Combined piston type pulse solenoid valve

A pulse solenoid valve and piston-type technology, applied in the field of solenoid valves, can solve the problems of continuous leakage of compressed gas, loss of compressed gas, short life of the diaphragm, etc., and achieve rapid opening and closing, reduced volume, and short response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

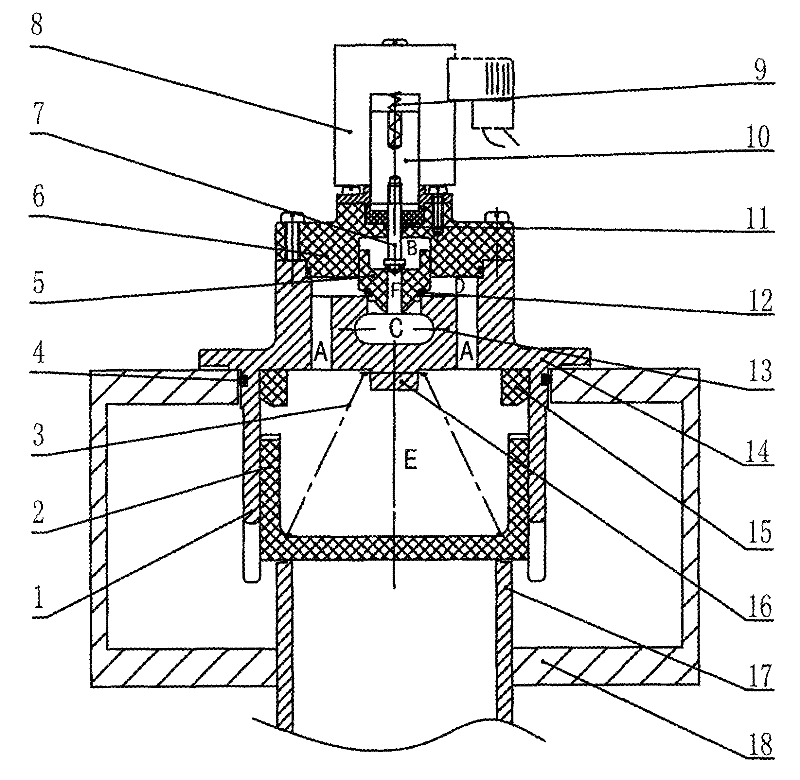

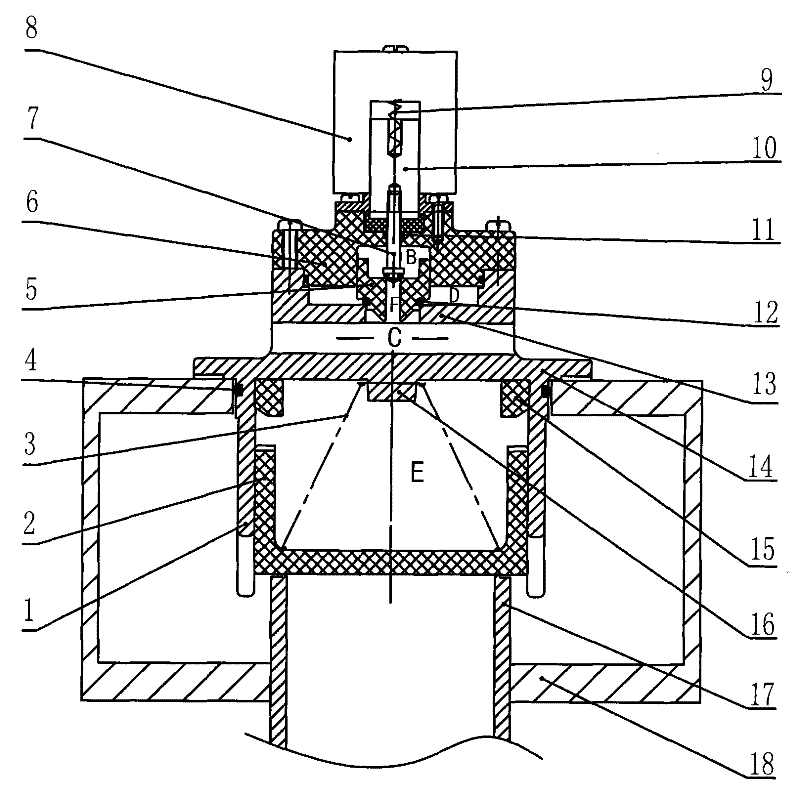

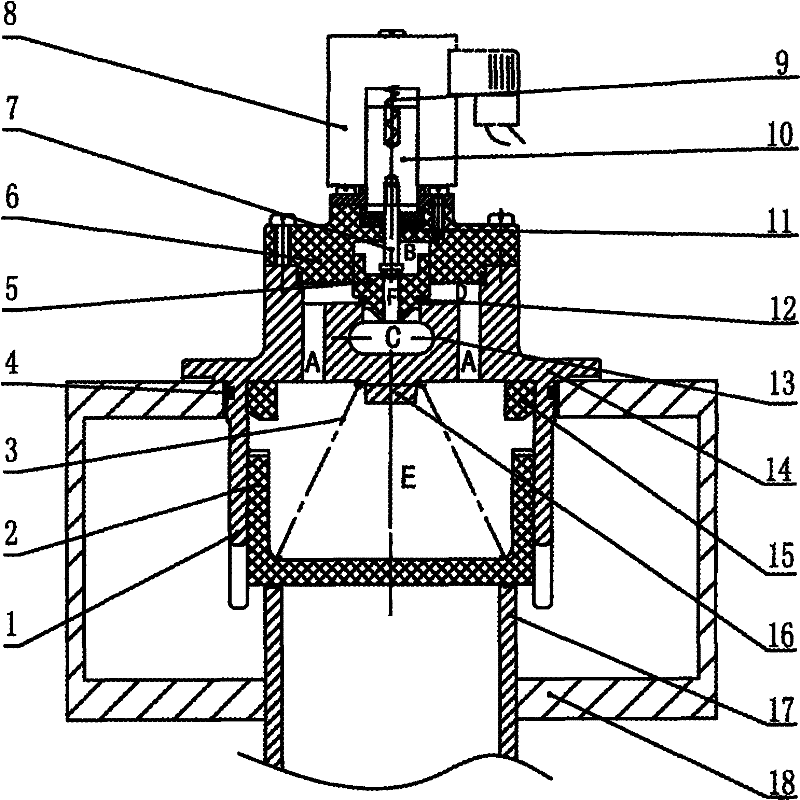

[0017] The composite piston pulse solenoid valve of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0018] The composite piston type pulse solenoid valve shown in the figure has a valve body 1 with an irregular H-shaped structure. The middle part of the outer wall of the valve body 1 is provided with a positioning flange 14, which is used to install and fix the valve body on the high-pressure air bag. 18 on. A ring of wing seals 4 is provided at the contact between the lower side of the positioning flange 14 and the mounting hole seat of the high-pressure air bag 18 to prevent the compressed air in the high-pressure air bag 18 from leaking.

[0019] The inner chamber of the valve body 1 is divided into an upper chamber D and a lower chamber E by a diaphragm 13 . A through hole A connecting the upper chamber D and the lower chamber E is provided on the diaphragm 13, and there may be one o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com