Non-groove stator of evaporative cooling motor

A slotless stator, evaporative cooling technology, applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of wire density, wire load increase, and excitation magnetic potential increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

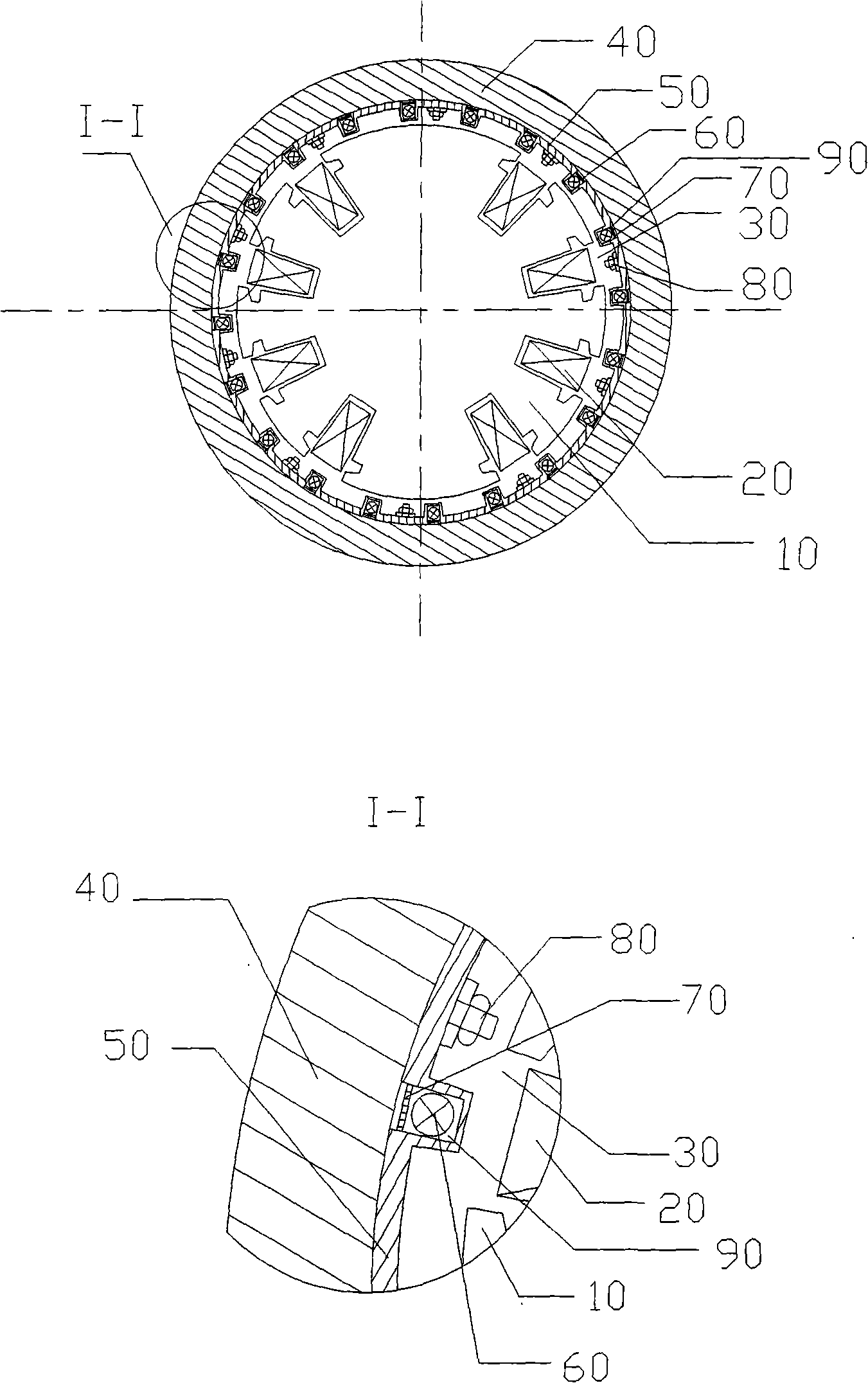

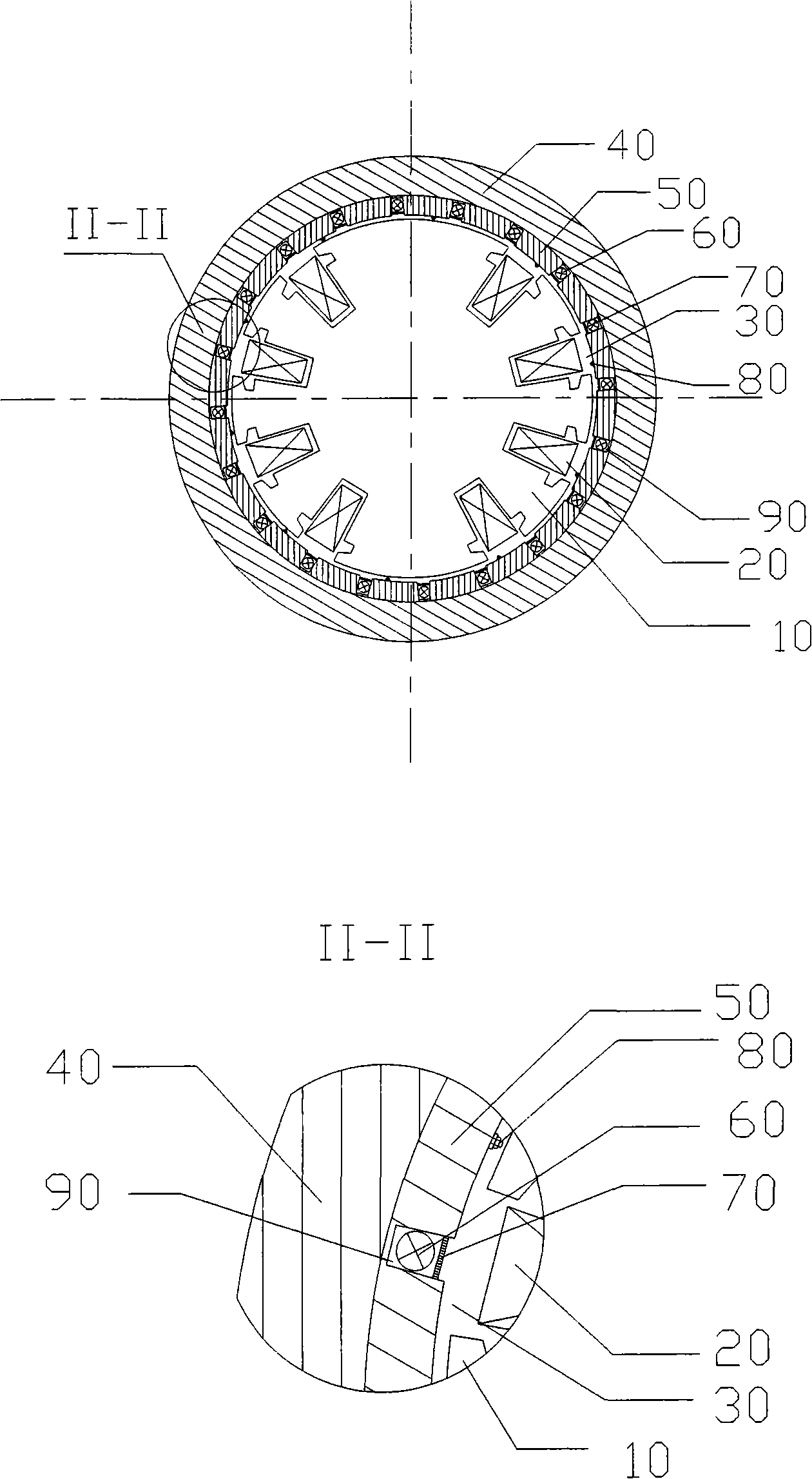

[0014] The structure of the slotless stator of the present invention is as follows: figure 1 shown.

[0015] figure 1 Among them, the rotor coil 20 is placed in the rotor core 10 slot, the stator core 40 does not open the stator slot, the stator core is sleeved on a non-ferromagnetic material cylinder 50, and a plurality of bolts 80 distributed along the circumference connect the stator The iron core and the non-ferromagnetic material cylinder are fixedly connected. The non-ferromagnetic material cylinder 50 defines a plurality of non-ferromagnetic material slots 90 along the circumferential direction, and the stator coil 60 is placed in the non-ferromagnetic material slots 90 . In addition, a stator slot wedge 70 is provided at the opening of the non-ferromagnetic material slot 90 to fix the stator coil 60 , and an air gap exists between the stator core 40 and the rotor core 10 . figure 1 The notch of the non-ferromagnetic material groove 90 opened on the middle non-ferrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com