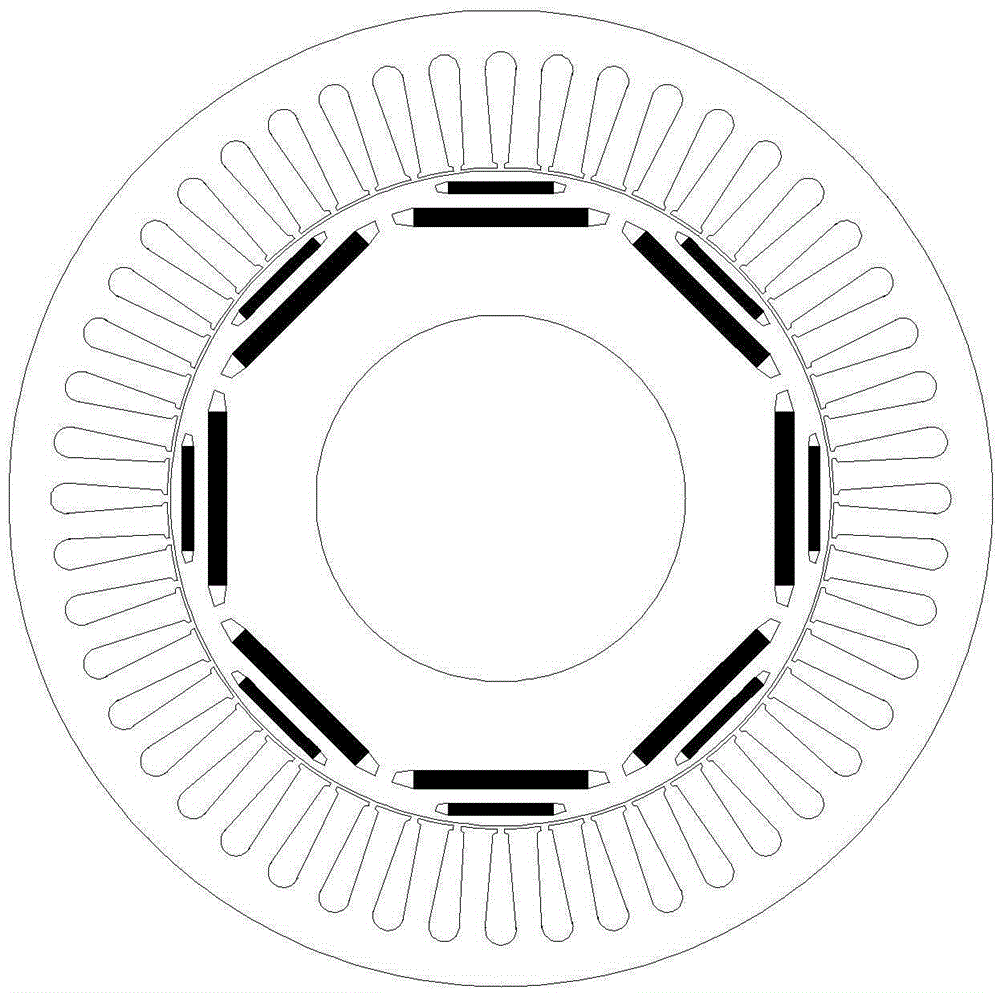

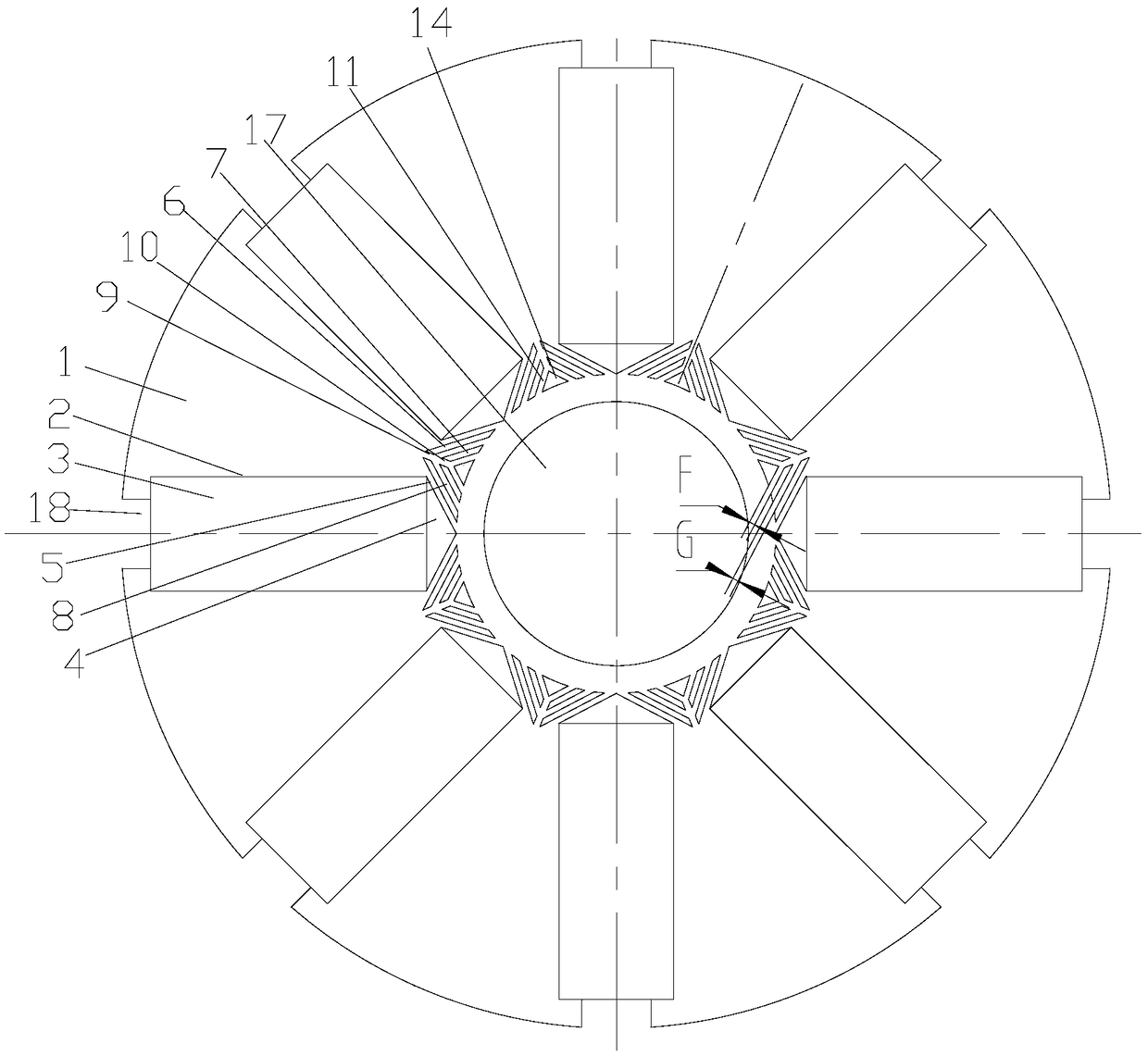

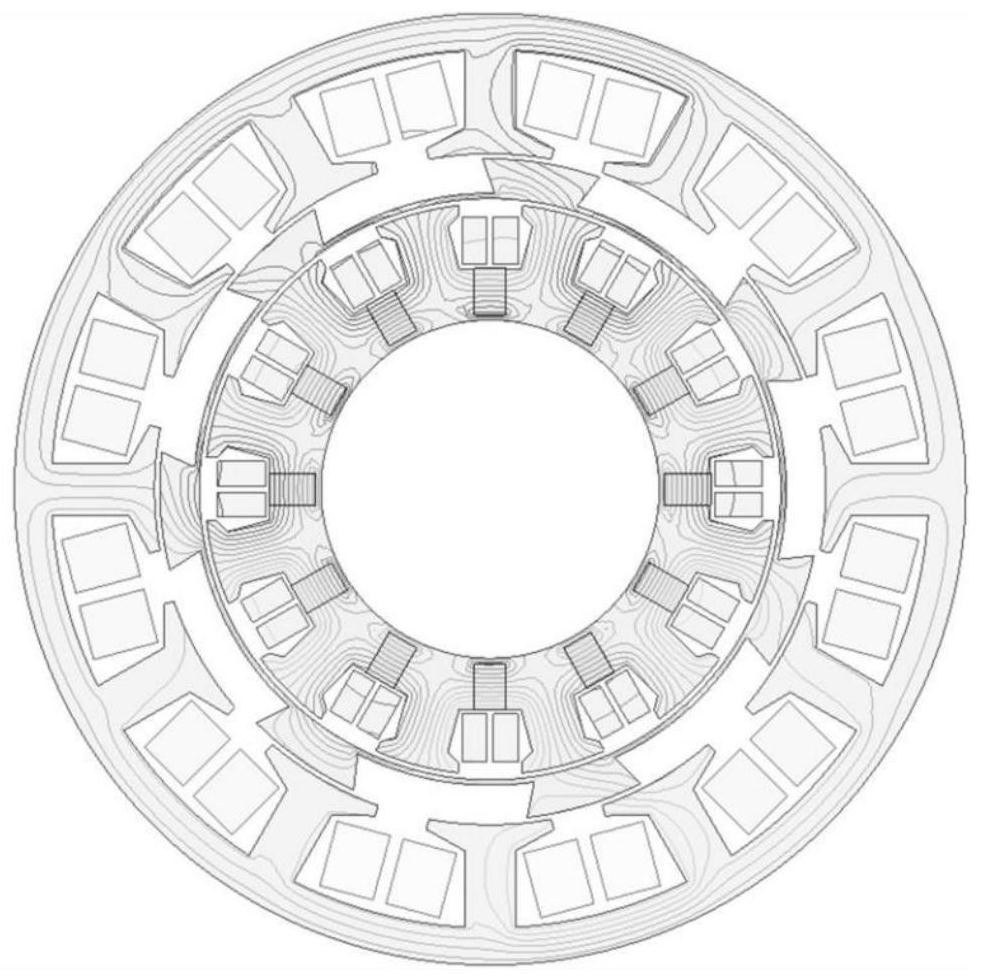

Modularized flux switching permanent magnet (FSPM) motor

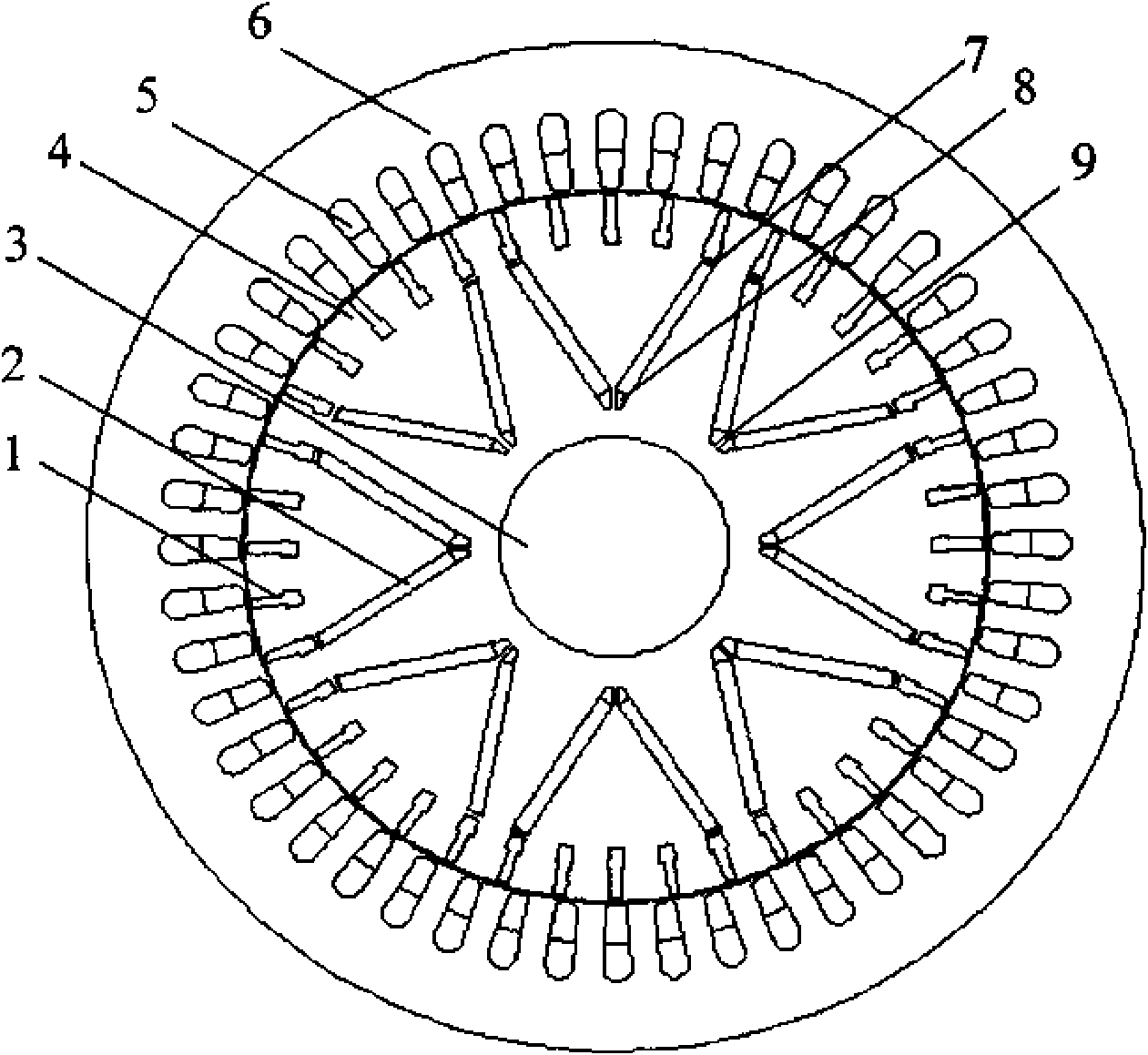

InactiveCN102157993AImprove cooling conditionsSimple and strong structureMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical resistance and conductanceElectric machine

The invention discloses a modularized flux switching permanent magnet (FSPM) motor, which is used for solving the problem of such a motor in which a permanent magnet is placed in a rotor. The motor comprises a stator and a rotor and adopts an inner rotor mode or an external rotor mode. The stator and the rotor are respectively a convexo-convex pole and slot structure. A magnetic module and a centralized armature winding are arranged on the stator; the magnetic module comprises one male concentrating flux iron core and one female concentrating flux iron core of the stator as well as a permanent magnet embedded in the stator; and the rotor is not provided with a permanent magnet and a winding. The motor has the beneficial effects that the structure is simple, compact and stable, and the volume is small; the windings are high in slot fullness, the resistance and the copper consumption are decreased and the efficiency is higher; the linear charge density, the torque output capacity and the power density are improved; the magnetic flux gathering effect exists, and the no-load air gap magnetic density is higher; and the armature reaction flux is vertical to the permanent magnet flux in space, and the stronger demagnetization-resisting capacity is ensured.

Owner:DALIAN MINGYANG IND +1

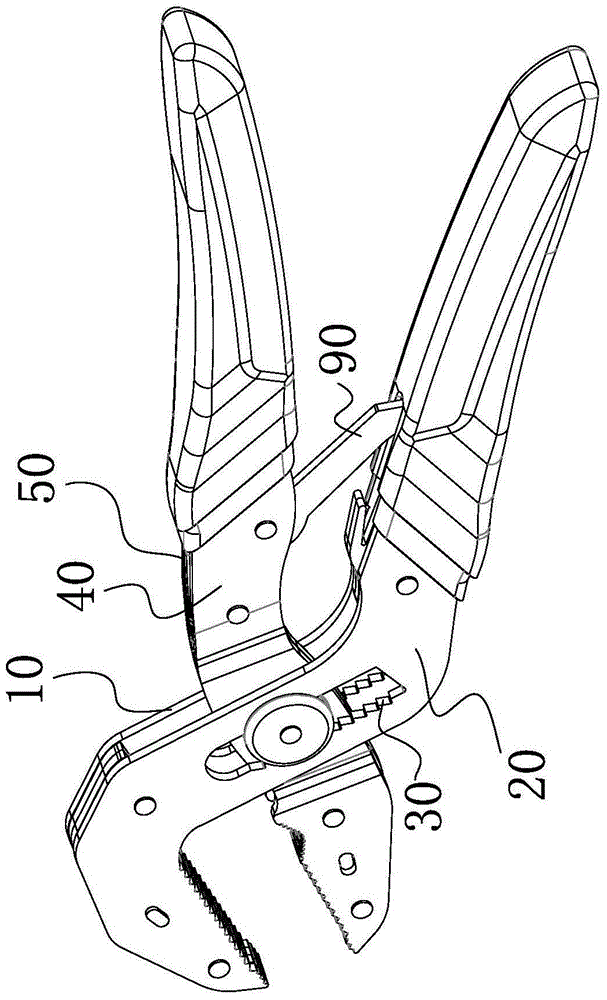

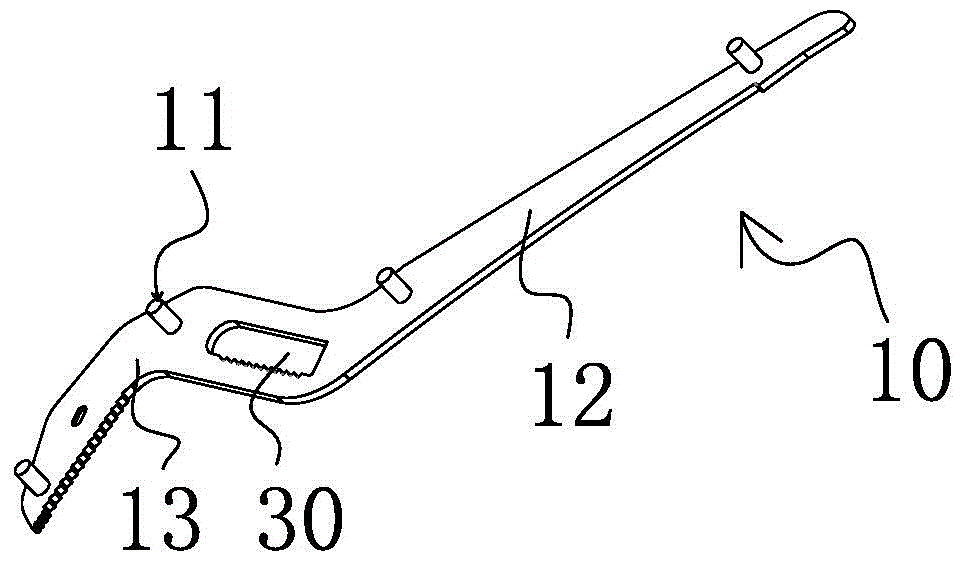

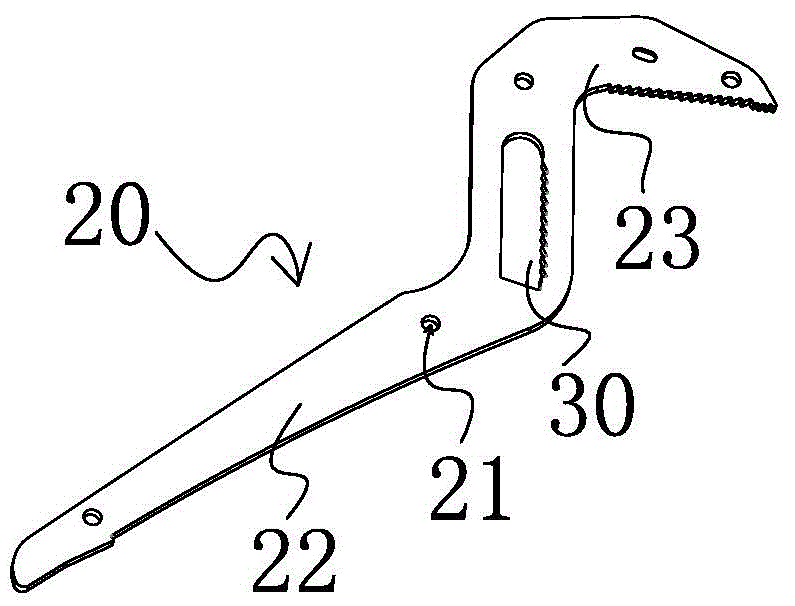

Water pump pliers

The invention provides water pump pliers. The water pump pliers comprise a first fixed pliers arm, a second fixed pliers arm, a first movable pliers arm, a second movable pliers arm, a first clamping part, a second clamping part, a limiting rod and a connecting rod, wherein the first fixed pliers arm and the second fixed pliers arm are fixedly connected to from a fixed pliers arm assembly, the first movable pliers arm and the second movable pliers arm are hinged to the space between the first fixed pliers arm and the second fixed pliers arm through a sliding piece, through grooves are formed in the middle of the first fixed pliers arm and in the middle of the second fixed pliers arm respectively, the two ends of the sliding piece are movably installed in the two through grooves respectively, the limiting rod is arranged between the first fixed pliers arm and the second fixed pliers arm, a sliding groove is formed in the limiting rod, one end of the connecting rod is installed on the first fixed pliers arm, and the other end of the connecting rod is installed on the movable pliers arms. According to the water pump pliers, both the first clamping part and the second clamping part are made of rare earth permanent magnetic materials, are magnetic and can attract each other, in this way, a part is clamped by a pliers head, the clamping force is increased, operation is convenient, and working efficiency is improved; the water pump pliers are simple in structure, detachable and high in safety performance.

Owner:NINGBO YINZHOU YONGJIA ELECTRICAL TOOLS

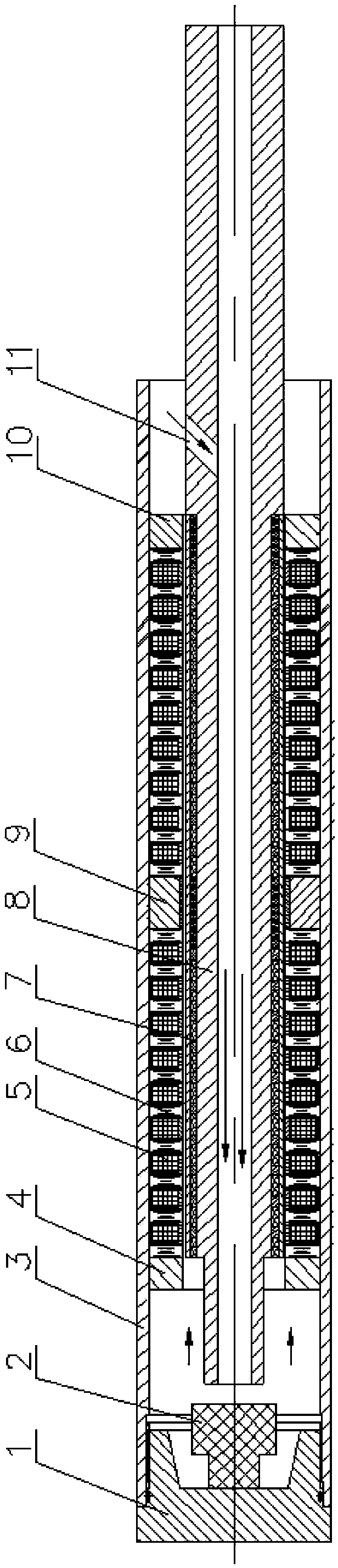

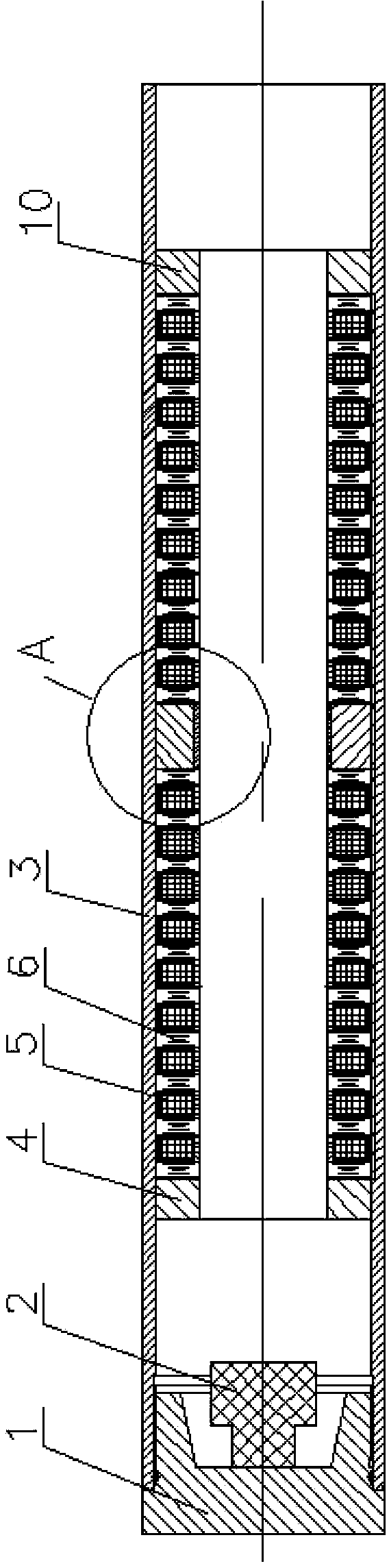

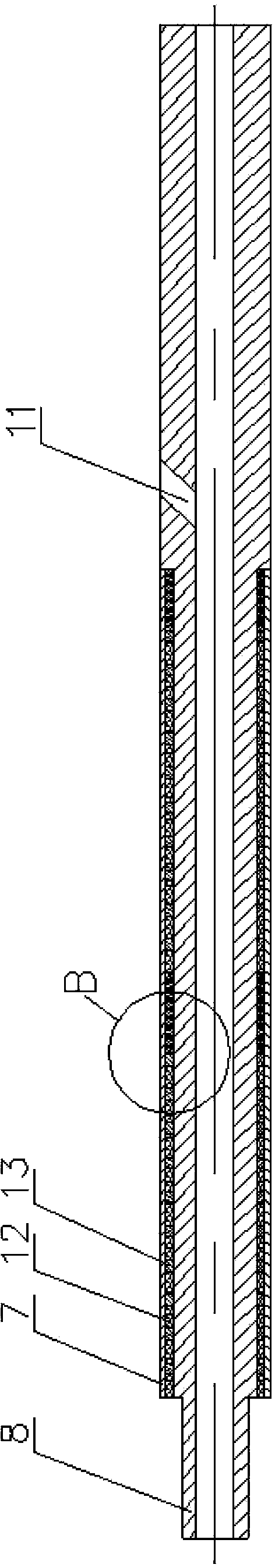

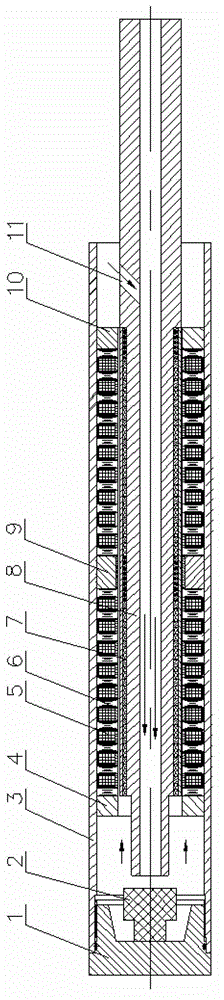

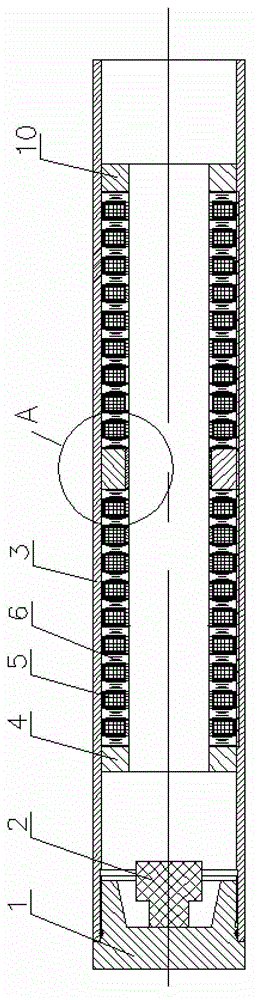

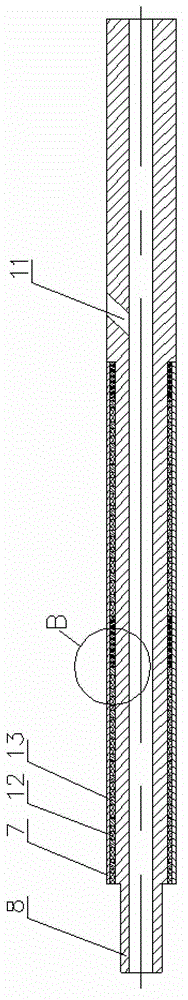

High-thrust tubular linear motor

ActiveCN103427587AStrong resistance to demagnetizationReduce magnetic densityPropulsion systemsTubular linear motorConductor Coil

The invention relates to a high-thrust tubular linear motor which comprises a stator shell, a stator and a rotor. The stator is coaxially and fixedly mounted in the stator shell, the rotor is coaxially and slidably mounted in an inner cavity of the stator, the stator comprises silicon steel sheets and windings which are arranged at intervals and fixedly mounted on the stator shell, the rotor comprises a rotor shaft, permanent magnets and magnetic conduction rings, and the permanent magnets and the magnetic conduction rings are arranged at intervals on the rotor shaft. The high-thrust tubular linear motor is characterized in that the rotor shaft is made of hollow soft magnetic materials, a copper tube is coaxially sleeved outside the rotor, the windings and the silicon steel sheets are fixedly mounted at intervals to form the stator, and the windings and the silicon steel sheets correspond to the permanent magnets and the magnetic conduction rings of the rotor. The high-thrust tubular linear motor is ingenious in design, reasonable in structure, large in starting force, fine in tightness and reliable in operation.

Owner:伟力驱动技术(深圳)有限公司

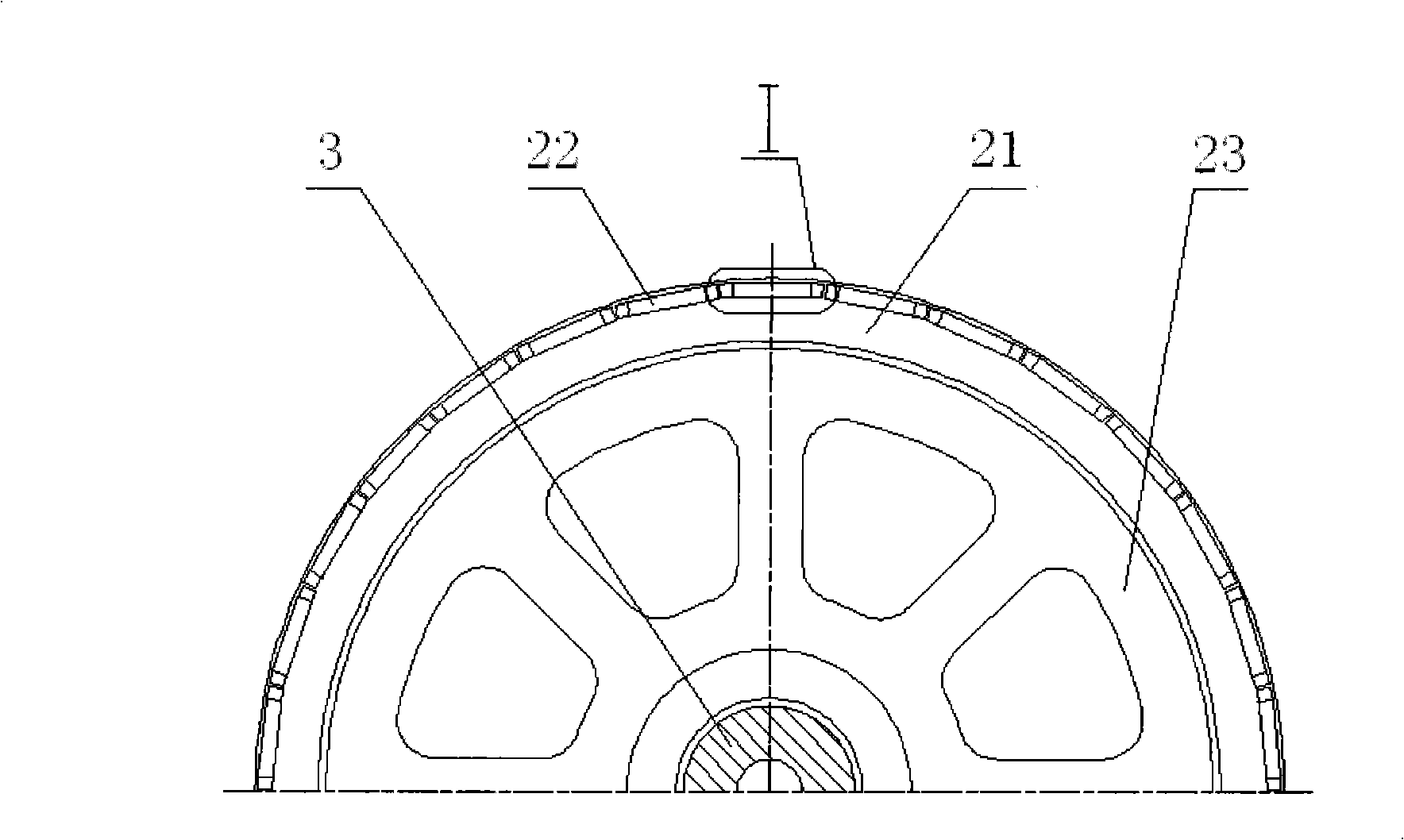

Large-sized speed-changing wind power generator with embedded permanent magnet

InactiveCN101494397AEasy to installEase of mass productionMagnetic circuit rotating partsWind energy generationDrive shaftEngineering

The invention relates to a permanent-magnet embedded type large-scale speed change aerogenerator and belongs to the technical field of wind power generation. The aerogenerator includes a stator, a rotor, a main shaft, a rear end cover and a front end cover. The rotor is installed on the main shaft and supported by a bearing, the rear end cover and the front end cover. The main shaft is connected with a driving shaft of a prime motor through a flange. The aerogenerator is characterized in that the surface of the rotor is a disk formed by a laminated core, the rotor comprises a rotor core, a permanent-magnet and a rotor field spider, the rotor core is piled on the rotor field spider and provided with a groove matched with the permanent-magnet which is embedded in the groove of the rotor core, and the rotor field spider is sheathed on the main shaft for transmitting torque. The permanent-magnet has convenient installation and strong anti-demagnetization capacity, can reduce the manufacture labor hour and enhance the reliability of a permanent-magnet generator.

Owner:上海荟懿环保科技有限公司

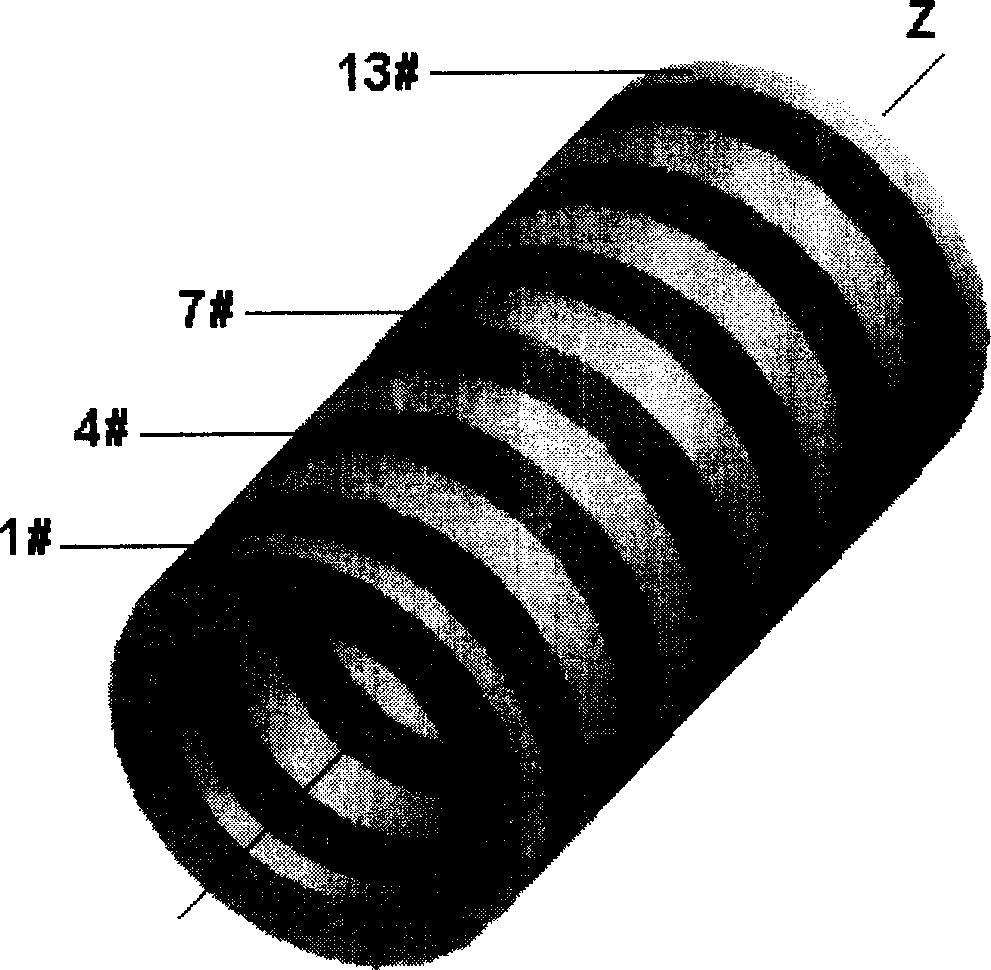

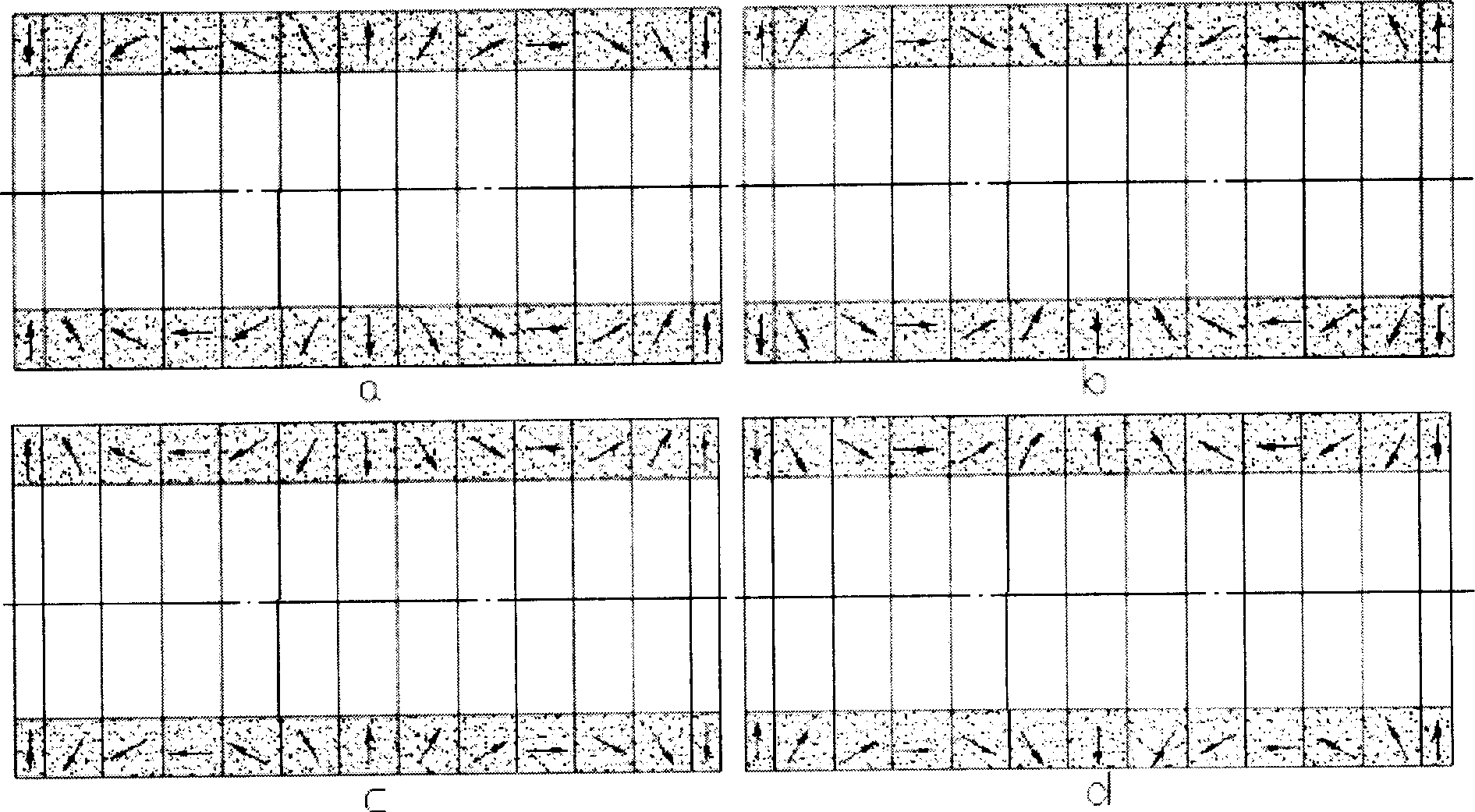

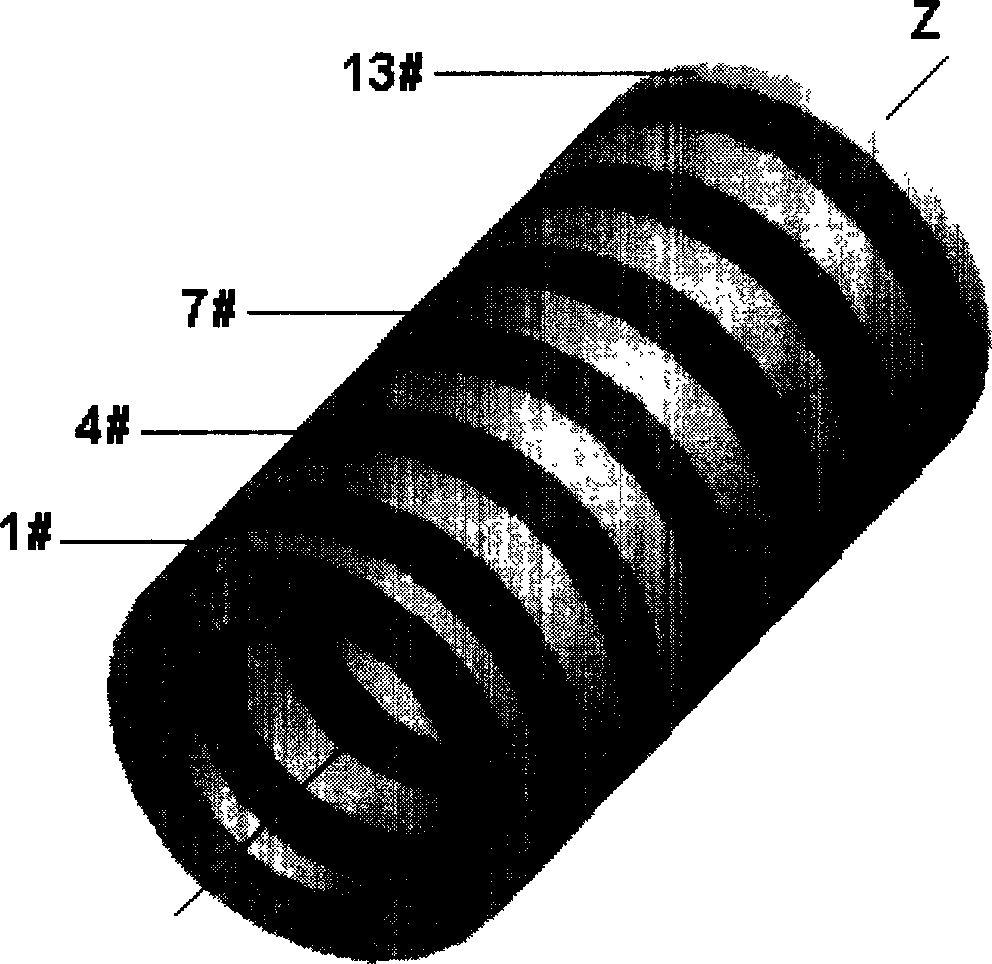

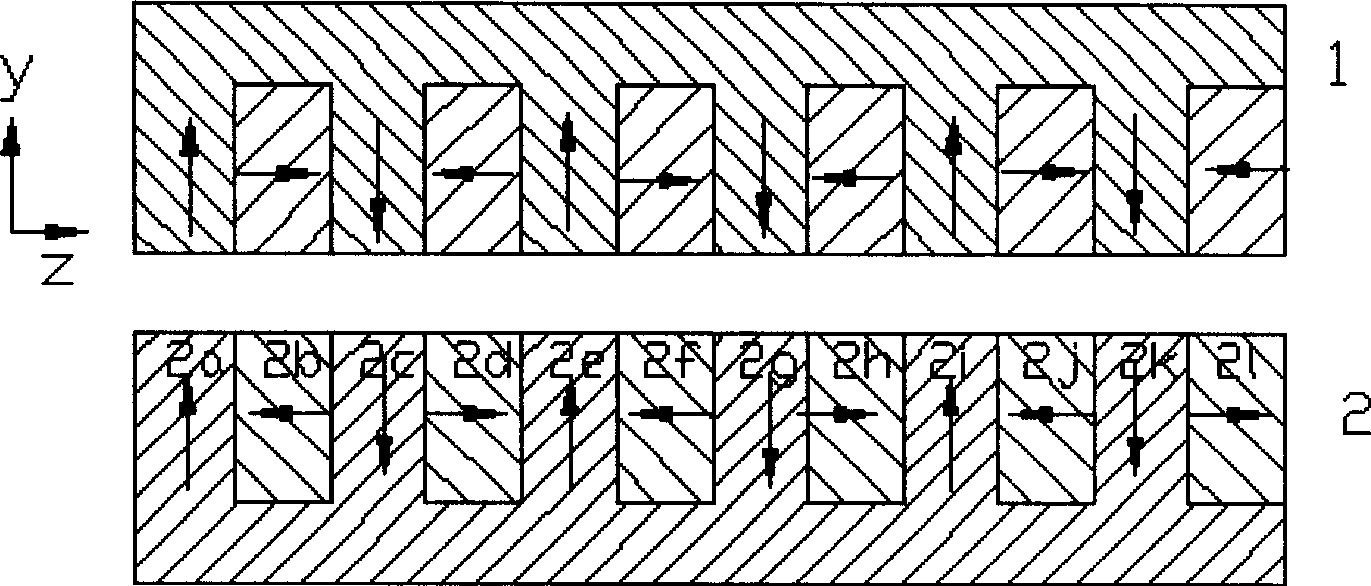

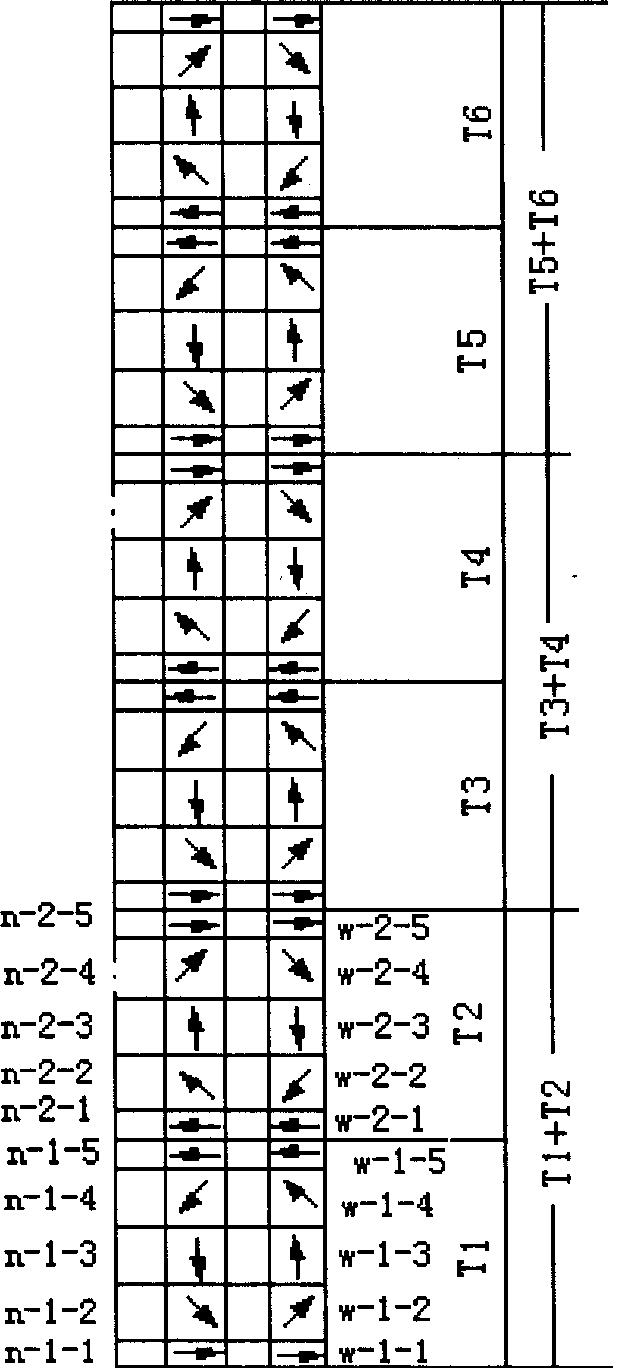

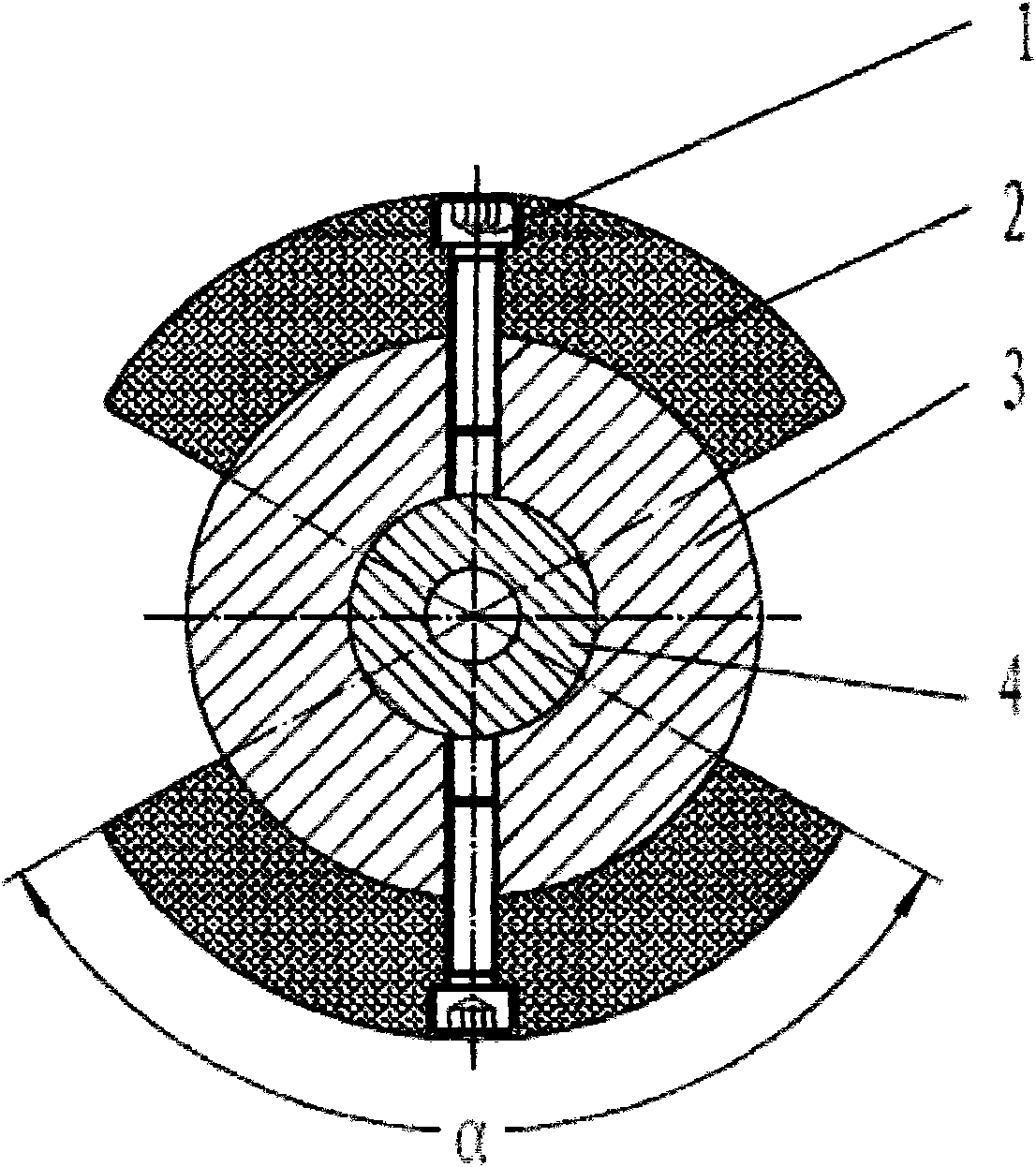

Bipolar permanent magnet

InactiveCN1862718ASimple structureEasy to manufacture and installPermanent magnetsMagnetizationElectrical polarity

This invention relates to antipole permanent magnet, it consists of 2n+1 neodymium iron boron magnetic loop axial overlay. Geometry and magnetization direction of each loop are axial symmetry, their magnetization direction change along certain rule. The adjoint loop magnetization directions are 360 degrees per 2n different look from any axial cross section. Inner or outer air gap is magnetic work space according to the different magnetic circuit. The 2n+1 loop are fixed by nonmagnetic metal inner and outer shells. There is no ferromagnetic part in the magnetic circuit, series structure is used, and the whole magnetic potential is the stacking of potentials provided by each loop. This invention can generate strong magnetic field with unchanging polar along circle direction. Its structure is simple, it's manufacturing and installation is simple. There is no ferromagnetic part, its weight is light. There is nearly no flux leakage, the anti demagnetizing action ability is strong, its adjustability is good.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

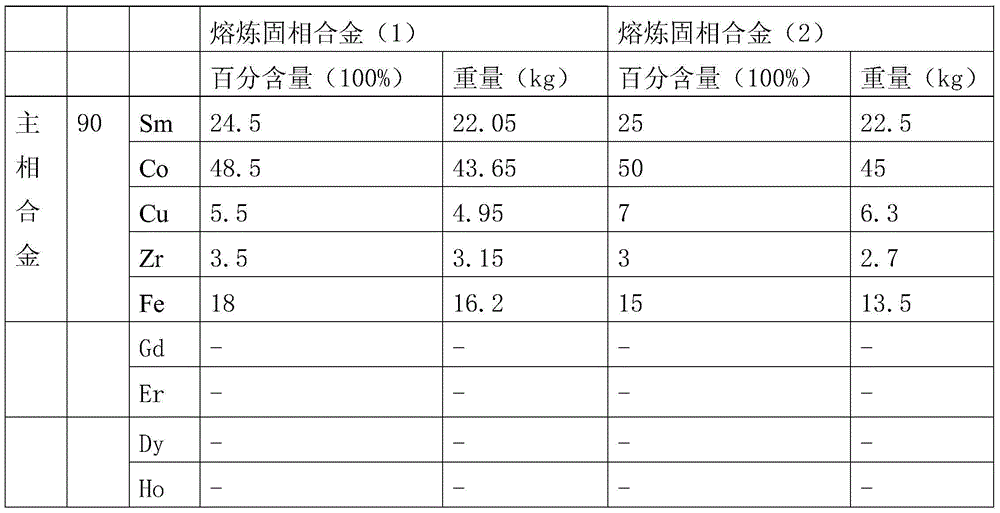

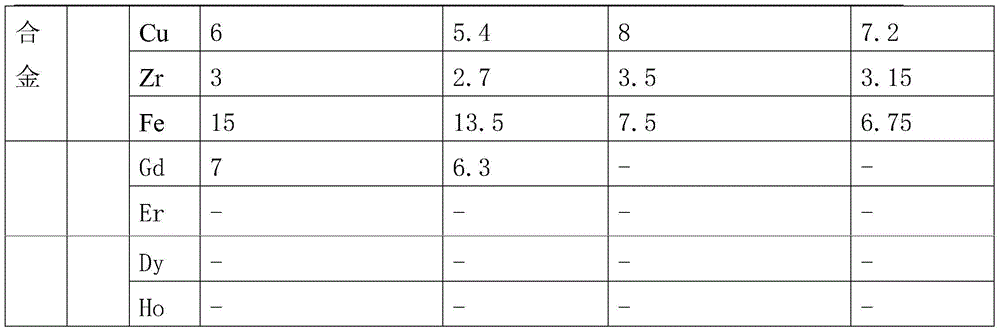

Rare earth permanent magnetic material Sm2(CoFeCuZr)17 and preparation method thereof

The invention provides a rare earth permanent magnetic material Sm2(CoFeCuZr)17 which comprises the following components by weight percentage: 87-100% of main phase alloy, 0-10% of Gd or Er, and 0-3% of Dy or Ho, wherein the main phase alloy is a 2:17 sintered samarium cobalt based rare earth permanent magnetic material and comprises the following components by atomic weight percentage: 20-40% of Sm, 40-65% of Co, 0-10% of Cu, 0-5% of Zr and 10-20% of Fe. Compared with the prior art, the rare earth permanent magnetic material Sm2(CoFeCuZr)17 has the benefits that all properties can be covered by a preparation method according to different material property requirements of users without changing pulverization, forming, sintering or aging treatment, the production cycle is shortened, and the raw material cost and labor cost are lowered as compared with the common sintered 2:17 permanent magnet.

Owner:CHENGDU 899 SCI & TECH

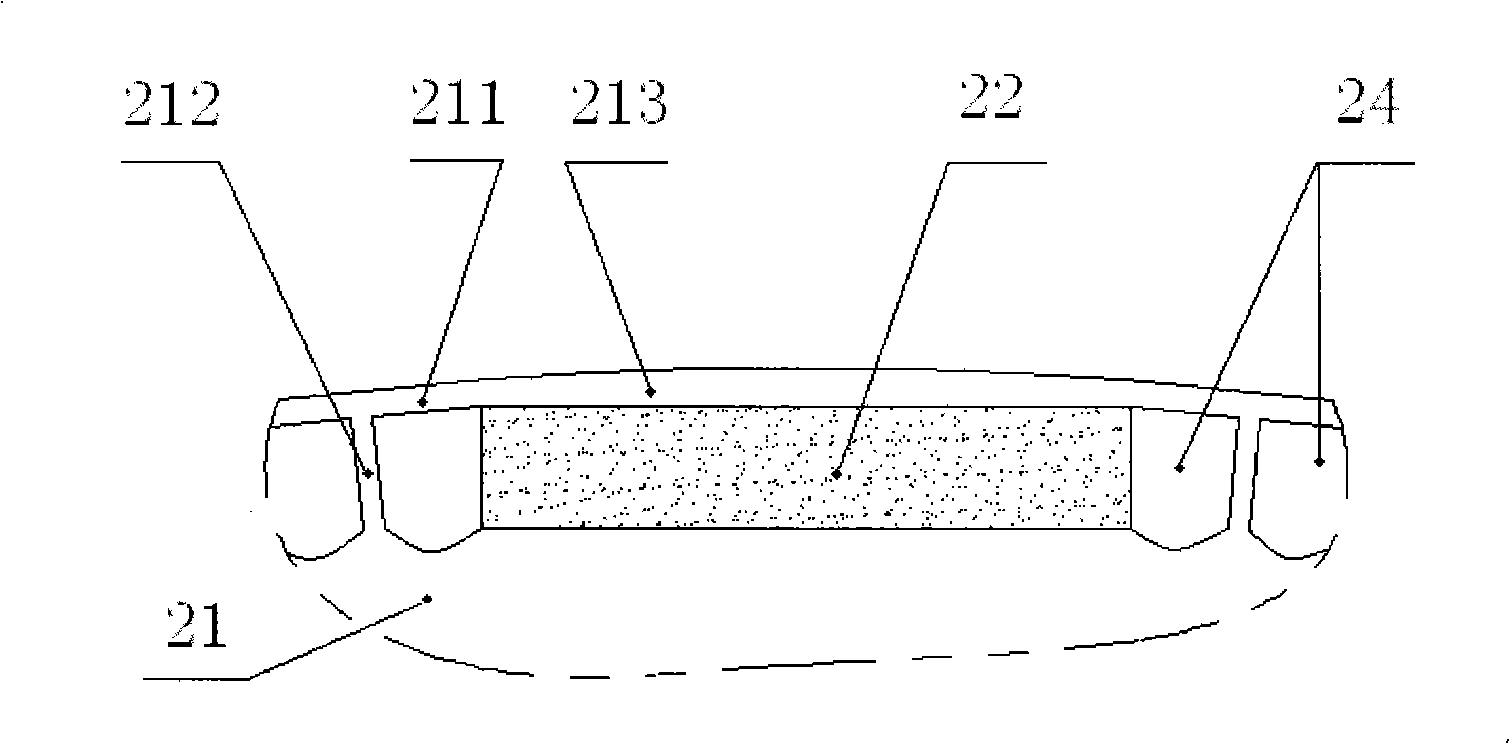

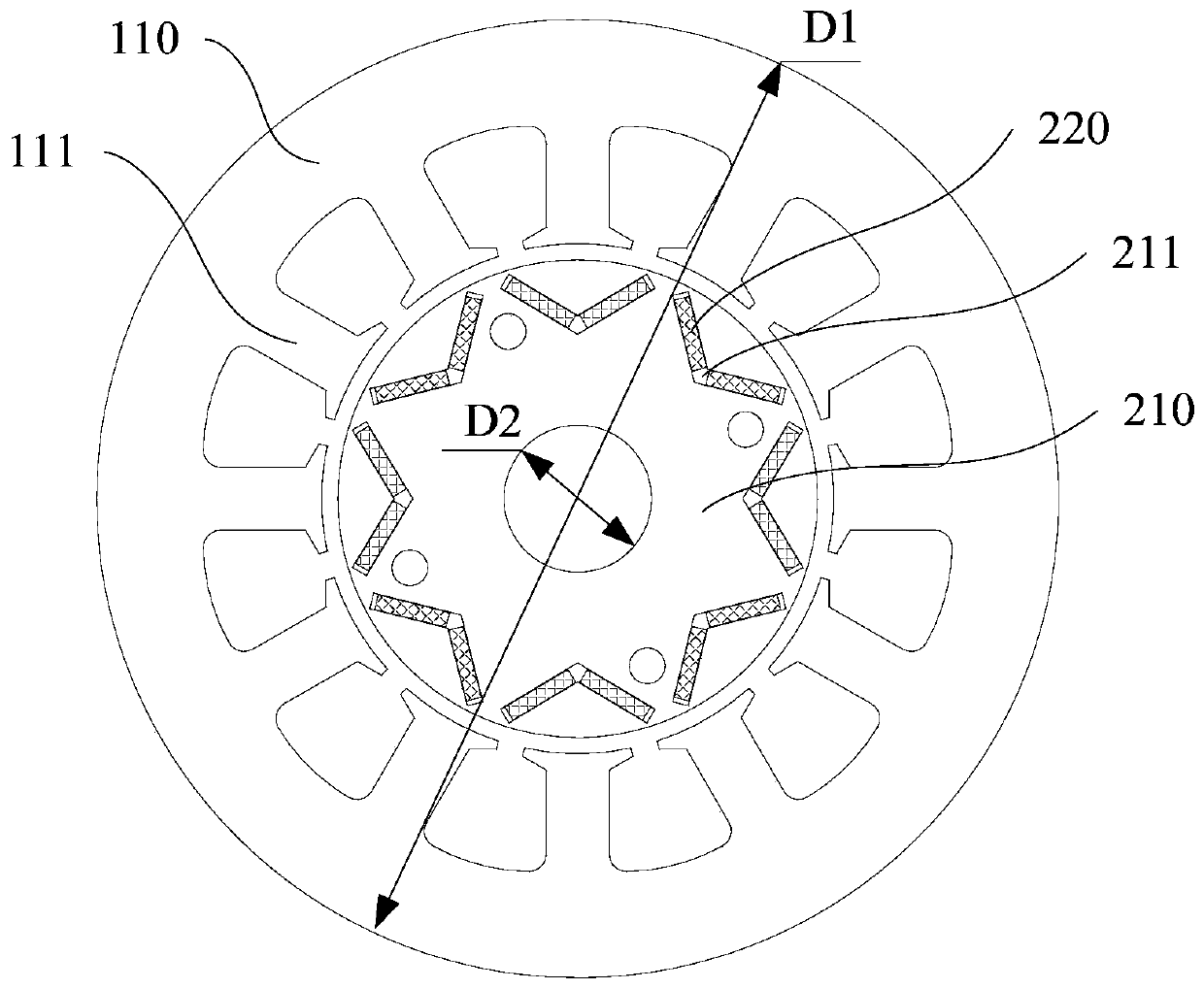

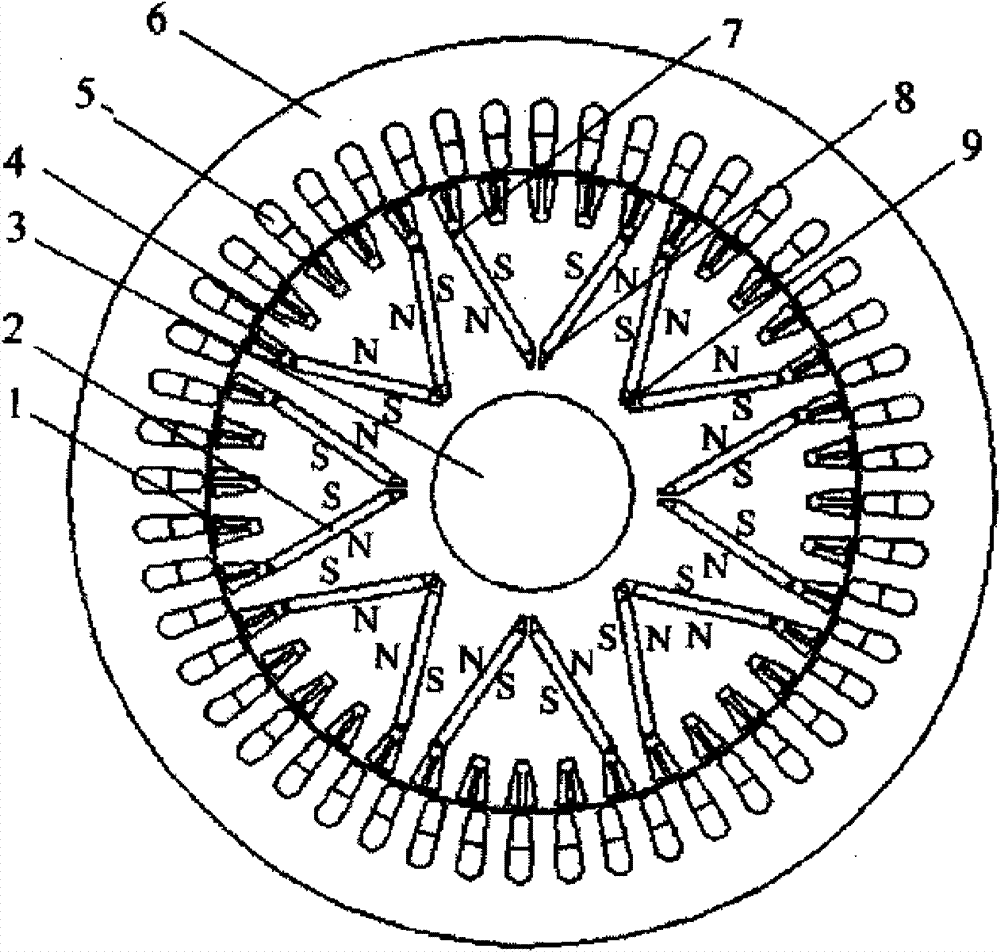

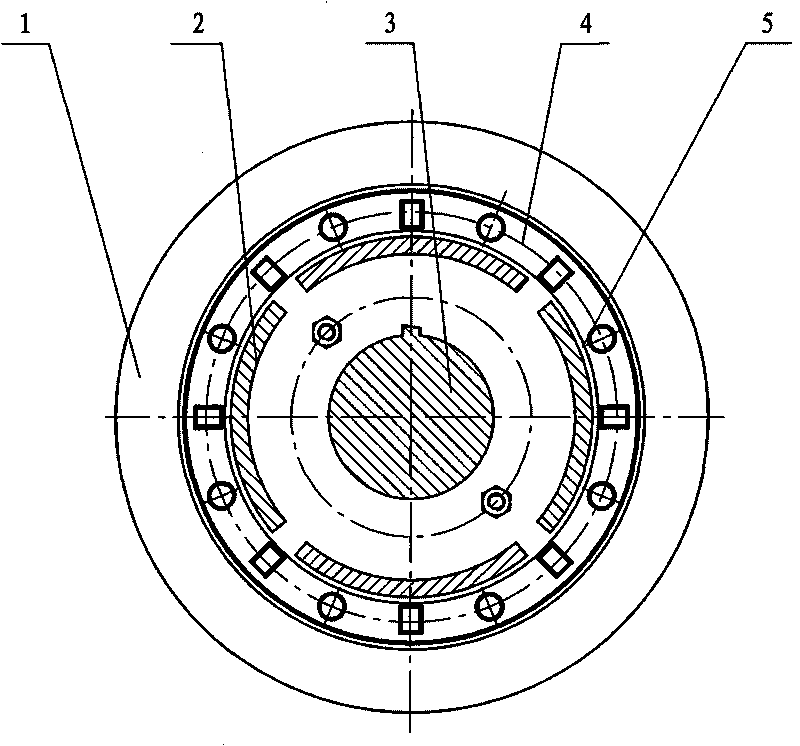

Combination magnetic pole type build-in tangential permanent magnet synchronous motor

ActiveCN105391264AImprove operational reliabilityStrong resistance to demagnetizationSynchronous machine detailsMagnetic circuit rotating partsHarmonicPermanent magnet synchronous motor

The invention provides a combination magnetic pole type build-in tangential permanent magnet synchronous motor, and belongs to the field of permanent magnet motors. The invention solves problems that harmonics exist in an air-gap magnetic field of a rare earth permanent magnet synchronous motor driven by sine waves, and partial irreversible demagnetization is prone to occur. The permanent magnet synchronous motor comprises a rotor and a stator. The rotor comprises a plurality of rotor poles and a rotor core, the plurality of rotor poles are uniformly distributed on a circumferential direction of the rotor core, and each rotor pole is vertically embedded within the stator core along a radial direction; the rotor pole comprises a rare earth permanent magnet pole and a ferrite permanent magnet pole; the ferrite permanent magnet pole is close to the air-gap side, and an internal end surface of the ferrite permanent magnet pole is combined with an external end surface of the rare earth permanent magnet pole; and both magnetization directions of the rare earth permanent magnet pole and the ferrite permanent magnet pole are parallel magnetization, and the magnetization directions are the same and are both perpendicular to the radius. The permanent magnet synchronous motor of the structure enables the air-gap magnetic field to contain a smaller number of harmonics, thereby improving motor efficiency; and moreover, ferrite permanent magnet materials are cheap, thereby reducing costs.

Owner:HARBIN INST OF TECH

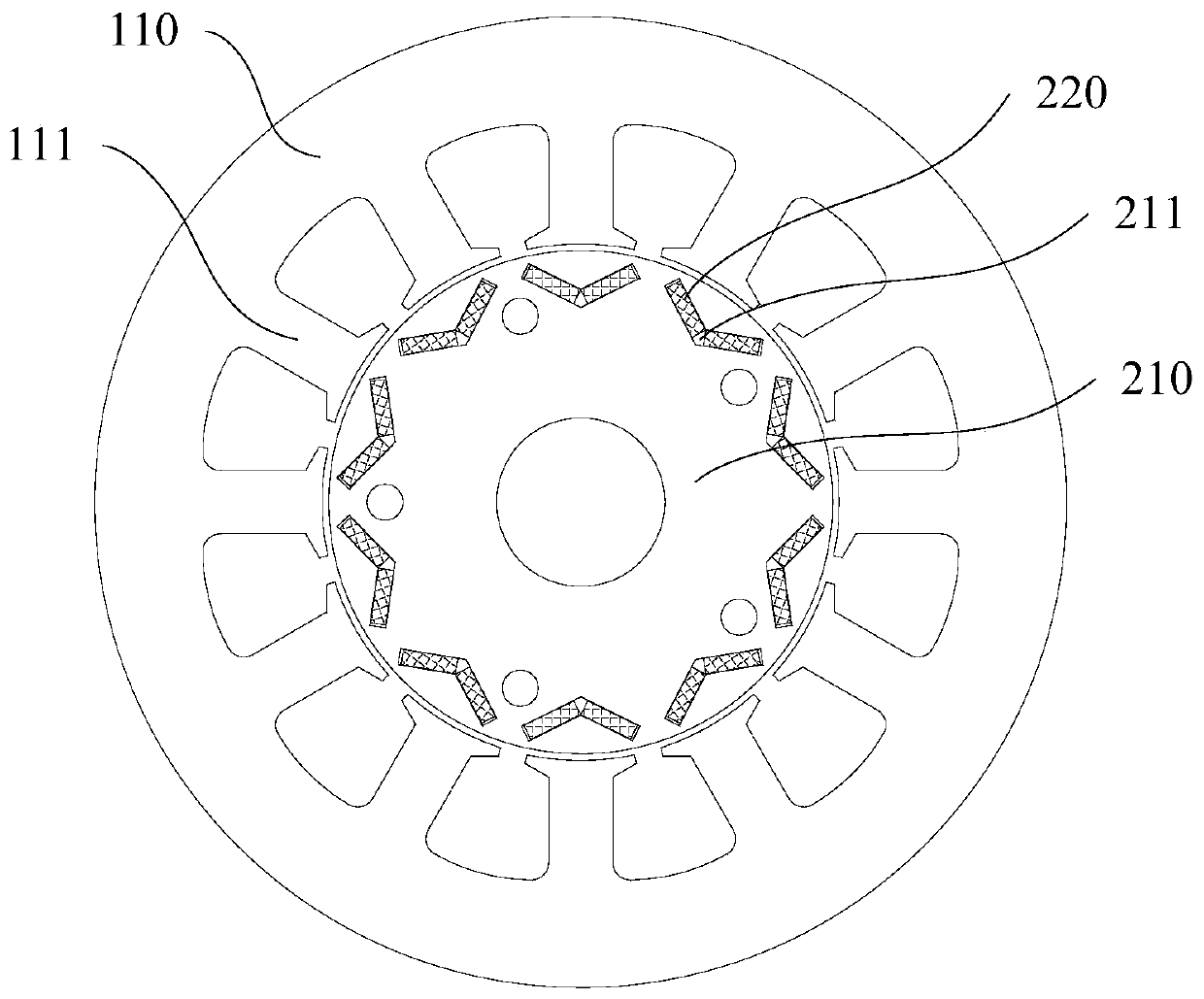

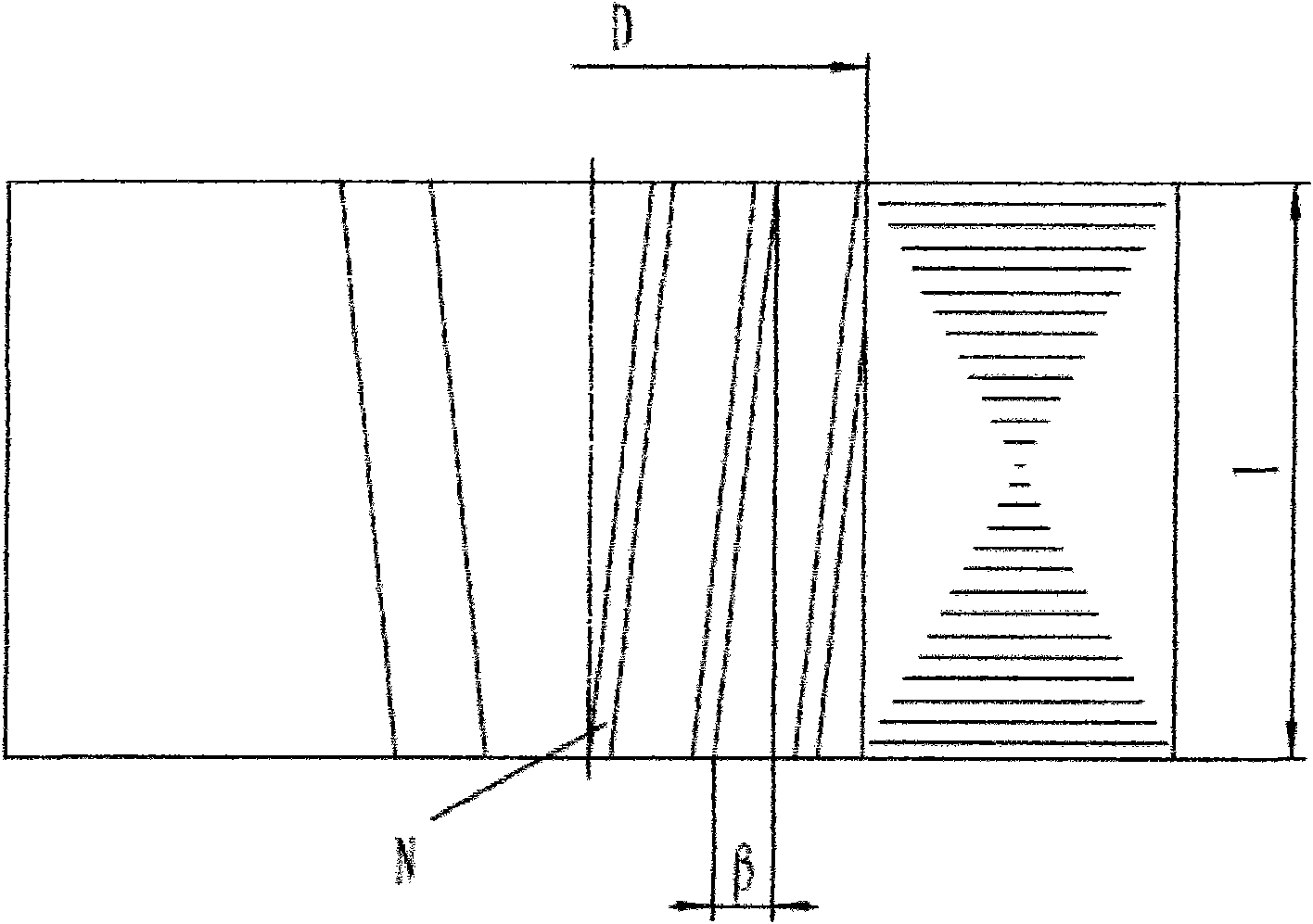

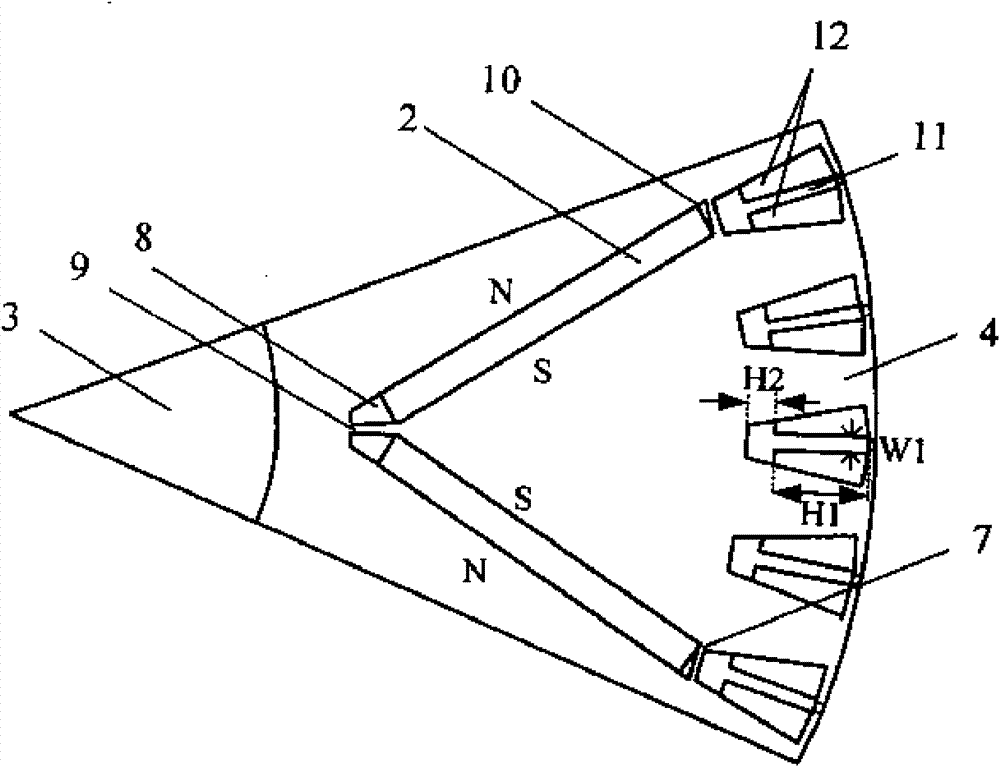

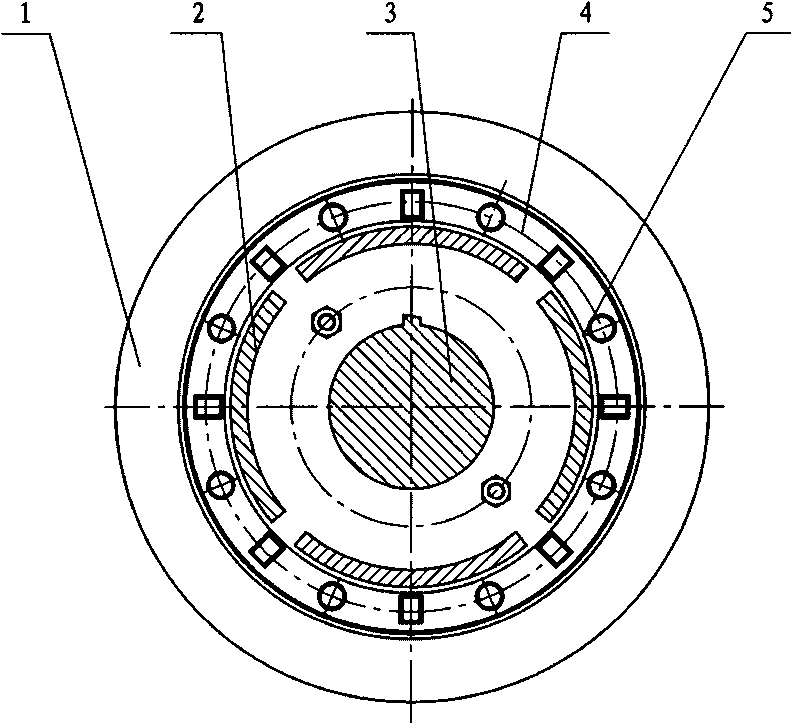

Combined magnetic pole type built-in radial linear permanent magnet synchronous motor

ActiveCN105375726AImprove operational reliabilityStrong resistance to demagnetizationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsRare earthPermanent magnet synchronous motor

A combined magnetic pole type built-in radial linear permanent magnet synchronous motor belongs to the field of a permanent magnet motor, and aims to solve the problems that a harmonic wave easily occurs in an air gap magnetic field of a rare earth permanent magnet synchronous motor driven by a sine wave and local irreversible demagnetization occurs easily. The combined magnetic pole type built-in radial linear permanent magnet synchronous motor comprises a rotor and a stator, one or multiple layer of linear permanent magnet mounting grooves are uniformly and circumferentially distributed in a rotor core, a rotor magnetic pole is disposed in each mounting groove, and each mounting groove extends in an axial direction; each rotor magnetic pole comprises a rare earth permanent-magnet magnetic pole and two ferrite permanent-magnet magnetic poles; the left and right end faces of each rare earth permanent-magnet magnetic pole are respectively provided with the one corresponding ferrite permanent-magnet magnetic pole, and the rare earth permanent-magnet magnetic pole and the two corresponding ferrite permanent-magnet magnetic poles form continuous linear magnetic pole structure; and the magnetizing directions of each rare earth permanent-magnet magnetic pole and the corresponding two ferrite permanent-magnet magnetic poles are parallel and same. The permanent magnet synchronous motor having structure enables a harmonic wave content of the air gap magnetic field to be reduced, and improves motor efficiency; and price of a ferrite permanent magnetic material is low, so cost is lowered.

Owner:HARBIN INST OF TECH

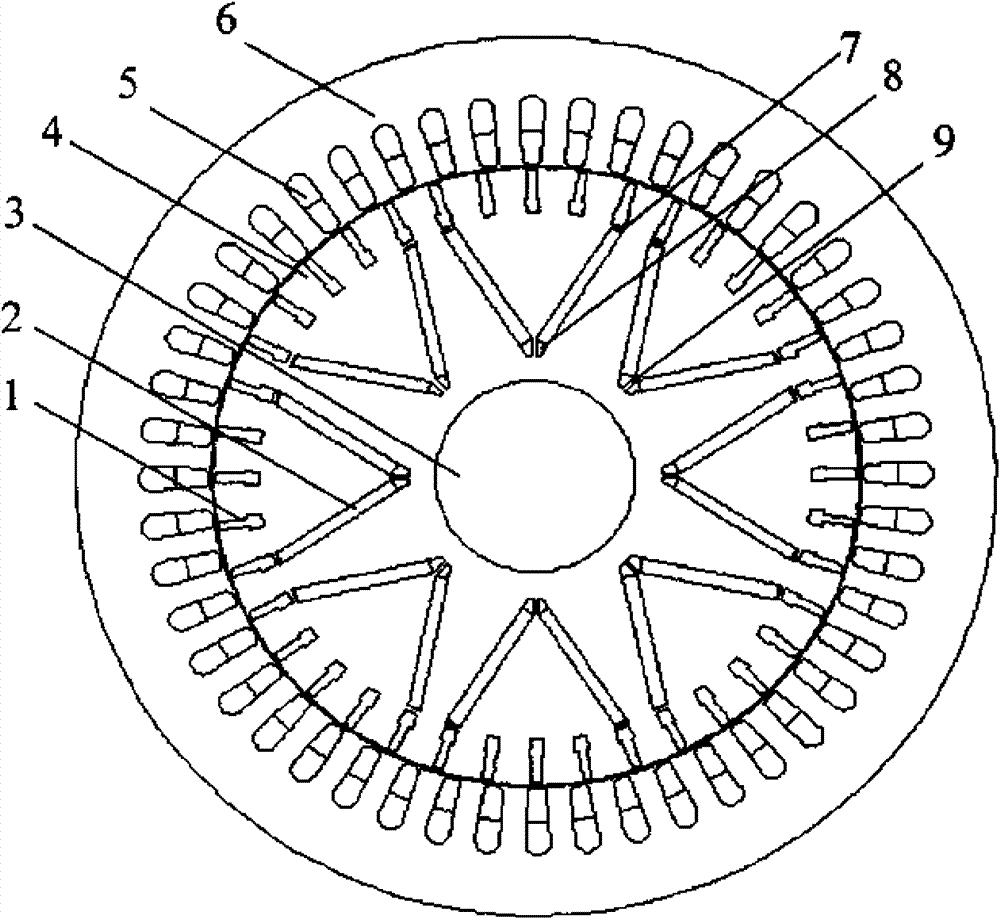

Composite magnetic pole type axial-flux permanent magnet synchronous motor

ActiveCN105429409AReduced risk of demagnetizationImprove reliabilitySynchronous machinesMagnetic circuit characterised by magnetic materialsSurface mountingHarmonic

The invention discloses a composite magnetic pole type axial-flux permanent magnet synchronous motor, belongs to the field of permanent magnet motors, and aims at solving the problems that a harmonic wave exists in an air-gap magnetic field of a sine wave-driven rare-earth permanent magnet synchronous motor and local irreversible demagnetization easily occurs. The composite magnetic pole type axial-flux permanent magnet synchronous motor comprises a rotor and a stator, wherein the rotor and the stator are oppositely arranged in parallel; a plurality of rotor poles are evenly arranged on the surface, facing the stator, of a rotor core along the peripheral direction in a surface-mounted manner; the rotor poles are in an arc structure; each rotor pole comprises a rare-earth permanent magnet pole and two ferrite permanent magnet poles; one ferrite permanent magnet pole is arranged on each of the left end surface and the right end surface of each rare-earth permanent magnet pole; each rare-earth permanent magnet pole and each two ferrite permanent magnet poles form a continuous arc magnetic pole structure; and the magnetizing directions of the each rare-earth permanent magnet pole and each two ferrite permanent magnet poles all adopt axial magnetization and are the same. According to the permanent magnet synchronous motor with the structure, the harmonic content of the air-gap magnetic field is reduced; the motor efficiency is improved; meanwhile, the ferrite permanent magnet material is low in price; and the cost is reduced.

Owner:HARBIN INST OF TECH

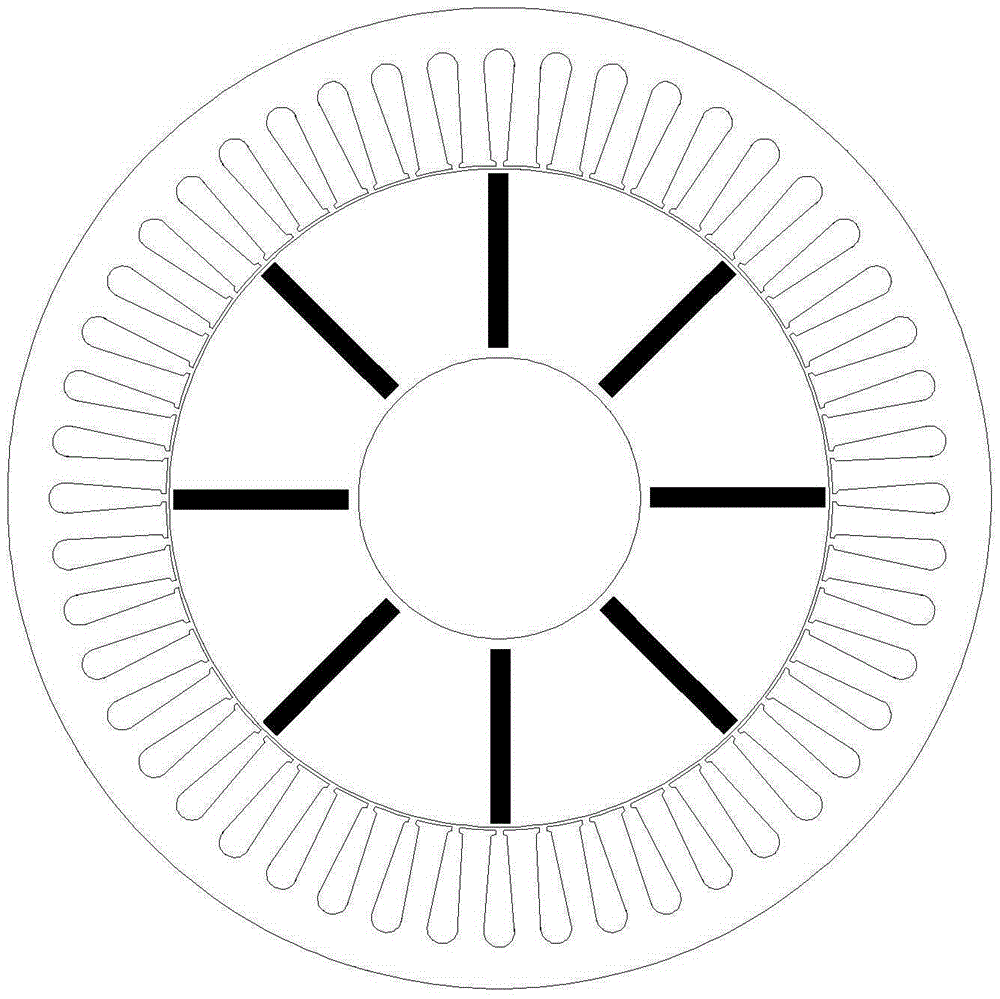

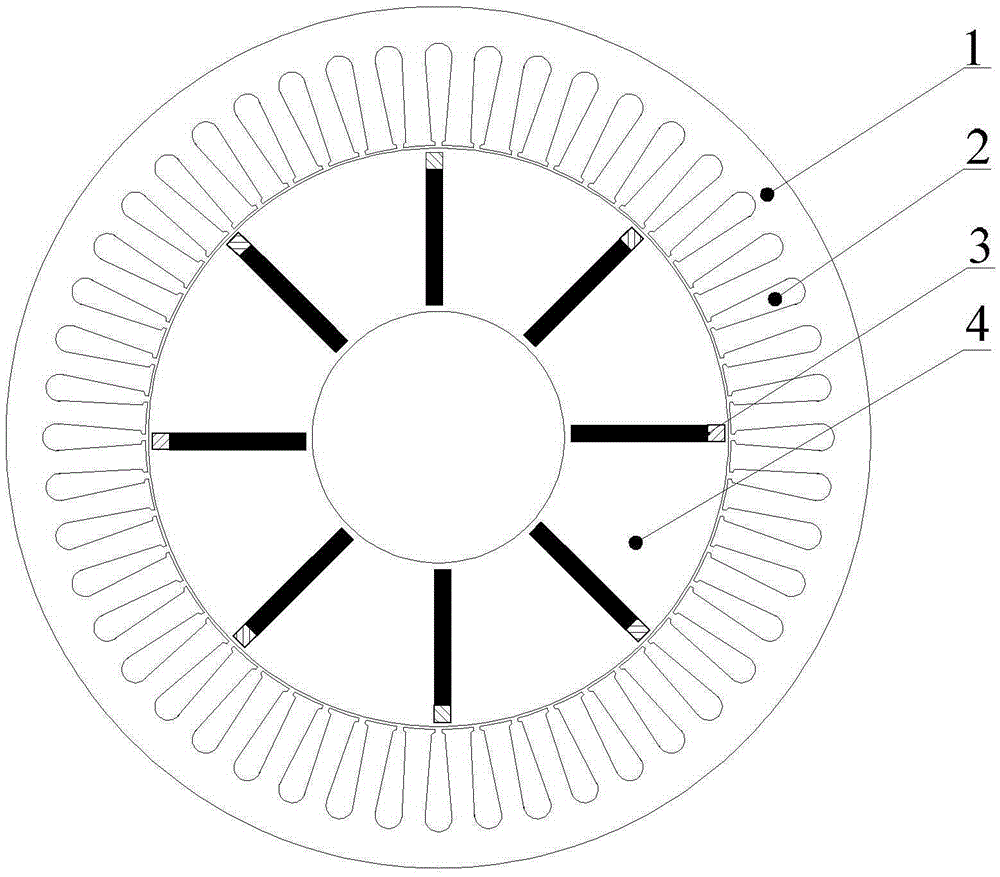

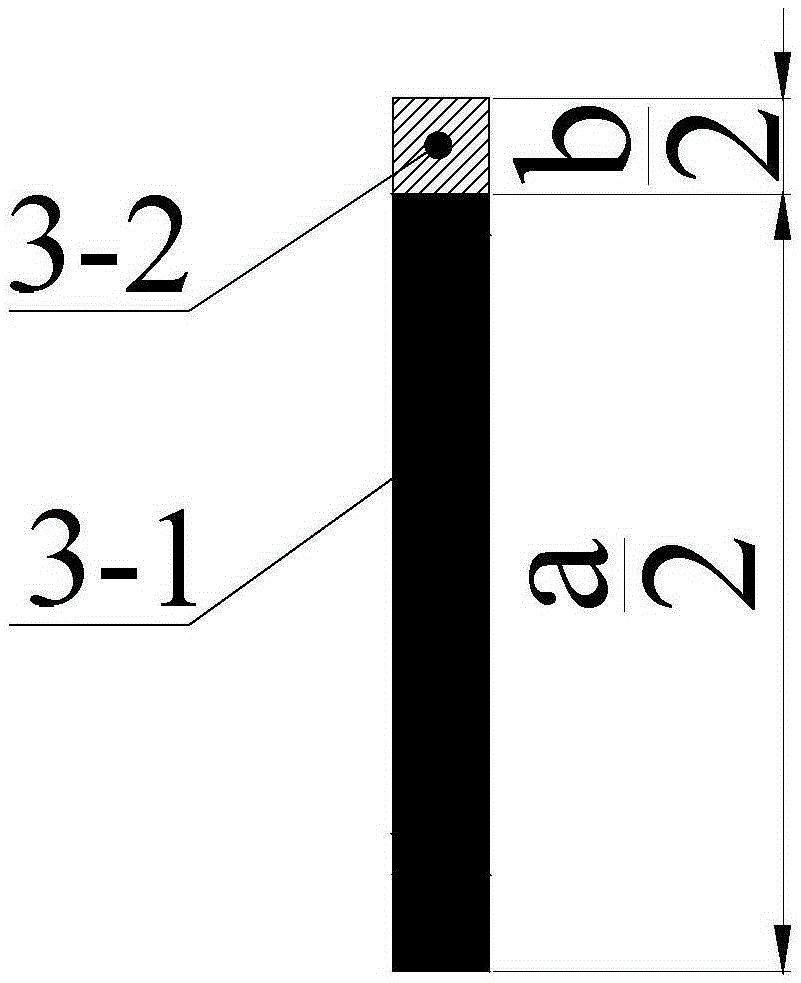

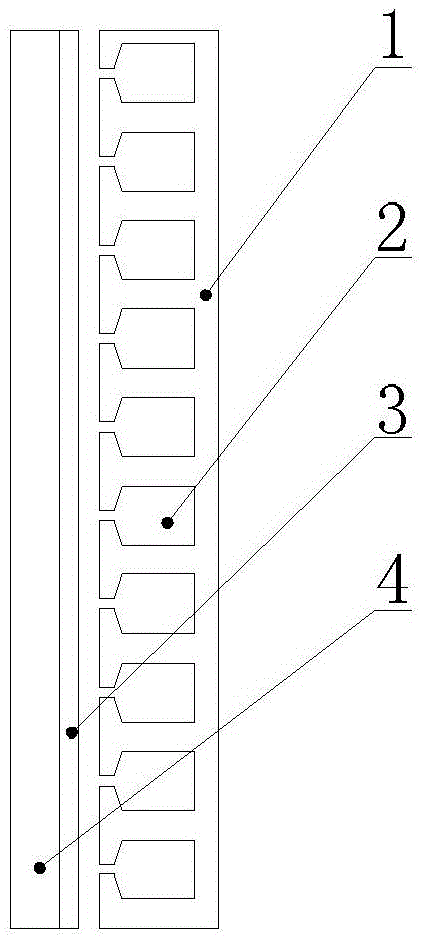

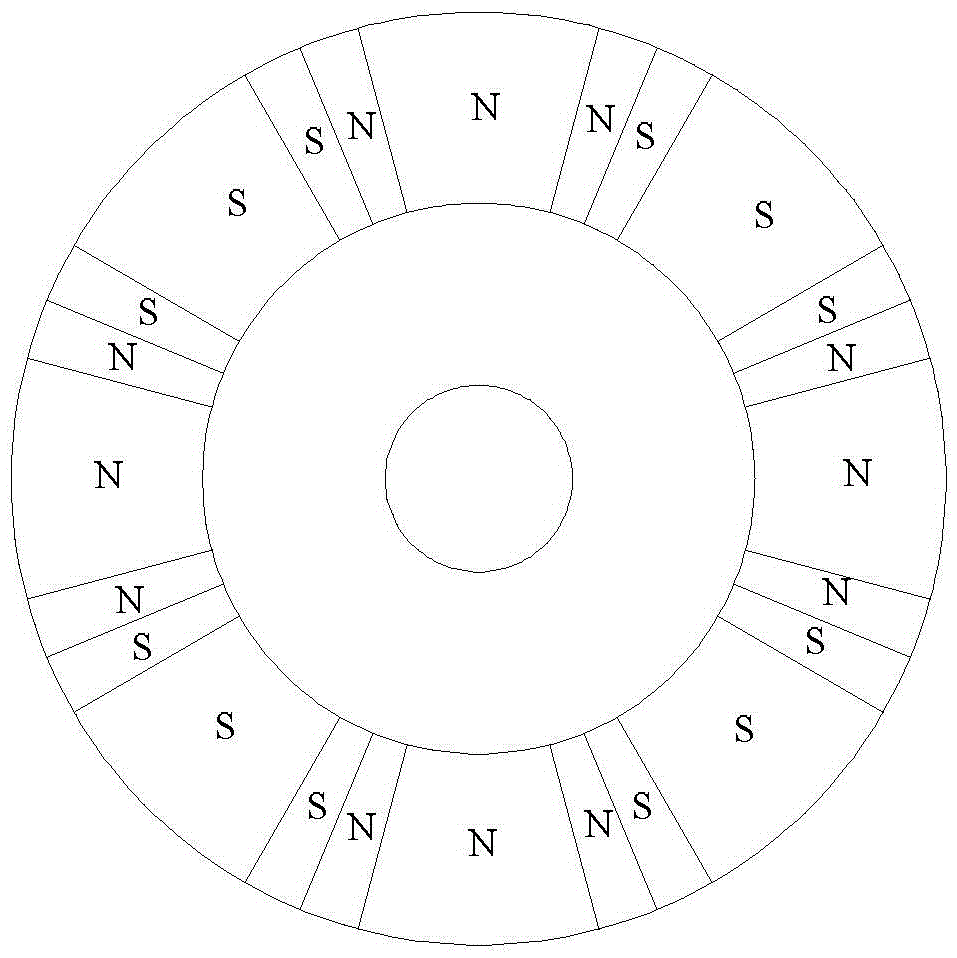

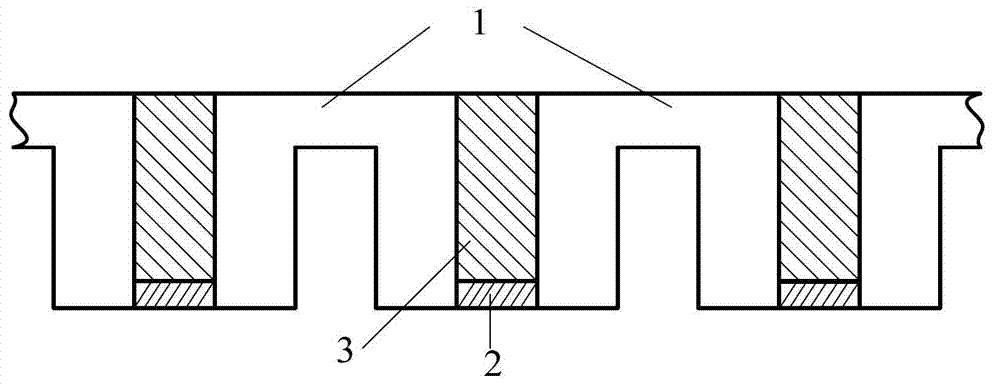

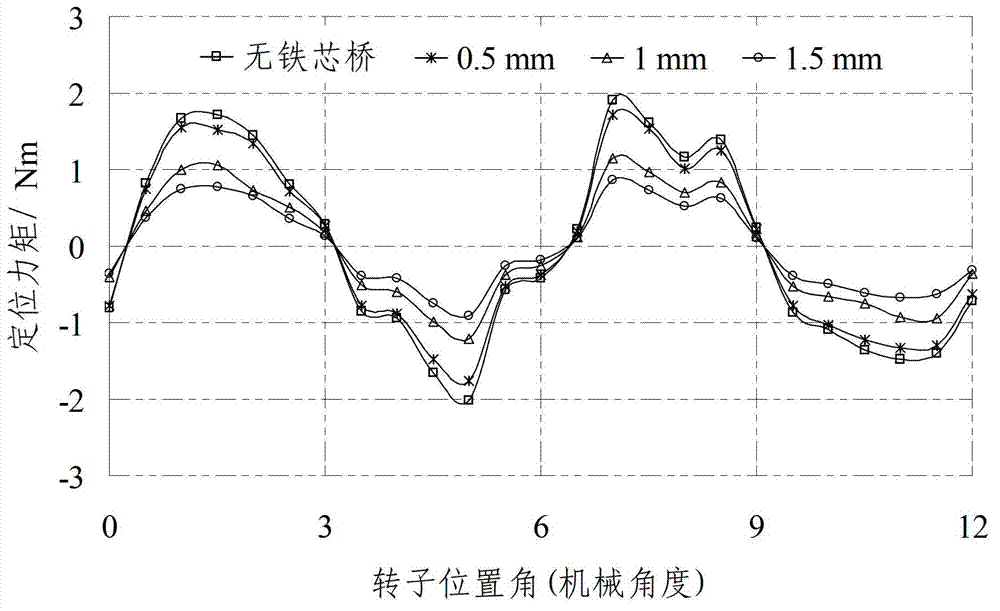

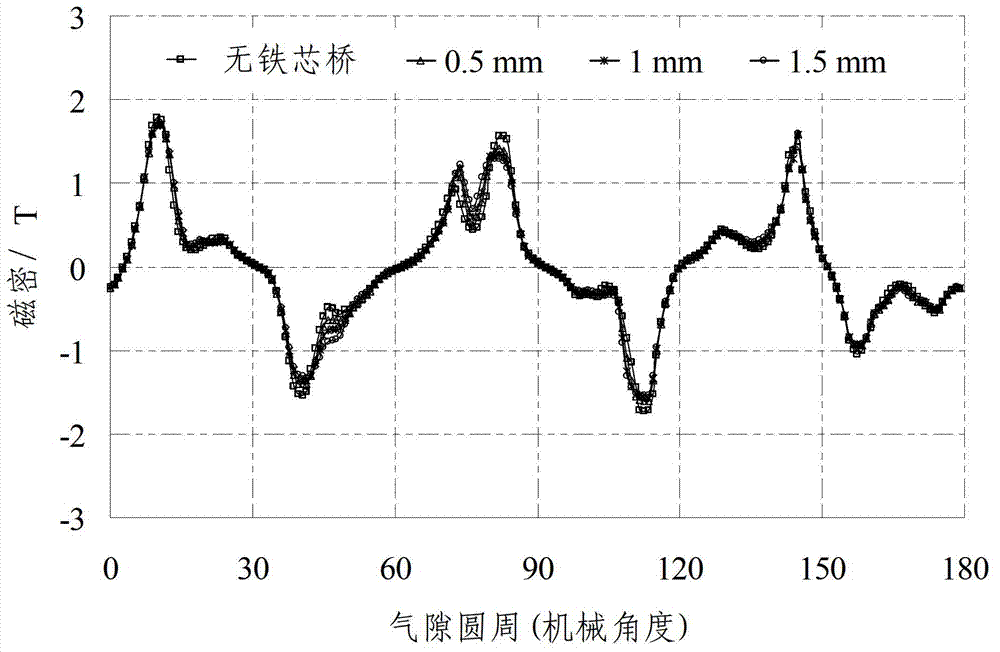

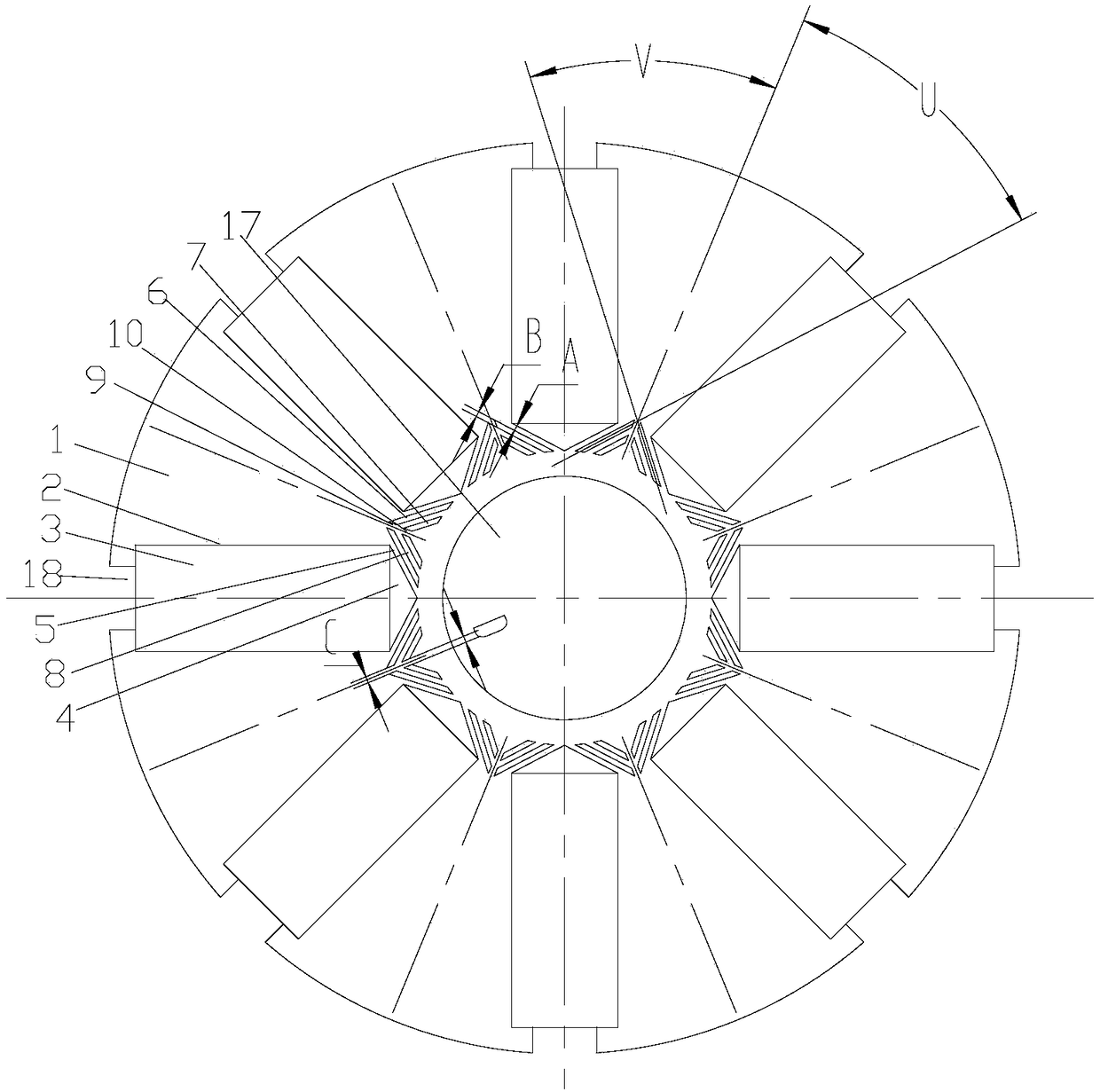

Method for reducing positioning torque of magnetic-flux switching permanent magnet motor

ActiveCN102820715AImprove cooling conditionsStrong resistance to demagnetizationMagnetic circuit stationary partsFinite element methodPermanent magnet motor

The invention provides a method for reducing the positioning torque of a magnetic-flux switching permanent magnet motor, comprising the following steps: arranging an iron core bridge between stator iron cores of the magnetic-flux switching permanent magnet motor; arranging a permanent magnet in a groove which is formed by adjacent stator iron cores and the iron core bridge, and setting the initial thickness of the iron core bridge as the length of the air gap of the magnetic-flux switching permanent magnet motor; determining the performance parameter involved in the iron core bridge thickness optimization process of the magnetic-flux switching permanent magnet motor; and optimizing and determining the thickness of the iron core bridge. The method is simple and efficient, the project is easy to implement, the thickness of the iron core bridge can be optimized by adopting the finite element method, the positioning torque of the magnetic-flux switching permanent magnet motor is reduced effectively, and the other performances of the magnetic-flux switching permanent magnet motor are hardly affected.

Owner:CHINA ELECTRIC POWER RES INST +1

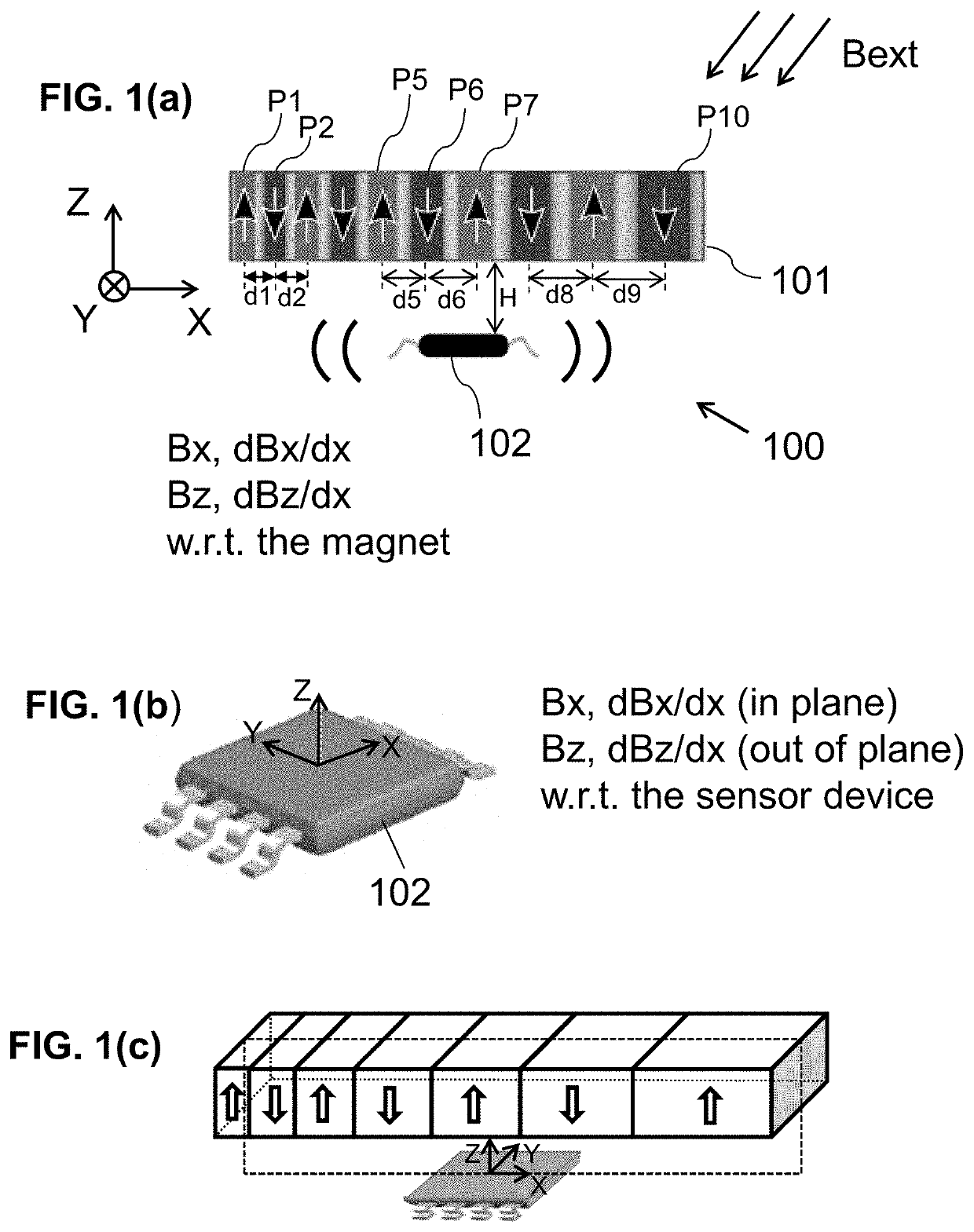

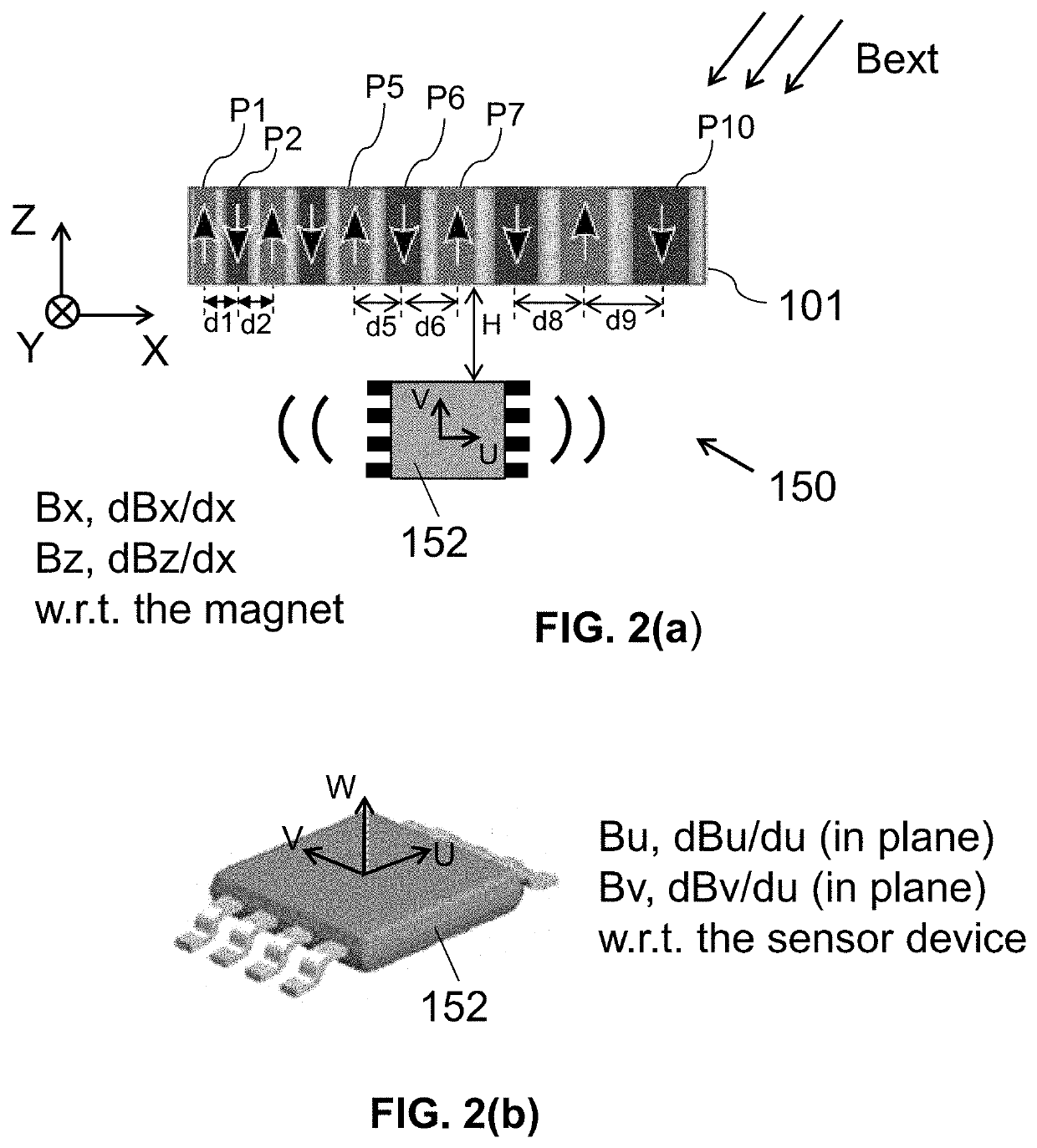

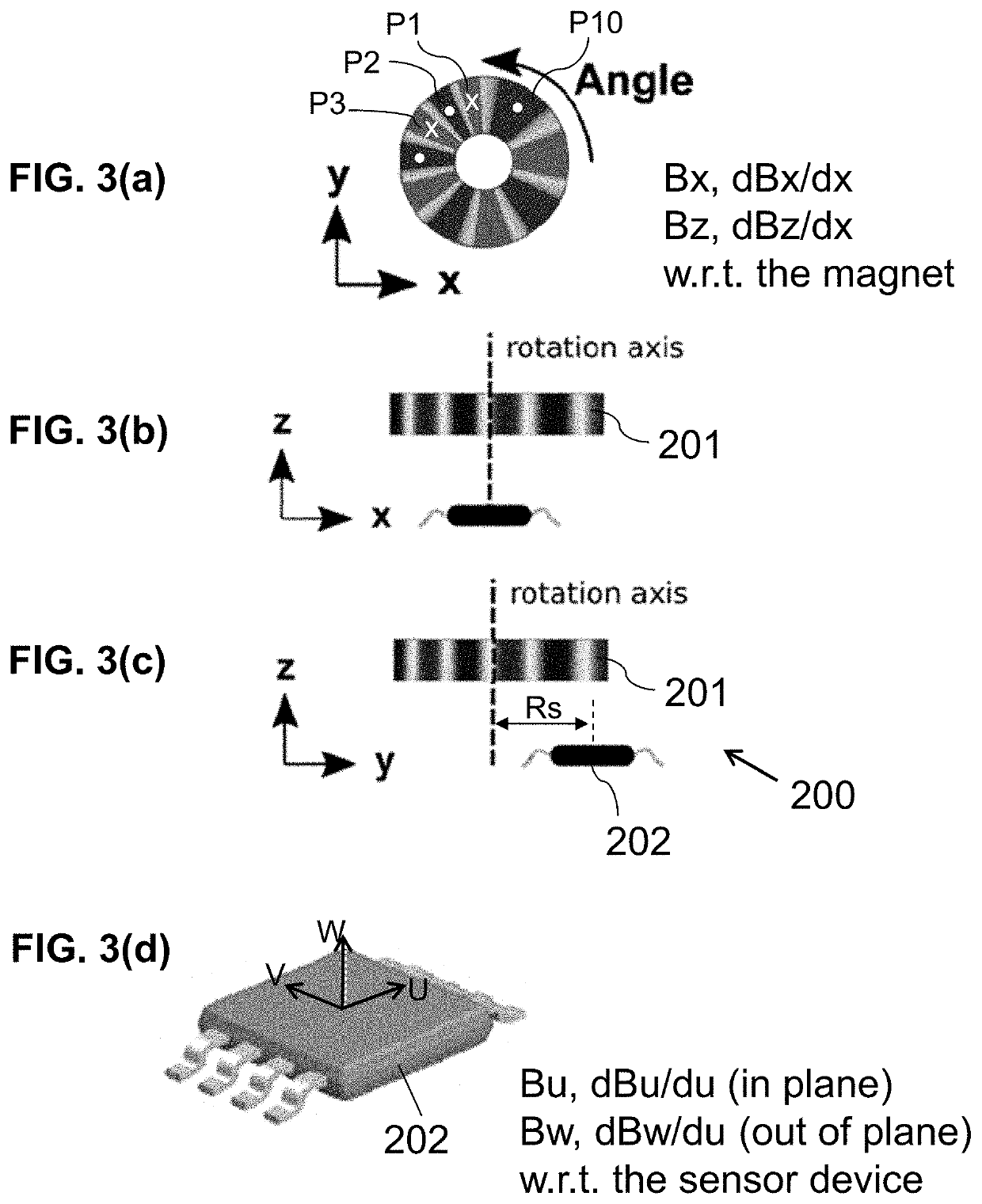

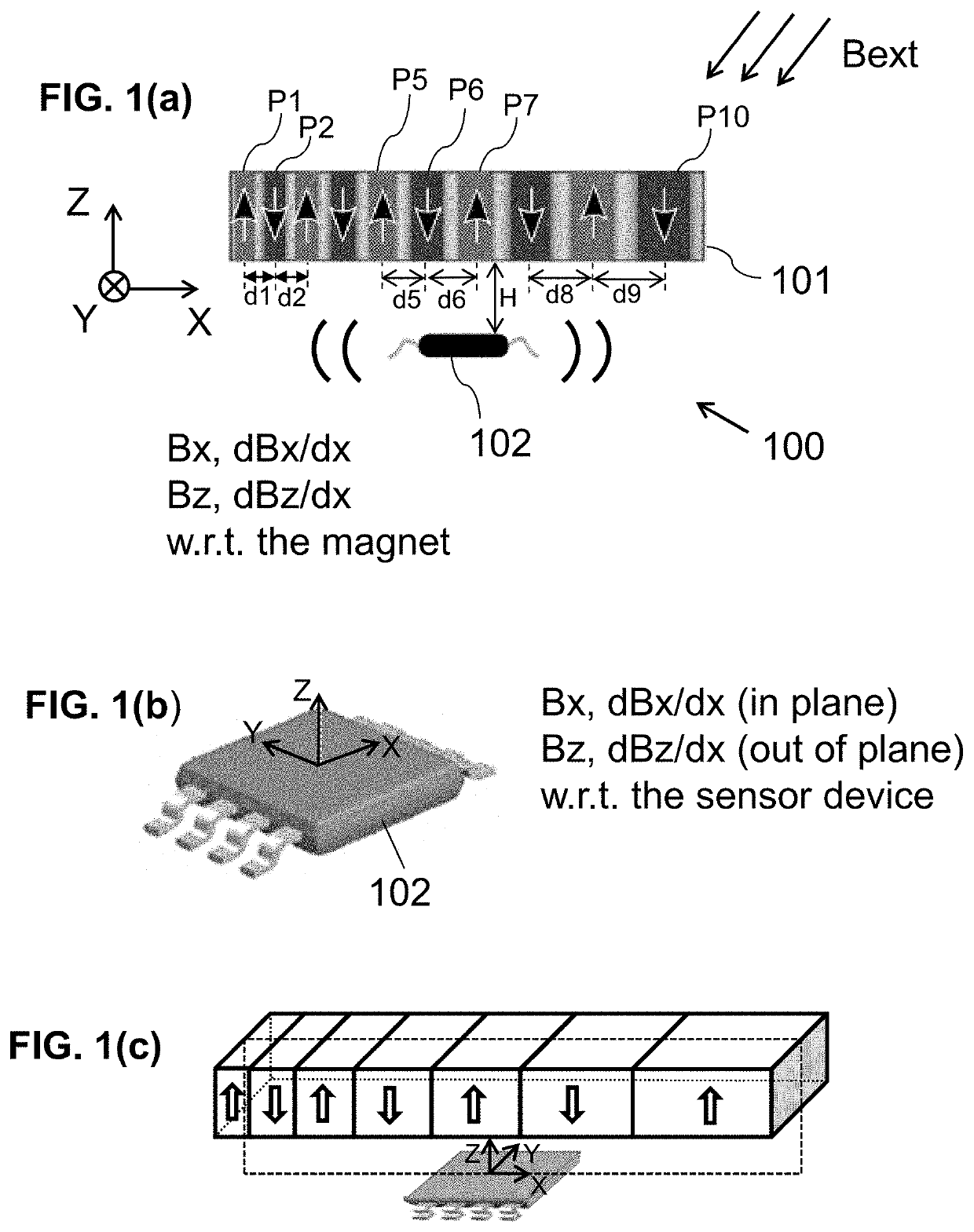

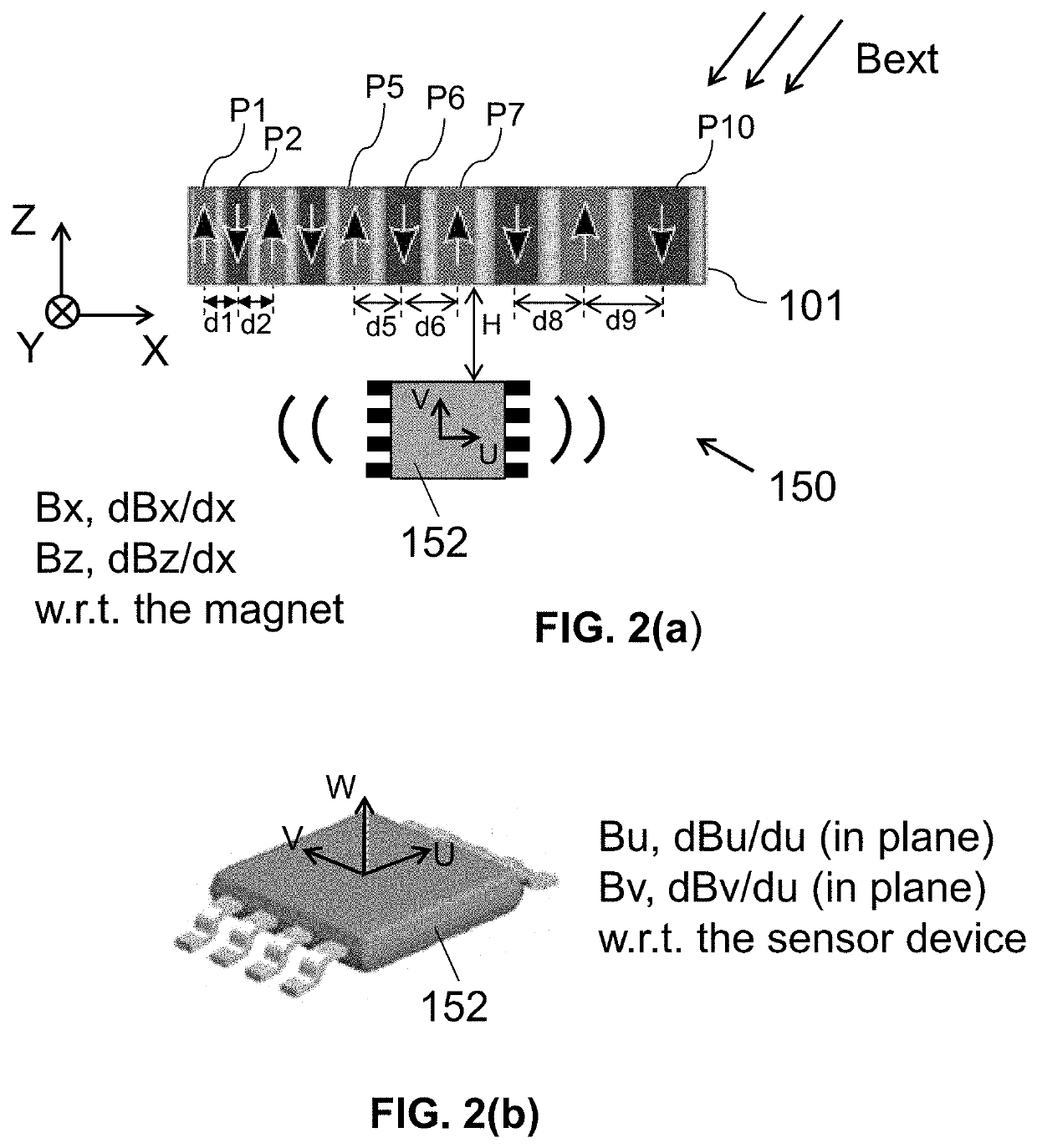

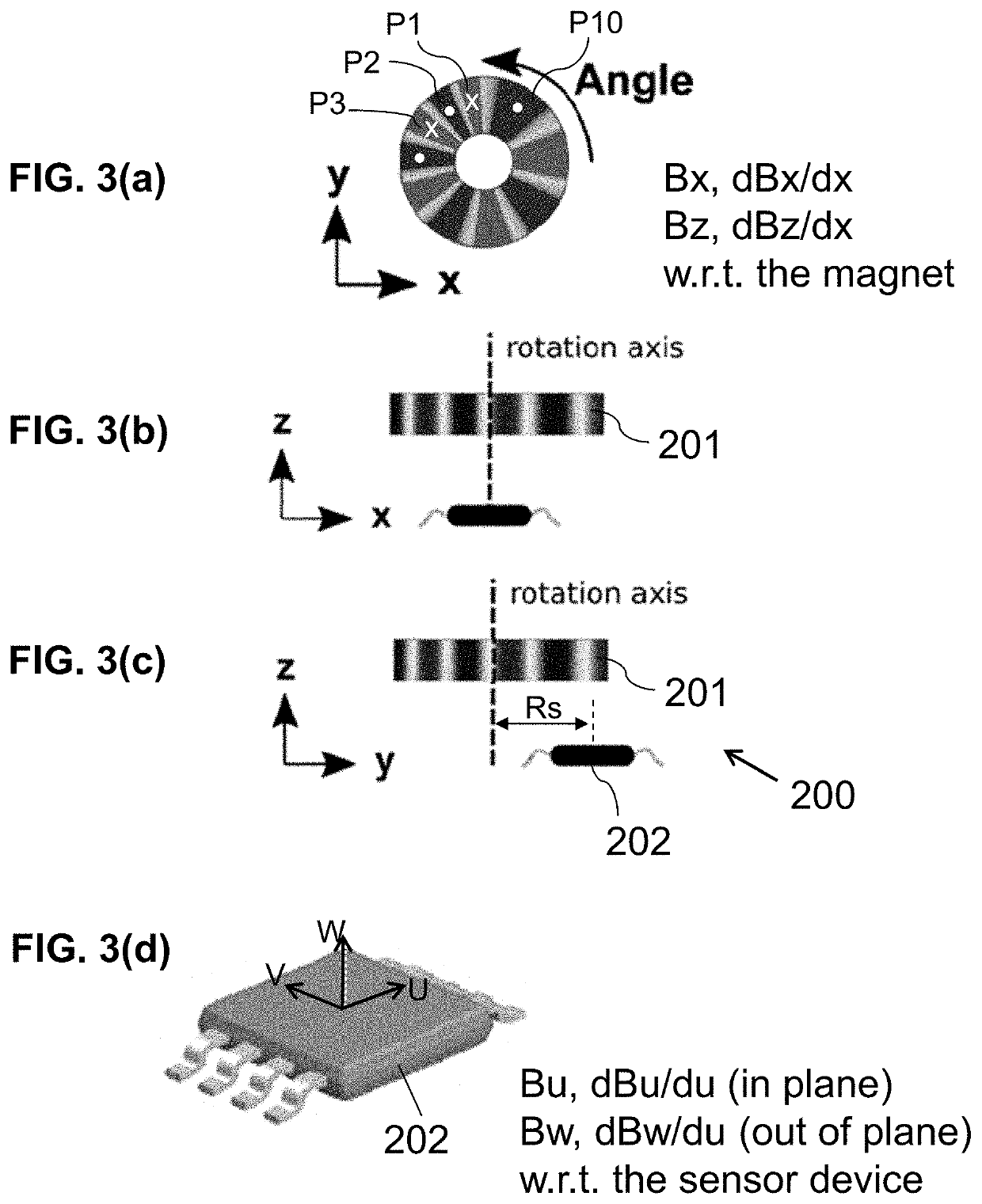

Magnetic position sensor system and method

ActiveUS20200149925A1Good signalStrong resistance to demagnetizationMagnetic field measurement using flux-gate principleElectric/magnetic position measurementsMagnetic polesEngineering

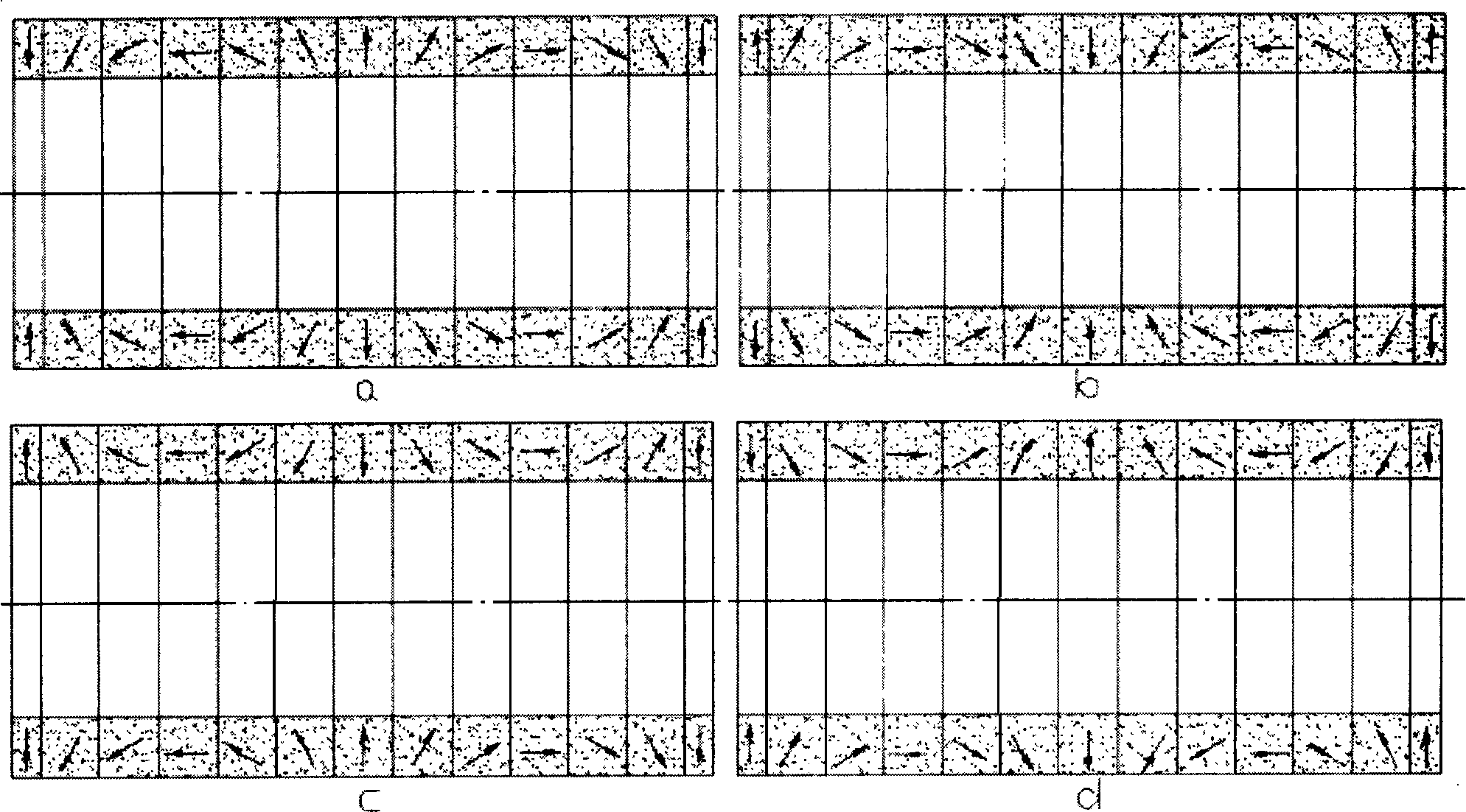

A position sensor system for determining a position of a sensor device relative to a magnetic structure, the system comprising: said magnetic structure comprising a plurality of poles; said sensor device comprising a plurality of magnetic sensors; the magnetic structure being movable relative to the sensor device, or vice versa; wherein: a distance between centres of adjacent poles varies along the movement direction; the sensor device is adapted: for determining a first magnetic field component parallel to, and a second magnetic field component perpendicular to a movement direction, and for calculating a coarse signal based on these components; and for determining a first and second gradient of these signals along the movement direction, and for calculating a fine signal based on these gradients; and for determining said position based on the coarse signal and the fine signal.

Owner:MELEXIS TECH NV

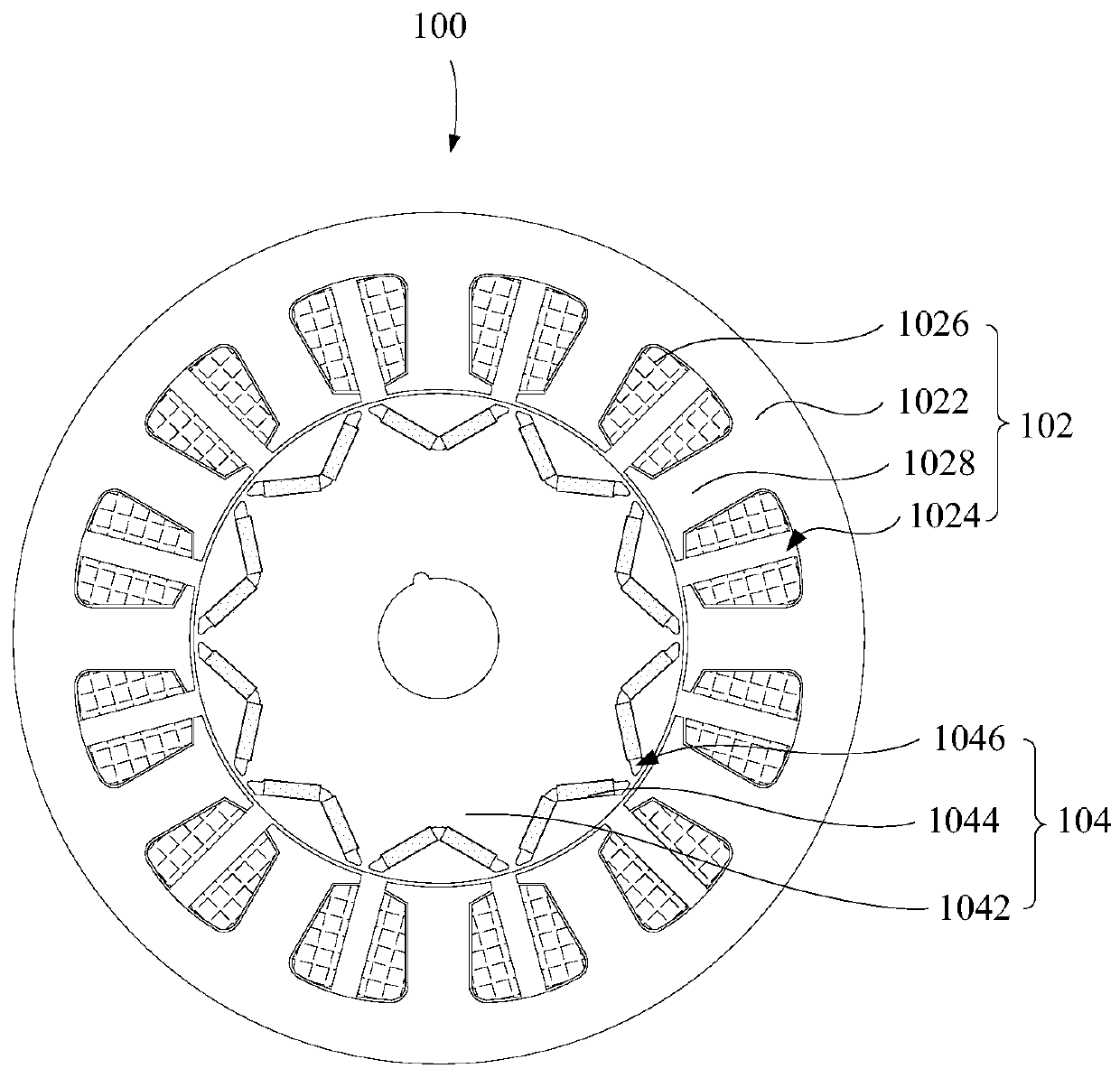

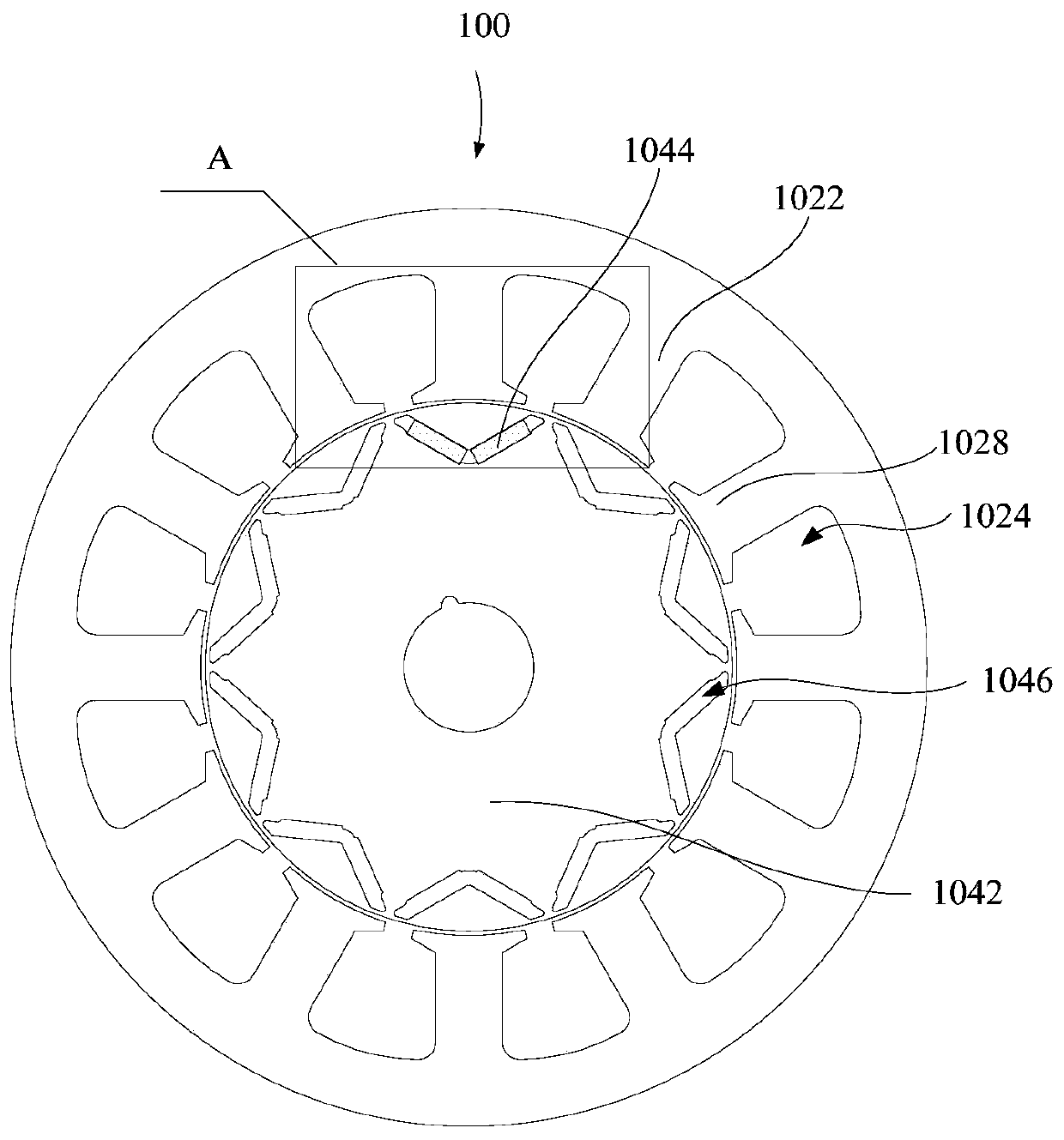

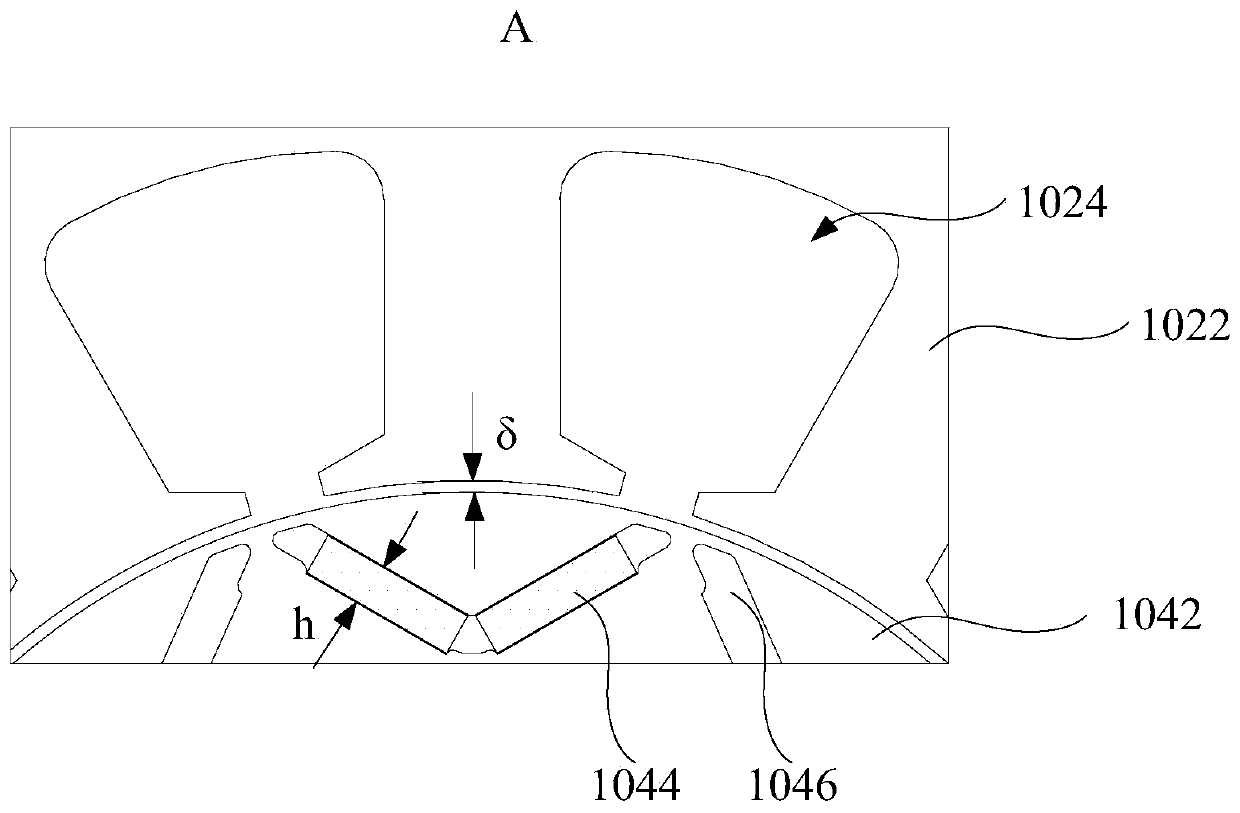

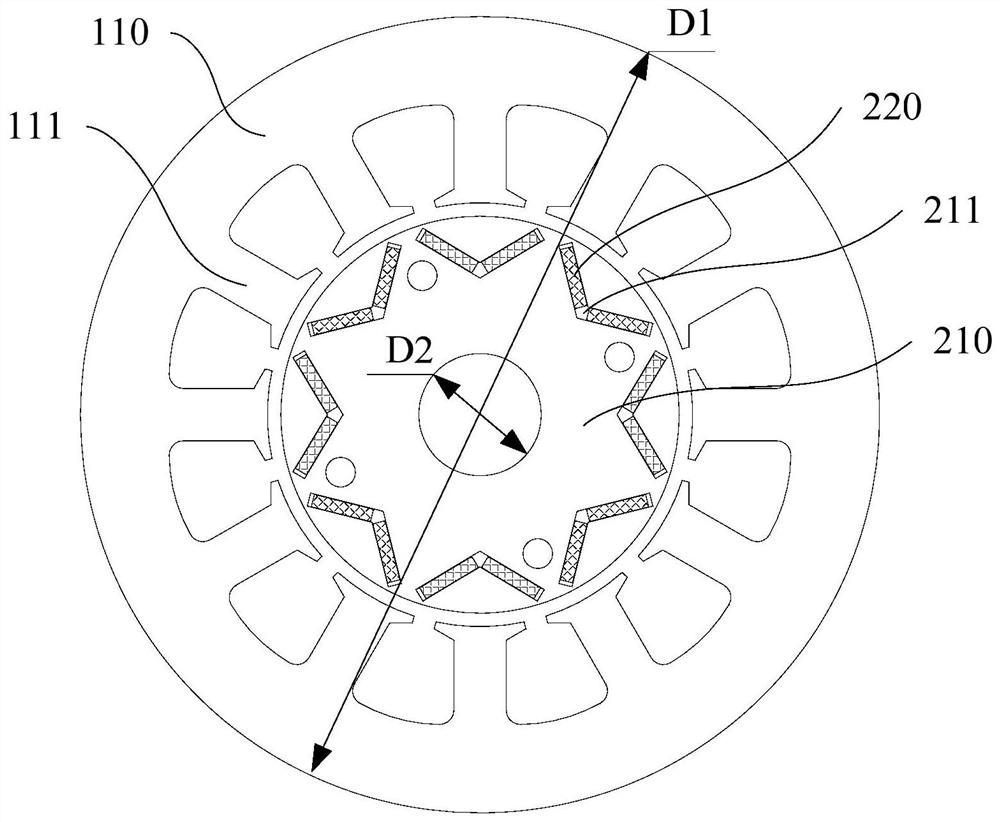

Motor, compressor and refrigeration equipment

ActiveCN111555480AIncrease profitReduce dosageCompressorMagnetic circuit rotating partsRare-earth elementElectric machine

The invention provides a motor, a compressor and refrigeration equipment. The motor comprises: a stator assembly, wherein the stator assembly comprises a stator iron core, and the stator iron core isprovided with a stator slot gap; a rotor assembly which comprises a rotor iron core and a permanent magnet, wherein one of the stator iron core and the rotor iron core is arranged on the outer side ofthe other one in a surrounding manner, and the permanent magnet is arranged on the rotor iron core, wherein in the section perpendicular to the axis of the rotor core, the distance between the statorcore and the rotor core is [delta]mm, the length of the permanent magnet in the magnetization direction of the permanent magnet is h mm, the number of the stator slots is Q, the intrinsic coercive force of the permanent magnet is Hcj kA / m, and Hcj is smaller than or equal to 1800 kA / m, and the numerical value of h meets the equation that h is larger than or equal to 80*(43-Q) / Hcj and smaller thanor equal to 1.6+[delta]. According to the motor provided by the invention, the use of heavy rare earth elements is reduced, the cost is reduced, the use requirements of the compressor can be met, andthe cost performance of the motor is improved.

Owner:ANHUI MEIZHI PRECISION MFG

Motor rotor and permanent magnet motor

PendingCN108768024AImprove unloaded flux linkageIncrease output torqueMagnetic circuit rotating partsPhysicsPermanent magnet motor

The invention provides a motor rotor and a permanent magnet motor. The motor rotor comprises a rotor iron core (1), multiple permanent magnet slots (2) are arranged along the circumference of the rotor iron core (1), the permanent magnets (3) are arranged in the permanent magnet slots (2), a magnetic shield slot (4) is arranged at the inner side of the permanent magnet slot (2), the width of the magnetic shield slot (4) is gradually reduced along a radial reaction of the central axis close to the rotor iron core (1); a strip-shaped first magnetic shield hole is arranged between two adjacent magnetic shield slots (4), a magnetic shield bridge is formed between the first magnetic shield hole and the magnetic shield slot (4), and the magnetic shield bridge and the magnetic pole center line are in a preset included angle. According to the motor rotor provided by the invention, the magnetic shield effect can be effectively improved, the flux leakage at the inner side of the motor is reduced, the magnetizing saturation of the motor rotor is improved, and the motor performance is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Bipolar permanent magnet

InactiveCN1862718BSimple structureEasy to manufacture and installPermanent magnetsMagnetic materialsMagnetizationElectrical polarity

This invention relates to antipole permanent magnet, it consists of 2n+1 neodymium iron boron magnetic loop axial overlay. Geometry and magnetization direction of each loop are axial symmetry, their magnetization direction change along certain rule. The adjoint loop magnetization directions are 360 degrees per 2n different look from any axial cross section. Inner or outer air gap is magnetic workspace according to the different magnetic circuit. The 2n+1 loop are fixed by nonmagnetic metal inner and outer shells. There is no ferromagnetic part in the magnetic circuit, series structure is used, and the whole magnetic potential is the stacking of potentials provided by each loop. This invention can generate strong magnetic field with unchanging polar along circle direction. Its structure is simple, it's manufacturing and installation is simple. There is no ferromagnetic part, its weight is light. There is nearly no flux leakage, the anti demagnetizing action ability is strong, its adjustability is good.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

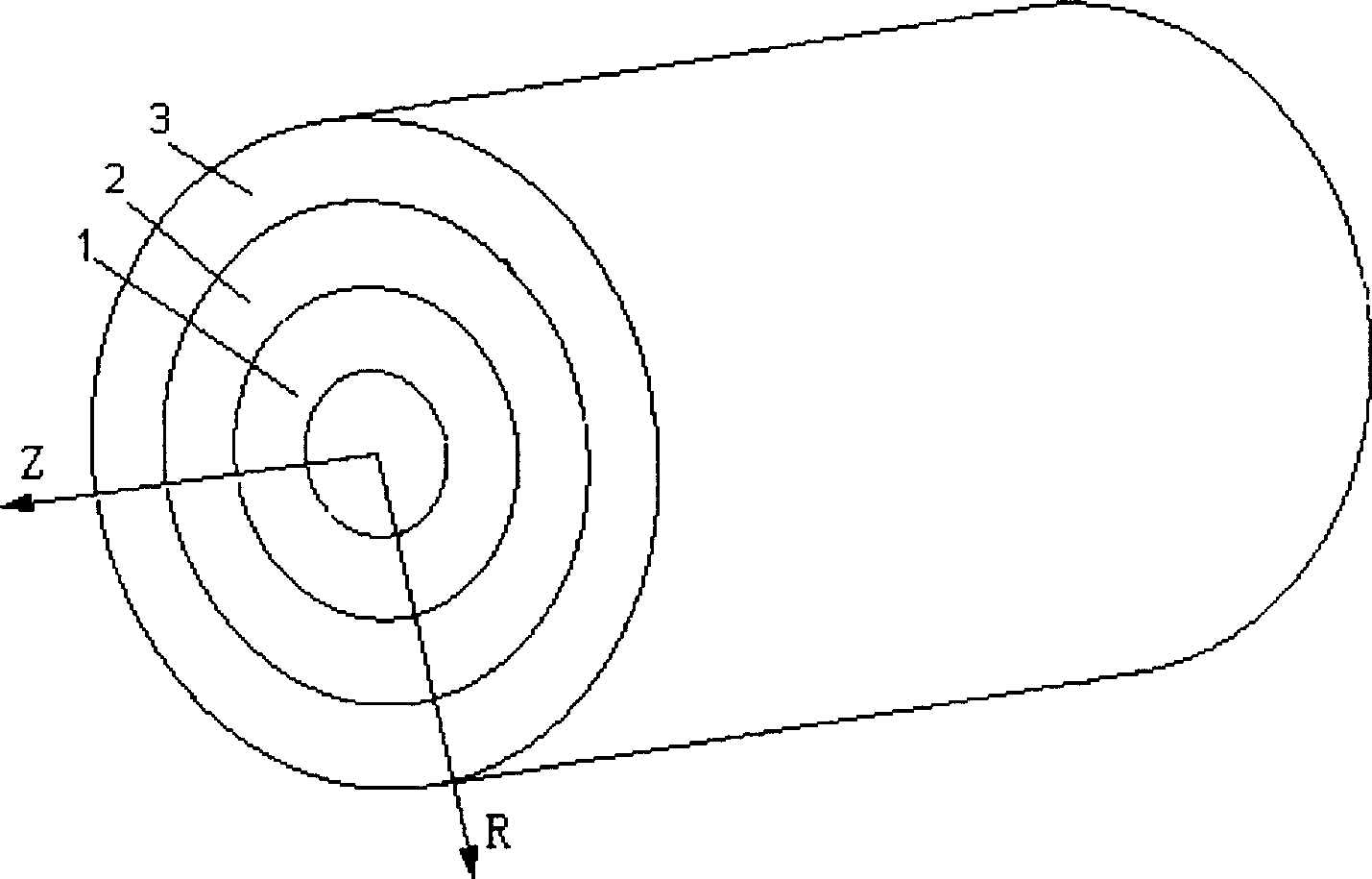

Cylindrical permanent magnetic system

InactiveCN1866700BImprove effective utilizationImprove adjustabilityMagnetic circuit stationary partsPropulsion systemsPermanent magnet linear motorCondensed matter physics

The invention discloses a cylinder-typed permanent magnetic system, which is composed of axial direction leveling and periodical inner ring-shaped permanent array and outer ring-shaped permanent array at the same shaft. The sine waveshape periodical magnetic field is formed on random axial cross section of ring-shaped gap between inner and outer ring-shaped permanent magnetic arrays, which is composed of several equal radial thickness neodymium ferroboron magnetic ring axial gapless periodical superpositions, whose geometrical structure and magnetic direction possess axial symmetry and periodicity. The invention reduces gap magnetic resistance and axial component of gap magnetic density, which improves spatial distribution pattern of gap magnetic density and utility rate.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Washable metal

InactiveCN103381678AHigh hardnessStrong resistance to demagnetizationMetal layered productsManganeseHardness

The invention discloses a washable metal. The washable metal comprises a composite material layer, a deformable permanent magnet alloy layer and a hard magnetic alloy layer. The composite material layer is made of thermometal which comprises brass, nickel, iron-nickel-chromium alloy, iron-nickel-manganese alloy and manganese-nickel-copper alloy; the deformable permanent magnet alloy layer is made of iron-nickel-aluminum dispersion hardened alloy; the hard magnet alloy layer is made of aluminum-nickel-cobalt hard magnet alloy. The washable metal comprises the components of, by weight ratio, 30%-45% of the thermometal, 21%-37% of iron-nickel-aluminum dispersion hardened alloy, and 33%-34% of aluminum-nickel-cobalt hard magnet alloy, thereby having effects of being high in hardness, strong in demagnetization-resistant capacity and good in washable performance.

Owner:常熟市东方特种金属材料厂

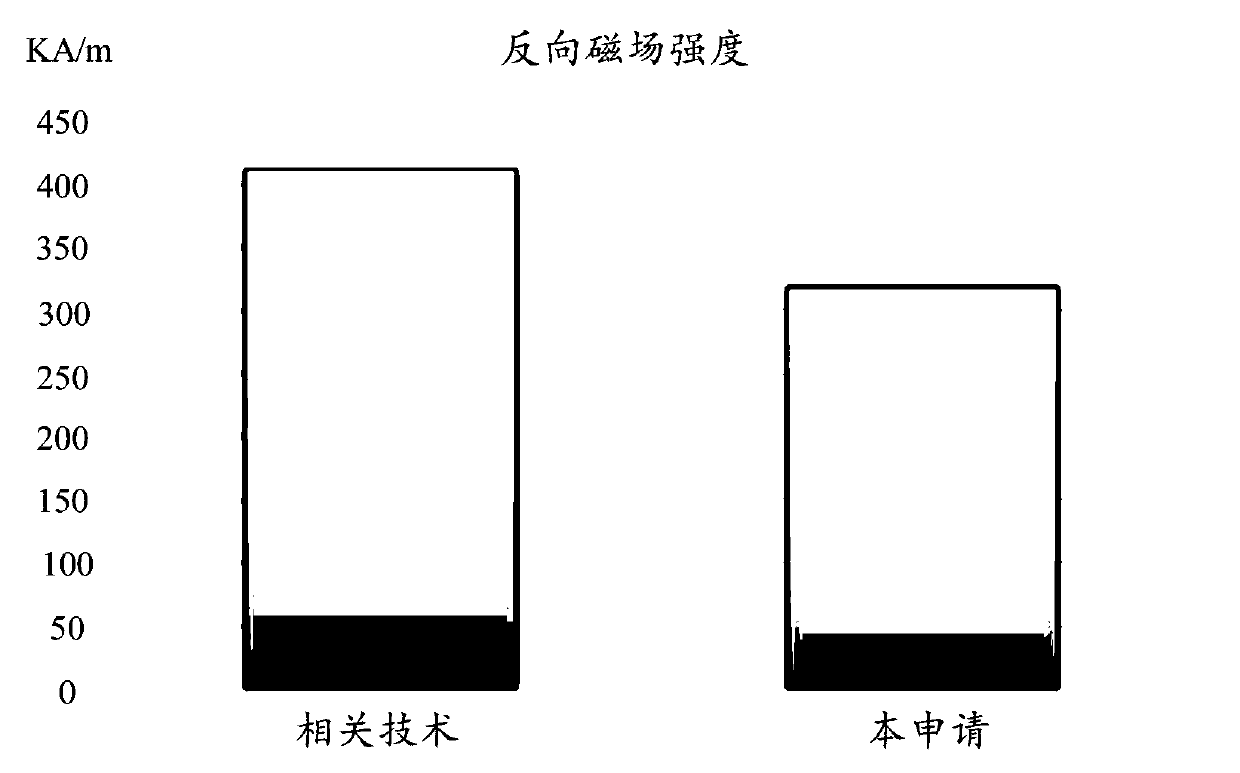

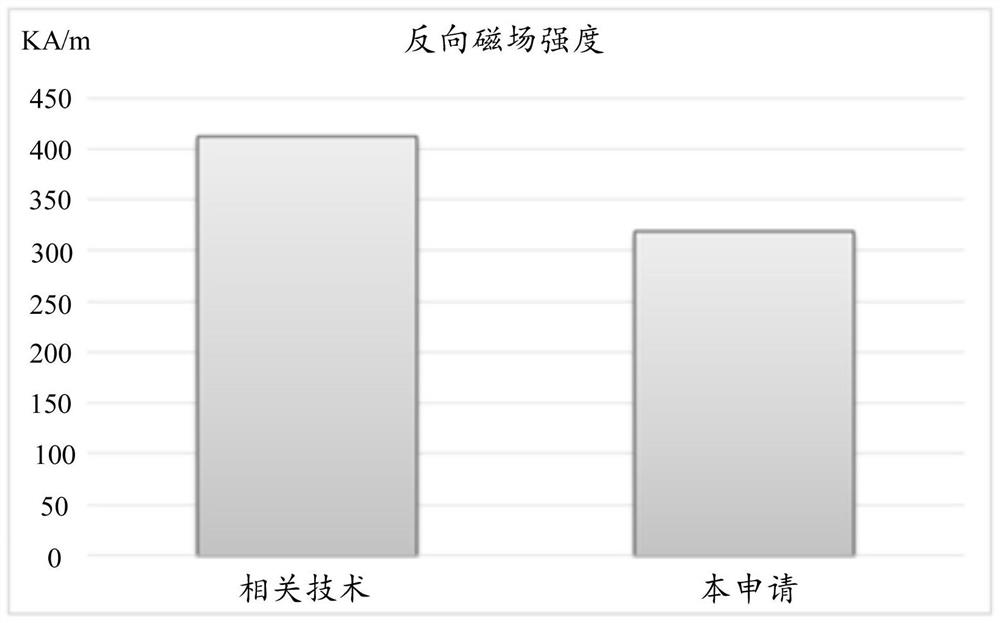

Motor, compressor and refrigeration equipment

ActiveCN111555479AReduce usageReduce consumptionCompressorMagnetic circuit rotating partsRare-earth elementElectric machine

The invention provides a motor, a compressor and refrigeration equipment. The motor comprises: a stator, wherein the stator comprises a stator core and a winding, the stator core is provided with a plurality of stator convex teeth, and the winding is wound on the plurality of stator convex teeth; and a rotor which comprises a rotor iron core and a permanent magnet, and the permanent magnet is arranged on the rotor iron core, and the ratio of the number of the stator convex teeth to the phase number of the windings is configured to be suitable for adjusting the demagnetization reverse magneticfield intensity generated by energization of the windings. The ratio of the number of the stator convex teeth to the phase number of the windings is designed; the demagnetization reverse magnetic field intensity generated by electrifying the winding is adjusted; and even if the permanent magnet is lack of heavy rare earth elements such as dysprosium and terbium; however, the ratio of the number ofthe stator convex teeth to the phase number of the windings can still be increased, and the demagnetization reverse magnetic field generated by energization of the winding is reduced, so that the demagnetization reverse magnetic field is not enough to demagnetize the permanent magnet, the demagnetization resistance of the whole motor is improved, and the motor which can reduce heavy rare earth elements and ensure the demagnetization resistance of the motor is provided.

Owner:ANHUI MEIZHI PRECISION MFG

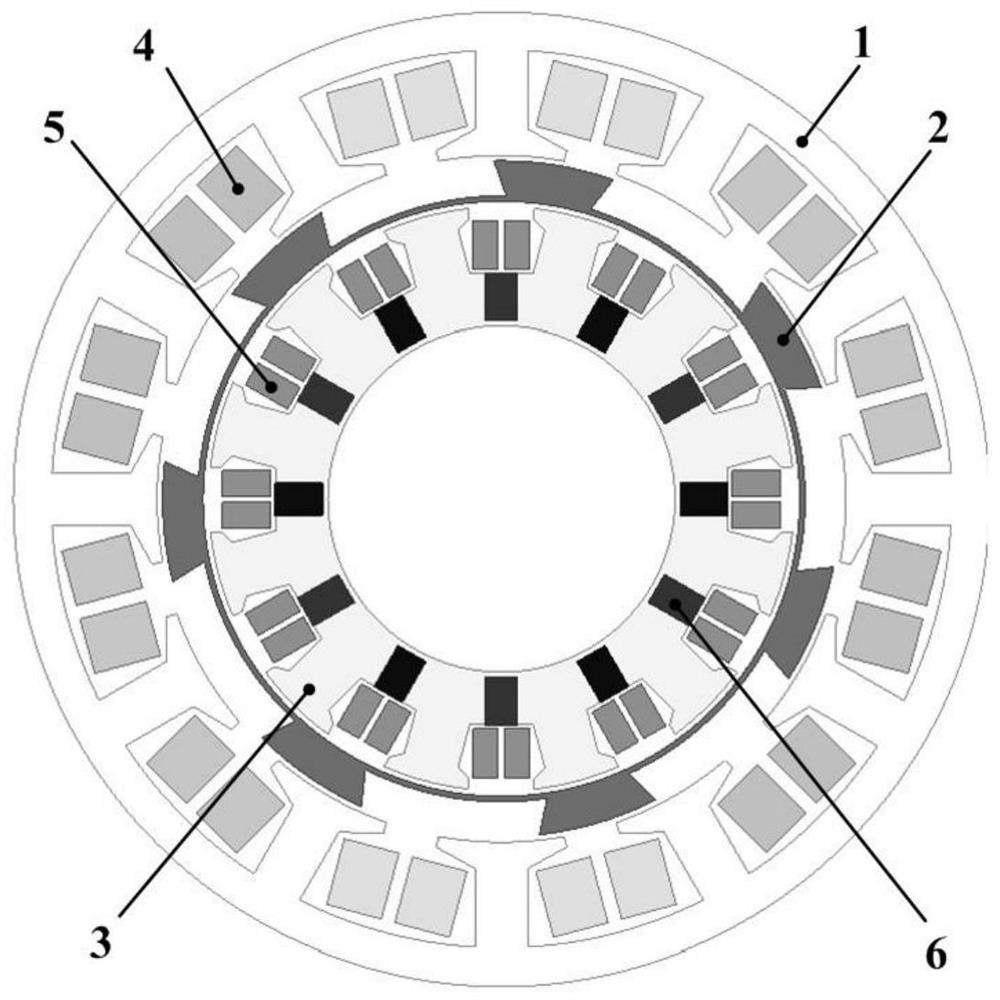

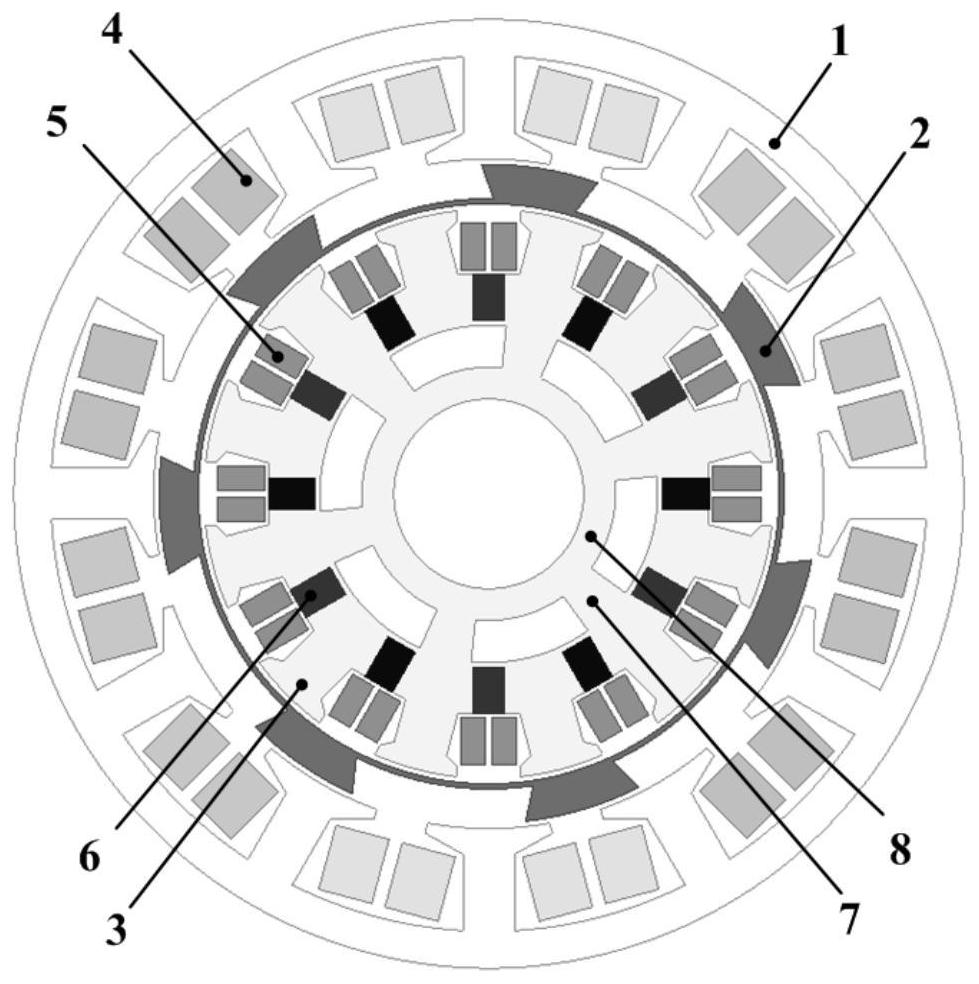

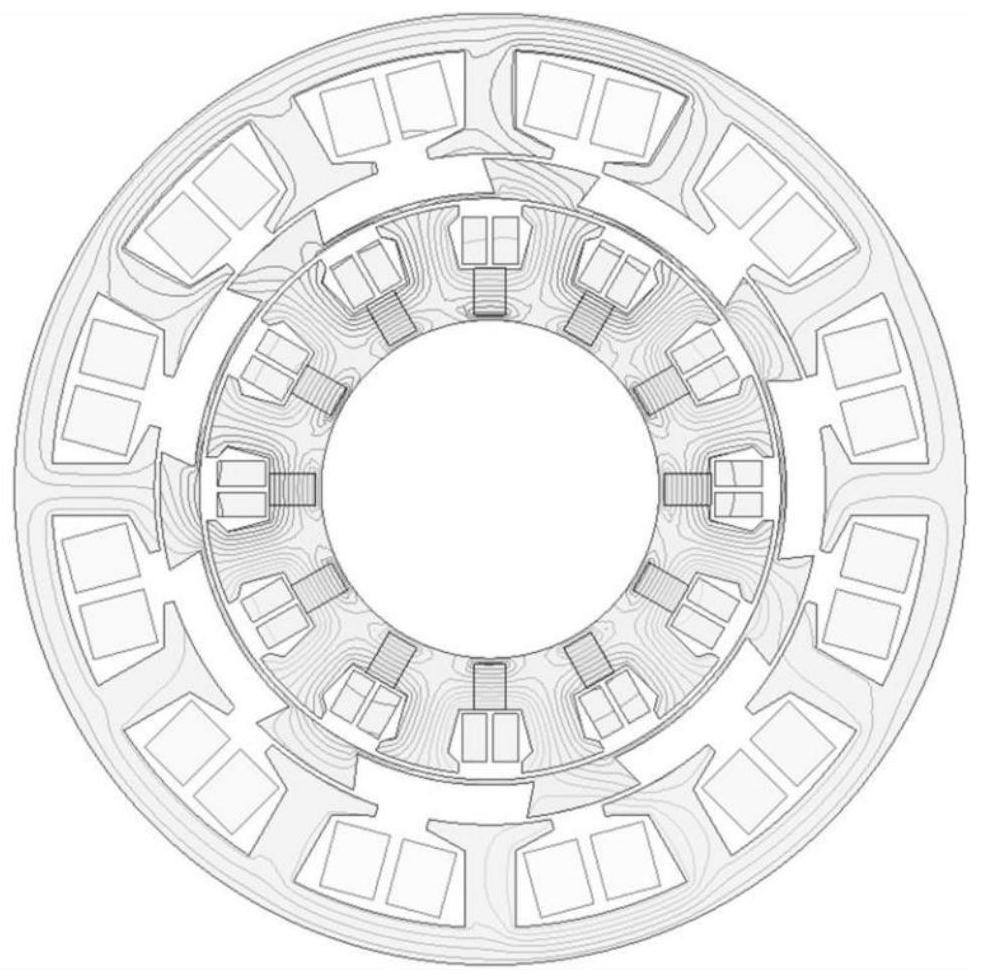

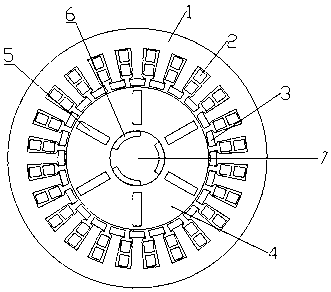

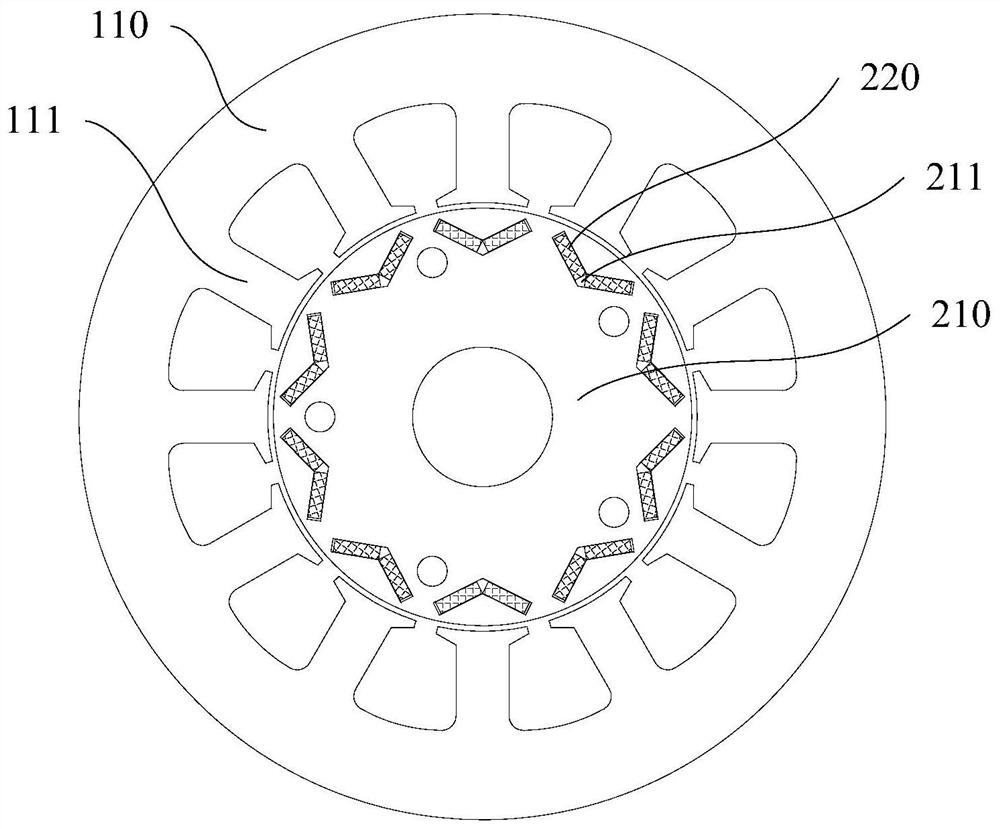

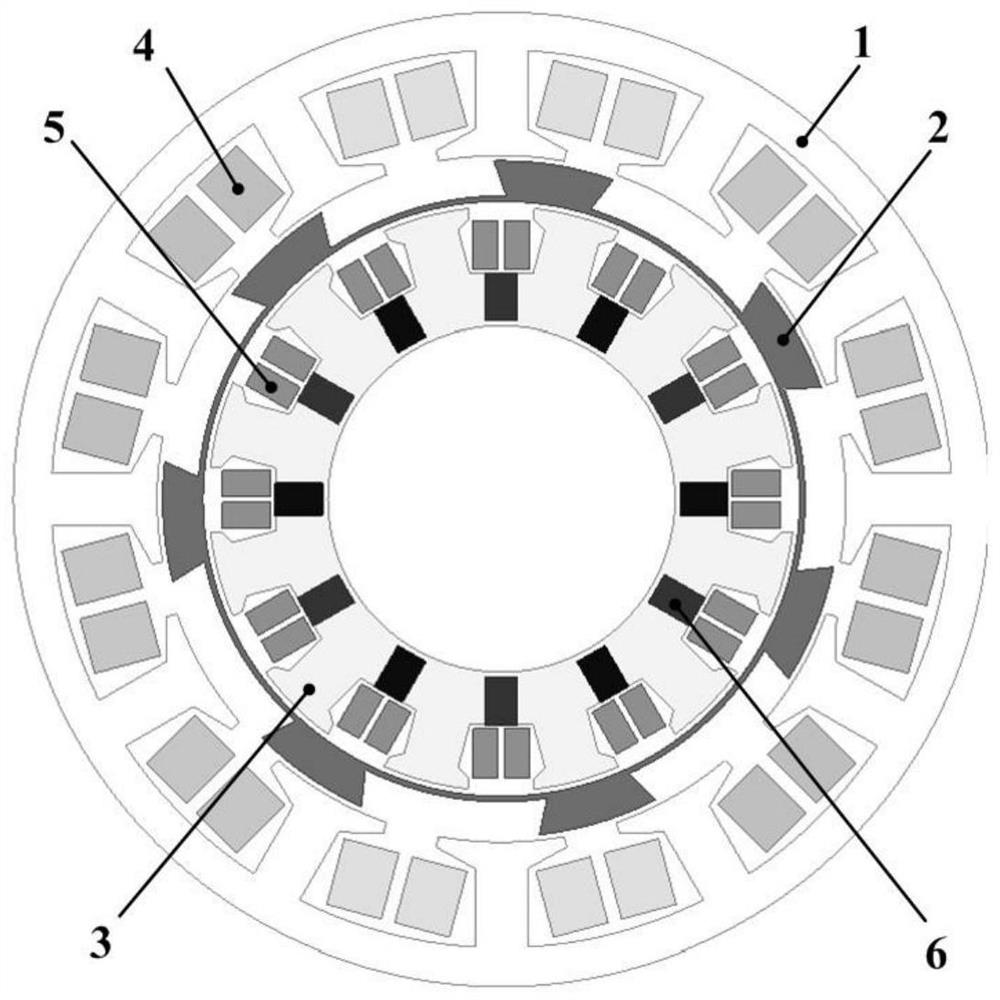

Stator partition type hybrid excitation motor with built-in magnetic field adjusting ring structure

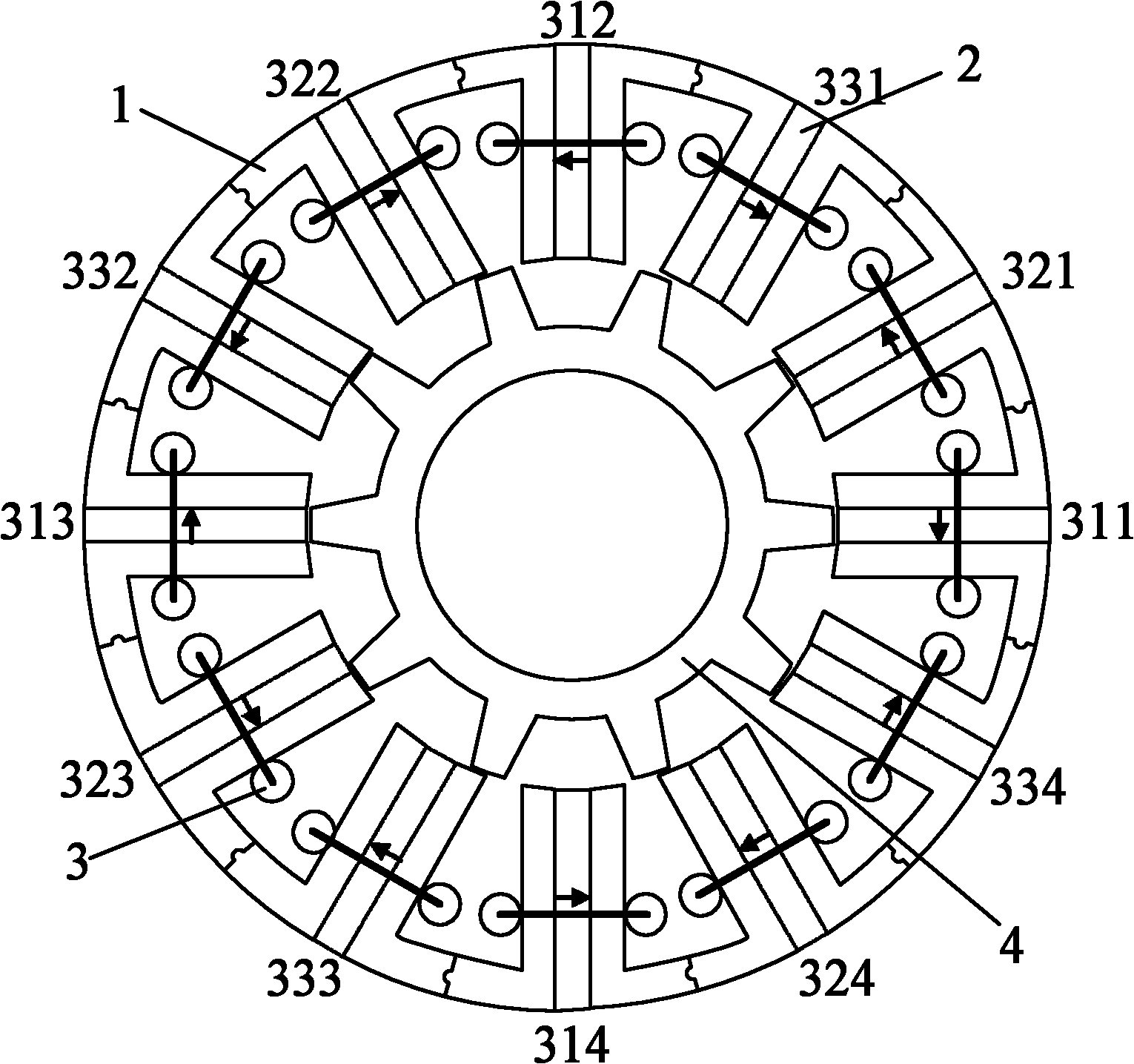

ActiveCN113078789AImprove space utilizationPreserve high power densityMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineCondensed matter physics

The invention discloses a stator partition type hybrid excitation motor with a built-in adjustable magnetic ring structure. The motor comprises an outer stator, a rotor and an inner stator, the outer stator (1) and the rotor (2) are separated by an air gap, and the inner stator (3) and the rotor (2) are separated by an air gap; 12 outer stator teeth are uniformly arranged on the outer stator (1) along the circumferential direction, and armature windings (4) are wound on the outer stator teeth; 12 inner stator teeth are uniformly arranged on the inner stator (3) along the circumferential direction, a centralized excitation winding (5) is wound on the inner stator teeth, 12 permanent magnets (6) are uniformly inserted into a yoke part of the inner stator along the circumferential direction, each permanent magnet is magnetized in the tangential direction, the difference between the magnetizing directions of the two adjacent permanent magnets is 90 degrees, and 6 alternating magnetic bridges (7) are uniformly arranged on the inner side of the inner stator (3) and connected with a magnetism adjusting ring (8); and the middle rotor is composed of seven magnetism adjusting blocks which are evenly arranged. According to the invention, the output torque can be adjusted up and down according to the requirements of application occasions, and the flexibility is high.

Owner:JIANGSU UNIV

Magnetic position sensor system and method

ActiveUS11092461B2Strong resistance to demagnetizationMagnetic field measurement using flux-gate principleElectric/magnetic position measurementsMagnetic polesEngineering

A position sensor system for determining a position of a sensor device relative to a magnetic structure, the system comprising: said magnetic structure comprising a plurality of poles; said sensor device comprising a plurality of magnetic sensors; the magnetic structure being movable relative to the sensor device, or vice versa; wherein: a distance between centres of adjacent poles varies along the movement direction; the sensor device is adapted: for determining a first magnetic field component parallel to, and a second magnetic field component perpendicular to a movement direction, and for calculating a coarse signal based on these components; and for determining a first and second gradient of these signals along the movement direction, and for calculating a fine signal based on these gradients; and for determining said position based on the coarse signal and the fine signal.

Owner:MELEXIS TECH NV

Novel permanent magnet synchronous motor structure

PendingCN109768688AImprove running characteristicsReduce vibration noiseMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machinePermanent magnet synchronous motor

The invention provides a novel permanent magnet synchronous motor structure, belonging to the technical field of motor structures. A motor body comprises a stator, a magnet adjusting iron block, a rotor and a permanent magnet; the magnet adjusting iron block is combined with the stator of the motor to form a stator gear; a magnetic spacing bridge is used between the rotor and a rotor shaft; and the rotor adopts a permanent magnet tangential built-in rotor. The technical points of the novel permanent magnet synchronous motor structure are as follows: the magnet adjusting iron block is added tothe motor to convert the traditional mechanical gear into a magnetic gear, so that the vibration noise of the motor becomes smaller and the torque density becomes higher; then the magnet adjusting iron block is combined with the stator of the motor to form the stator gear, therefore, one layer of air gap is decreased, and the motor structure is simplified; the magnetic spacing bridge is used between the rotor and the rotor shaft, so that a magnetic spacing air gap with high reluctance is introduced into the magnetic leakage loop, and the leakage magnetic flux at the inner diameter of the rotorcan be effectively suppressed; and the rotor adopts a permanent magnet tangential built-in rotor, so that the anti-demagnetization ability of the magnet becomes stronger, and the torque output rangebecomes larger, which facilitates the weak magnetic control.

Owner:HARBIN UNIV OF SCI & TECH

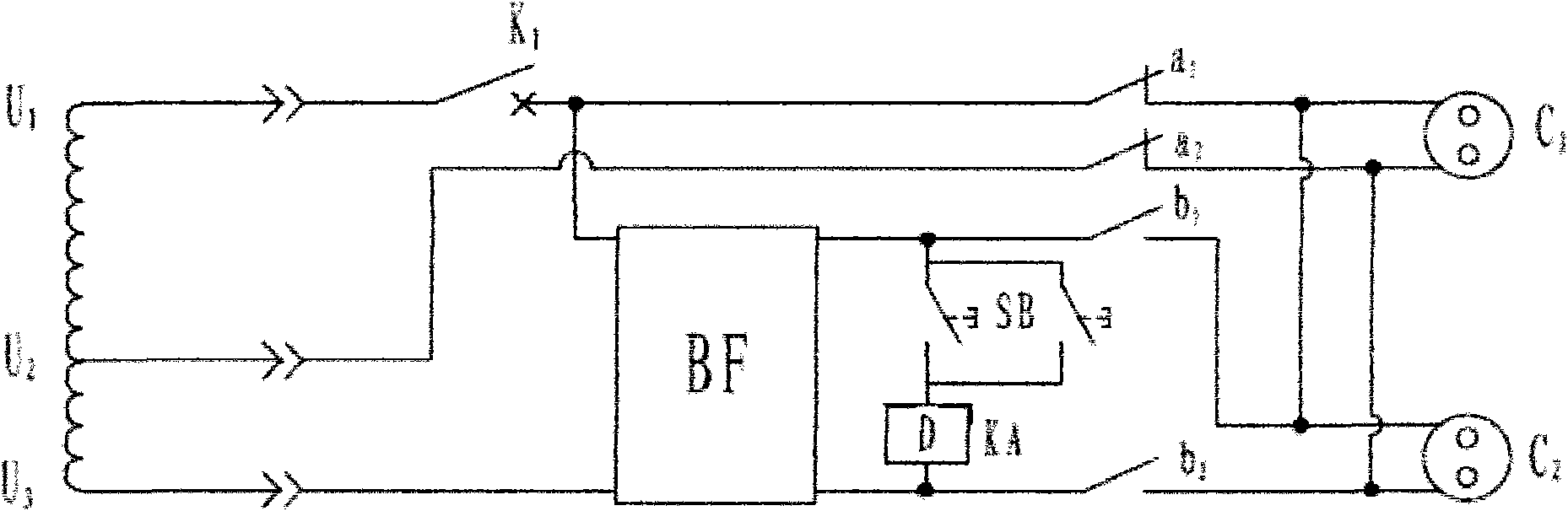

Single-phase multifunctional rare-earth permanent magnet generator

InactiveCN101562361AIncrease the cross-sectional areaIncrease the output voltageMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingControl system

The invention relates to a single-phase multifunctional rare-earth permanent magnet generator, mainly consisting of a shell, a stator, a rotor, an inverter and a control system. The stator comprises a stator iron core and an armature winding; the stator iron core is repeatedly pressed into a chute by stator punching, and the armature winding adopts concentric windings with different turns; the rotator consists of a rotating shaft, a cylindrical magnetic-permeability yoke and paired tile shape magnetic steels which respectively fix N pole and S pole respectively on the excircle of the magnetic yoke; and the control system consists of two circuits. The single-phase multifunctional rare-earth permanent magnet generator not only has the characters of small volume, light weight, high efficiency, simple structure and reliable operation, simultaneously overcomes the defects that the permanent magnet is difficult to adjust magnetic field to control voltage from the outside so as to cause that the voltage stability is poor and the waveform distortion factor is large, also can automatically switch to a first circuit of the control system for supplying power continuously when the inverter fails, realizes multifunctional and continuous power supply with more reliability and has outstanding practical value.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

Self-starting permanent magnet motor provided with composite material starting conducting bars

InactiveCN102111051BSmall starting currentStrong resistance to demagnetizationMagnetic circuit rotating partsSynchronous machinesPermanent magnet rotorHybrid type

The invention discloses a self-starting permanent magnet motor provided with composite material starting conducting bars, which belongs to the technical field of permanent magnet motors. A rotor of the permanent magnet motor has a stamping type structure; a permanent magnet is arranged on the inner side of a rotor core, N and S magnetic poles are arranged alternately; a permanent magnet rotor adopts a magnetic pole structure of a U type, V type or mixed type magnetic circuit; composite material rat cage starting conducting bars are uniformly distributed close to the surface of the rotor core;and the composite material rat cage starting conducting bars is made of two types of materials including brass and copper-iron alloy. The brass is positioned on a middle part between the bottom part of a rotor groove and the upper part of the rotor groove; two side parts of the upper part of the rotor groove are made of the copper-iron alloy; or the middle part of the rotor groove is made of the brass, while the two sides of the rotor groove are made of the copper-iron alloy. Two ends of each composite material starting conducting bar are shorted out outside the rotor core through a welded brass end ring. Through the adjustment of the structure sizes of the brass and the copper-iron alloy materials, the obtained permanent magnet motor has a small starting current multiple and strong demagnetization resistance, can be started smoothly, and is suitable for workplaces requiring long-time continuous operation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Motors, compressors and refrigeration equipment

ActiveCN111555479BReduce usageReduce consumptionCompressorMagnetic circuit rotating partsRare-earth elementElectric machine

The invention provides a motor, a compressor and refrigeration equipment. The motor includes: a stator, the stator includes a stator core and windings, the stator core is provided with a plurality of stator convex teeth, and the winding is wound on a plurality of stator convex teeth; the rotor, the rotor includes a rotor core and a permanent magnet, and the permanent magnet is arranged on the rotor The iron core; the ratio of the number of stator teeth and the number of phases of the winding is configured to be suitable for adjusting the strength of the demagnetizing reverse magnetic field generated by electrifying the winding. By designing the ratio of the number of stator convex teeth to the phase number of the winding, the strength of the demagnetization reverse magnetic field generated by the electrification of the winding can be adjusted, so that even if the permanent magnet lacks heavy rare earth elements such as dysprosium and terbium, it can still increase the stator convex teeth. The ratio of the number to the number of winding phases is used to reduce the demagnetization reverse magnetic field generated by the winding energization, so that the demagnetization reverse magnetic field is not enough to demagnetize the permanent magnet, improve the overall anti-demagnetization ability of the motor, and then help to propose a method that meets the requirements of reducing weight. Rare earth elements can also ensure the motor's ability to resist demagnetization.

Owner:ANHUI MEIZHI PRECISION MFG

Corrosion-resistant and high-temperature-resistant composite metal

InactiveCN109664570AHigh hardnessStrong resistance to demagnetizationMetal layered productsTemperature resistanceCorrosion resistant

The invention discloses a corrosion-resistant and high-temperature-resistant composite metal, which comprises a composite material layer, a deformed permanent magnet alloy layer and a hard magnet alloy layer, wherein the composite material layer is a thermal bimetal, the thermal bimetal comprises phosphor copper, nickel, a titanium alloy, copper-nickel-manganese and a manganese-nickel-copper alloy, the deformed permanent magnet alloy layer is a copper-nickel-aluminum-based dispersion hardening alloy, the hard magnet alloy layer is an aluminum-nickel-cobalt hard magnet alloy, the thermal bimetal accounts for 30-45 wt%, the copper-nickel-aluminum-based dispersion hardening alloy accounts for 21-37 wt%, and the aluminum-nickel-cobalt hard magnet alloy accounts for 33-34 wt%. According to thepresent invention, the prepared corrosion-resistant and high-temperature-resistant composite metal has effects of high hardness, strong demagnetization resistance and high-temperature resistance.

Owner:王磊

A stator partition type hybrid excitation motor with built-in magnetic control ring structure

ActiveCN113078789BImprove space utilizationPreserve high power densityMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineMagneto

The invention discloses a stator partition type hybrid excitation motor with a built-in magnetic adjustment ring structure, which includes an outer stator, a rotor and an inner stator, the outer stator (1) and the rotor (2) are separated by an air gap, and the inner stator ( 3) and the rotor (2) are separated by an air gap; the outer stator (1) is evenly provided with 12 outer stator teeth along the circumferential direction, and the armature winding (4) is wound on the outer stator teeth; the inner stator (3) There are 12 inner stator teeth evenly arranged along the circumferential direction, and a centralized excitation winding (5) is wound on the inner stator teeth, and 12 permanent magnets (6) are evenly inserted into the inner stator yoke along the circumferential direction, and each permanent magnet is cut For magnetization, the inside of the inner stator (3) is evenly provided with 6 alternating magnetic bridges (7) connected to the magnetic adjustment ring (8); the intermediate rotor is composed of 7 magnetic adjustment blocks evenly placed. The invention realizes that the output torque can be adjusted up and down according to the requirement of the application occasion, and has superior flexibility.

Owner:JIANGSU UNIV

A Large Thrust Cylindrical Linear Motor

ActiveCN103427587BStrong resistance to demagnetizationReduce magnetic densityPropulsion systemsTubular linear motorLinear motor

The invention relates to a high-thrust tubular linear motor which comprises a stator shell, a stator and a rotor. The stator is coaxially and fixedly mounted in the stator shell, the rotor is coaxially and slidably mounted in an inner cavity of the stator, the stator comprises silicon steel sheets and windings which are arranged at intervals and fixedly mounted on the stator shell, the rotor comprises a rotor shaft, permanent magnets and magnetic conduction rings, and the permanent magnets and the magnetic conduction rings are arranged at intervals on the rotor shaft. The high-thrust tubular linear motor is characterized in that the rotor shaft is made of hollow soft magnetic materials, a copper tube is coaxially sleeved outside the rotor, the windings and the silicon steel sheets are fixedly mounted at intervals to form the stator, and the windings and the silicon steel sheets correspond to the permanent magnets and the magnetic conduction rings of the rotor. The high-thrust tubular linear motor is ingenious in design, reasonable in structure, large in starting force, fine in tightness and reliable in operation.

Owner:伟力驱动技术(深圳)有限公司

Efficient permanent magnet synchronous motor

InactiveCN101728913AImprove power factorHigh pull-in synchronization capabilityMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorConductor Coil

The invention relates to the field of motor, in particular to an efficient permanent magnet synchronous motor which comprises a stator, a rotor, a fan and an end cap. The stator comprises a base and a winding stator core. The rotor comprises a rotating shaft, a rotor core, an aluminum ring and a permanent magnet, wherein an arc permanent magnet is arranged. An arc groove which is matched with the arc permanent magnet is arranged inside of the rotor. The arc permanent magnet is inlayed in the arc groove. By adopting the structure, the invention has the advantages of high utilization factor of permanent magnet, high demagnetizing property, high pull-in synchronism capability of motor, big reluctance torque and motor overloading times, and the like.

Owner:山东工友集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com