Efficient permanent magnet synchronous motor

A permanent magnet synchronous motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problem of low overload multiples of reluctance torque motors, weakened permanent Problems such as the mutual magnetic interaction of magnets and the low pull-in synchronization ability of the motor can achieve obvious energy-saving effects, reduced stator current and stator resistance losses, and high pull-in synchronization capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with accompanying drawing:

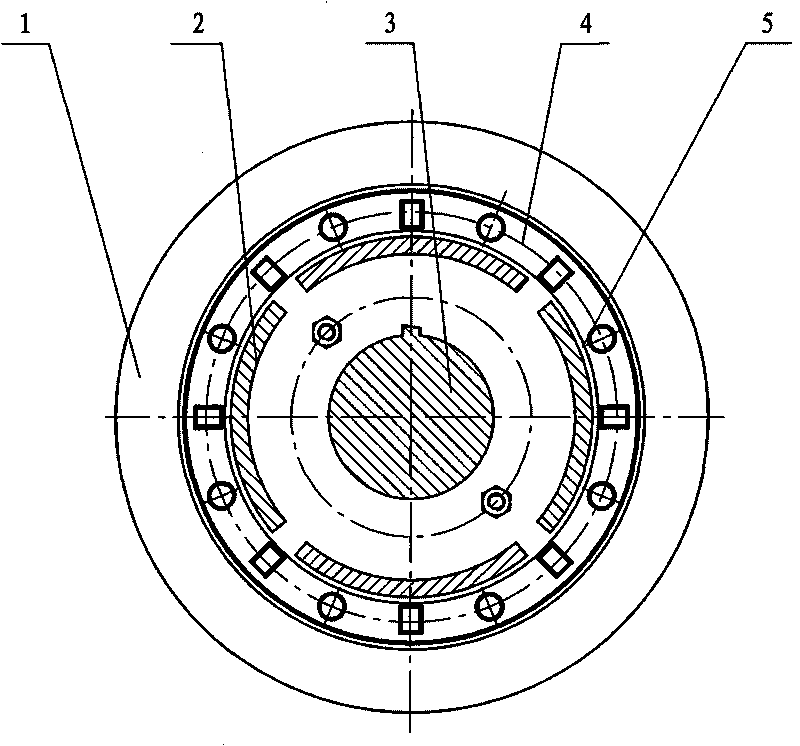

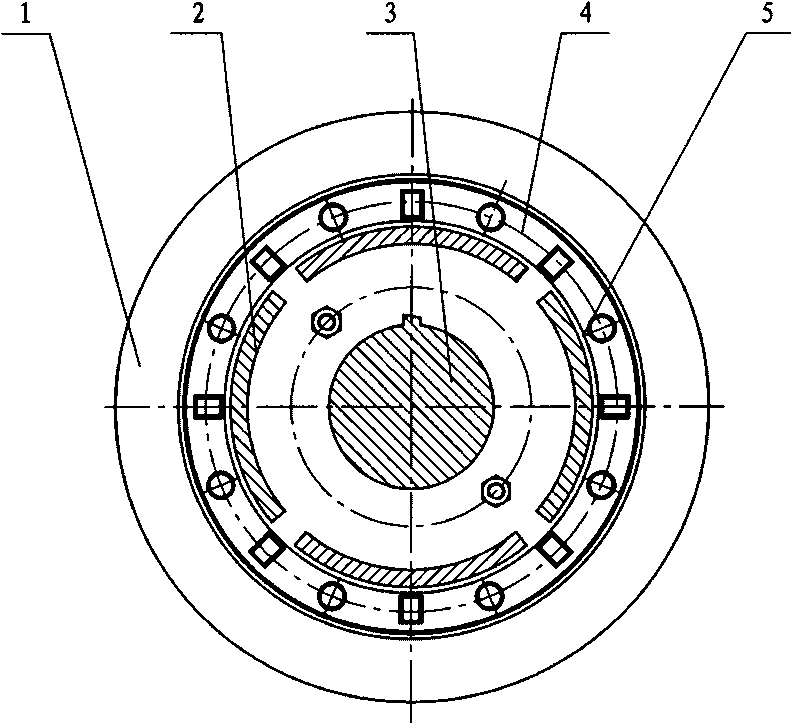

[0010] As shown in the drawings, a high-efficiency permanent magnet synchronous motor is composed of a stator 1, a rotor, a fan and an end cover. The stator 1 includes a machine base and a stator core with windings. The rotor includes a rotating shaft 3, a rotor core 4, and an aluminum ring 5. And permanent magnet 2, the connection relation of stator 1, rotor, end cap, the structure and connection relation of rotating shaft 3, rotor iron core 4 and aluminum ring 5 are the same as the prior art, this does not go into details, it is characterized in that arc permanent magnet 2 is adopted , the inner side of the rotor is provided with an arc-shaped groove matching the arc-shaped permanent magnet 2. The direction of the arc-shaped groove is the same as the center line of the rotating shaft. , High coercive force, high magnetic energy product, linear demagnetization curve characteris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com