Low-noise iron core reactor and preparation method thereof

An iron-core reactor and low-noise technology, applied in the field of low-noise iron-core reactors and their preparation, can solve the problems affecting passenger comfort, the reactor is noisy, and the sound is sharp, and achieves compact structure, tight core stacking, and magnetic hysteresis. Small stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

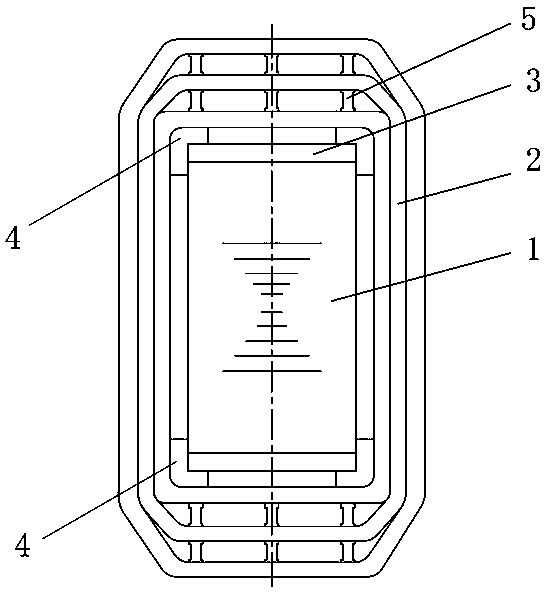

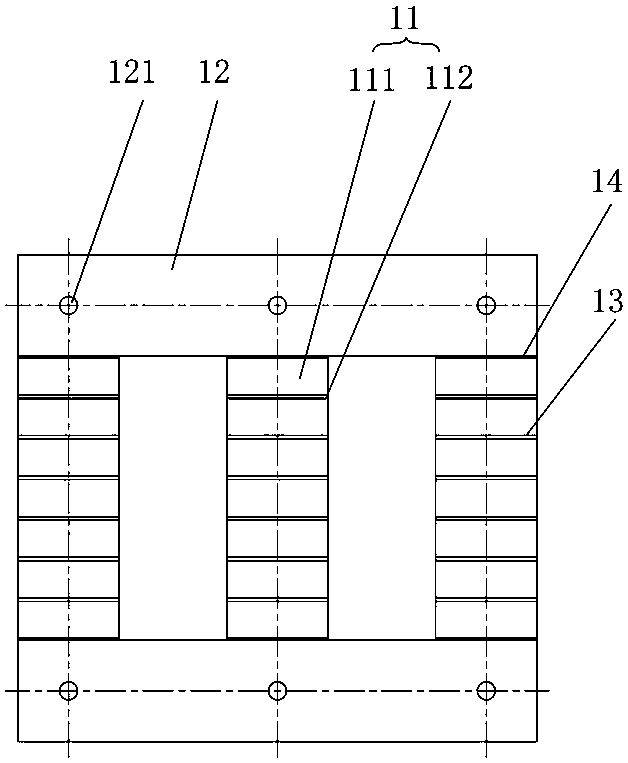

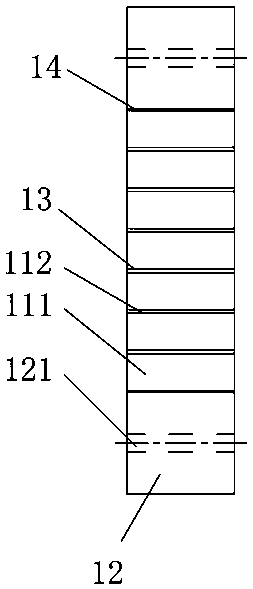

[0029] Figure 1 to Figure 3 An embodiment of the present invention is shown. The low-noise iron core reactor of this embodiment includes an iron core 1 and a coil winding 2. The iron core 1 includes a core post 11 and iron yokes 12 arranged at the upper and lower ends of the core post 11. The core post 11 and the iron yoke 12 form a horizontal "day"-shaped structure, and the coil winding 2 is arranged on the core column 11. A first cured adhesive layer 13 is provided between the column air gap plate 112 , the stem laminations 111 and the stem air gap plate 112 , and a second cured adhesive layer 14 is provided between the iron yoke 12 and the stem laminations 111 .

[0030] The low-noise iron-core reactor of the present invention, its stem 11 is formed by stacking alternately the stem laminations 111 and the stem air-gap plates 112,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com