A non-traction inclined elevator and its control method

An oblique elevator, non-traction technology, applied to elevators in buildings, sustainable buildings, elevators, etc., can solve the problems of oblique elevators with complex structure, inconvenient installation and maintenance, and high production costs, and achieve light weight , easy maintenance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

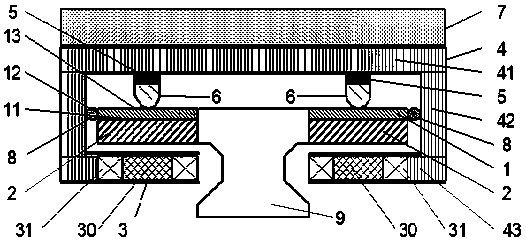

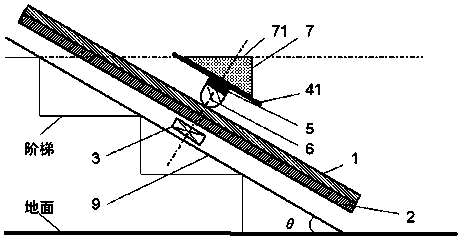

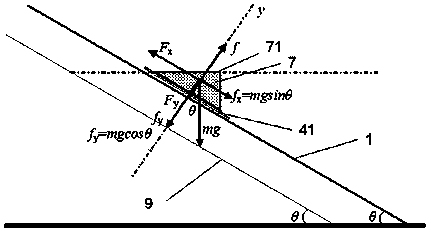

[0034] as attached figure 1As shown, the non-traction inclined elevator of the present invention includes: an inclined track 1, a support system, a drive system, a control system, a load cell 5, a pedal 7, a guide 8, and an inclined buttress 9.

[0035] The line track of the non-traction type inclined elevator of the present invention includes an inclined track 1 and an inclined support pier 9, and its function is to guide the direction of the elevator, and simultaneously bear the load of the elevator and transmit it to the support pier 9. Inclined track 1 includes stator surface 11 (for fixing stator 2), side guide rail surface 12 (contacts with guider 8 to control the running direction of the elevator), slide rail surface 13 (for supporting people or goods on pedal 7) And its fixing accessories, the inclined track 1 is installed and fixed on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com