A stator partition type hybrid excitation motor with built-in magnetic control ring structure

A hybrid excitation motor and internal stator technology, applied in the magnetic circuit shape/style/structure, winding conductor shape/style/structure, magnetic circuit, etc., can solve the problem of increasing the torque density of the stator partition hybrid excitation motor and weakening the working magnetic field Strength and other issues, to avoid irreversible demagnetization, improve space utilization, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

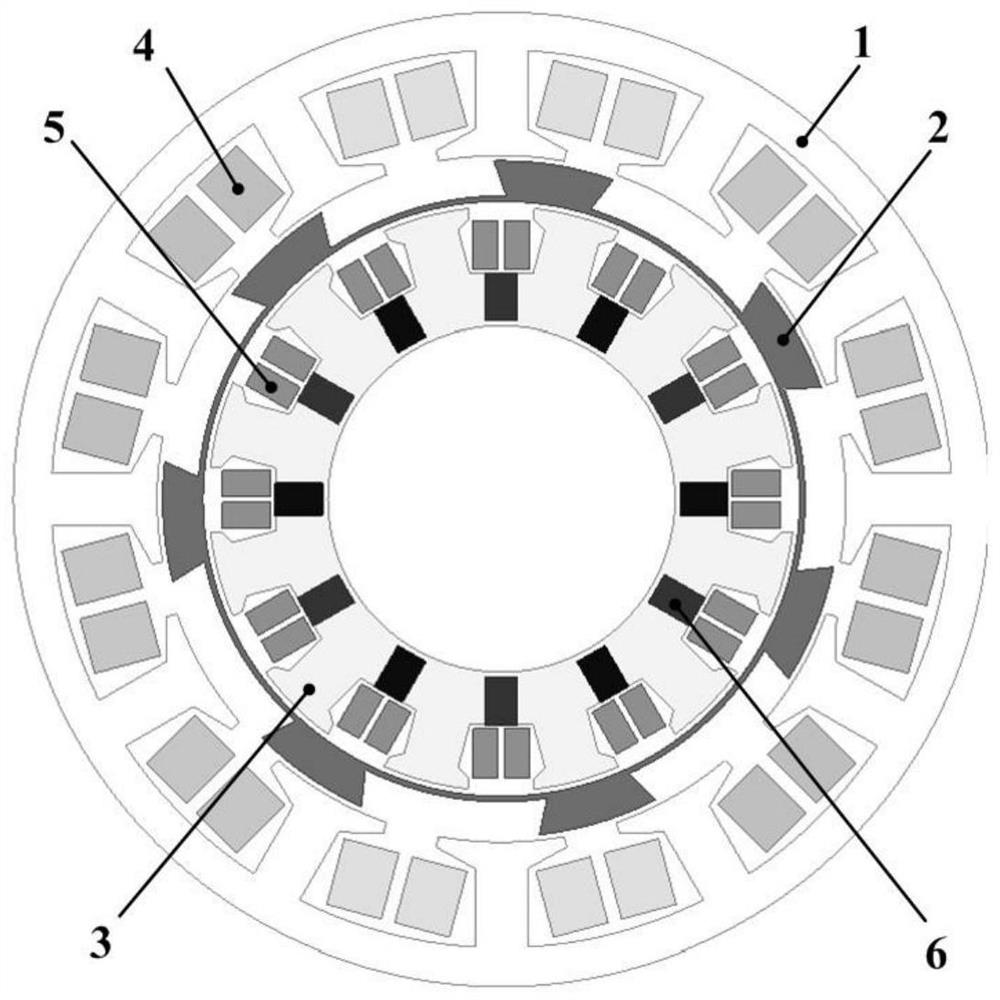

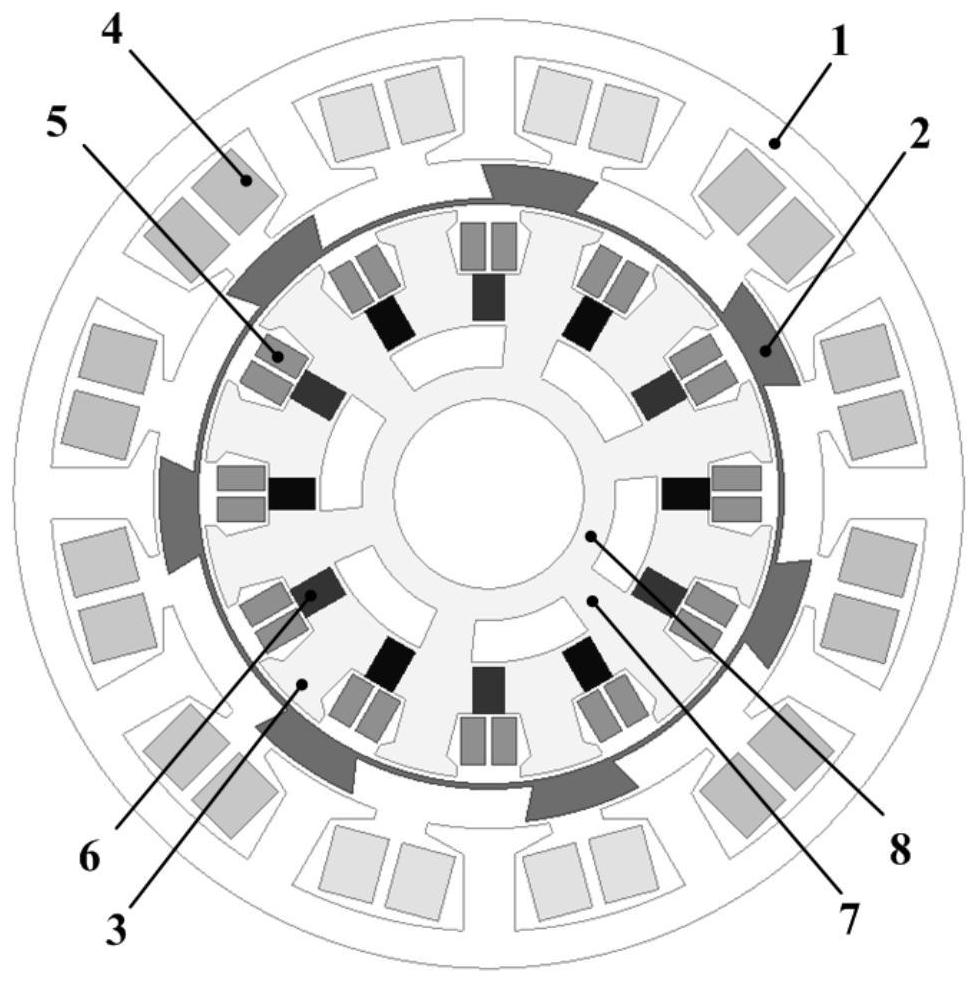

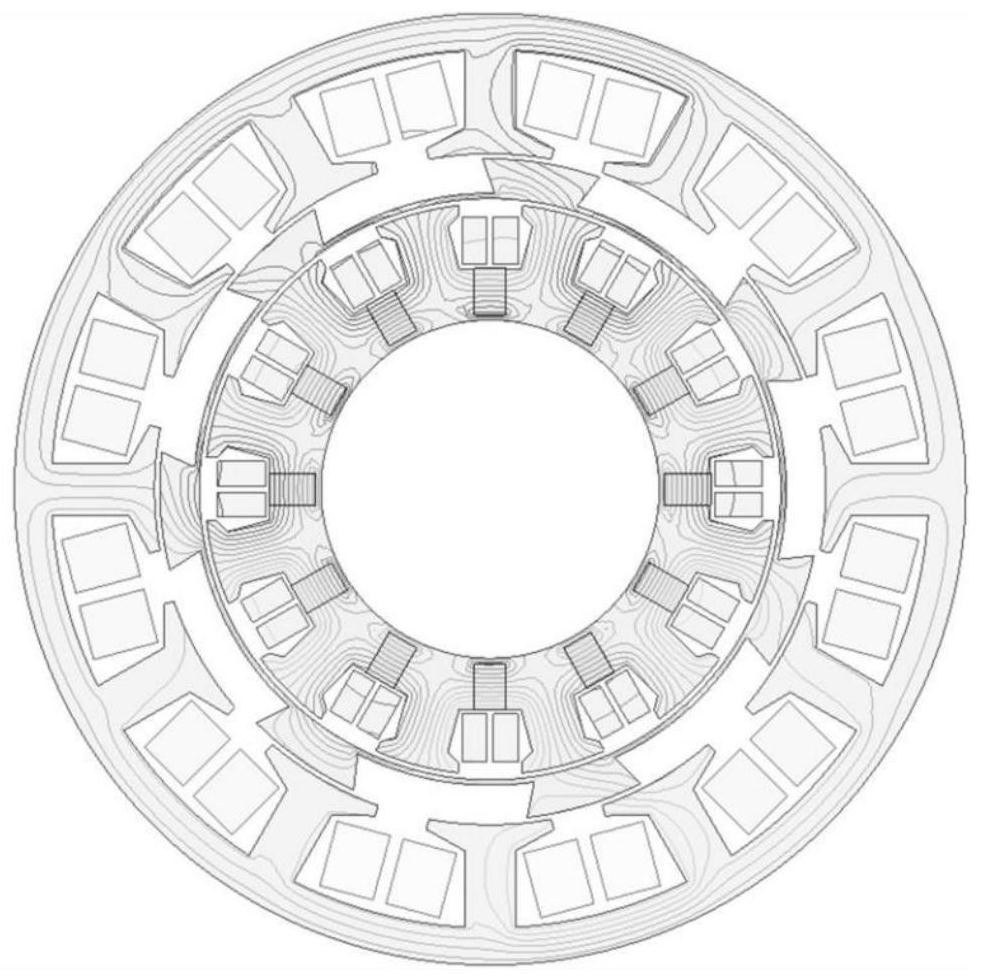

[0035] The present invention provides a stator partition type hybrid excitation motor with a built-in magnetic control ring structure, figure 1 It is a traditional stator partition motor structure, figure 2 It is a stator partition type hybrid excitation motor structure with a built-in magnetic regulating ring structure of the present invention. The motor includes an outer stator, a rotor and an inner stator; an outer stator, an intermediate rotor and an inner stator, an outer air gap is formed between the inner surface of the outer stator and the outer surface of the intermediate rotor, and an inner air gap is formed between the inner surface of the intermediate rotor and the outer surface of the inner stator. Air gap; the outer stator, the middle rotor and the inner stator are coaxially installed, the inner stator is of a salient pole structure, the salient pole teeth are wound with excitation windings, and the yoke of the inner stator is inserted into a permanent magnet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com