Insulation structure for cold shield of fusion device

A technology of insulating structure and insulating sleeve, which is applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problems that the cold screen cannot meet the structural strength and deformation requirements, and the difficulty of processing, so as to facilitate modular design and facilitate installation and maintenance, reduce the effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

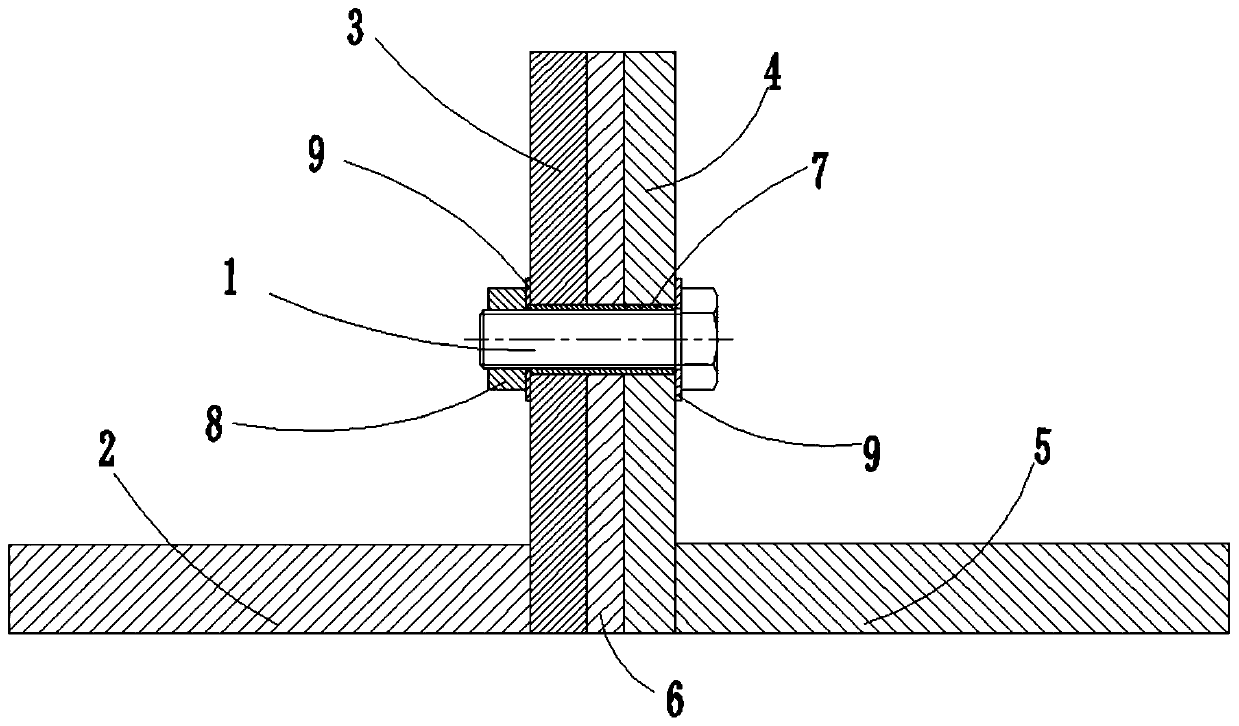

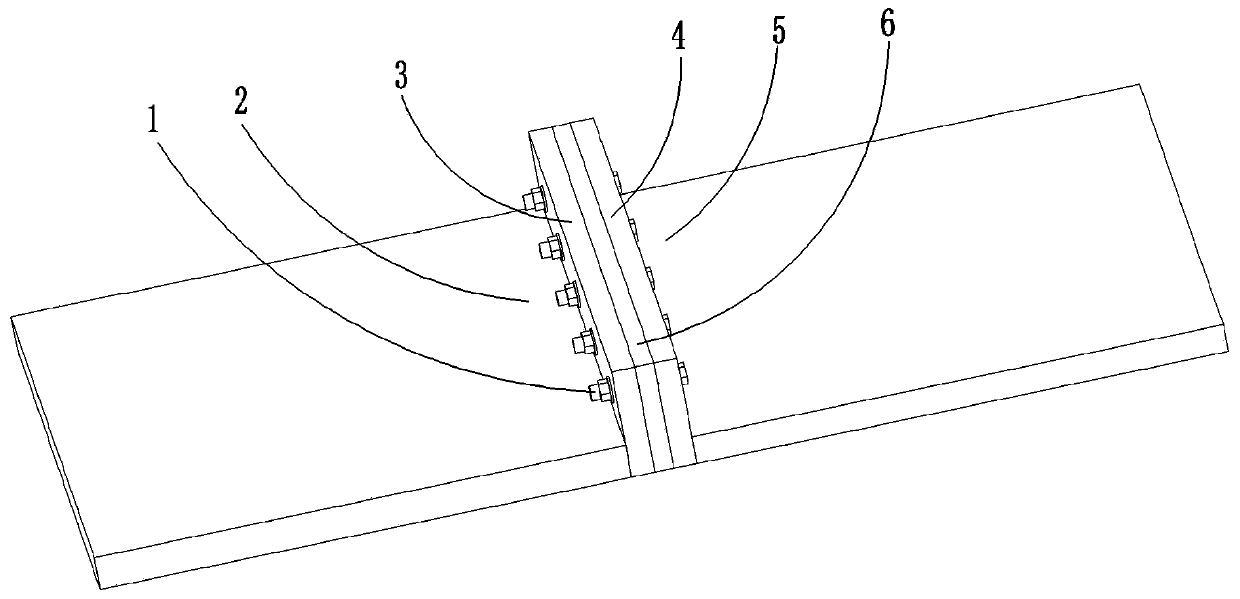

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and examples.

[0020] The theoretical basis on which the present invention is based is as follows:

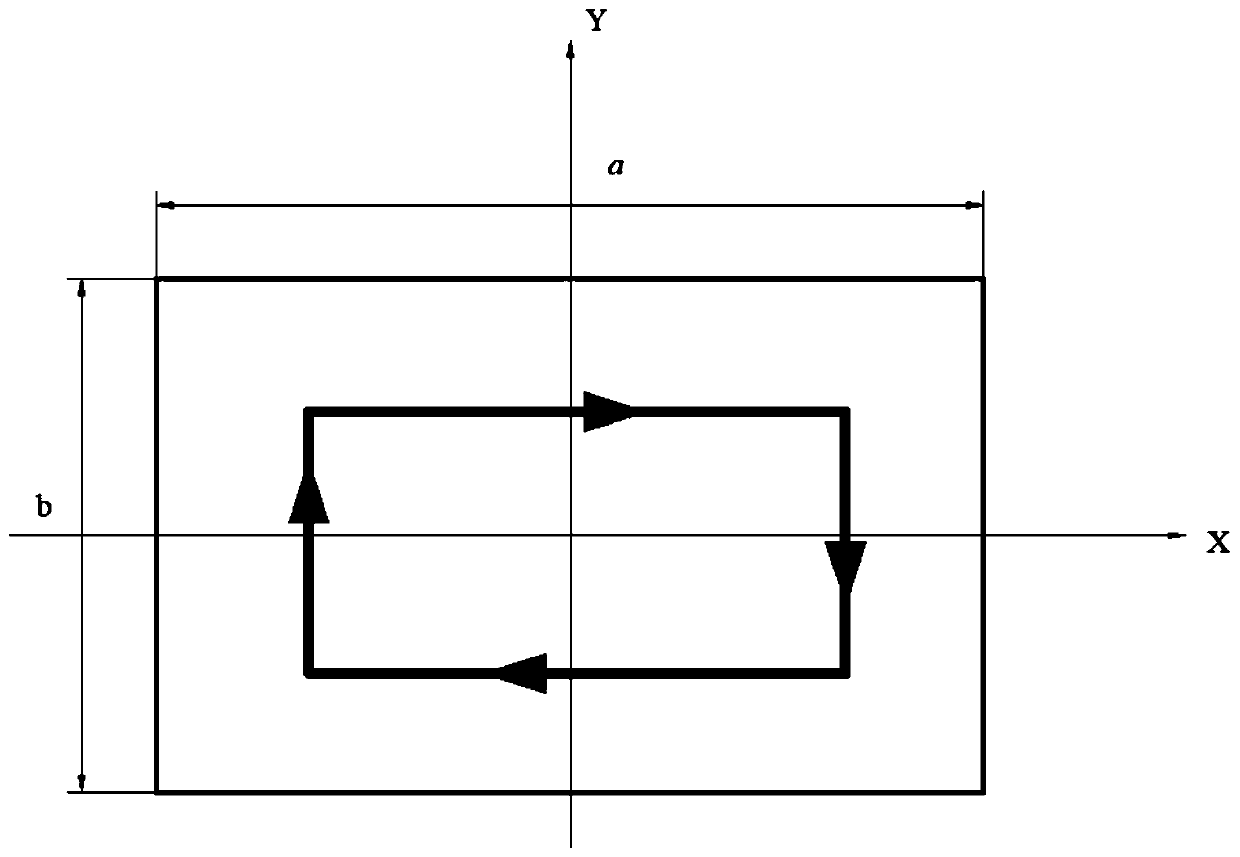

[0021] During the operation of the fusion device, eddy currents are generated on the cold shield due to changes in the electromagnetic field. Eddy current will not only increase the heat loss of the cold screen, but also cause the electromagnetic force of the cold screen. Since the thickness of the cooling panel of the cold shield is much smaller than the length and width, the eddy current caused by the change of the magnetic field Bt in the tangential direction can be ignored, and only the eddy current caused by the change of the normal magnetic field Bn (such as image 3 shown). Using the method of calculus, the eddy current loss power Pn of the cold screen panel, the electromagnetic force in the X direction and the electromagnetic force in the Y direction are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com