Motors, compressors and refrigeration equipment

A stator and winding technology, applied in compressors, mechanical equipment, lighting and heating equipment, etc., can solve problems such as the decline of motor anti-demagnetization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

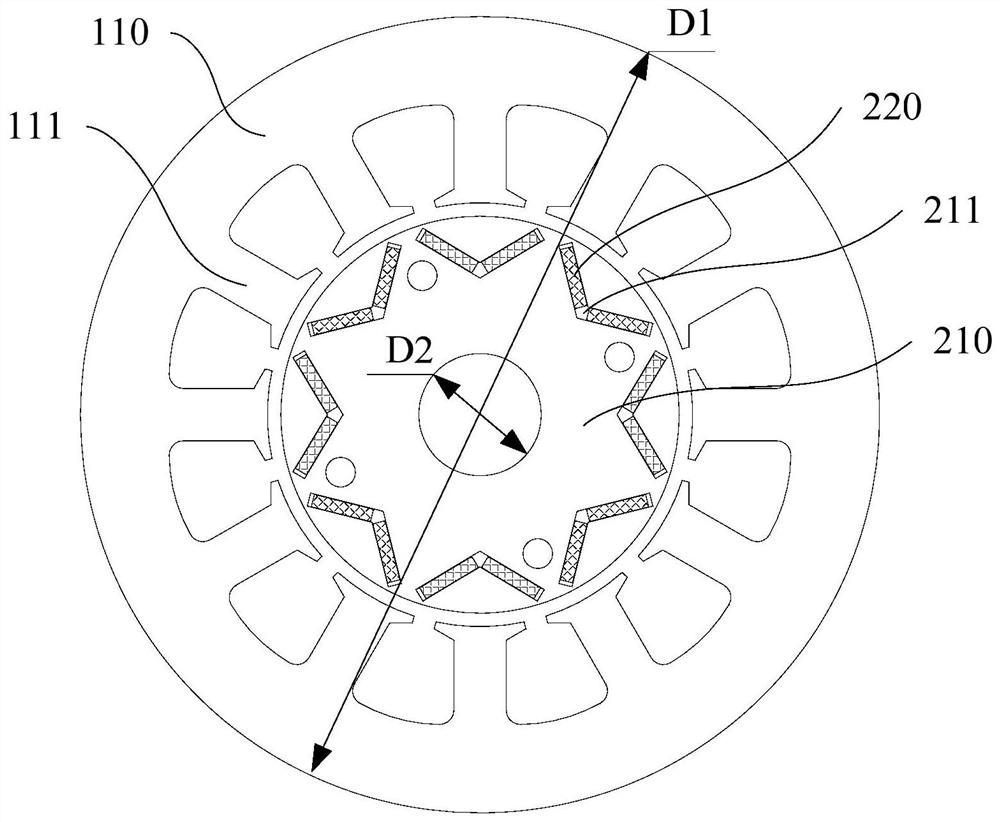

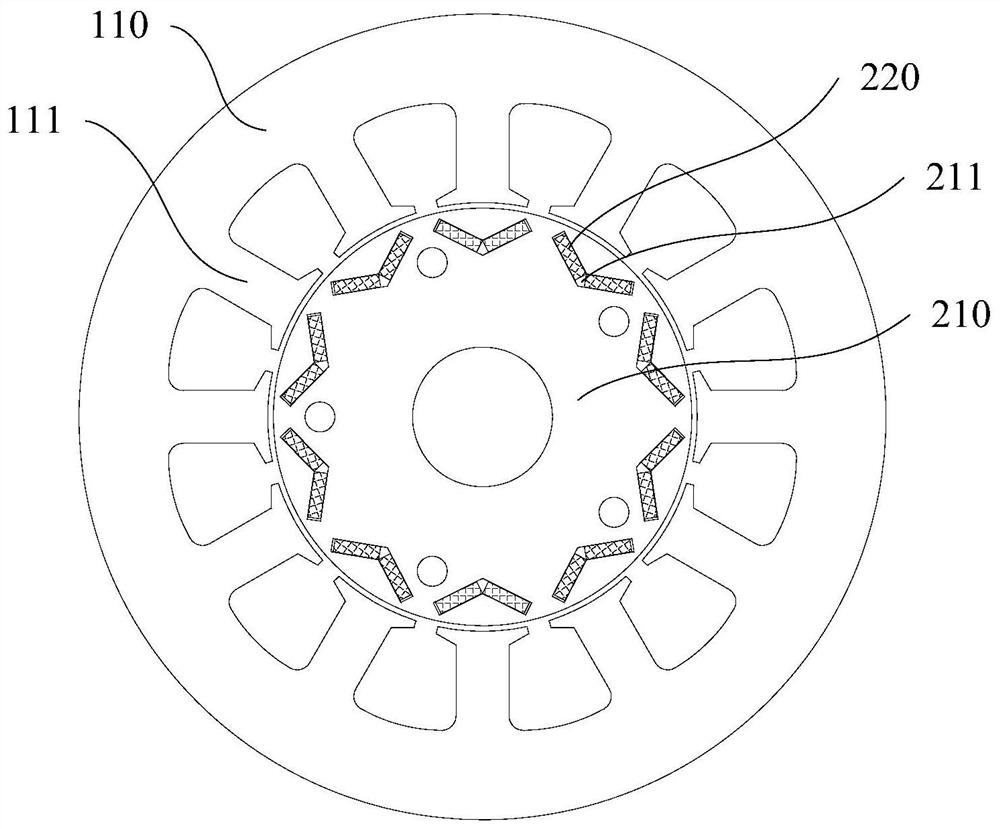

[0049] Such as figure 1 and figure 2 As shown, a motor includes: a stator and a rotor. The stator includes a stator core 110 and a winding (not shown in the figure), the stator core 110 is provided with a plurality of stator teeth 111 , and the winding is wound around the plurality of stator teeth 111 . The rotor includes a rotor core 210 and a permanent magnet 220 , and the permanent magnet 220 is disposed on the rotor core 210 . Wherein, the ratio of the number of stator teeth 111 and the phase number of the winding is configured to be suitable for adjusting the strength of the demagnetization reverse magnetic field generated by the winding energization.

[0050] The motor proposed by the present invention adjusts the demagnetization reverse magnetic field intensity generated by winding energization by designing the ratio of the number of stator convex teeth 111 to the phase number of windings, that is, adjusting the reverse direction of demagnetization of permanent magne...

Embodiment 2

[0060] On the basis of the first embodiment above, the value range of the mass percentage of dysprosium and / or terbium in the permanent magnet 220 is further limited to 0 to 0.5%, or the value range of the mass percentage of heavy rare earth elements in the permanent magnet 220 is 0 to 0.5%.

[0061] In this embodiment, since dysprosium and terbium are heavy rare earth elements, heavy rare earth elements are national strategic resources. Therefore, by limiting the mass percent of dysprosium and / or terbium in the permanent magnet 220 to 0 to 0.5%, and / or limiting the mass percent of heavy rare earth elements in the permanent magnet 220 to 0 to 0.5%, it is beneficial to ensure In the case of good anti-demagnetization ability of the motor, the use of heavy rare earth elements such as dysprosium and terbium is reduced, and the consumption of strategic resources is reduced, which in turn helps to reduce the manufacturing cost of the motor and improve the cost performance of the mot...

Embodiment 3

[0068] On the basis of any of the above embodiments, it is further defined that the intrinsic coercive force of the permanent magnet 220 at 20° C. is less than or equal to 1800 kA / m.

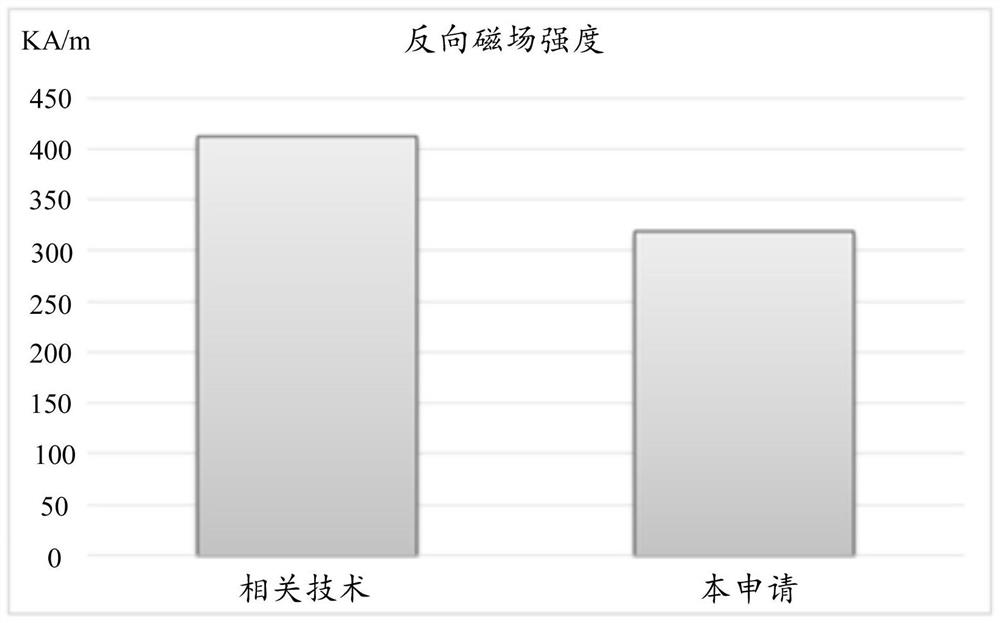

[0069] In order to meet the demand for demagnetization current of household air conditioners, the intrinsic coercive force of the NdFeB permanent magnet 220 used in the frequency conversion models of compressor manufacturers in the related art is greater than or equal to 1830kA / m at 20°C. The permanent magnets 220 under force all contain heavy rare earth elements, especially the elements dysprosium and terbium. In order to reduce the dependence on heavy rare earth elements, even if no heavy rare earth permanent magnet 220 is used, the intrinsic coercive force of the permanent magnet 220 will drop below 1800kA / m. However, due to the reduction of the intrinsic coercive force, the demagnetization capability of the motor in the related art (the motor in the related art is listed here having 9 slots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com