Fuel injection executing valve

A fuel injection and actuating valve technology, which is applied to fuel injection devices, charging systems, engine components, etc., can solve the problems of low oil drainage capacity, insufficient oil drainage, and large liquid resistance on the suction surface, so as to improve the overall strength and accuracy, avoid cavitation bubbles, reduce the effect of liquid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

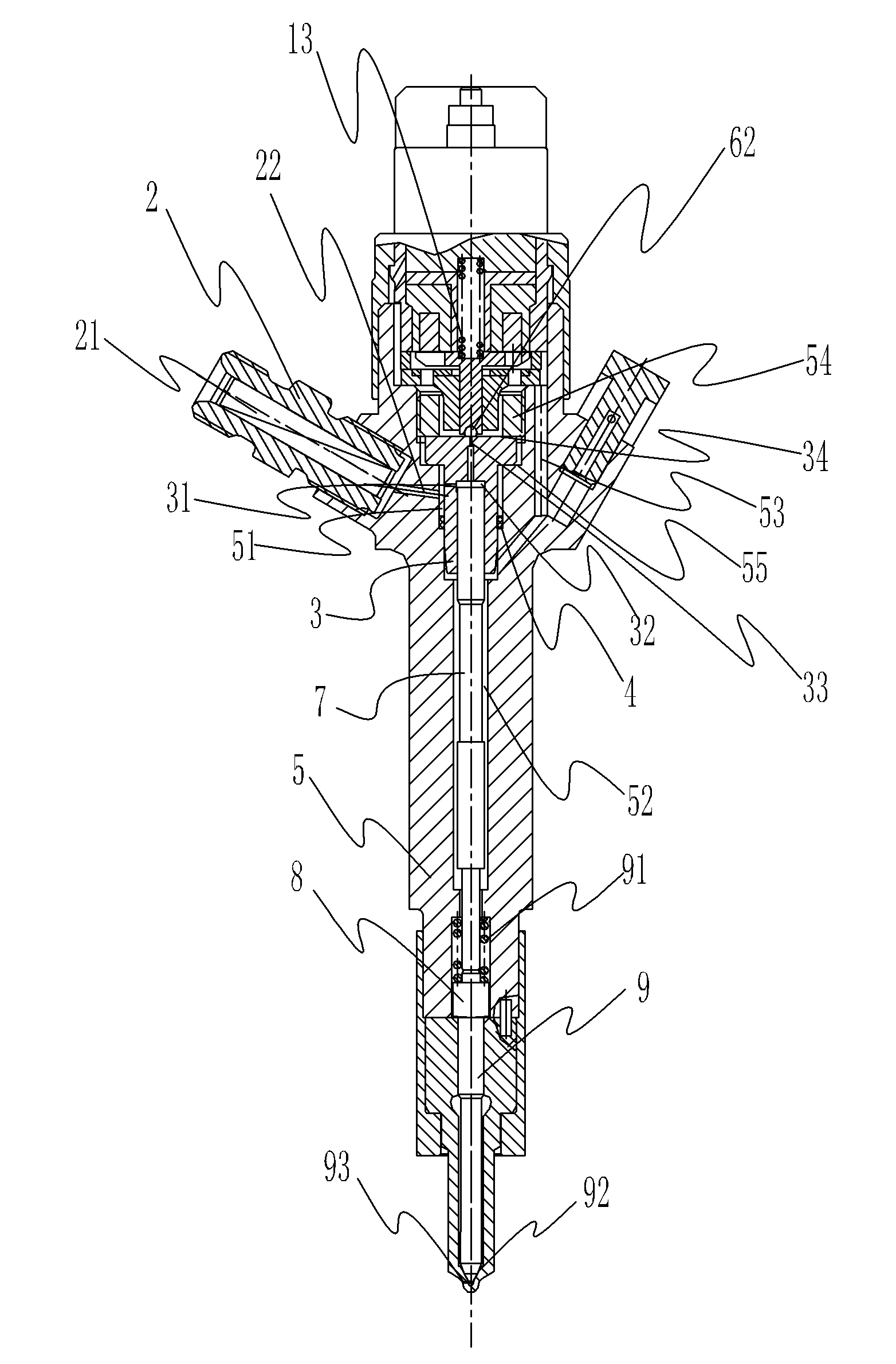

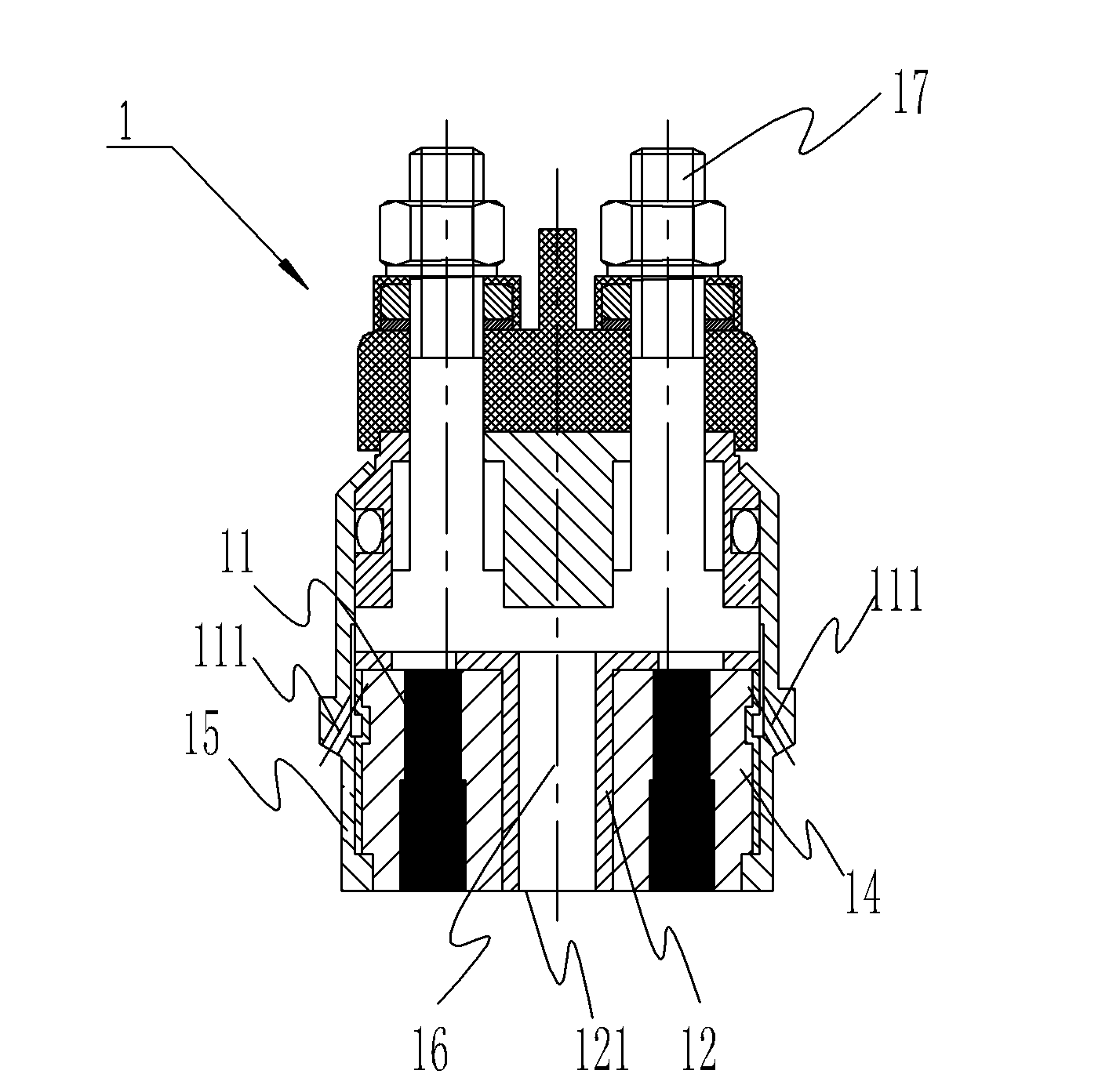

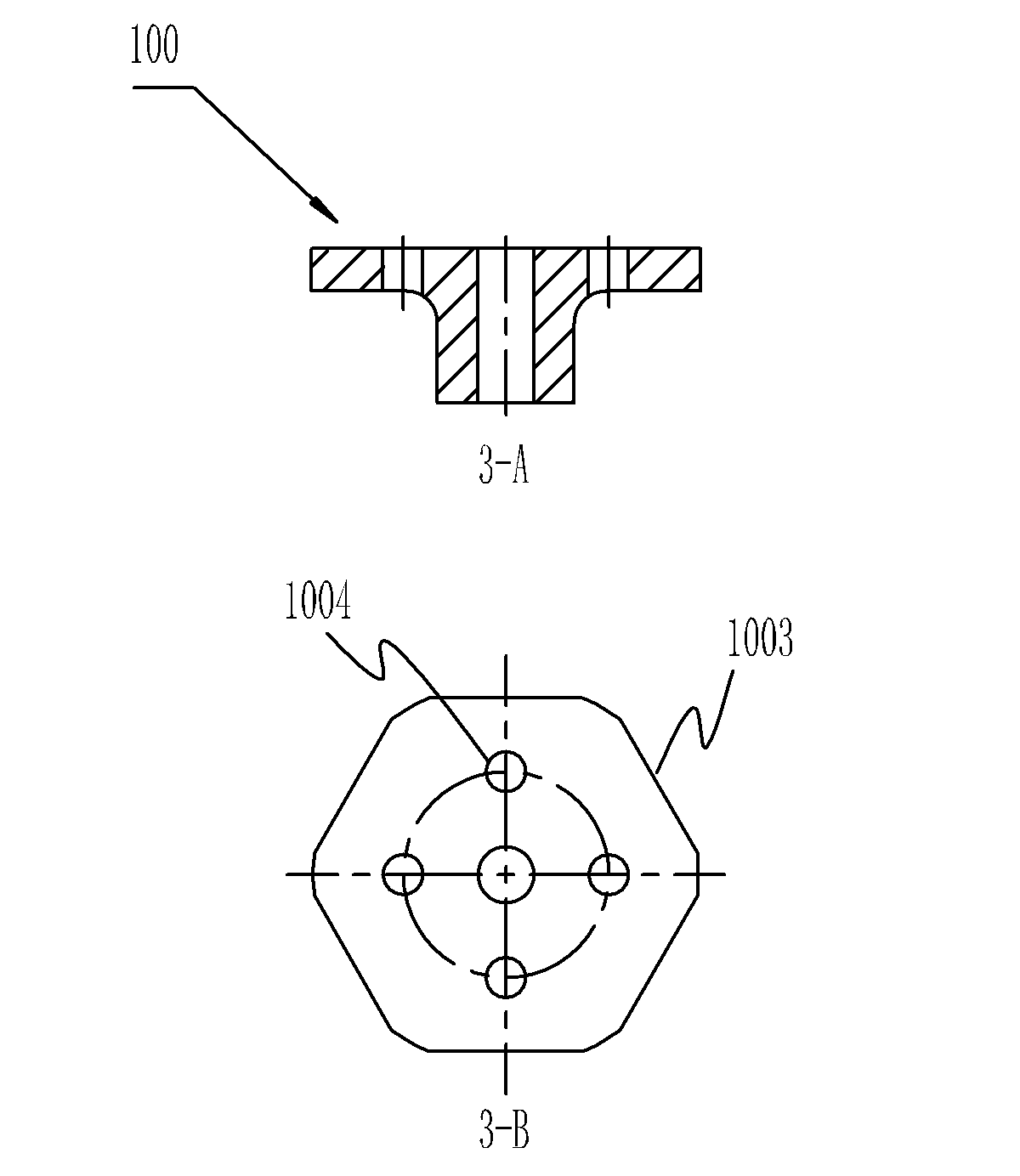

[0043] Such as Figure 4 As shown, the guide shaft 63A of the actuator valve in Embodiment 1 extends downward from the center of the back of the suction surface 61A, and cooperates with the guide sleeve 100 capable of magnetic isolation, so that the actuator valve 6A can slide vertically along the middle hole of the guide sleeve 100 ( refer to figure 1 , 3 ). The center hole of the guide sleeve is guided by the guide shaft 63A of the actuator valve 6A, the outer circle is guided by the solenoid valve cavity installed on the injector body, and the bottom of the hole of the injector body is used as the supporting surface, as shown in image 3 As shown in -B, the outer circle of the guide sleeve 100 is cut with an oil-passing hexagon 1003, and the guide sleeve 100 axially penetrates the guide sleeve oil-passing hole 1004 on the same circumference, and the position of the oil-passing hole is the same as that of the actuator valve oil-passing hole 66A There is a corresponding re...

Embodiment 2

[0052] Such as Figure 5 As shown, the actuator valve 6B involved in Embodiment 2 has an oil passage 64B that runs through the suction surface and the lower surface on the suction surface 61B. The difference from Embodiment 1 is that the oil passage 64B in Embodiment 2 is Long strip shape, that is, a straight groove opening is formed from the outer circle of the suction surface 61B toward the center, and the strip-shaped oil passages are regularly distributed on the radial circumference of the suction surface 61B. There is a circular recess 68B in the center of the suction surface 61B, which can be used to accommodate the solenoid valve spring 13 and play a supporting role for it. An annular contact surface is formed around the outer circumference of the circular recess 68B, and the annular contact surface is opposite. The annular protrusion 69B on the suction surface 61B is vertically raised by 0.05mm from the annular contact surface to the surface of the suction surface, and...

Embodiment 3

[0057] The structure difference from Embodiment 2 is that the oil passage 64C used by the executive valve 6C in Embodiment 3 is in the shape of a flask, and the mouth of the flask is located on the outer peripheral edge of the suction surface 61C. The circular parts of the flask-shaped oil passages respectively communicate with the three oil passages 65C arranged at intervals, and the centers of the circular parts of the three oil passages 64C are located on the same circumference, as Figure 6 shown by the dotted line inside. The circular part of the oil passage 64C and the oil passage 66C are alternately arranged, and the centers of the three oil passages 66C are located on the same circle, that is, as Figure 6 shown by the dotted line on the outside. Compared with Embodiment 2, the flask-shaped oil passage of this embodiment has a larger oil passage area, which will make the fuel liquid flow more smoothly, speed up the oil drain, and greatly reduce the displacement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com