Self-starting permanent magnet motor provided with composite material starting conducting bars

A technology of permanent magnet motors and composite materials, which is applied to magnetic circuits characterized by magnetic materials, synchronous machines, electrical components, etc. It can solve the problem that the rotor cannot use deep grooves or double-layer guide bar structures, and achieve anti-demagnetization The effect of superior ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

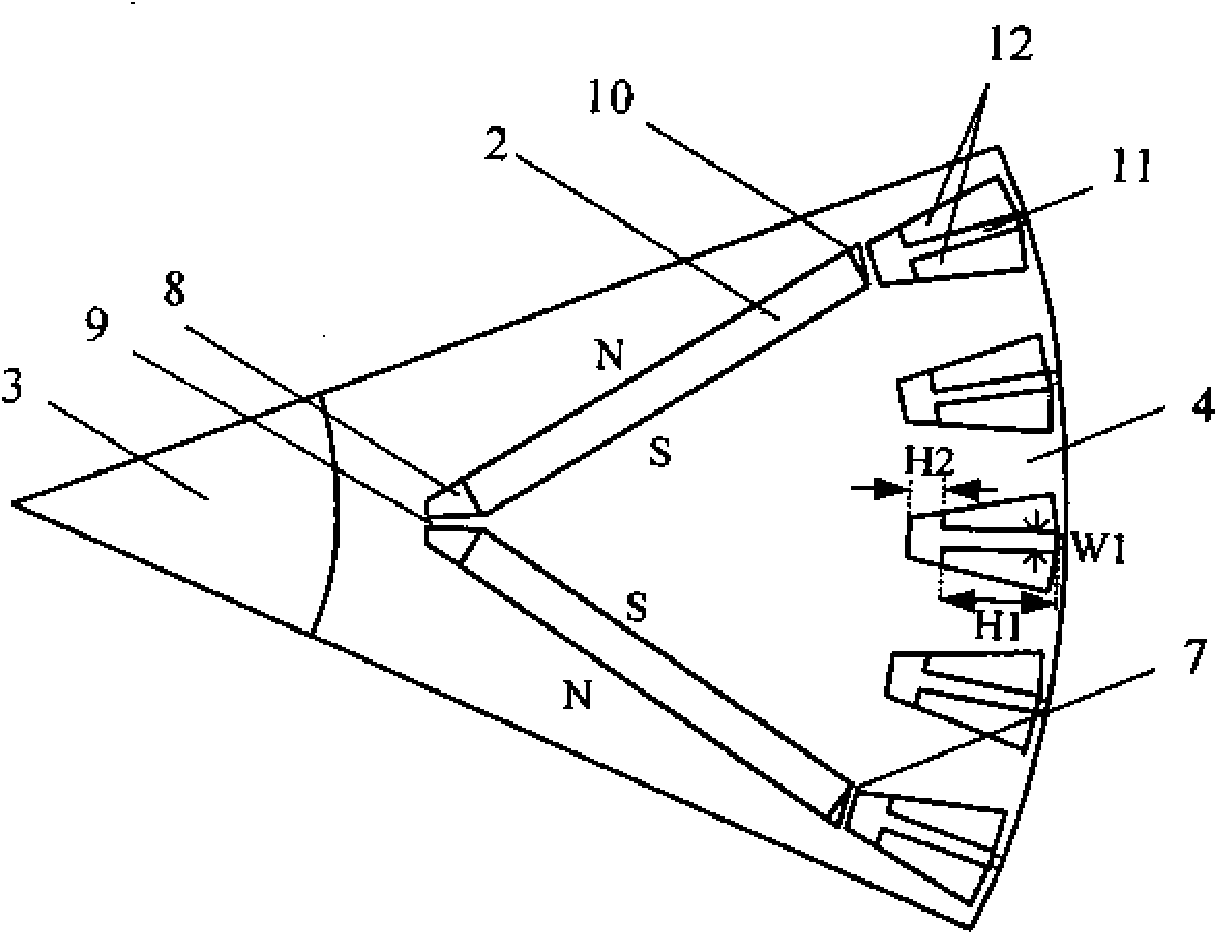

[0032] Such as figure 2 Shown is an enlarged schematic diagram of one magnetic pole of the rotor of a composite material starting bar permanent magnet motor. Each squirrel cage starting bar 1 consists of two materials: brass material and copper-iron alloy material. The brass guide bar 11 has a convex structure and is located in the middle of the bottom and upper part of the rotor slot, and the copper-iron alloy material 12 is located on both sides of the upper part of the rotor slot. The two ends of each squirrel cage starting bar 1 are short-circuited outside the core of the rotor iron 4 through brass end rings welded; in this embodiment, the conductivity of the copper-iron alloy material is 6825.4726S, which is between copper and iron. The height of the brass at the bottom of the rotor slot is 3mm, the height of the upper brass is 16mm, and the width is 2mm.

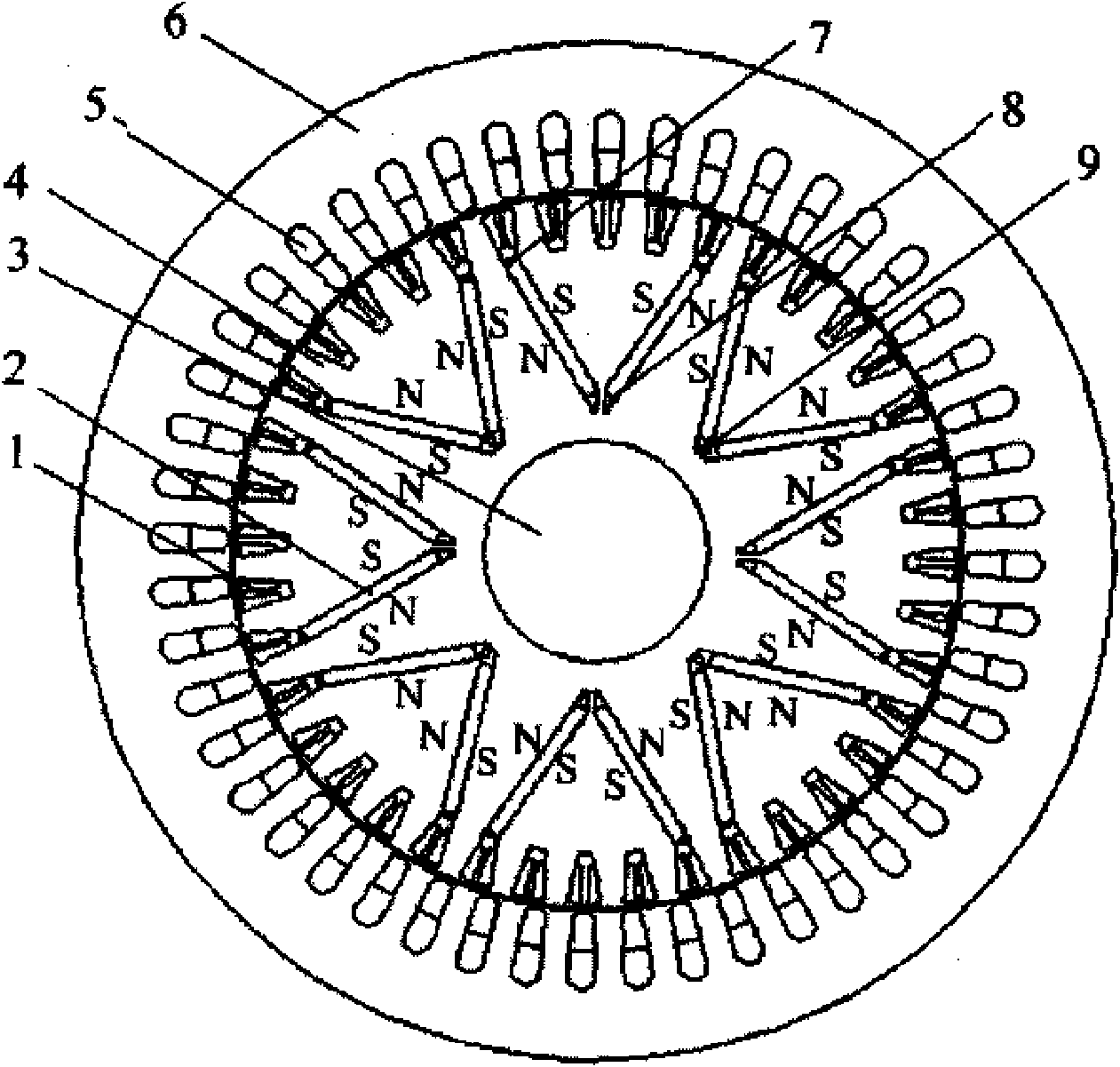

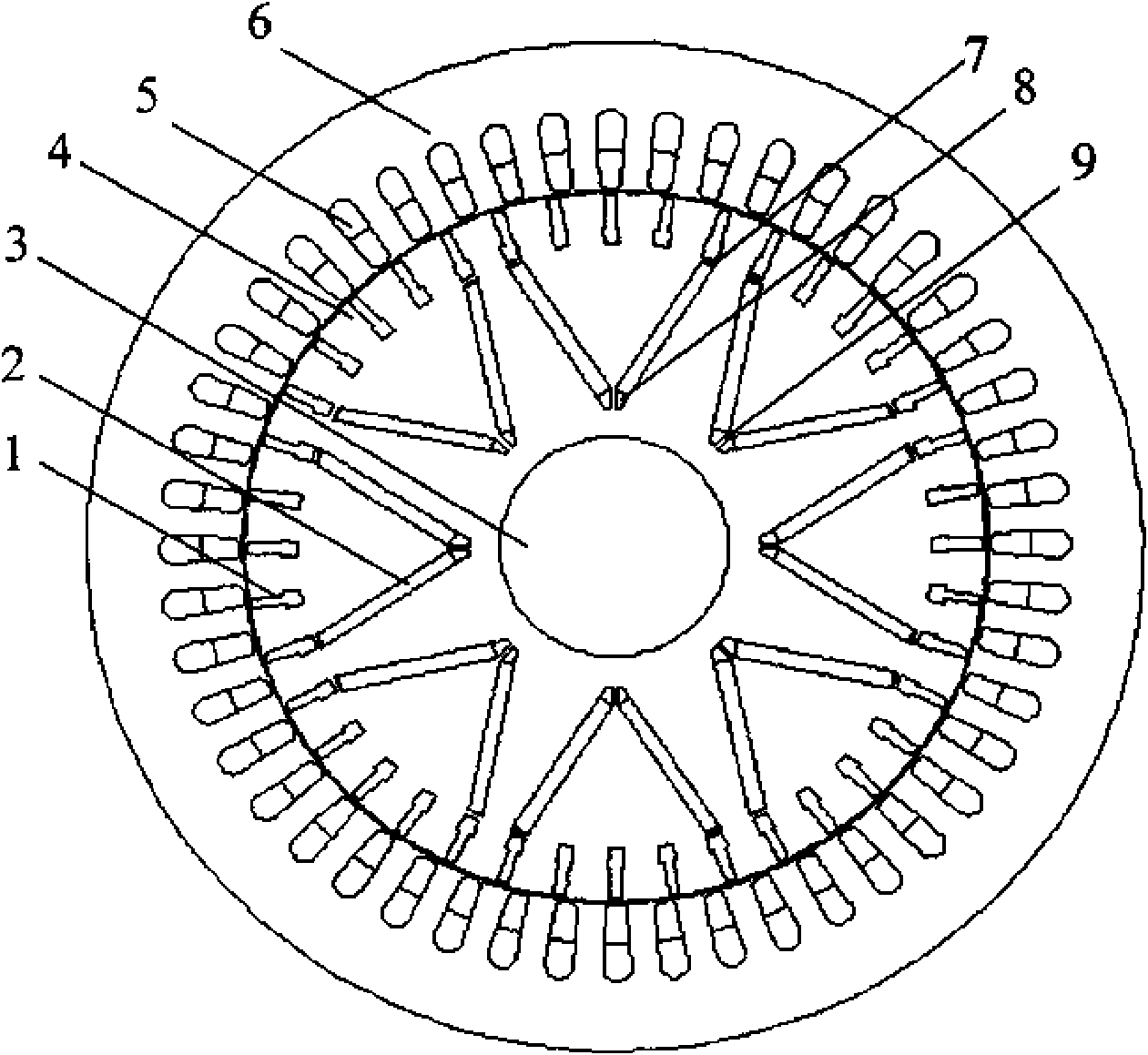

[0033] Compared figure 1 and 3 It can be seen that the biggest difference between the composite material starting ...

Embodiment 2

[0038] The overall structure of the permanent magnet motor of the composite material starting guide bar of embodiment 2 is the same as that of embodiment 1, the difference is that the structure of brass in the rotor guide bar is different from that of embodiment 1, that is, in figure 2 In the enlarged schematic diagram of one magnetic pole of the rotor of the composite material starting bar permanent magnet motor shown, the middle part of the squirrel cage starting bar 1 is all brass guide bars 11, and the two sides of the guide bar grooves are copper-iron alloy materials 12, so the squirrel cage The processing of starting guide bar 1 is also simpler than that of embodiment 1. In embodiment 2, the width of brass is selected as 2mm. The starting current multiple of the permanent magnet motor in this embodiment is 7.56, the stall torque multiple is 3.2, and the minimum magnetic density at a certain point of the permanent magnet in the starting process is 0.277T, which is obviou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com