Noise-reducing transformer iron core structure and manufacturing method thereof

A manufacturing method and technology for transformers, applied in the field of transformers, can solve problems such as high cost and large vibration noise of transformers, and achieve the effects of damping and reducing vibration noise, reducing vibration noise and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

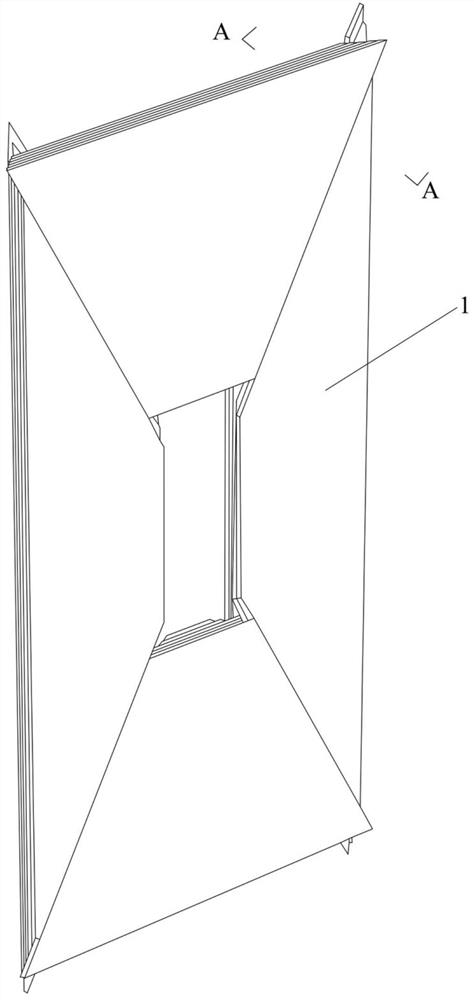

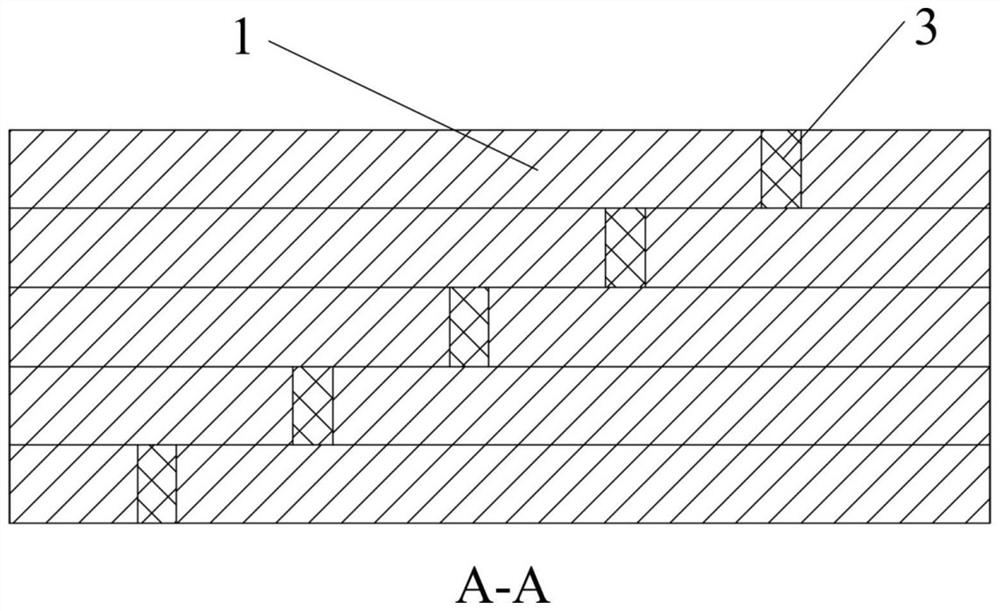

[0034] Such as Figure 1-8 The illustrated embodiment provides a noise-reducing transformer core structure of the present invention, which is formed by lapping several silicon steel sheets 1, and fills gaps between adjacent silicon steel sheets 1 laminated at the corners of the transformer core structure. Magnetorheological glue3.

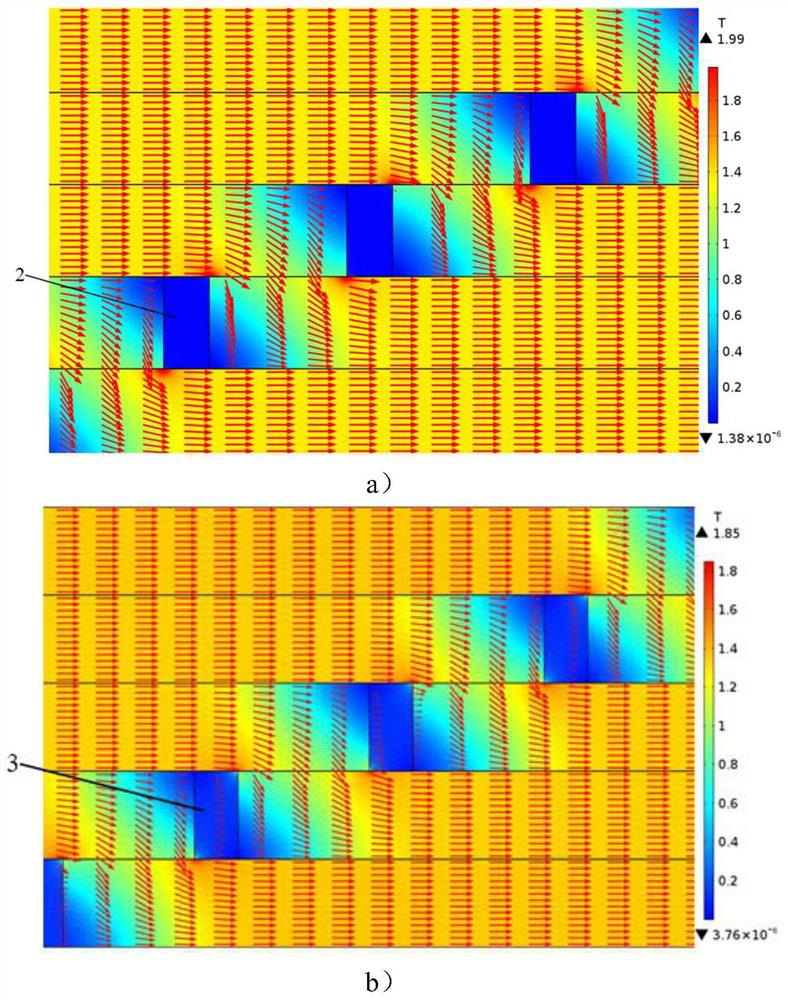

[0035] The magnetostriction curve of the silicon steel sheet used in the present embodiment is as follows Figure 5 As shown, the subsequent simulation and related calculations on the silicon steel sheet 1 are all based on this magnetization curve.

[0036] The magnetorheological glue used in this embodiment can be prepared by the following methods:

[0037] 1) Stir toluene diisocyanate (MDI-50) and castor oil (CO) in a container for 1 hour in a water bath at 75°C;

[0038] 2) In a water bath at 65°C, add 1,4-butanediol (BDO), organic bismuth catalyst, and stir for 1 hour;

[0039] 3) Add carbonyl iron powder and stir for one hour.

[0040] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com