Power-losing trigger device

A triggering device, electromagnetic technology, applied in the direction of the hoisting device, can solve the problems of the brake not working, high power consumption, opening failure, etc., to achieve the effect of the energy storage impact structure and the reset structure is simple, the current is reduced, and the service life is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] see Figure 5-6 , the frame 102 is in the shape of a square frame, and its rear side is fixedly connected to the rear plate 118 to form a fixed frame. The left and right sides of the frame 102 are respectively provided with holes, and the upper and lower sides are respectively provided with holes, and the lower holes are the lower guide holes 103 . The corresponding holes on the upper and lower sides of the frame 102 are adapted to the shape of the impact rod 3 , and the upper and lower holes vertically penetrate the impact rod 3 , and the upper and lower holes are used for guiding and installing the impact rod 3 . The upper section of the impact rod 3 is in the shape of a square column, and the side is a guide surface 110, which is used for vertical guidance during the impact and reset process. The middle section is also column-shaped, but the distance between the two sides (i.e. width) is smaller than that of the upper section. The two sides are the electromagnetic a...

Embodiment 2

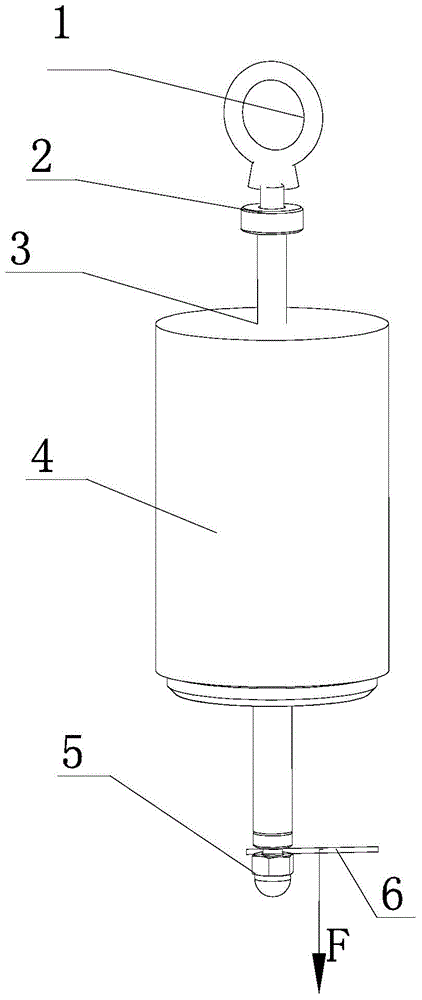

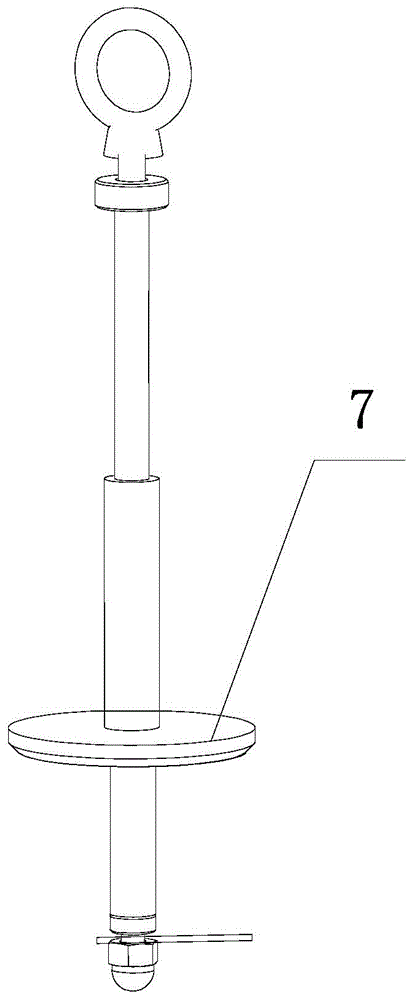

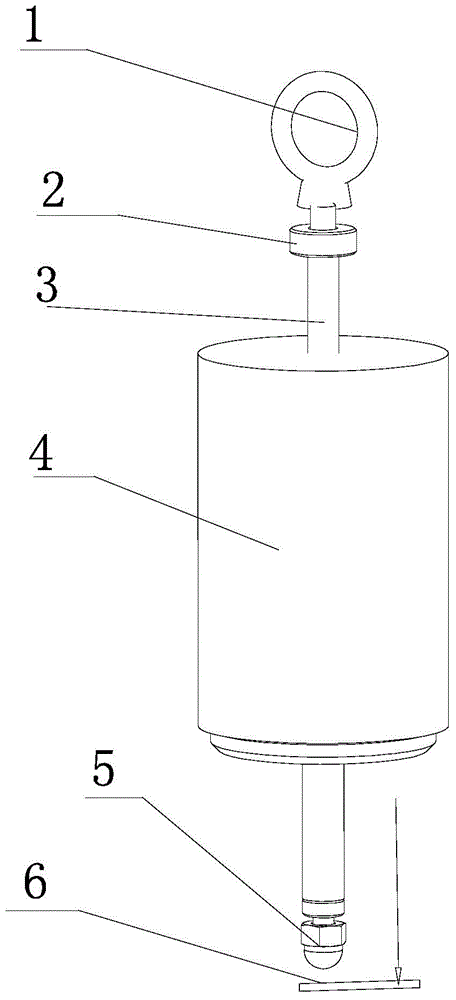

[0058] see Figure 7-10 , the frame 2-9 is in the shape of a square frame, the impact rod 2-3 vertically moves through the upper and lower edges of the frame 2-9, the two ends of the impact rod 2-3 are outside the frame 2-9, and the impact The upper end of the bar 2-3 is fixedly connected with the manual pull ring 1-1, and the upper section of the impact bar 2-3 is also equipped with a limit buffer pad 2-2, and the limit buffer pad 2-2 is on the top of the frame 2-9 and the manual pull ring 2-1 rooms.

[0059] The impact screw 2-5 is installed at the bottom of the impact rod 2-3, and the lower section of the impact rod 2-3 is also covered with an energy storage spring 2-8 and a retaining ring 2-13, and the retaining ring 2-13 rests on the impact screw 2- 5, the upper and lower ends of the spring 2-8 respectively push against the lower surface of the bottom edge of the frame 2-9 and the retaining ring 2-13.

[0060] The energy storage spring 2-8 is covered with a spring cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com