Score slot coil unit for low-speed high torque permanent magnetic brushless electromotor

A permanent magnet brushless motor, fractional slot technology, applied in the field of fractional slot winding, can solve the problems of low speed and large torque limitation, not too much, large number of slots, etc., to reduce the amount of iron used, the production process is simple, and the processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

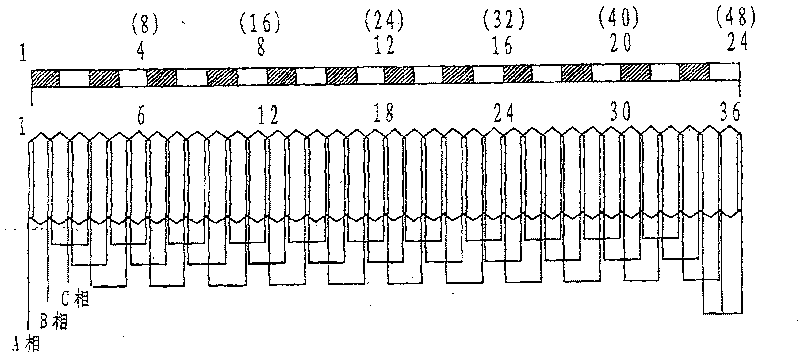

[0041] Fractional slot windings for in-wheel motors for electric vehicles

[0042] Figure 5 It is a schematic diagram of the local structure of the electric vehicle hub motor, in which the fractional slot winding form and connection refer to image 3 As shown in Table 2, the coils of this winding are embedded in the slots of the stator core, corresponding to the magnetic poles arranged alternately on the N and S poles on the rotor. Three (that is, distribution number Q=3) series windings are distributed in the phase band to form a phase winding, and the other phase windings are arranged circularly in sequence according to the phase sequence of the motor.

[0043] The number of magnetic poles P, the number of iron core slots Z, the number of phases M, and the number of distributions Q in this embodiment satisfy the condition 1) when the number of distributions Q is an odd number, the number of iron core slots Z=Q×M×K, and the number of magnetic poles P= Z±K; where Q=1, 3, 5,...

Embodiment 2

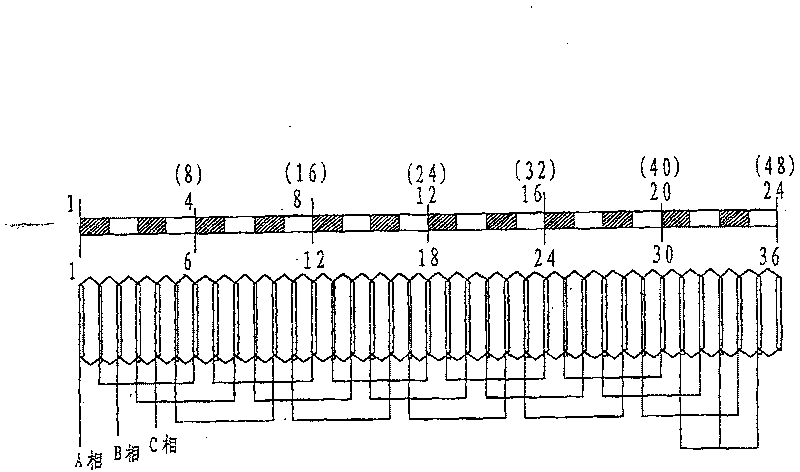

[0046] Fractional slot windings for wind turbines

[0047] Figure 6 It is a schematic diagram of the local structure of the permanent magnet wind turbine, and the fractional slot winding form and connection refer to Figure 4 And Table 5, the coil of this winding is embedded in the slot of the stator core, corresponding to the magnetic poles arranged alternately on the N and S poles on the rotor, the winding pitch of the winding is 1 slot pitch, double-layer stacked winding, in a Four windings in series (that is, the distribution number Q=4) are distributed in the phase band to form a phase winding, and the other phase windings are arranged circularly in sequence according to the phase sequence of the motor.

[0048] The number of magnetic poles P, the number of iron core slots Z, the number of phases M, and the number of distributions Q in this embodiment satisfy the condition 2) when the number of distributions Q is an even number, the number of iron core slots Z=Q×M×K, an...

Embodiment 3

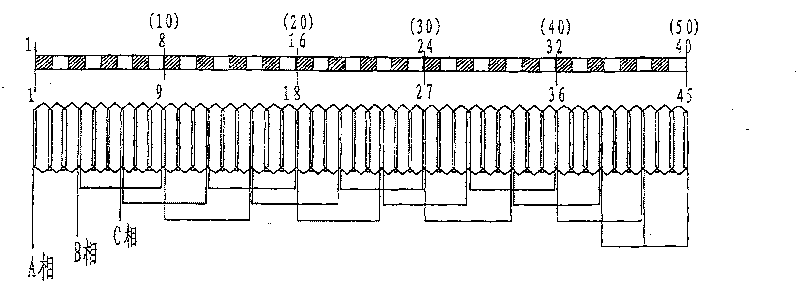

[0052] Small power permanent magnet slotless end face (plane) rotor brushless motor

[0053] Figure 7 Small power permanent magnet slotless end face (plane) rotor brushless motor winding surface schematic diagram, fractional slot winding form and connection reference image 3 And Table 2, the inner stator core 3 is made of magnetically permeable material (disc type), and the motor winding is glued on the end surface without slots, and 36 equal parts are evenly distributed on the end surface of the disc, that is, 36 virtual slots 4, each equal Parts have double-layer distributed windings. The permanent magnetic pole 2 adopts NdFeB fan-shaped magnetic steel, and the N and S magnetic poles are alternately and evenly distributed. The power of the motor is 500W, the slotless planar structure, the number of virtual slots Z = 36, the number of poles P = 32, three-phase low-speed and large-torque DC brushless motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com