Rotor of high-speed Halbach-type permanent magnet motor

A permanent magnet motor, high-speed technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electrical components, etc., can solve the problems of reducing the power density of the motor, reducing the power density of the motor, reducing the magnetic density of the air gap of the motor, and achieving improved Dynamic response capability, improved power density, and the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

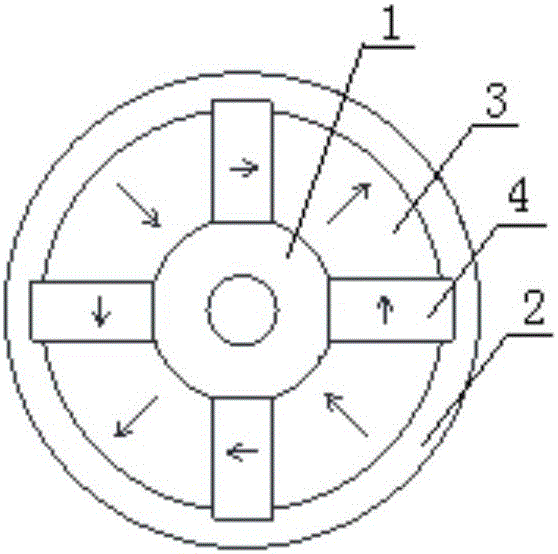

[0028] Example 1, such as figure 1 As shown, the outside of the strip-shaped rectangular permanent magnet 4 is higher than the adjacent strip-shaped arc-shaped permanent magnet 3, and the rotor sheath 1 is provided with concave holes corresponding to the strip-shaped rectangular permanent magnet 4. or correspondingly, the outside of the strip-shaped arc-shaped permanent magnet 3 is higher than the adjacent strip-shaped rectangular permanent magnet 4, and the rotor sheath 1 is provided with the bar-shaped arc-shaped permanent magnet 3 the corresponding groove.

Embodiment 2

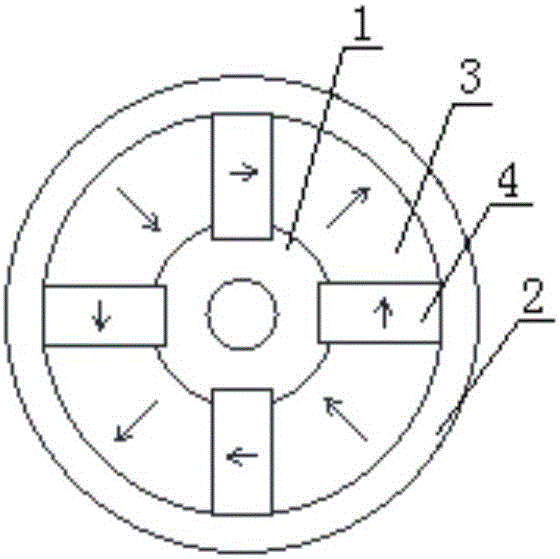

[0029] Example 2, such as figure 2 As shown, the inside of the strip-shaped rectangular permanent magnet 4 protrudes from the adjacent strip-shaped arc-shaped permanent magnet 3, and the rotor shaft 1 is provided with a groove corresponding to the strip-shaped rectangular permanent magnet 4 or correspondingly, the inside of the strip-shaped arc-shaped permanent magnet 3 protrudes from the adjacent strip-shaped rectangular permanent magnet 4, and the rotor shaft 1 is provided with a set corresponding to the strip-shaped arc-shaped permanent magnet 3 groove.

Embodiment 3

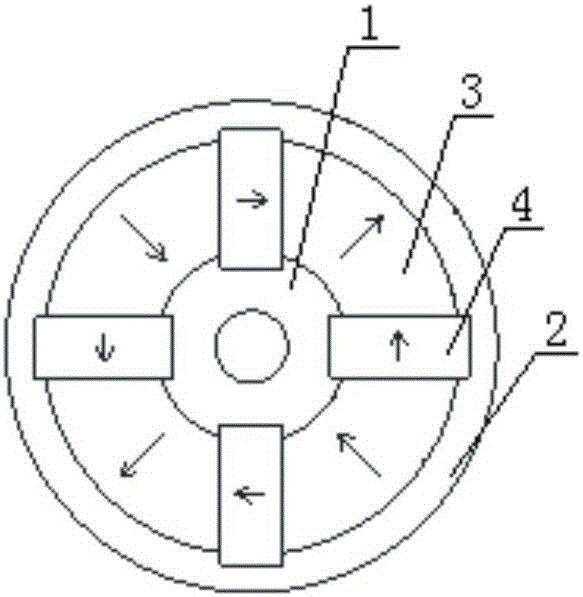

[0030] Example 3, such as image 3 As shown, the outside and inside of the strip-shaped rectangular permanent magnet 4 are higher than the adjacent strip-shaped arc-shaped permanent magnet 3, and the rotor shaft 1 and the rotor sheath 2 are provided with The corresponding groove of the permanent magnet 4; or correspondingly, the outside and the inside of the strip-shaped arc-shaped permanent magnet 3 are higher than the adjacent strip-shaped rectangular permanent magnet 4, and the rotor shaft 1 and the rotor sheath 2 is provided with a groove corresponding to the strip arc permanent magnet 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com