Electromagnetic drive system

An electromagnetic drive and motion technology, applied in the direction of electromagnets, electromagnets with armatures, circuits, etc., can solve the problems of large inertia and delayed response of the drive device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

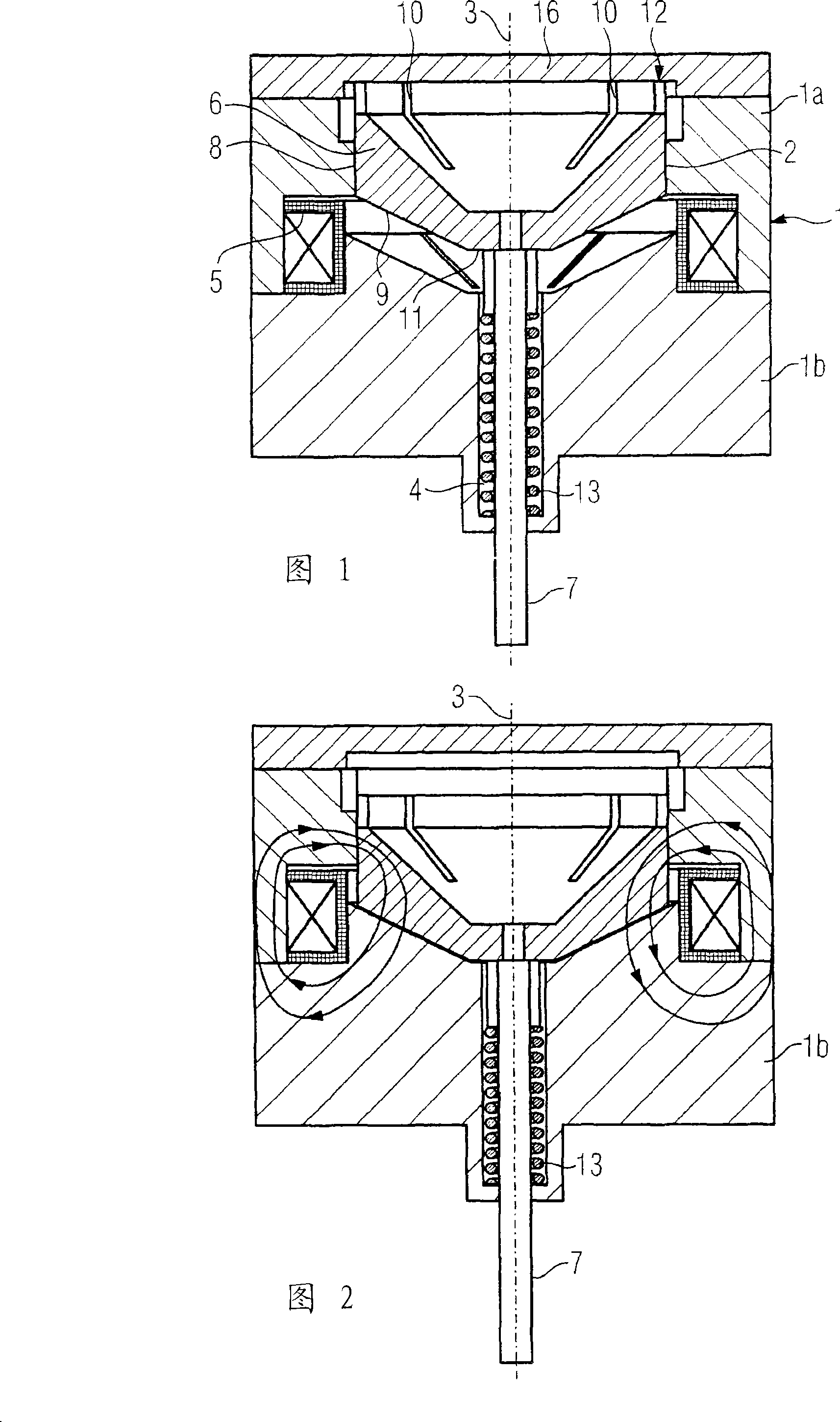

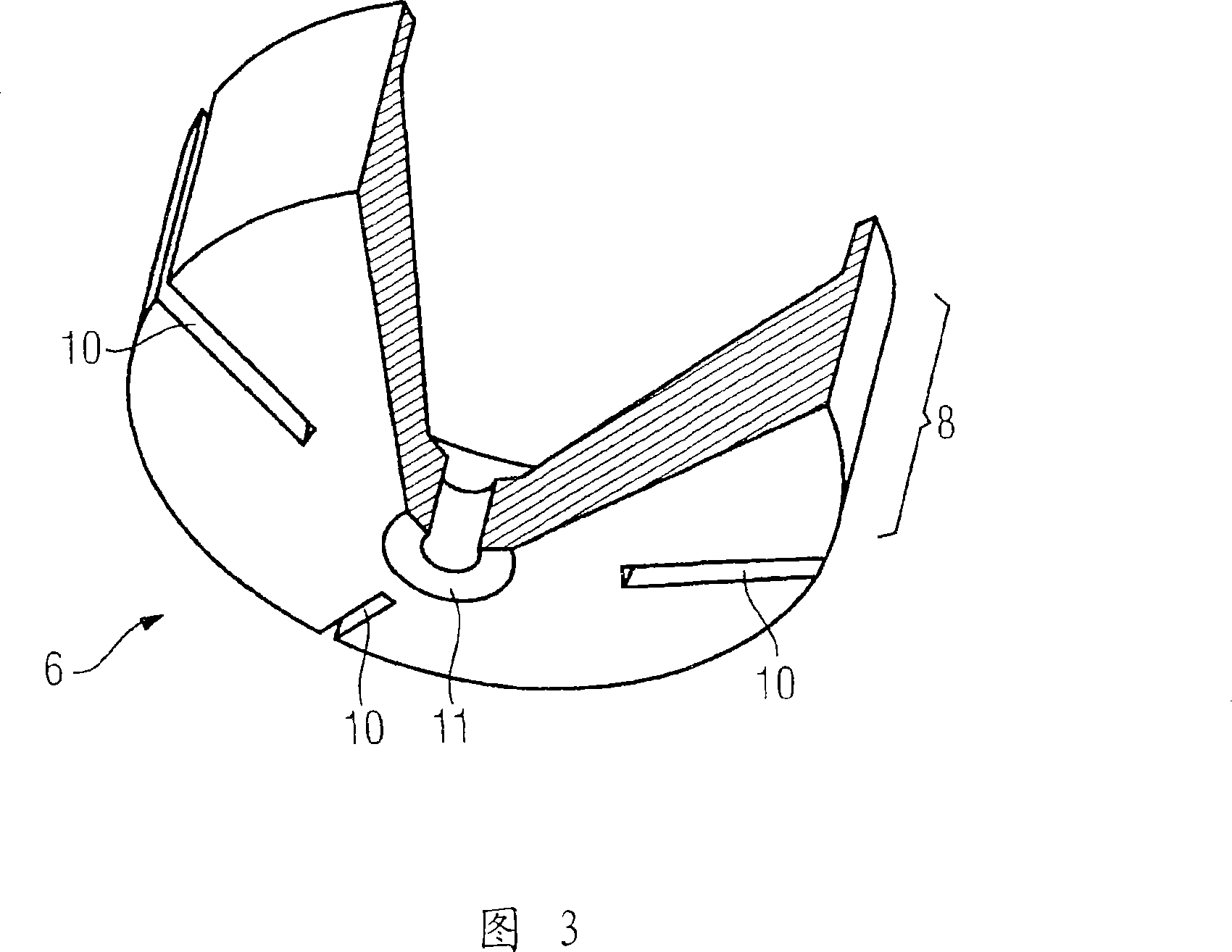

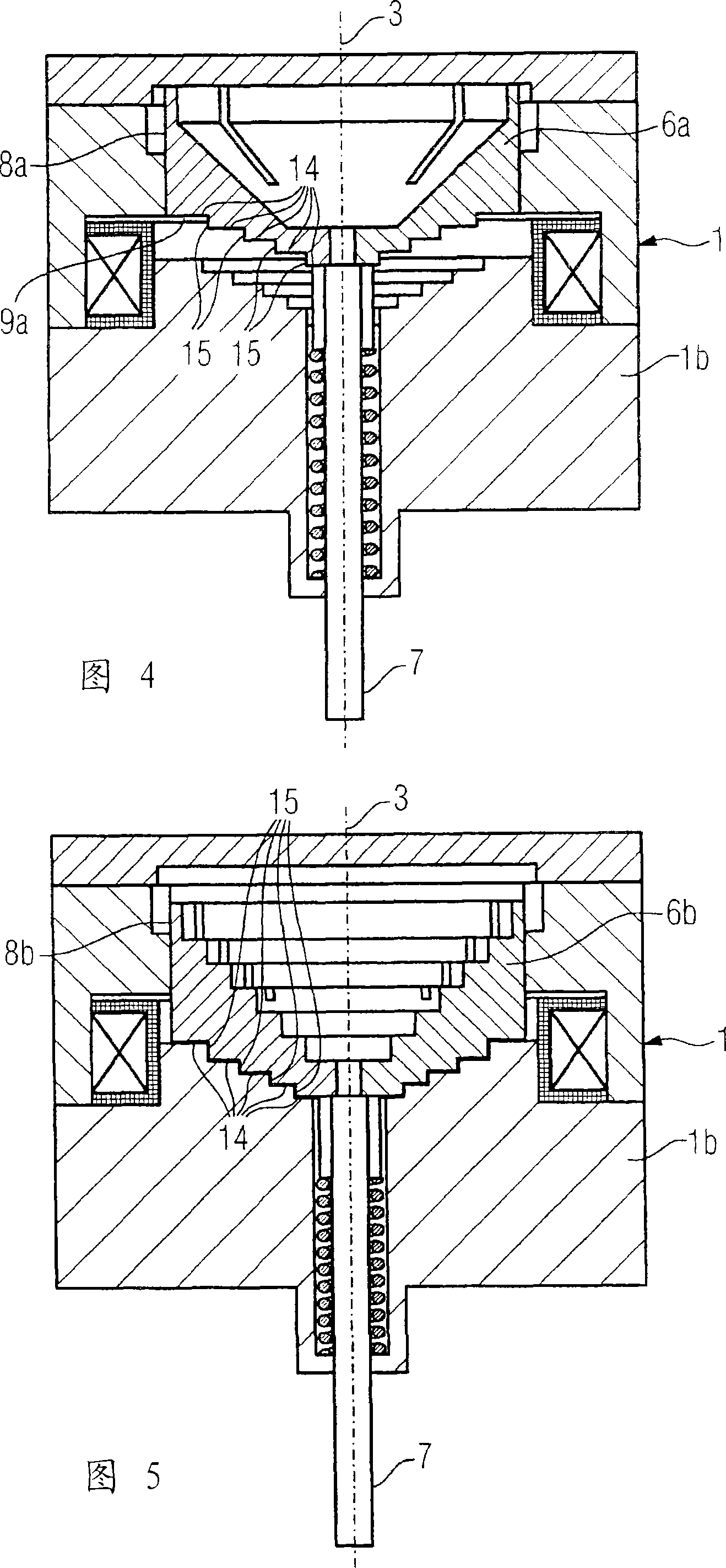

[0036]First, the principle structure of the electromagnetic drive device according to the present invention is explained by way of example with reference to FIG. 1 . The embodiments shown in FIGS. 4 and 5 are designed in principle identically, but differ in the design of the armature.

[0037] The first embodiment of the electromagnetic drive has a stator 1 . The stator 1 consists of a first part 1a and a second part 1b. The first part 1 a has a cylindrical section 2 . The cylinder section 2 has a circular cross section. The cylinder section 2 is arranged coaxially to an axis 3 . The second part 1 b of the stator 1 has a channel 4 arranged coaxially to the axis 3 and having a circular cross-section. The first part 1a and the second part 1b of the stator are connected to each other, thus creating a compact body guiding the magnetic field lines. In the stator 1 , an energizable winding 5 with an iron core is inserted into an annular gap formed in the joining region of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com