Patents

Literature

38results about How to "Realize flexible manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

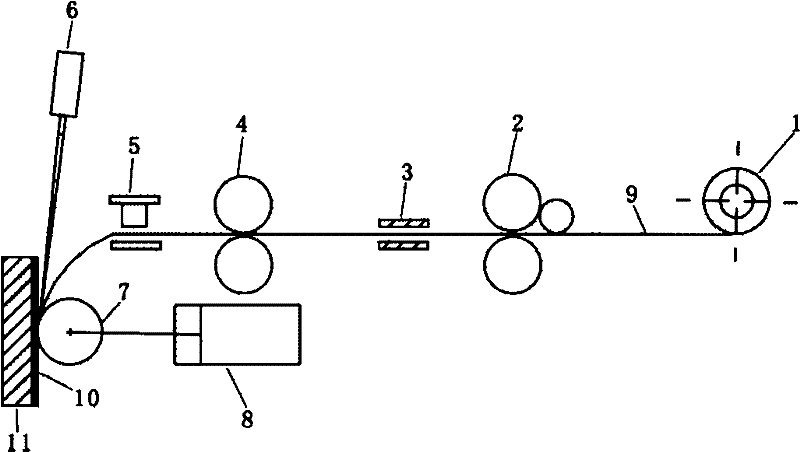

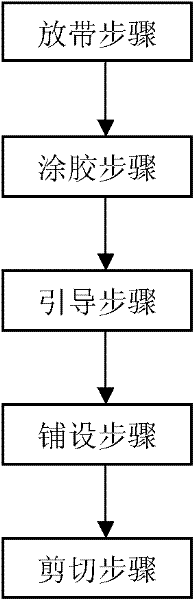

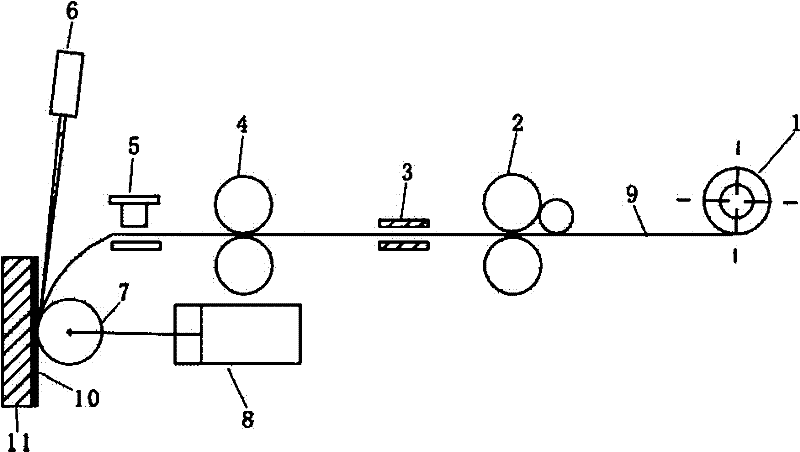

Composite Ribbon Laying Apparatus and Method Using Laser

The invention relates to a composite material ribbon laying device using laser, which has a tape unwinding roll, a glue roller, a guide unit and a pressure roller, wherein a laser device is also included, which is arranged to be able to face the processed member and the composite material ribbon The bonding part of the laser beam is used to scan point-by-point the bonding surface of the composite material ribbon laid on the processed member by using the laser beam, so that the thin layer on the surface of the scanned area undergoes a photopolymerization reaction and reaches a cured state. According to the present invention, the continuous laser curing process is used to scan the surface of the ribbon of the composite material point by point during the laying process of the composite material to make it reach a solidified state, and then press it with a pressure roller to form the profile of the product.

Owner:SHANXI FEIHONG LASER TECH +2

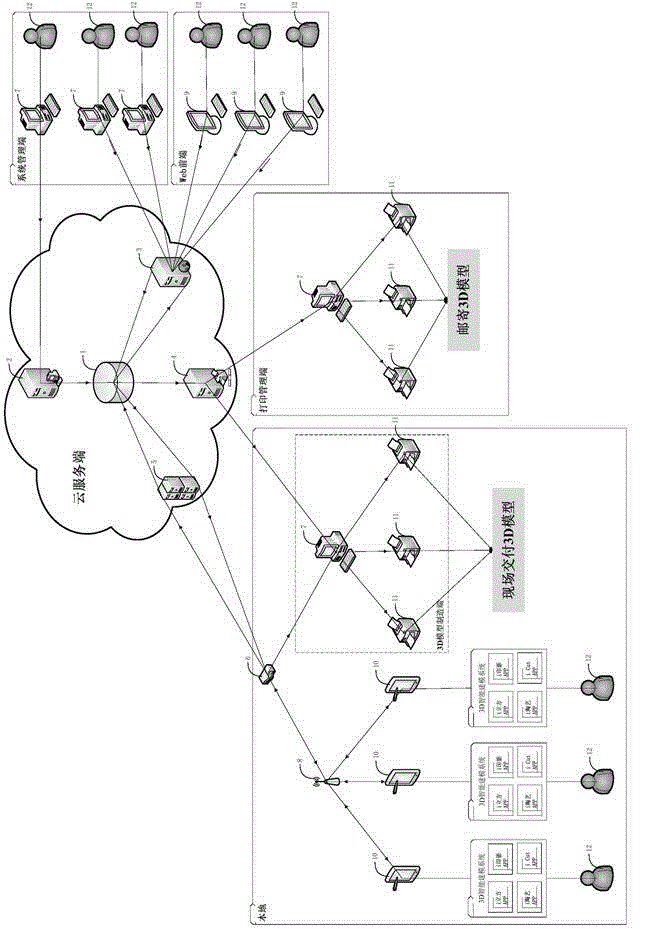

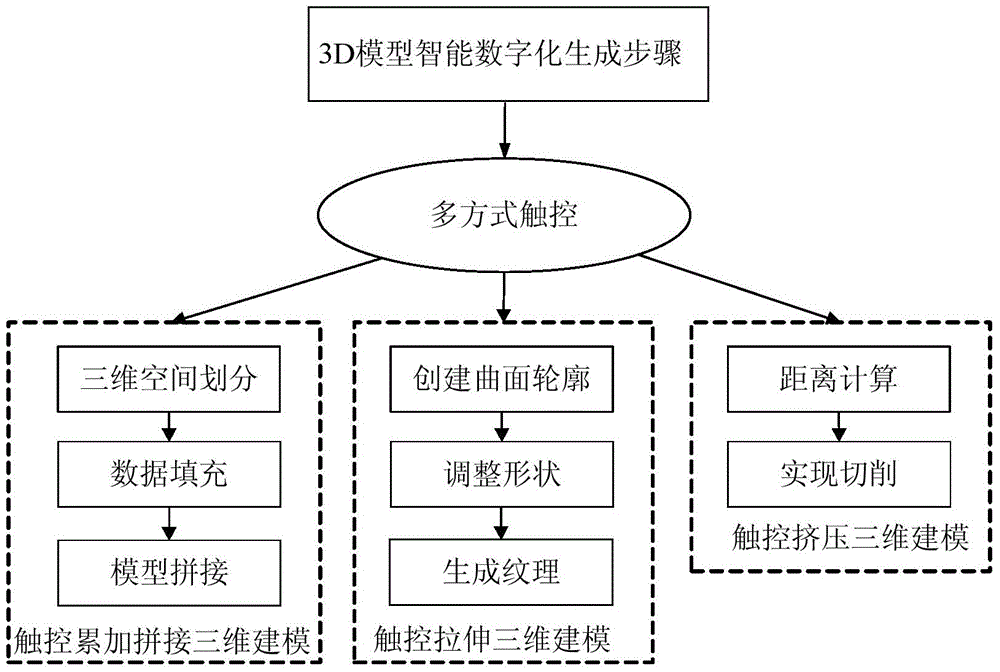

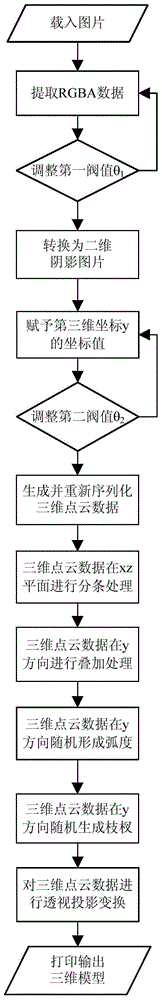

3D intelligent modeling method and system and a flexible manufacturing system of 3D model

ActiveCN104103091AReduce demandGuaranteed a high degree of freedom3D-image rendering3D modellingFlexible manufacturing systemIntelligent modeling

The invention relates to a 3D intelligent modeling method and system and a flexible manufacturing system of a 3D model. A single photograph or picture is converted into a 2D shadow picture; after a 3D model is constructed, the information of the 2D shadow picture is hidden in the 3D model, a shadow presented by the 3D model with the hidden information of the 2D shadow picture through illumination angle projection is in an original picture or photograph shape, and 3D intelligent modeling can be realized by methods, such as accumulation, splicing, stretching, extrusion and the like. The flexible manufacturing system of the 3D model enables a user to integrally experience the processes of 3D modeling and 3D printing, 3D modeling compatible data is created, stored, transmitted and managed for a user, and the user is guaranteed to carry out 3D printing at any time and place so as to realize the flexible manufacture of the 3D model.

Owner:北京毛豆科技有限公司

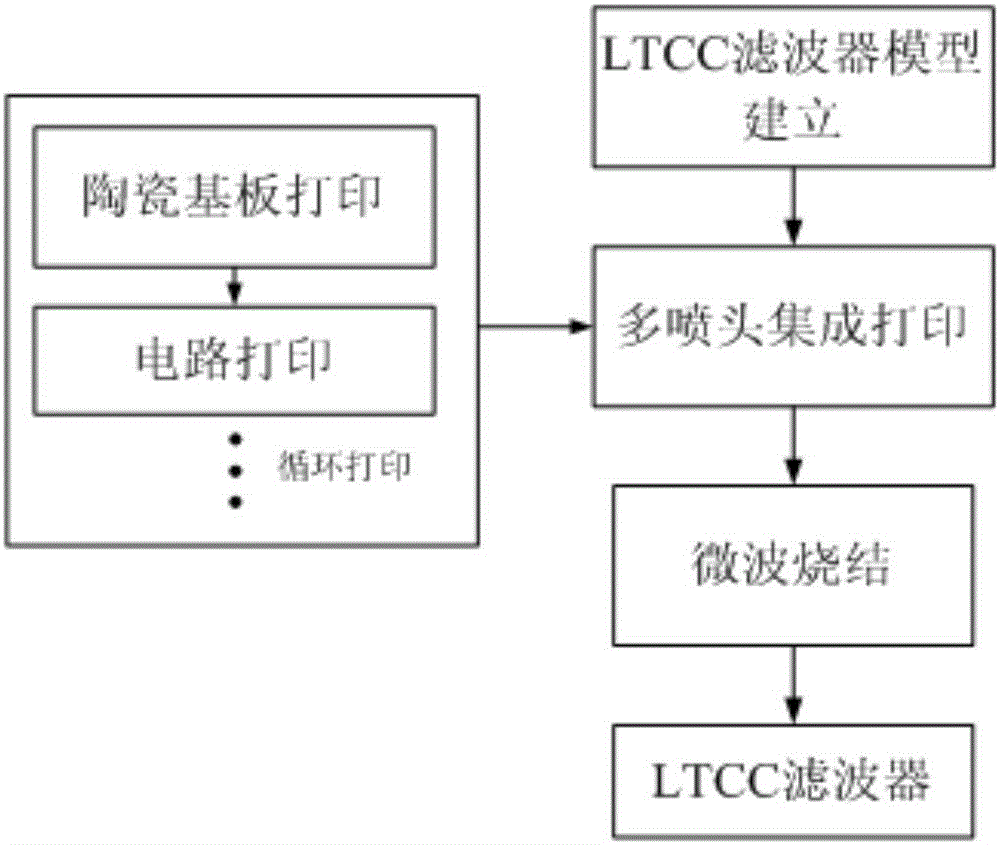

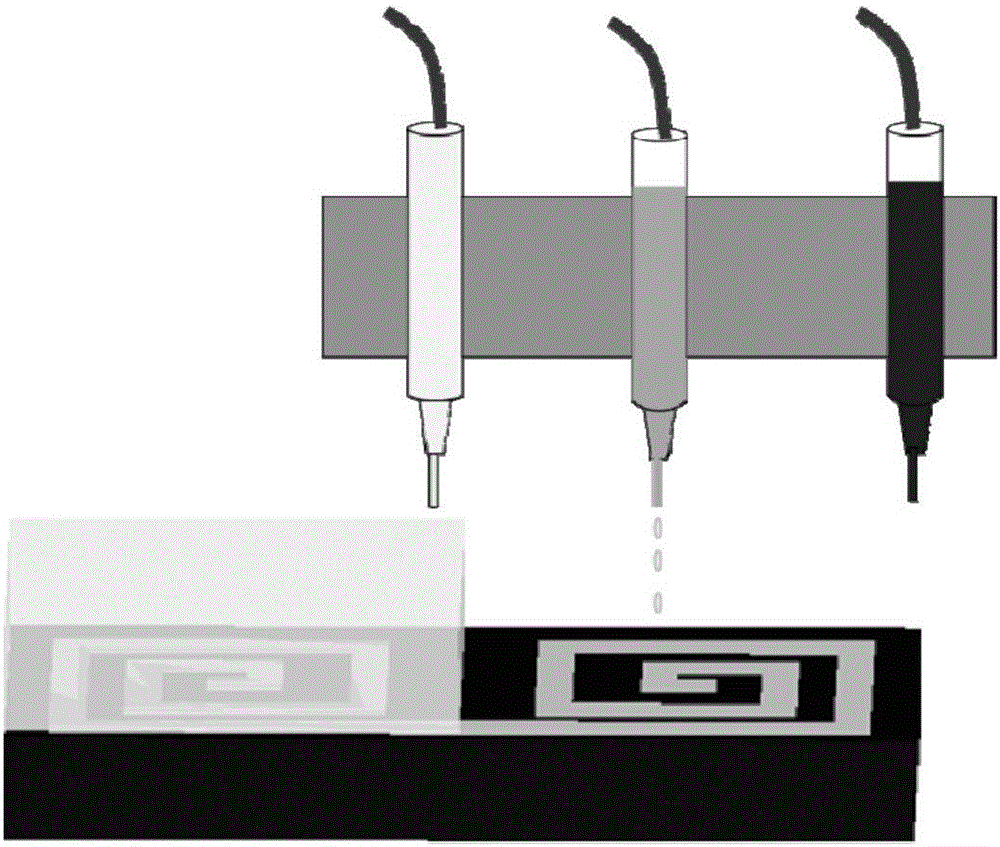

Multi-print head printing and integrated manufacturing method of LTCC (low temperature co-fired ceramic) filter

ActiveCN106747476ARealize flexible manufacturingFlexible Manufacturing FastAdditive manufacturing apparatusWaveguide type devicesDielectricMiniaturization

The invention discloses a multi-print head printing and integrated manufacturing method of an LTCC (low temperature co-fired ceramic) filter. The integrated jet printing of an LTCC filter is implemented through the following process flows: LTCC filter model building, multi-layer LTCC filter jet printing and firing. According to the manufacturing method provided by the invention, a multi-layer embedded integrated and miniature LTCC filter with required dielectric constant, low loss and high Q can be manufactured; flexible manufacturing of devices can be realized to satisfy special needs in different areas; and meanwhile, the method has the advantages of simple process, less required equipment, low cost and high manufacturing speed, thereby providing a new method for LTCC filter manufacturing.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

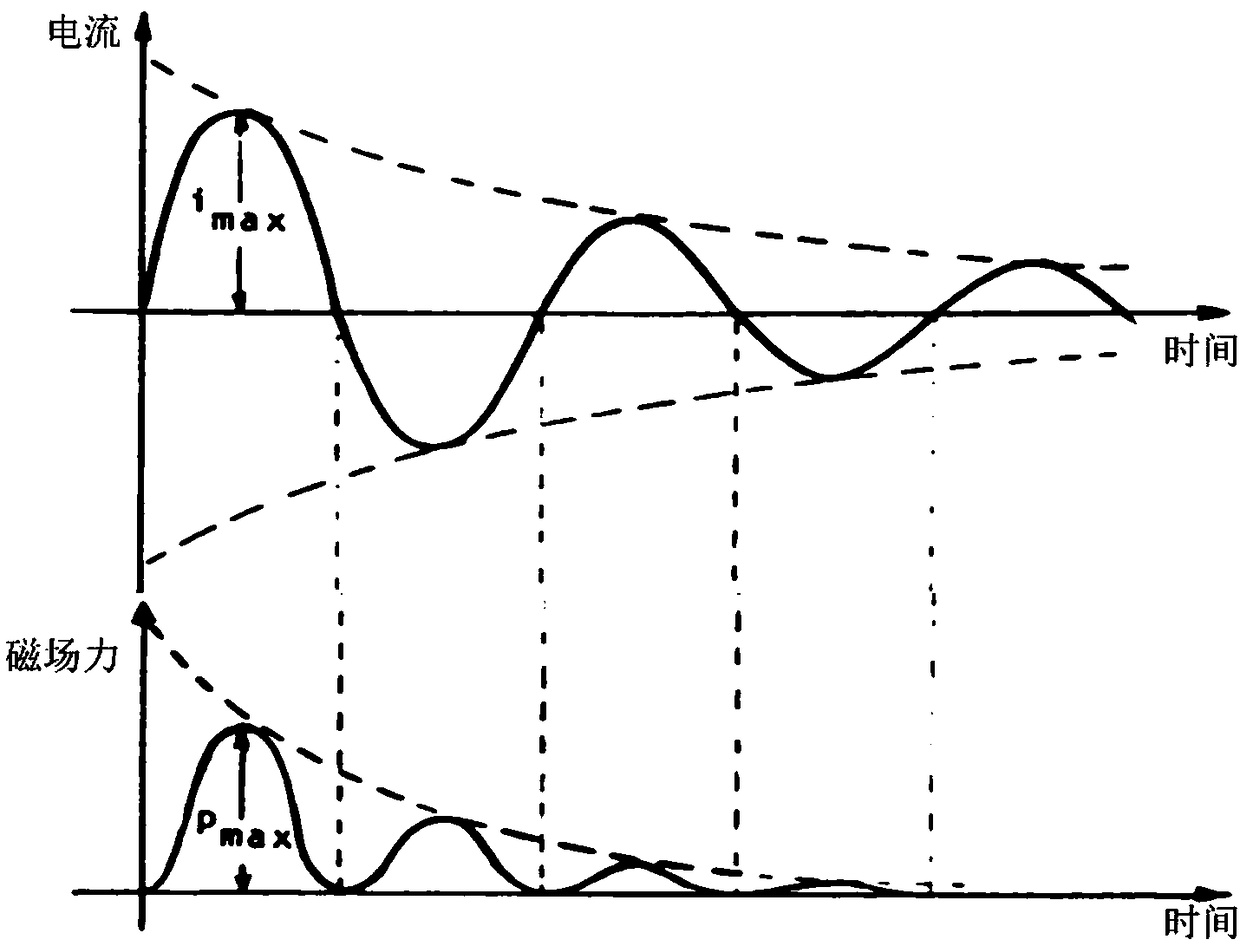

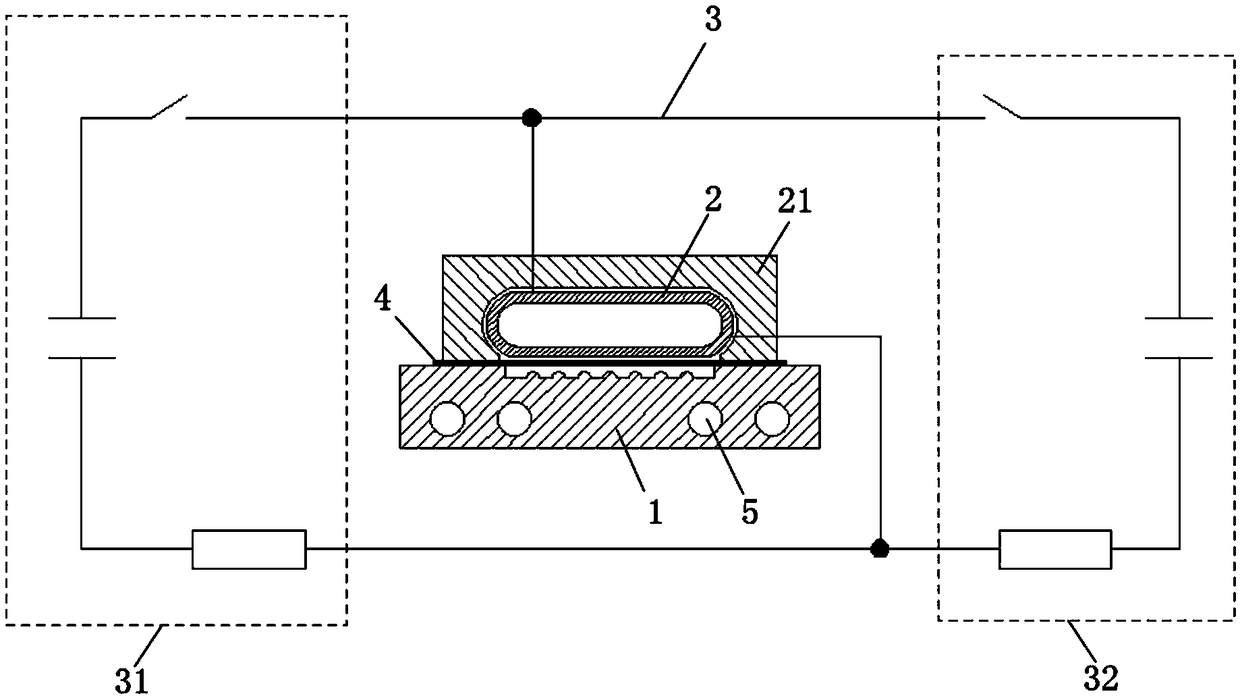

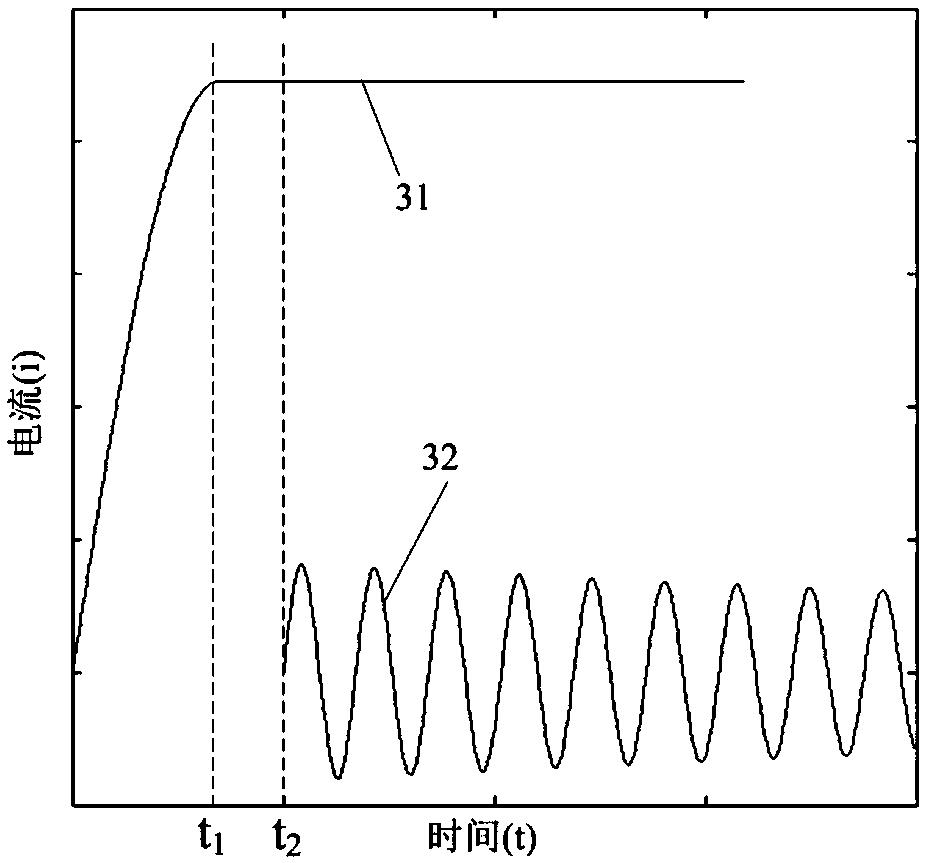

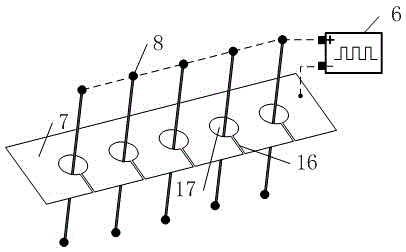

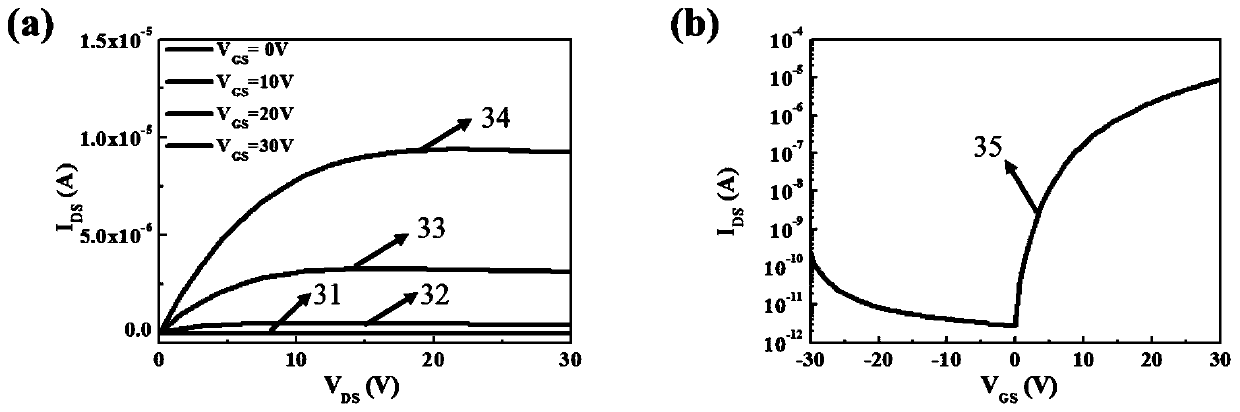

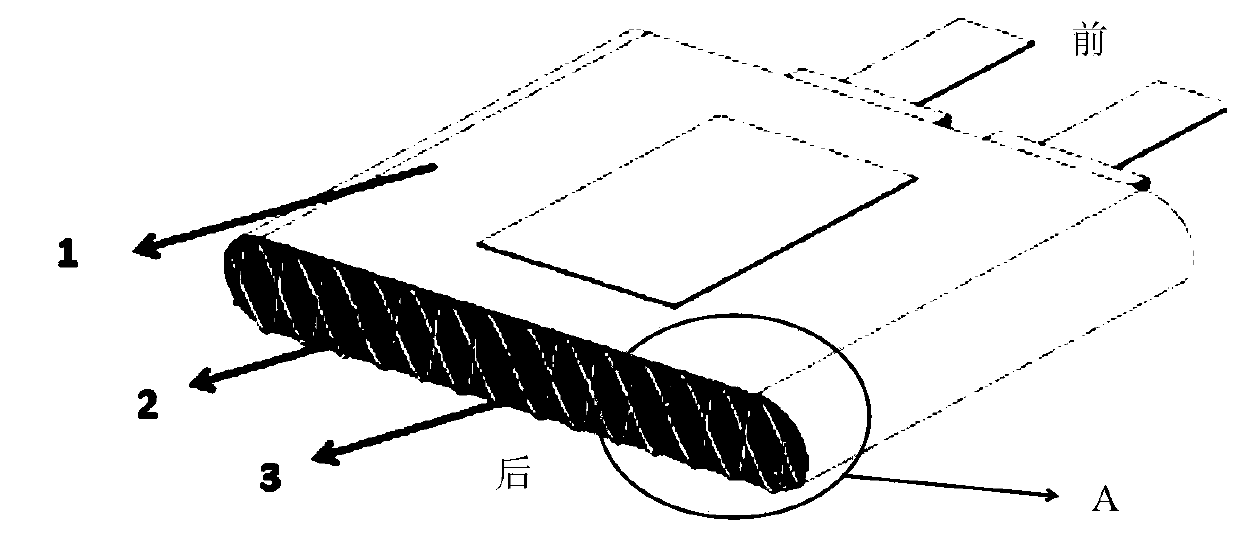

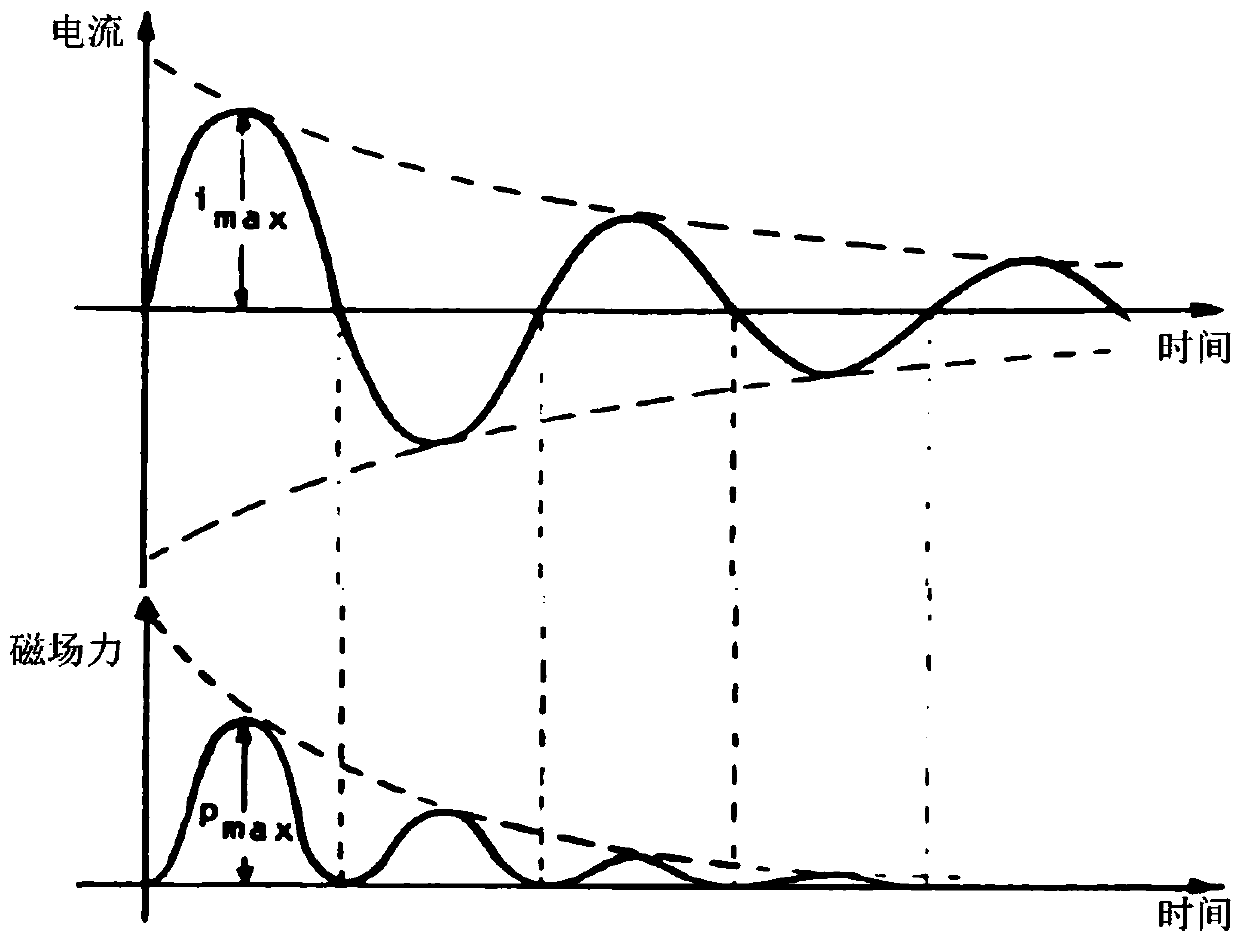

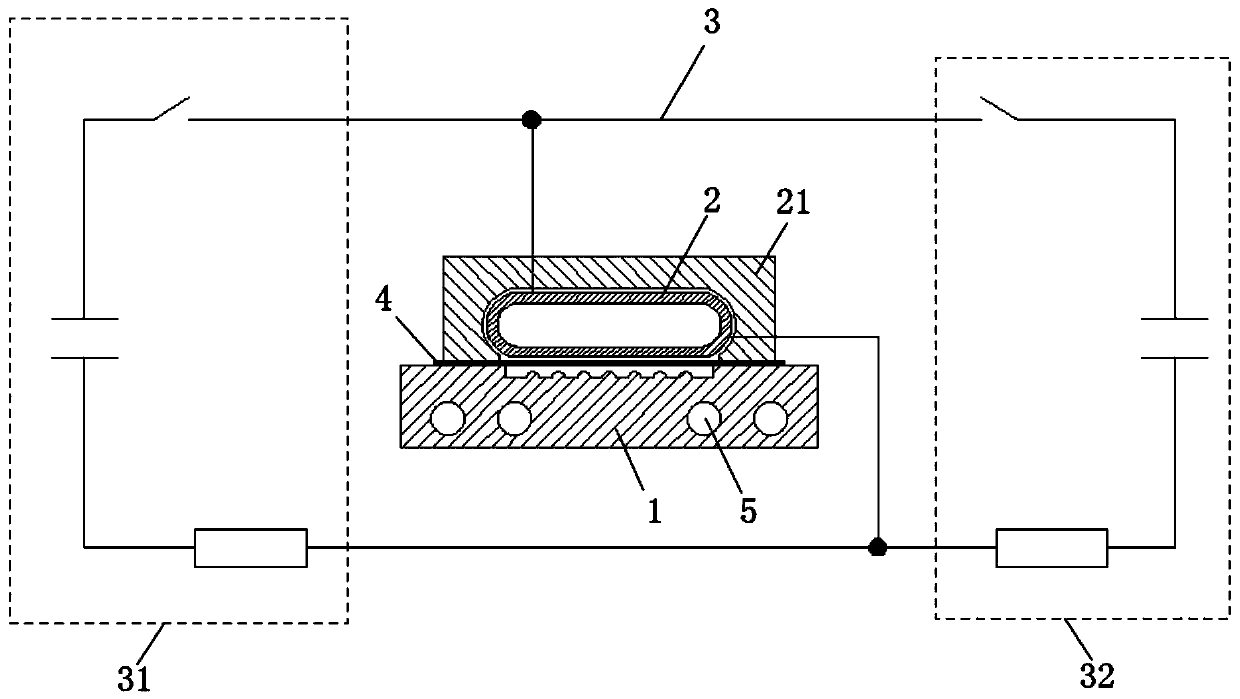

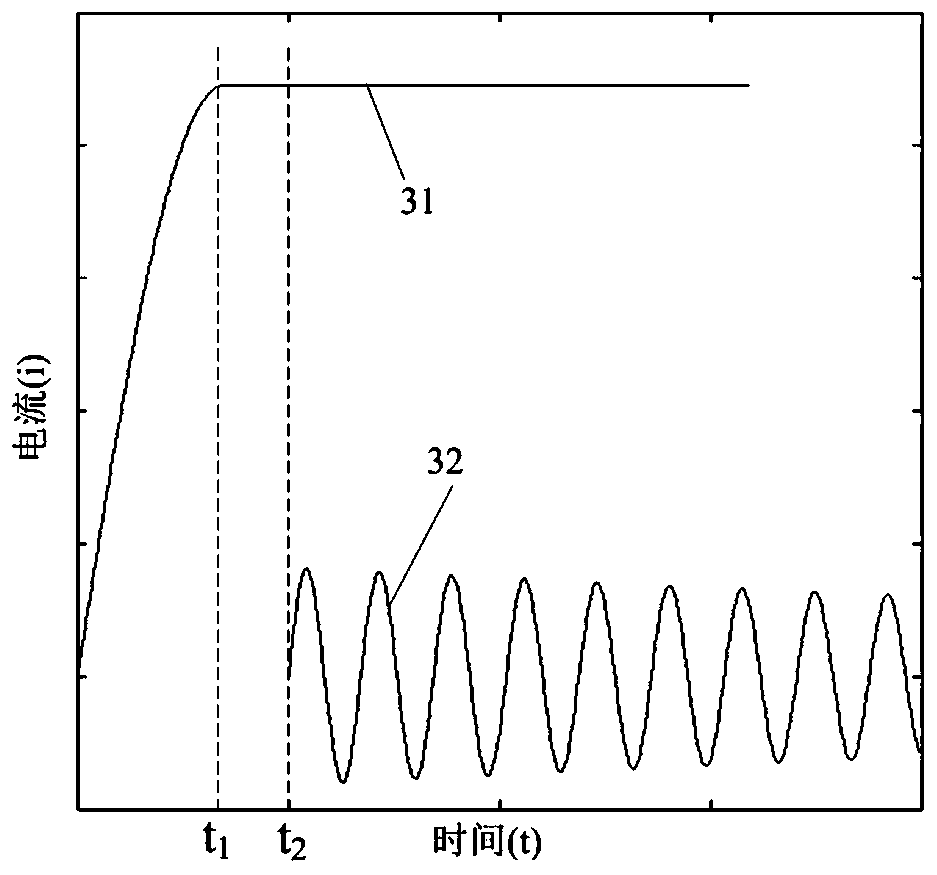

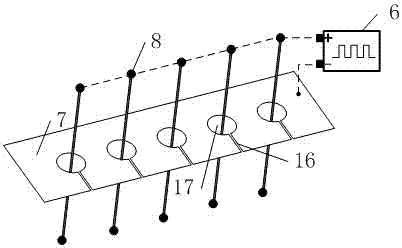

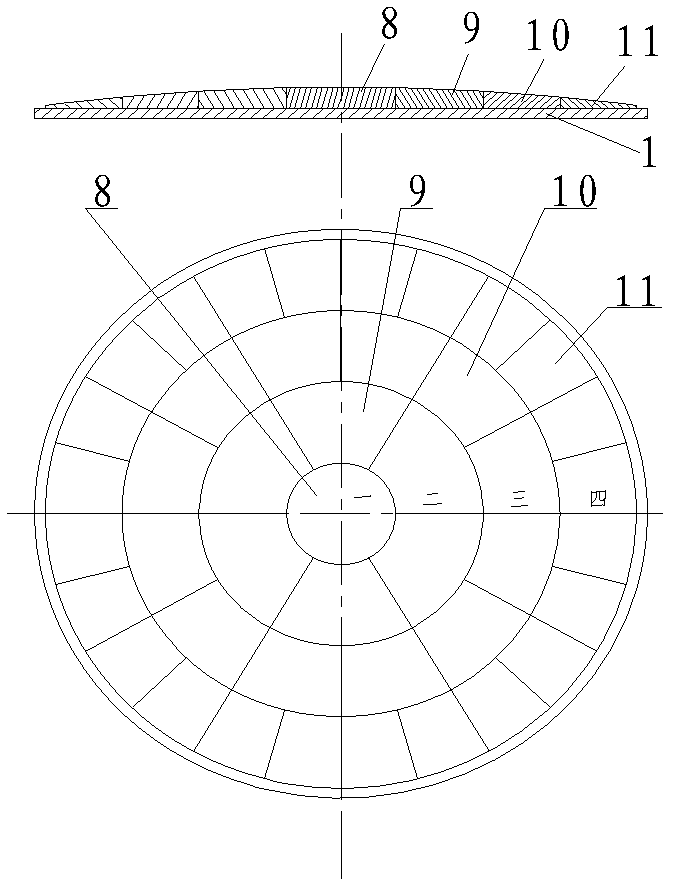

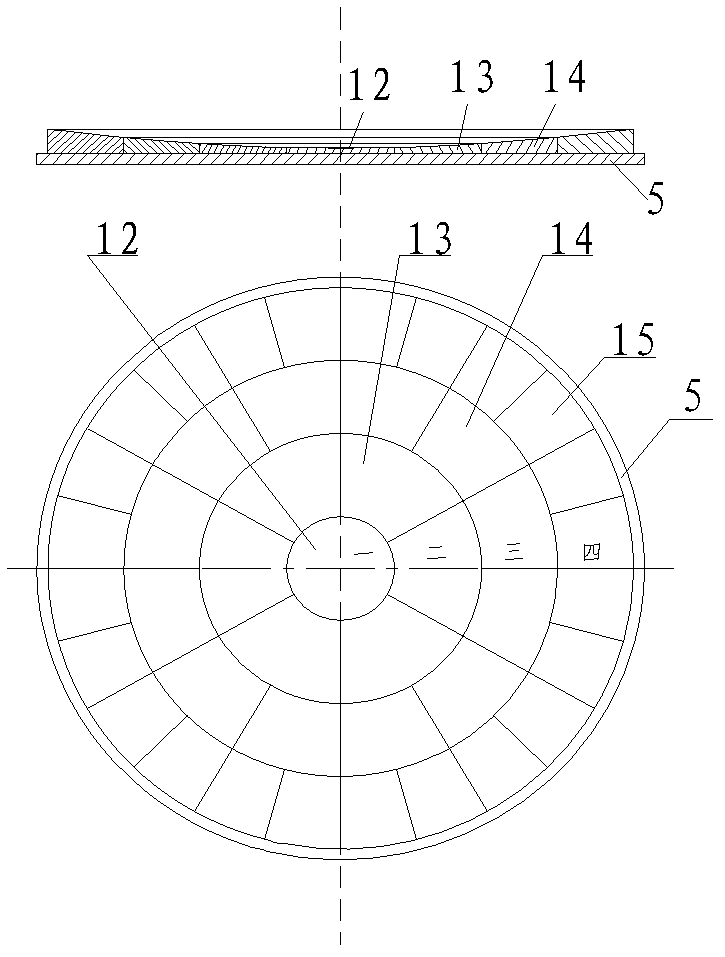

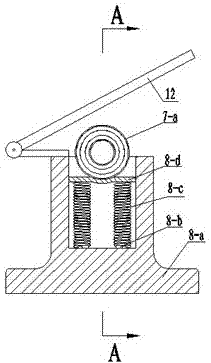

Electromagnetic forming device and method for providing continuous electromagnetic force

ActiveCN108856443APrecise control of magnetic field forceRealize flexible manufacturingShaping toolsElectricityEddy current

The invention discloses an electromagnetic forming device for providing continuous electromagnetic force. The electromagnetic forming device for providing the continuous electromagnetic force comprises a concave die, a coil and a discharging loop. The coil is arranged on the concave die, a sheet to be formed is arranged between the concave die and the coil, the coil is electrically connected withthe discharging loop, the discharging loop comprises a steady-state magnetic field discharging loop capable of generating a steady-state magnetic field and an alternating magnetic field discharging loop capable of generating an alternating magnetic field, and the steady-state magnetic field discharging loop and the alternating magnetic field discharging loop are electrically connected with the coil separately. The invention further discloses an electromagnetic forming method. The electromagnetic forming method comprises the steps of discharging of the steady-state magnetic field discharging loop, discharging of the alternating magnetic field discharging loop, superimposing of the current generated by the steady-state magnetic field discharging loop and the current generated by the alternating magnetic field discharging loop, obtaining induced eddy current by induction of alternating pulse current, forming completing of the sheet under the action of magnetic field force and the like. The electromagnetic forming device for providing the continuous electromagnetic force has the advantages of being high in forming efficiency and good in forming precision, effectively avoiding sheet rebound, being capable of providing the continuous electromagnetic force, accurately regulating and controlling the electromagnetic force to realize flexible manufacturing and the like.

Owner:CENT SOUTH UNIV

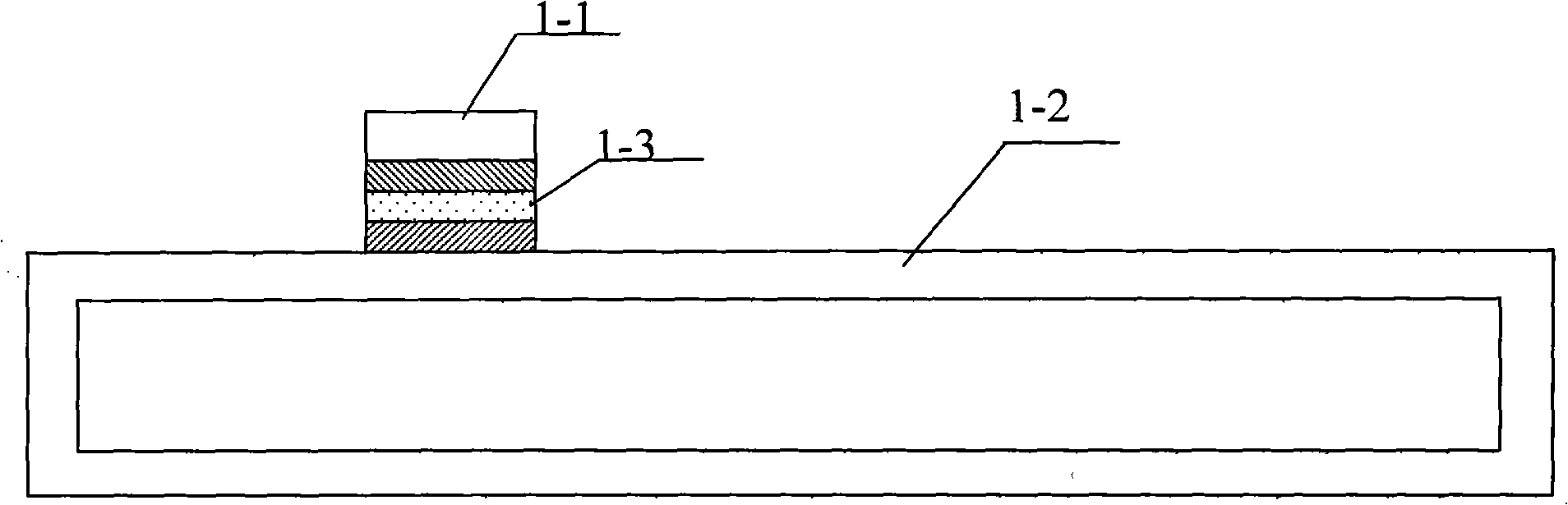

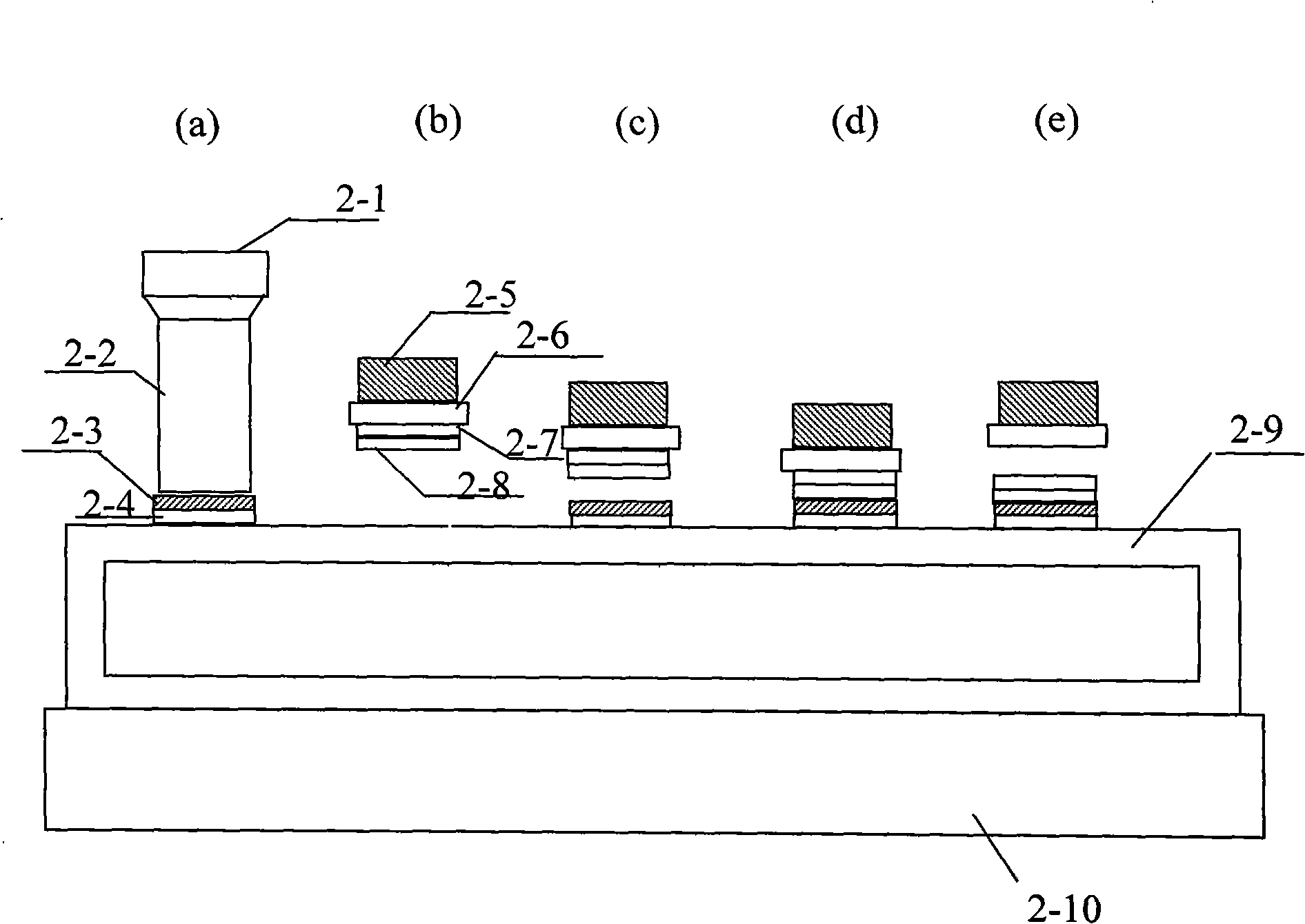

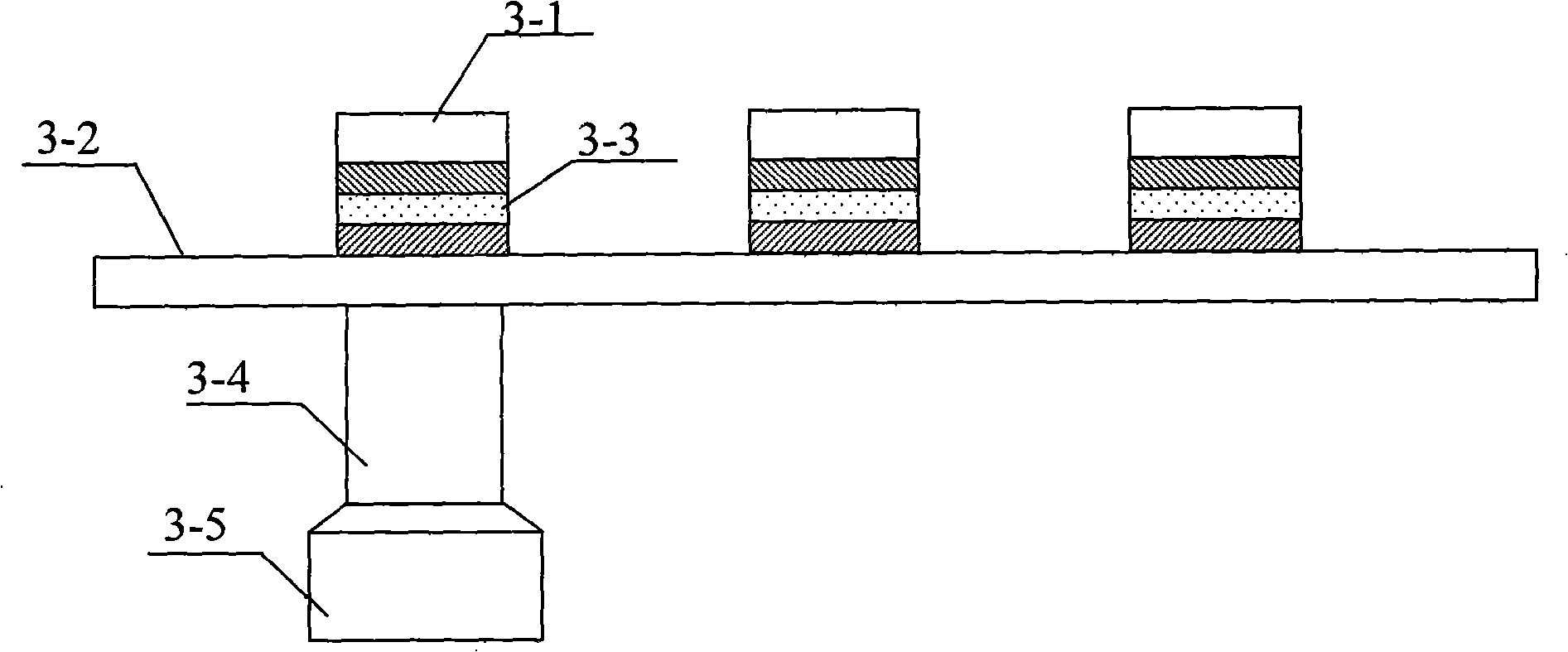

LED heating heat sink rear using laser and heat sink bonding method

InactiveCN101304064APrevent oxidationPrevent gasificationSoldering apparatusSemiconductor/solid-state device manufacturingOptoelectronicsVaporization

The invention relates to a method for bonding an LED chip and heat sink by adopting laser to heat the back of the heat sink, in particular to a method for bonding an LED chip and heat sink; the method solves the problems that when the laser beams directly radiate on a brazing filler metal layer, the brazing filler metal is to undergo oxidization and even vaporization due to rapid temperature raising in a short time, and the reliable bonding of the LED chip and heat sink cannot be ensured. The specific steps of the method are as follows: first, the metal Au is plated on the back of the LED chip and the bonding pad of the heat sink; then, the brazing filler metal layer is plated or printed on the Au-plated bonding pad; the LED chip is attached on the brazing filler metal layer of the Au-plated bonding pad; laser beams are pointed to the position on the back of the heat sink where the LED chip is positioned until the brazing filler metal is melted. The method has the advantages that: the laser beams heat the position on the back of the heat sink where the chip is positioned to avoid oxidation and vaporization of the brazing filler metal; a plurality of chips can be attached on the position waiting for bonding in advance and then bonding can be conducted. The method can be applied to the field of LED chip packaging.

Owner:HARBIN INST OF TECH +1

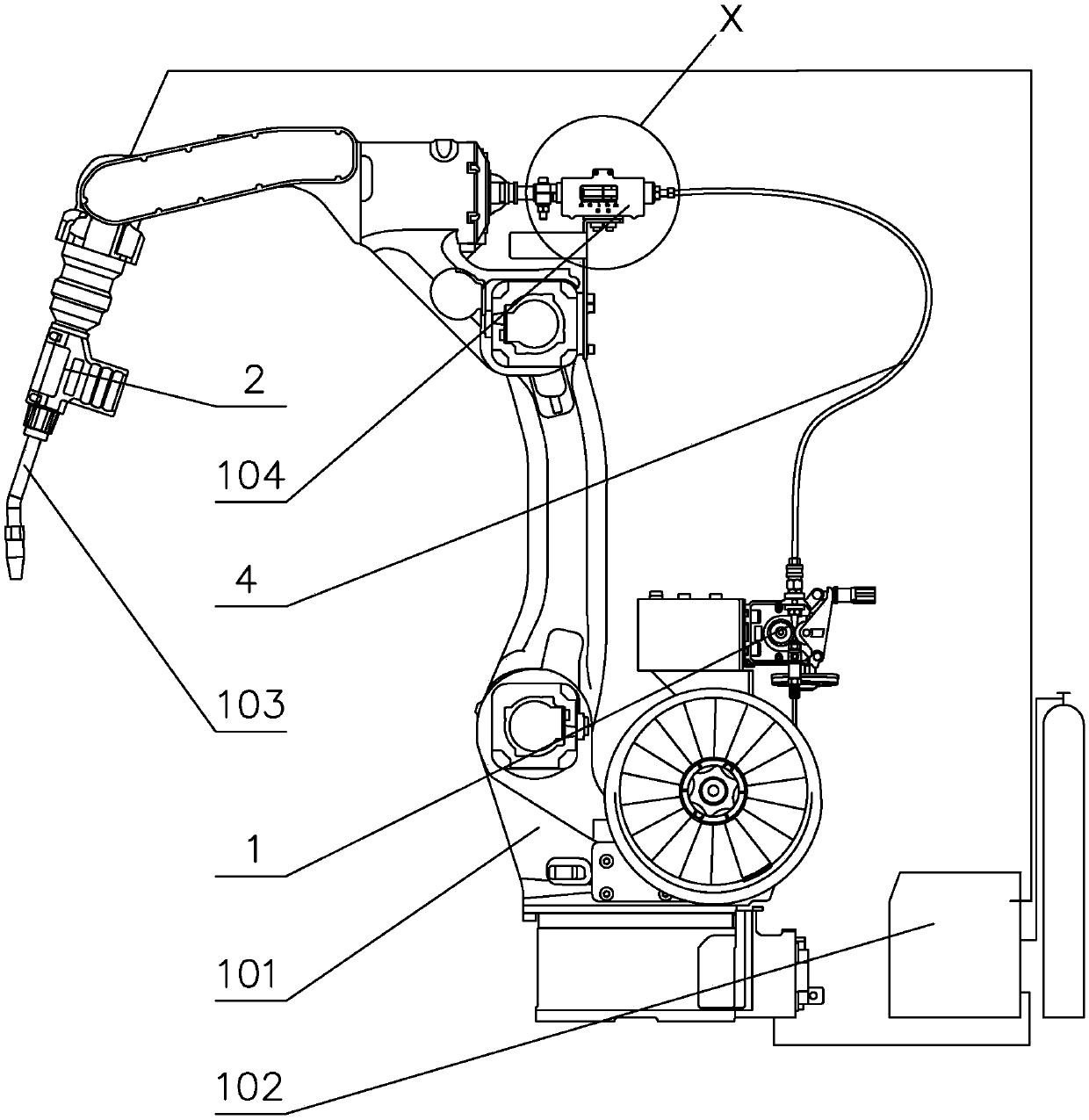

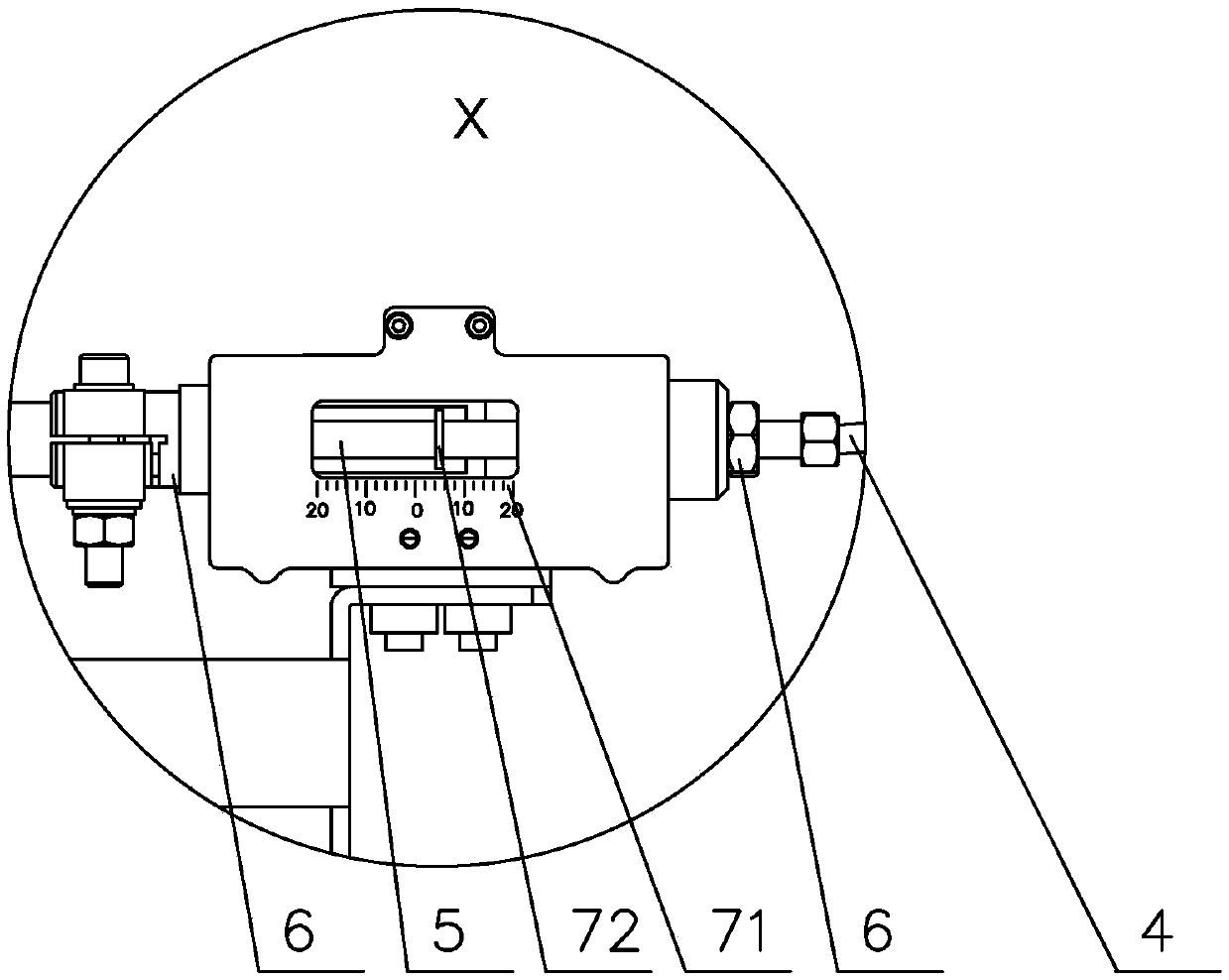

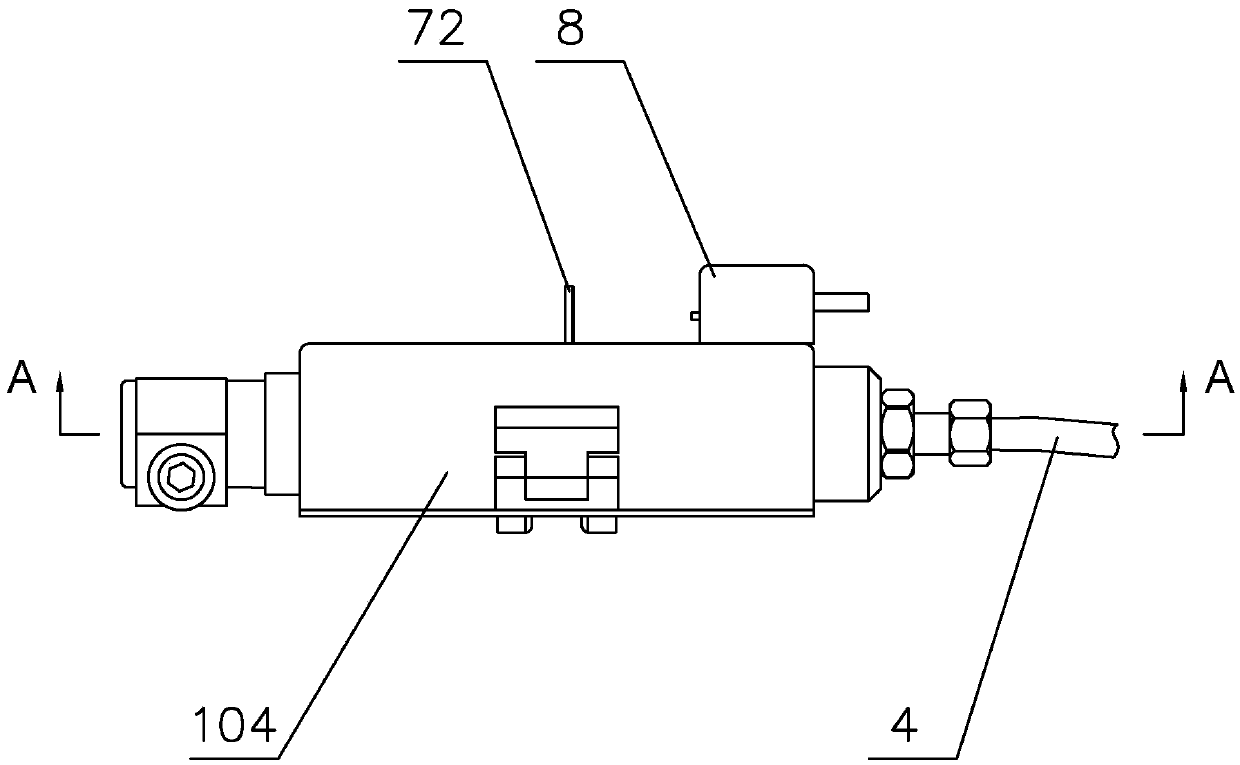

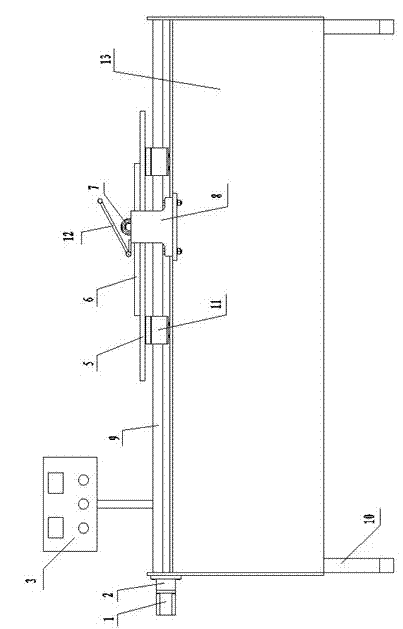

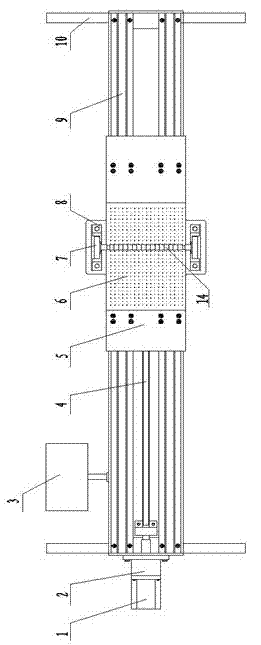

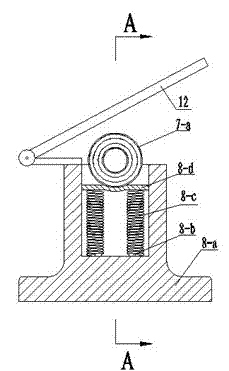

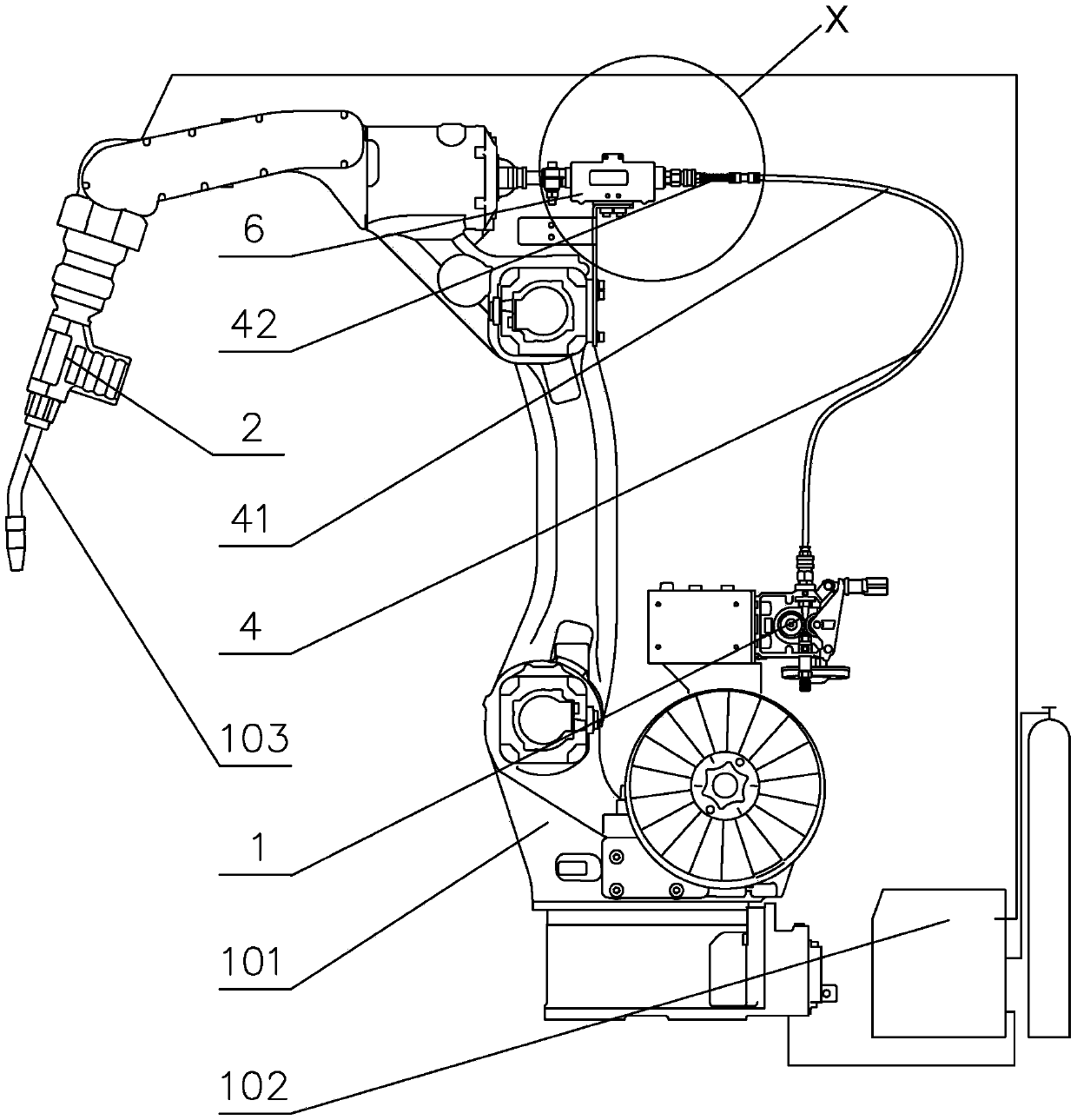

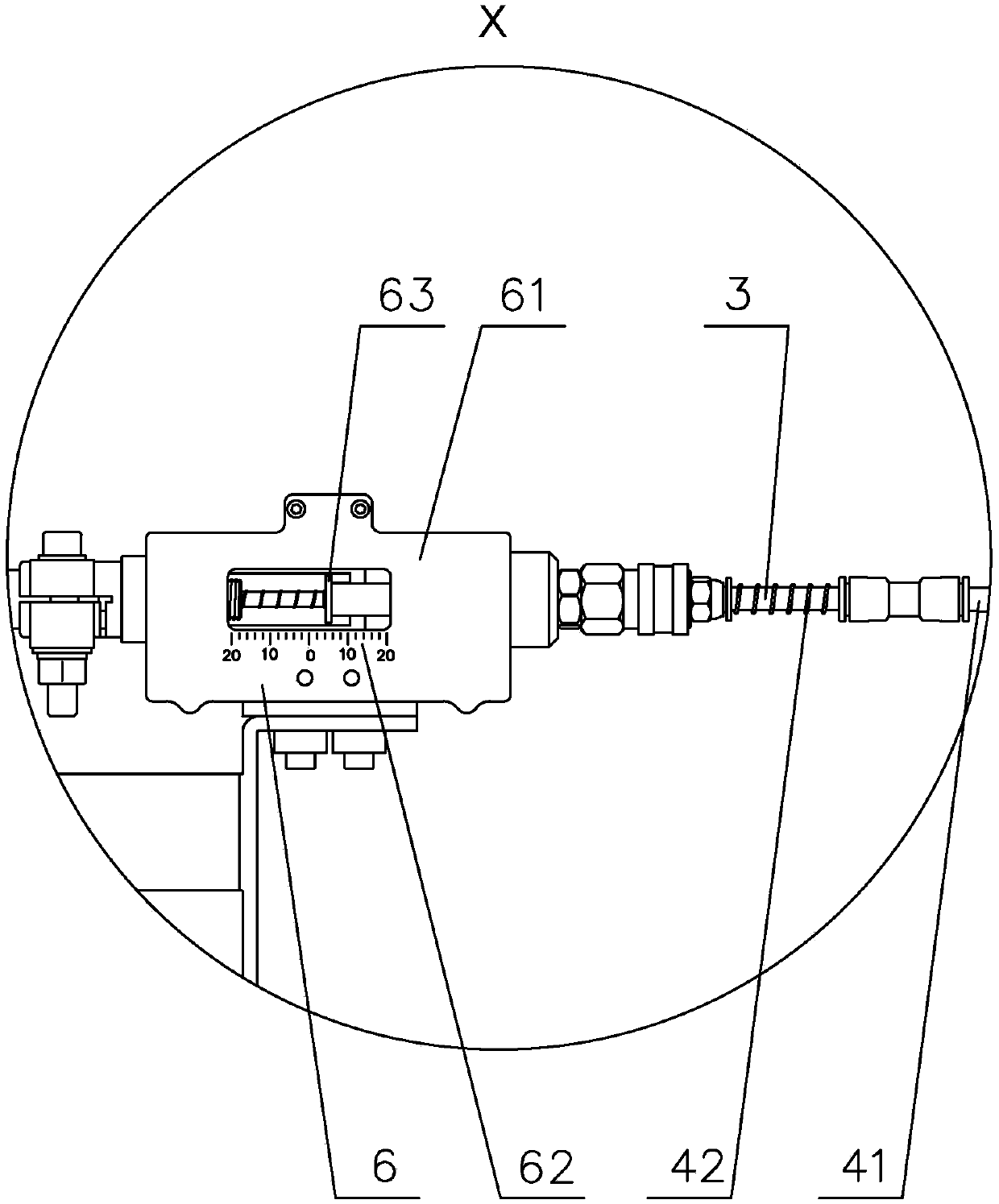

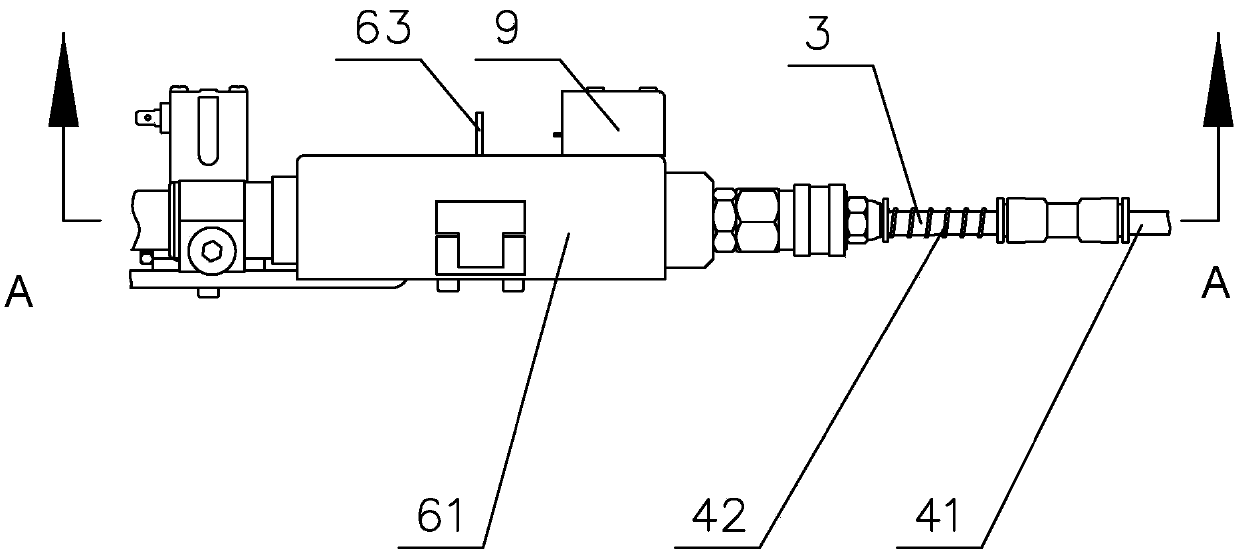

Welding wire buffer device, welding robot and welding system

PendingCN109623103AHigh precisionReduce gravityWelding accessoriesManufacturing cost reductionNeck parts

The invention provides a welding wire buffer device. The welding wire buffer device is arranged between a first wire feeding part and a second wire feeding part. The first wire feeding part conveys awelding wire to the buffer device, and the second wire feeding part conveys the welding wire to a neck part of a welding gun for welding. One end of an inner wire feeding pipe is fixedly connected with the first wire feeding part, and the other end of the inner wire feeding pipe is a free end and moves along with the welding wire in the axial direction to achieve a buffering function. According tothe welding wire buffer device, a buffer space is provided for the welding wire, the probability that the welding wire gets stuck due to a large curvature, caused by a large back-pulling quantity ofthe welding wire, of a wire feeding pipe is lowered, protection pipes with small diameters reduce the weight of the wire feeding pipe, and the gravity of the welding wire and the inner and outer protection pipes of the welding wire is further reduced, so that the friction force between the welding wire and the inner and outer protection pipes is reduced, and the precision of the welding wire buffer device is improved. According to a welding robot and welding system using the welding wire buffer device, the structure of a welding device is simplified, the manufacturing cost is reduced, the production cycle is shortened, and the economical performance and practicability of the welding robot and the welding system of the welding robot are improved.

Owner:HANGZHOU KAIERDA ROBOT TECH CO LTD

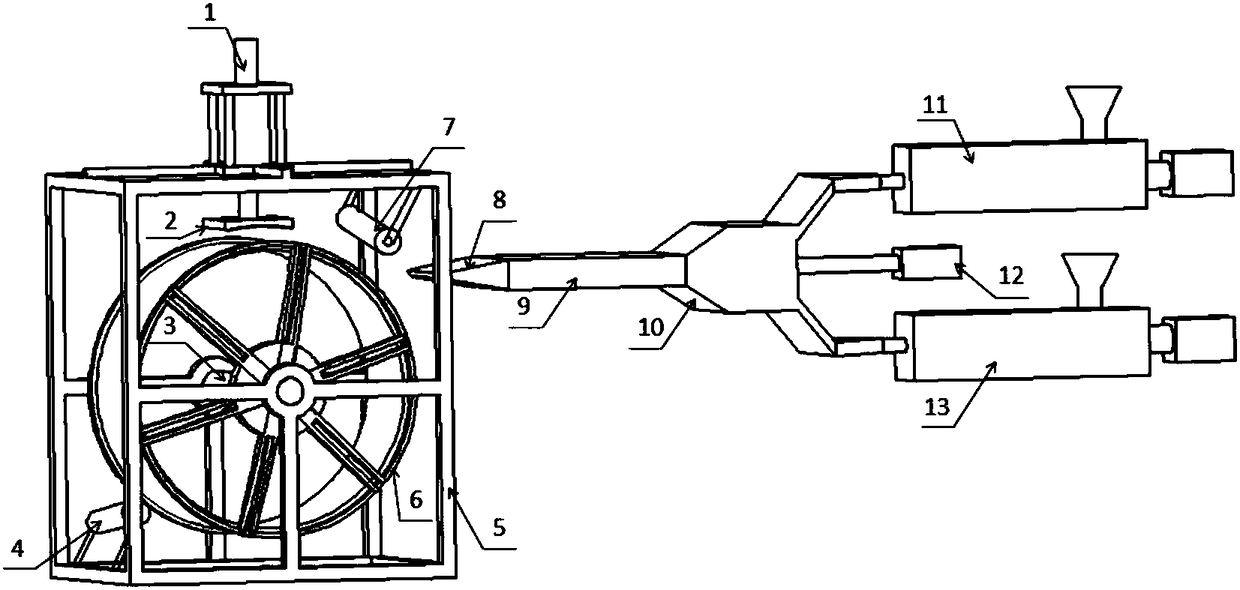

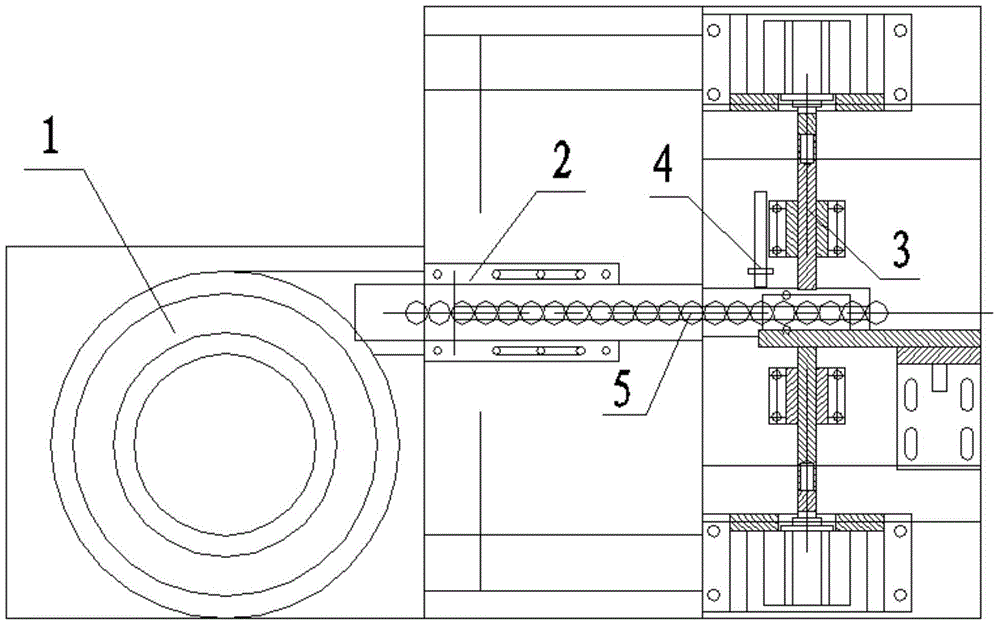

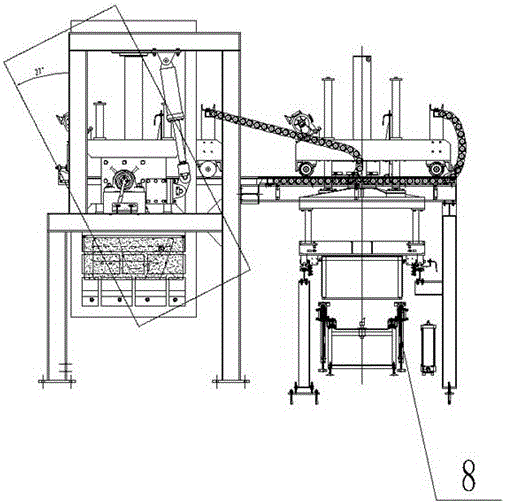

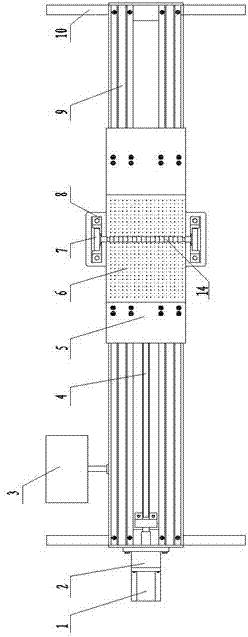

Equipment and method for orderly arranging beaded grinding material of super-hard brass solder grinding material

The invention discloses equipment and a method for orderly arranging beaded grinding materials of a super-hard brass solder grinding material. The equipment comprises a bracket with a guide track, wherein a working table is arranged on the guide track; a motor is further arranged on the bracket; the motor is connected with the working table through a screw rod; a material distributing die is arranged on the working table; uniformly distributed grooves or hole arrays are formed on the upper surface of the material distributing die; a bead adjusting driving device which is used for tightly compressing the beads and which synchronously rotates along with the material distributing die is further arranged on the bracket; the bead adjusting driving device comprises an automatic returning mechanism, a bead installing mechanism and a pressure mechanism. Compared with the prior art, a mode that the straight line feeding through a screw is combined with the self-rotation of the bead adjusting driving device is adopted. The grinding materials filled to the material distributing die are bonded through the self-rotation of the beads, and such a structure is not only simple to operate, but also has the characteristic that the grinding materials are uniformly distributed at the surfaces of the beads.

Owner:江苏韦尔博新材料科技有限公司

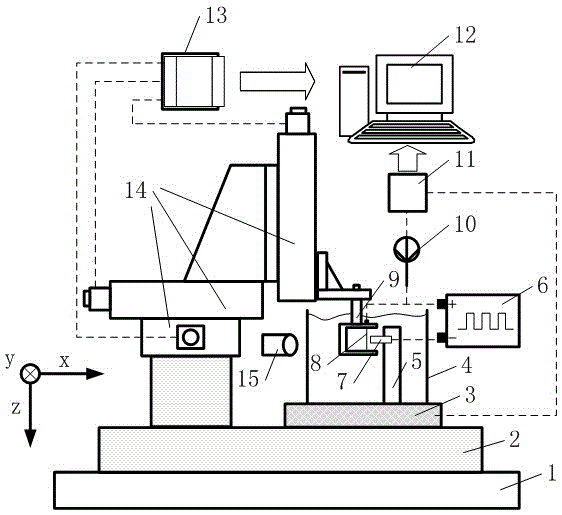

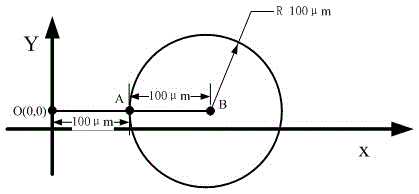

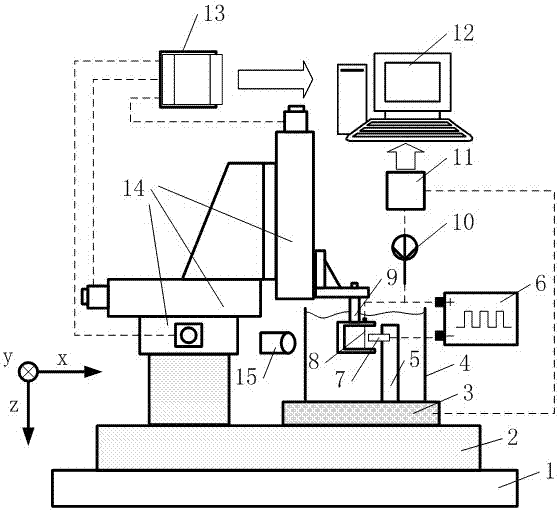

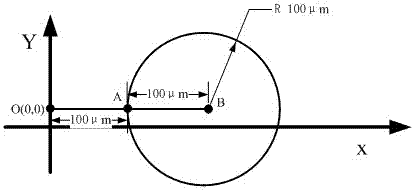

Method for flexibly online preparing micro line group electrode

ActiveCN105108250AAvoid the problem of poor positioning accuracyRealize flexible manufacturingElectrochemical machining apparatusElectrolysisWire cutting

The invention discloses a method for flexibly online preparing a micro line group electrode and belongs to the field of electrochemistry micro manufacturing. The method is characterized by comprising the following steps that firstly, a metal sheet and the line group electrode are fixed in a workpiece clamp and a line group electrode clamp respectively and are connected with the positive electrode and the negative electrode of an ultrashort pulse power source respectively to achieve flexible preparing of a cathode tool, the cathode tool is composed of hair cracks and cathode holes corresponding to electrode wires in the line group electrode, and after machining is over, the electrode wires are located in the centers of the cathode holes; secondly, the cathode tool and the line group electrode are connected with the positive electrode and the negative electrode of the ultrashort pulse power source respectively, and axial reciprocating movement of the line group electrode is used for achieving online preparing of the submicron line group electrode; thirdly, the electrode wires exit from the cathode tool along the hair cracks, and then the cathode tool is replaced by a workpiece to be machined; the line group electrode and the workpiece are connected with the negative electrode and the positive electrode of the ultrashort pulse power source respectively and conduct micro electrolytic line cutting machining of the multi-line electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Buffer device for welding wire, welding system and welding robot

PendingCN109648176AAvoid reductionOvercome the difficulty of blockingWelding accessoriesManufacturing cost reductionEngineering

The invention provides a buffer device for a welding wire. The buffer device for the welding wire is arranged between a first wire feeding part and a second wire feeding part, and one end of a wire feeding inner pipe is fixedly connected with a welding device body; the other end of the wire feeding inner pipe can axially move; a feeding sleeve is arranged at the outer part of the wire feeding inner pipe in a sleeving manner; and at least a part of the feeding sleeve is an axial telescopic elastic pipe. According to the buffer device, a buffer space is provided for the welding wire, the situation that the welding wire is blocked as the curvature of a wire feeding pipe is large due to relatively large welding wire back pulling quantity is reduced, the diameter of a protection pipe is relatively small, mass of the wire feeding pipe is reduced, gravity of the welding wire and inner and outer protection pipes is further reduced, friction force between the welding wire and the inner and outer protection pipes is further reduced, and precision of the welding wire buffer device is improved. According to a welding robot adopting the welding wire buffer device and a welding system thereof, the structure of welding equipment is simplified, besides, manufacturing cost is reduced, the production cycle is shortened, and economic practicability of the welding robot and the welding system thereof is improved.

Owner:HANGZHOU KAIERDA ROBOT TECH CO LTD

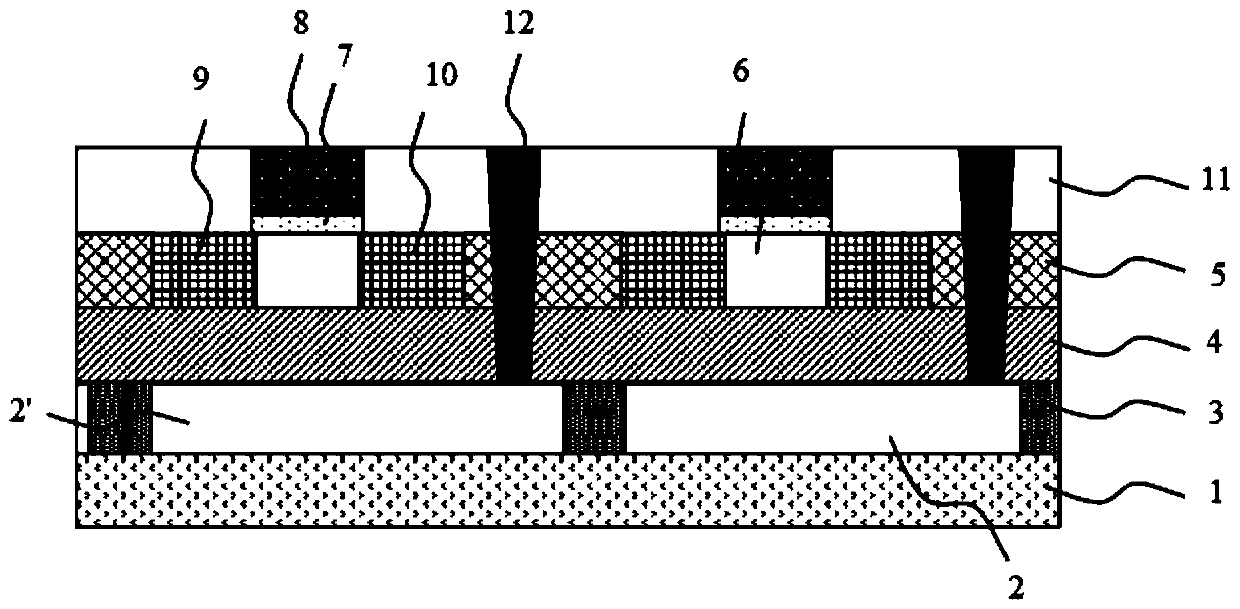

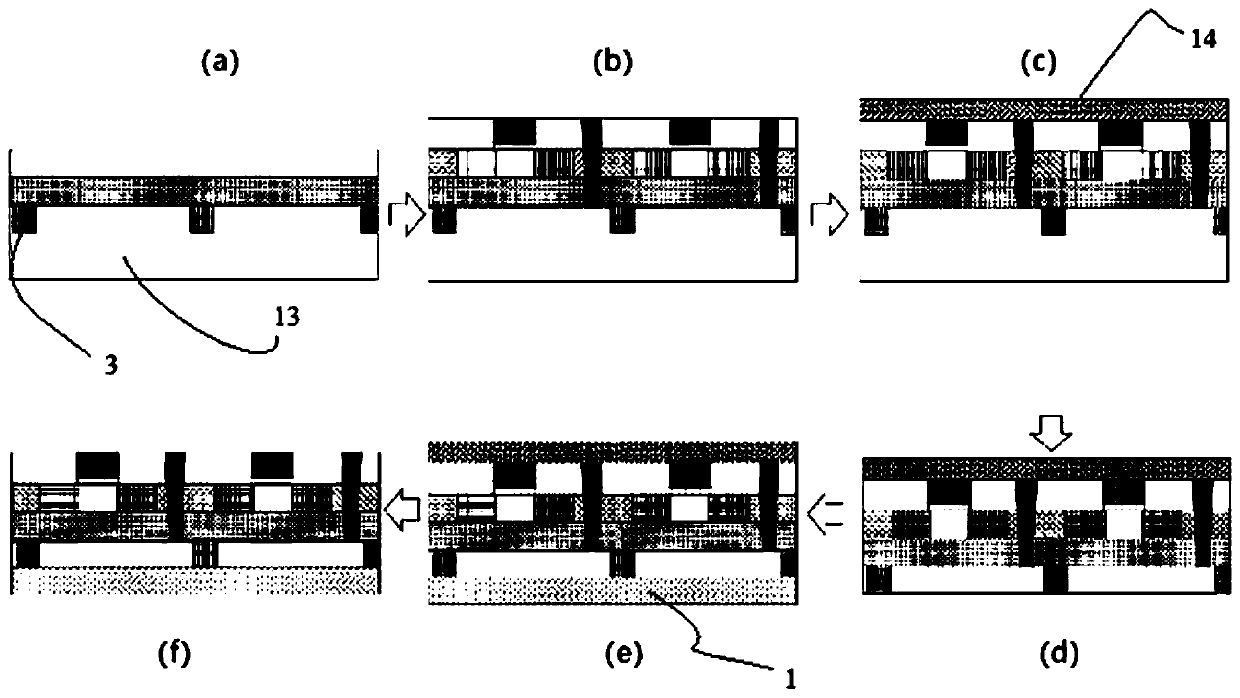

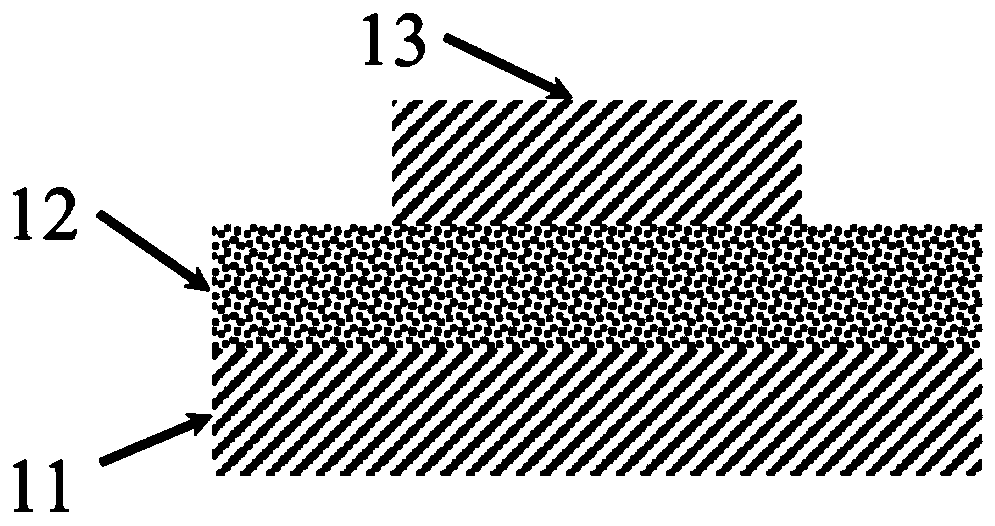

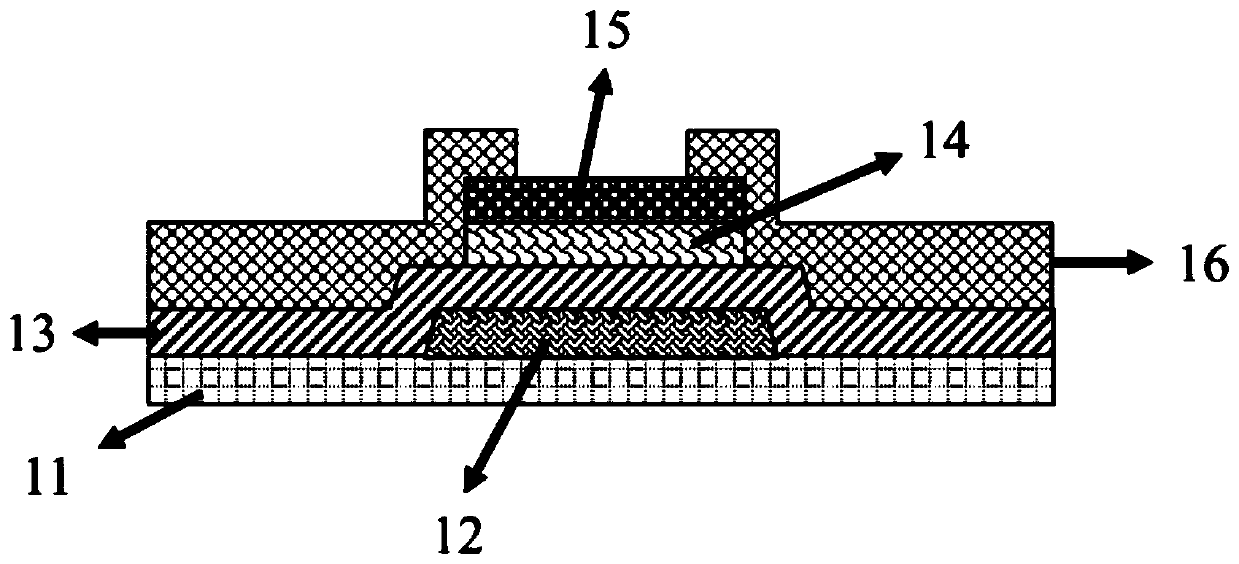

Flexible SOI device structure and preparation method thereof

InactiveCN110223981AChange electrical propertiesAchieve independent controlTransistorSemiconductor/solid-state device manufacturingConductive materialsBody region

The invention provides a flexible SOI device structure and a preparation method thereof; the flexible SOI device structure sequentially comprises a flexible substrate, a first back gate region, a second back gate region and an inter-back-gate isolation part, an insulating buried layer, a first active region, a second active region and a device isolation part, an interlayer dielectric layer and a contact hole from the bottom up, wherein the first back gate region, the second back gate region and the inter-back-gate isolation part are located above the insulating buried layer; each of the firstactive region and the second active region comprises a gate region, a body region located below the gate region, and a source and a drain which are located at the two transverse ends of the body region respectively; the interlayer dielectric layer is located at the highest position; the contact hole runs through the interlayer dielectric layer, the device isolation part and the insulating buried layer in sequence; and the contact hole is filled with a conductive material to form a contact part, and the first back gate region and the second back gate region are applied with a bias voltage by the contact part, wherein the first back gate region and the second back gate region are electrically isolated from each other by the inter-back-gate isolation part. According to the structure, the inter-back-gate isolation part is added to realize independent modulation of the back gate device; and meanwhile, the flexible preparation of the flexible SOI device structure is realized.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

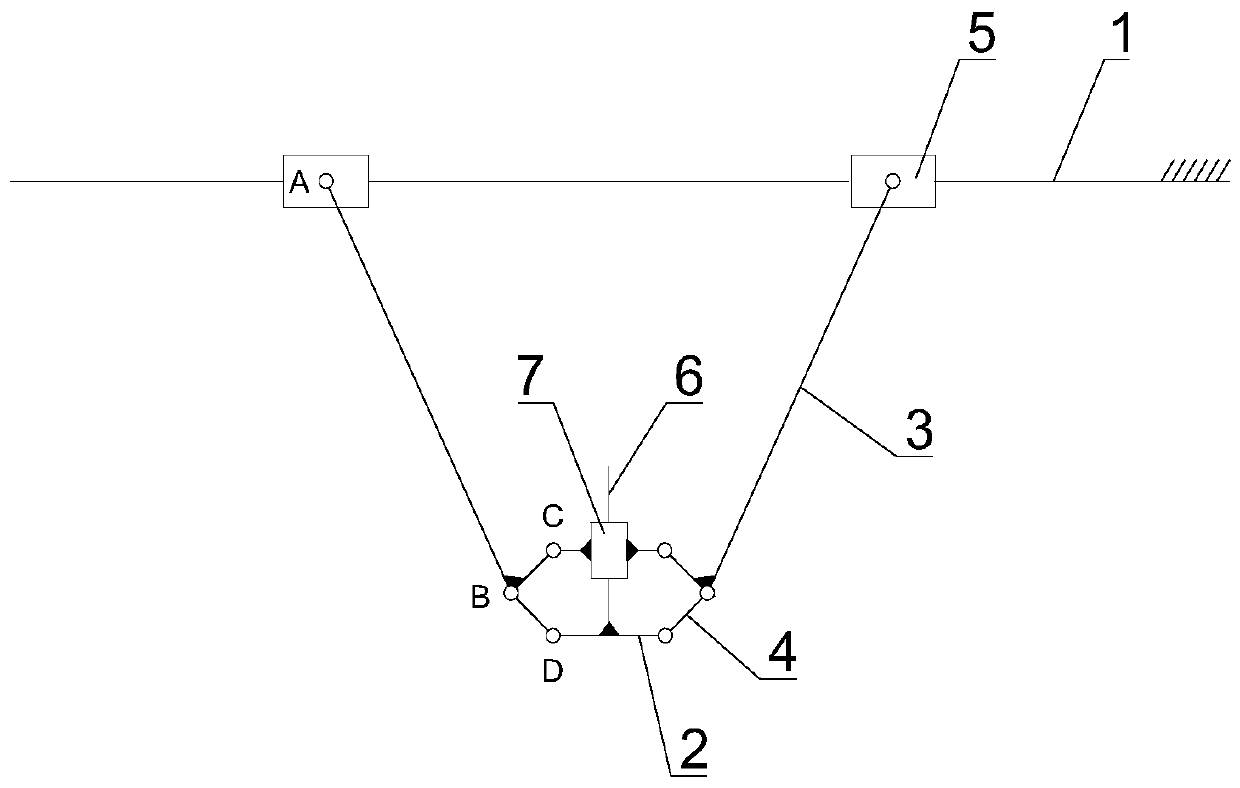

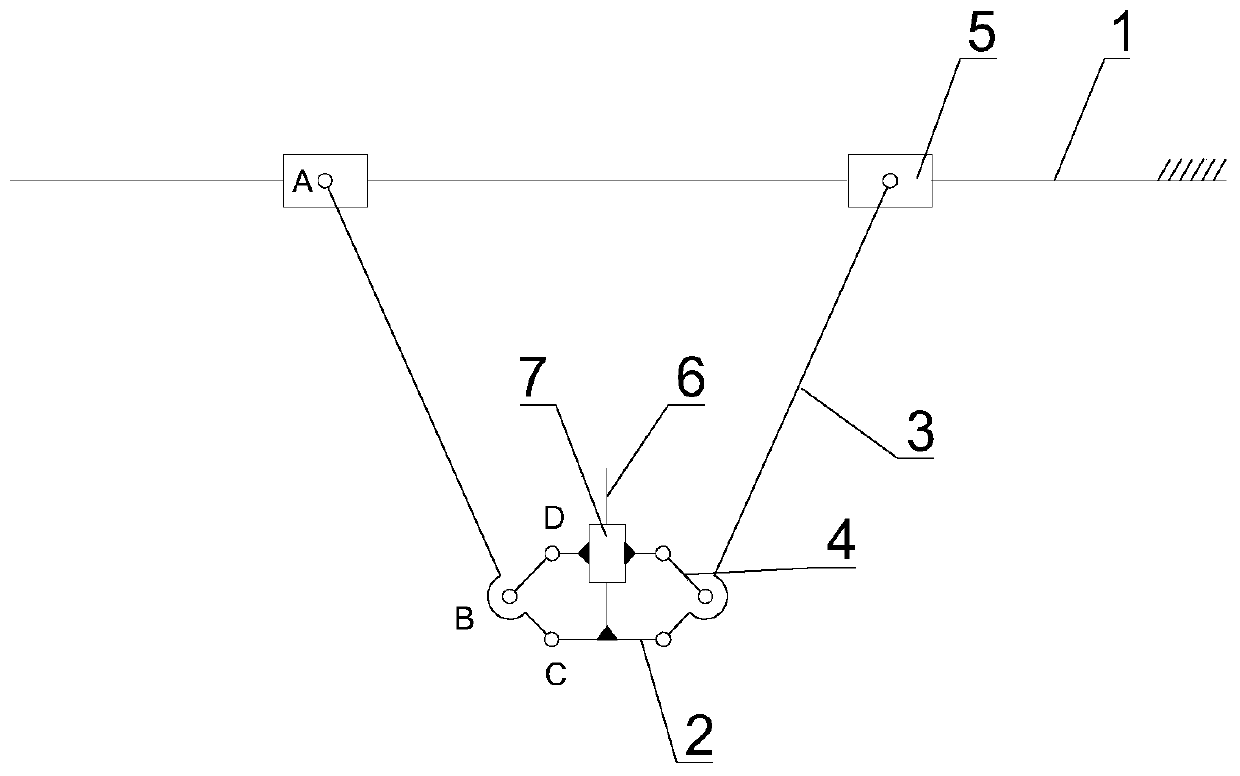

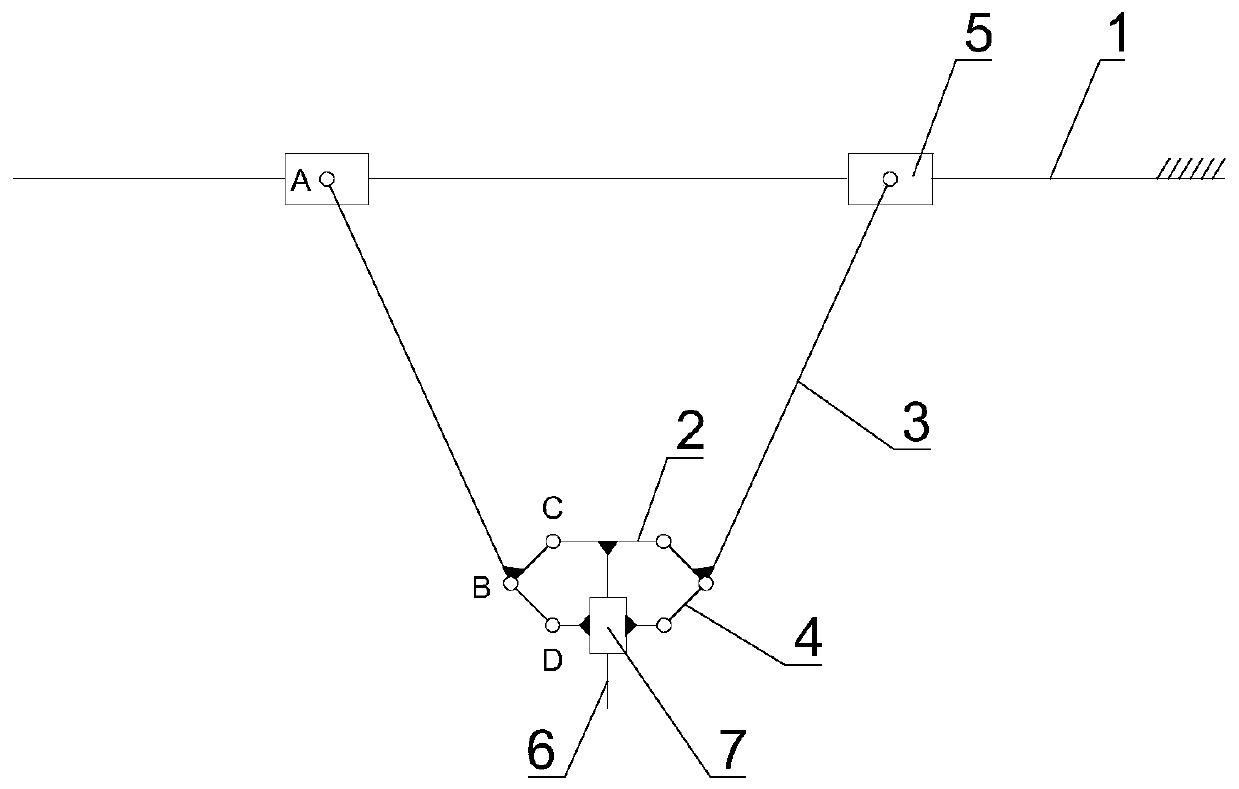

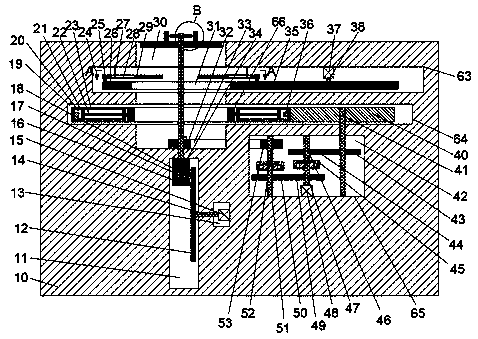

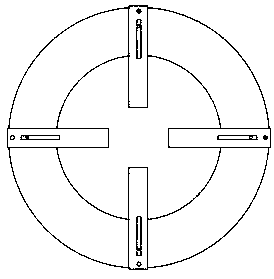

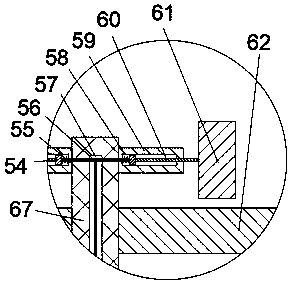

Plane two-freedom-degree parallel mechanism

PendingCN110154002ARealize flexible manufacturingGuaranteed running stabilityProgramme-controlled manipulatorDegrees of freedomEngineering

The invention discloses a plane two-freedom-degree parallel mechanism. The plane two-freedom-degree parallel mechanism comprises a fixed guiding rail, a tool flange, two members, and two connecting rods, wherein two driving sliding blocks forming moving pairs with the fixed guiding rail are arranged on the fixed guiding rail; the tool flange is used for mounting an outer connecting piece, a balancing sliding block is arranged on the tool flange, and the moving axis of the balancing sliding block is perpendicular to the straight line wherein the fixed guiding rail is located at; the two membersare distributed with the moving axis of the balancing sliding block as the central symmetry, a first hinging point, a second hinging point and a third hinging point sequentially distributed are arranged on each member, each hinging point is hinged to the corresponding driving sliding block to form a rotating pair, and each third hinging point is hinged to one of the tool flange or the balancing sliding block to form a rotating pair; and the two connecting rods are arranged corresponding to the members on the two sides, one end of each connecting rod is hinged to the second hinging point of the corresponding member to form a rotating pair, and the other end of each connecting rod is hinged to the balancing sliding block or the tool flange by being opposite to the corresponding third hinging point to form a rotating pair. By means of the plane two-freedom-degree parallel mechanism, the mounting plane of the outer connecting piece of the tool flange keeps always parallel to the axis of the fixed guiding rail.

Owner:无锡超通智能制造技术研究院有限公司

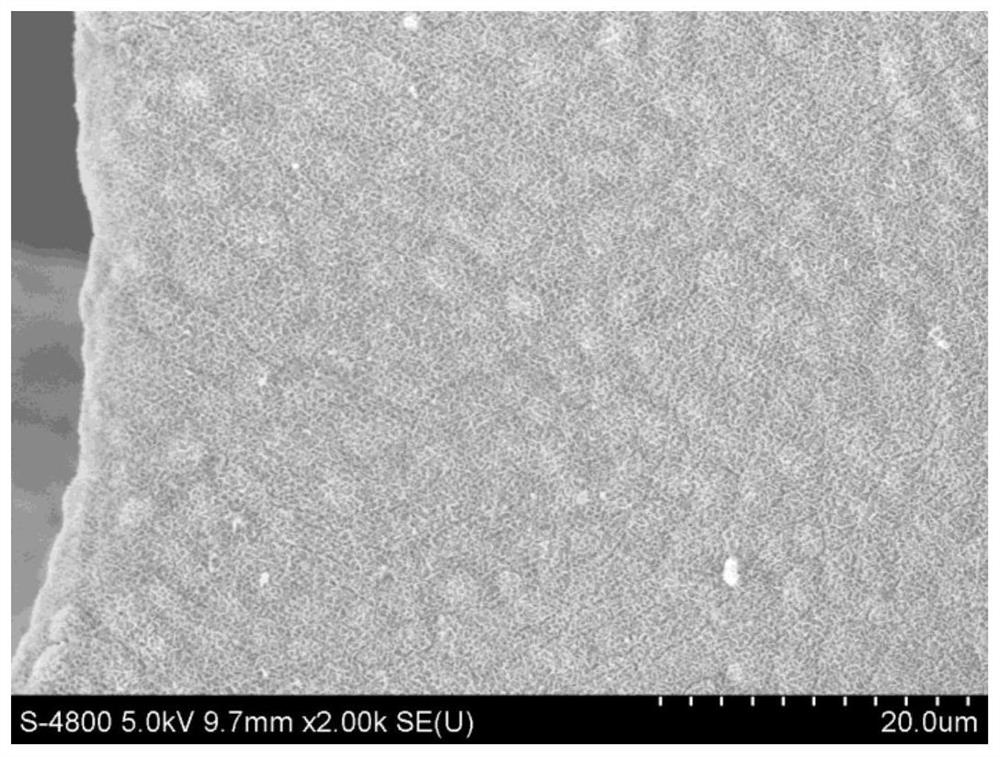

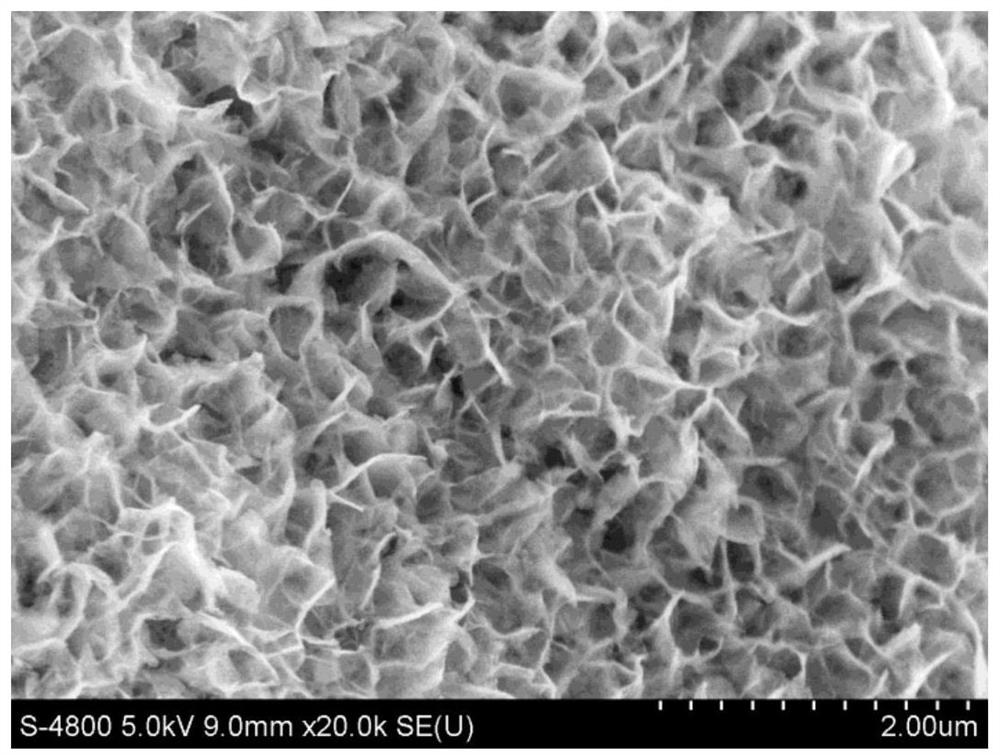

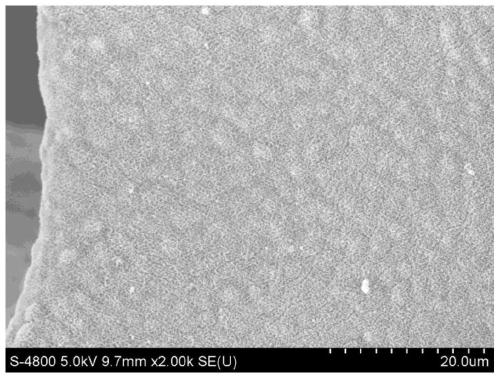

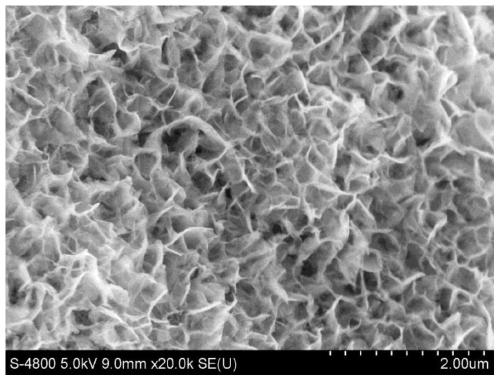

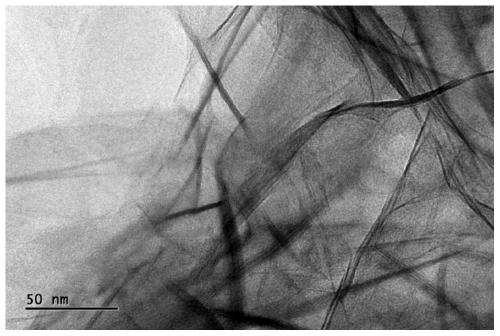

A preparation method of nickel hydroxide nanosheet array material grown on the surface of nickel foam

ActiveCN110040792BEfficient in situ array growthControllable in situ array growthMaterial nanotechnologyNickel oxides/hydroxidesChemical synthesisNickel salt

The invention relates to a method for preparing a nickel hydroxide nanosheet array material grown on the surface of foamed nickel; the foamed nickel is placed in alcohol for ultrasonic cleaning, after the foamed nickel is taken out, the foamed nickel is rinsed with deionized water, and the rinsed foam is Nickel is soaked in acid solution for 1-2 hours, taken out and placed in deionized water for ultrasonic cleaning; the foamed nickel obtained by surface activation treatment is immersed in deionized water for natural oxidation for 2-5 days, and the reaction temperature is room temperature to obtain vertical Nickel hydroxide nanosheet array material grown on the surface of nickel foam; the preparation method of the present invention does not require high temperature and high pressure reaction conditions, and does not require high-purity nickel salt as a reaction raw material, and the preparation process produces less pollutants, which is more in line with the concept of green chemical synthesis , and low cost.

Owner:TIANJIN UNIV

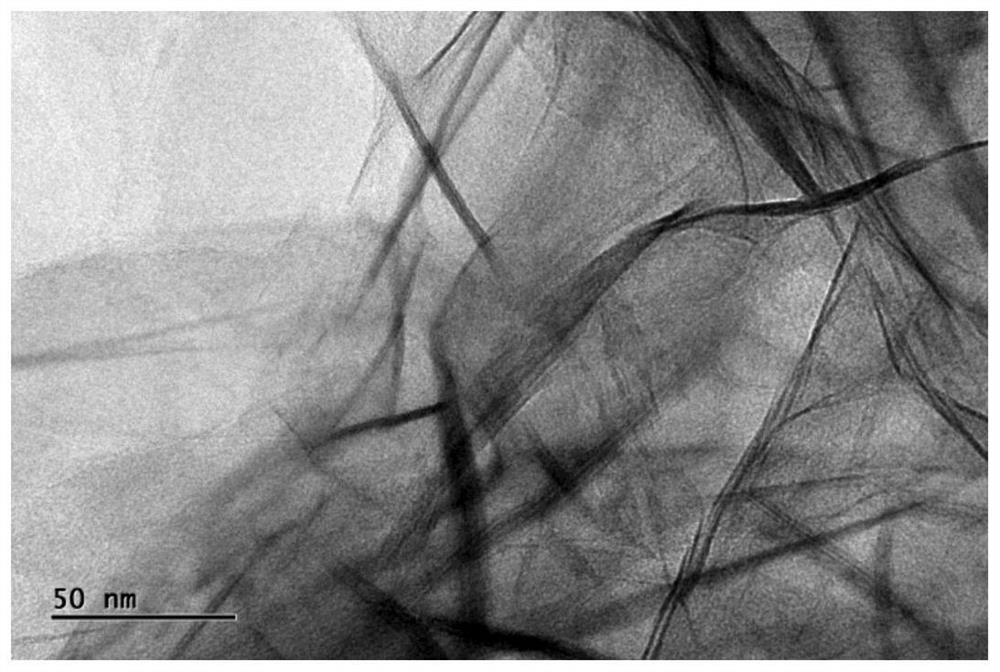

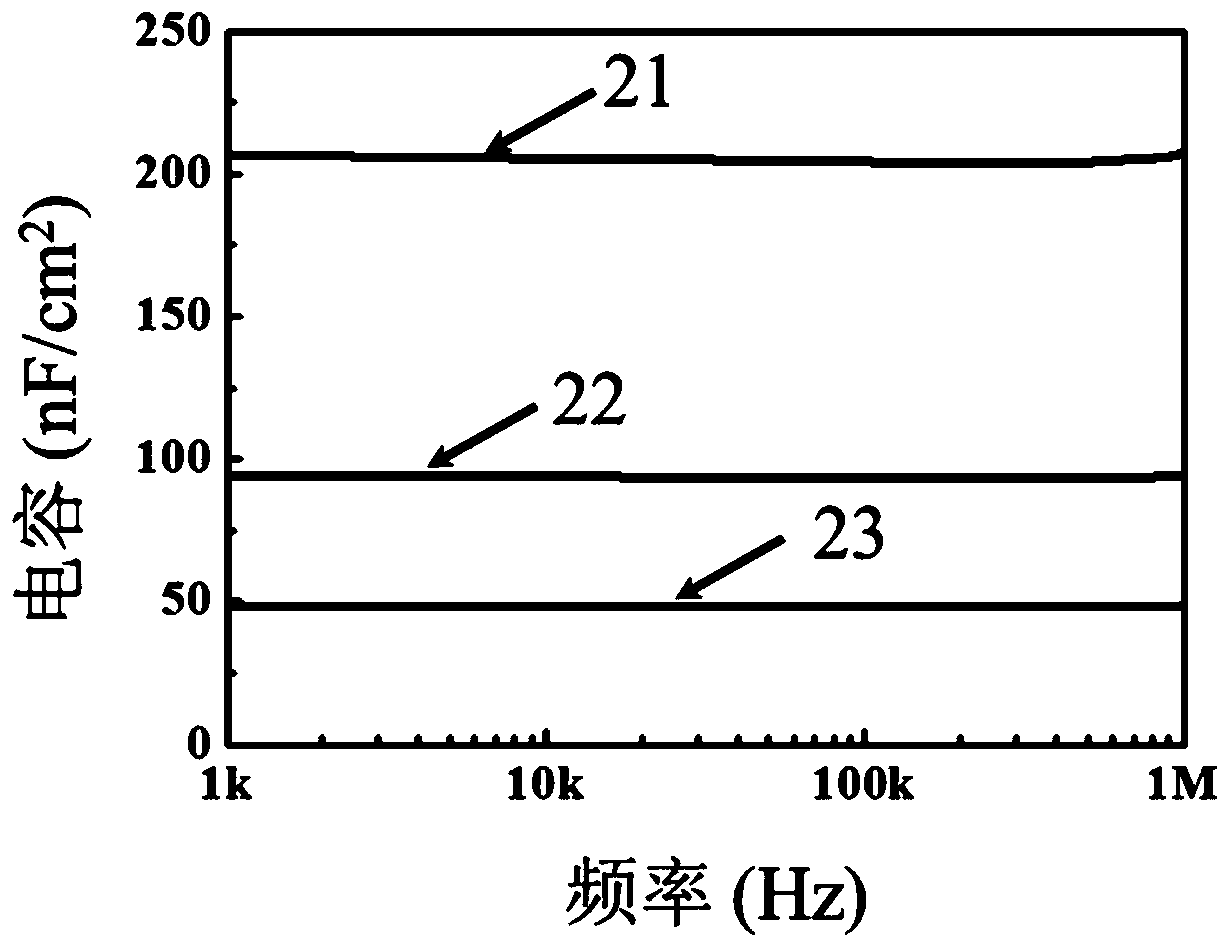

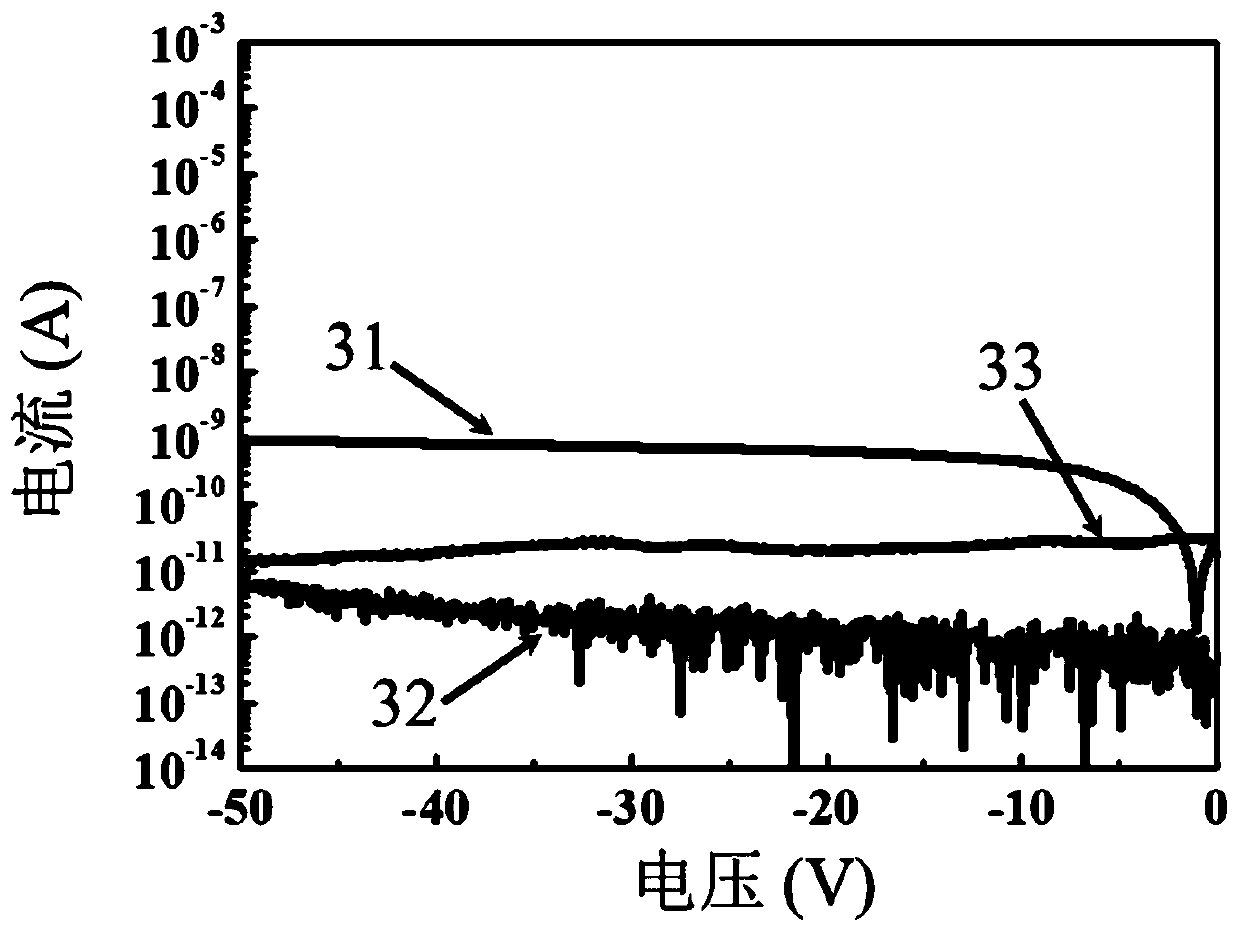

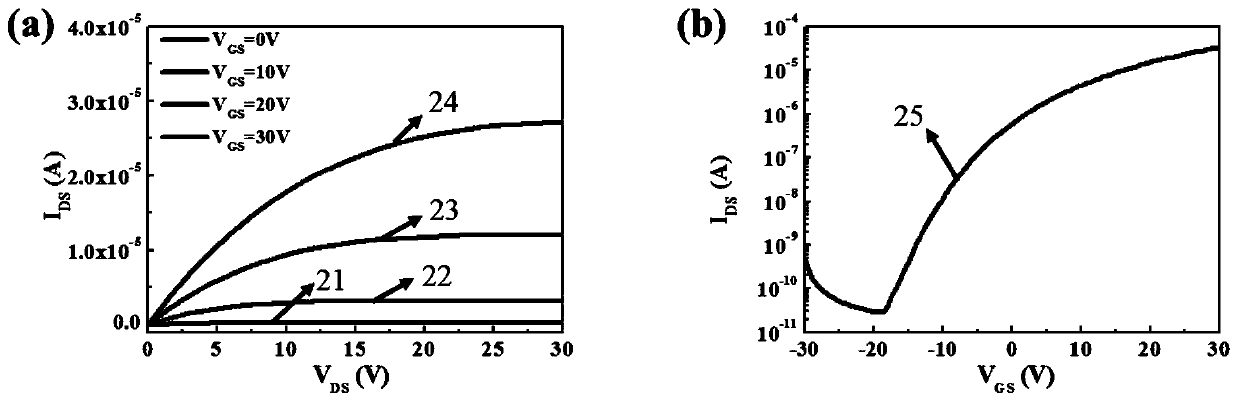

Tin oxide-based thin film transistor based on plasma enhanced atomic layer deposition gate insulating layer and preparation method

InactiveCN110783412AReduce interface defect statesLower turn-on voltageTransistorSemiconductor/solid-state device manufacturingSemiconductor materialsAtomic layer deposition

The invention belongs to the technical field of thin film transistors, and relates to a tin oxide-based thin film transistor based on a plasma enhanced atomic layer deposition gate insulating layer, which comprises a substrate, a gate, a gate insulating layer, an active layer, a source and a drain arranged in sequence, wherein the gate insulating layer is an aluminum oxide thin film prepared through plasma enhanced atomic layer deposition, and the active layer is a silicon-doped tin oxide thin film prepared through magnetron sputtering deposition. The tin oxide-based thin film transistor adopts a plasma enhanced atomic layer deposition method to prepare aluminum oxide with a high dielectric constant as a gate insulating layer, an amorphous silicon doped tin oxide semiconductor material isused as an active layer material, the interface defect mode of the active layer / gate insulating layer and the turn-on voltage of the device are reduced, and the mobility and the stability of the device are remarkably improved. The invention further provides a preparation method for the tin oxide-based thin film transistor based on the plasma enhanced atomic layer deposition gate insulating layer.

Owner:SOUTH CHINA UNIV OF TECH

Bearing outer ring grinding device

InactiveCN111215975AEasy to placeEasy to take outRevolution surface grinding machinesGrinding work supportsCircular discGear wheel

The invention discloses a bearing outer ring grinding device. The bearing outer ring grinding device comprises a machine enclosure, wherein a charging cavity is arranged in the machine enclosure, andthe upper-end opening of the charging cavity communicates with outside; a placing circular disc is connected in the charging cavity in a sliding mode; an inner grinding cavity is arranged in the machine enclosure; a fixed gear is rotatably connected in the inner grinding cavity; four rotary pins are rotatably connected on the fixed gear; fixing rods are rotatably connected on the rotary pins; thefixing rods can fix a bearing outer ring; an outer grinding gear is arranged in the machine enclosure; two inner grinding blocks are arranged on the hollow part in the outer grinding gear; the inner grinding blocks can grind the outer end surface of the bearing outer ring; a lifting shaft is arranged in the machine enclosure; the lifting shaft is fixedly connected to a lifting circular disc; a lifting rod is connected in the lifting cavity in the sliding mode; a lifting rod slot is formed in the lifting rod; the left end surface of the lifting circular disc is rotatably connected to a rotary pin positioned in the lifting rod slot; and the upper end surface of the lifting rod is fixedly connected with a movable shaft, upper end of which penetrates through the placing circular disc.

Owner:PUJIANG JISHU MASCH TECH CO LTD

Preparation method of nickel hydroxide nanosheet array material growing on surface of foamed nickel

ActiveCN110040792AEfficient in situ array growthControllable in situ array growthMaterial nanotechnologyNickel oxides/hydroxidesNickel saltReaction temperature

The invention relates to a preparation method of a nickel hydroxide nanosheet array material growing on the surface of foamed nickel. The preparation method comprises steps as follows: foamed nickel is placed in ethanol for ultrasonic cleaning, taken out and washed by deionized water, and washed foamed nickel is soaked in an acid solution for 1-2 h, taken out and then placed in the deionized waterfor ultrasonic cleaning; foamed nickel obtained after surface activation treatment is immersed in the deionized water and subjected to natural oxidation for 2-5 days, the reaction temperature is roomtemperature, and the nickel hydroxide nanosheet array material vertically growing on the surface of foamed nickel is obtained. According to the preparation method, high-temperature and high-pressurereaction conditions are not required, high-purity nickel salt is not needed to serve as the reaction raw material, fewer pollutants are produced in a preparation process, and therefore, the preparation method meets the green chemistry synthesis concept and is low in cost.

Owner:TIANJIN UNIV

Laminated silicon-doped tin oxide thin film transistor and preparation method thereof

ActiveCN109887991AGood device performanceSimple preparation processTransistorSemiconductor/solid-state device manufacturingSecondary layerPhysics

The invention belongs to the technical field of thin film transistors, and discloses a laminated silicon-doped tin oxide thin film transistor and a preparation method thereof. The laminated silicon-doped tin oxide thin film transistor comprises a substrate, a gate, a gate insulating layer, a first layer of active layer, a second layer of active layer, and a source drain electrode that are stackedin sequence, wherein the first layer of active layer is silicon-doped tin oxide with 0-3 mass percent of silicon, and the second layer of active layer is silicon-doped tin oxide with 5-10 mass percentof silicon. A silicon-doped tin oxide semiconductor material serves as a material of the active layers, and tin oxide active layer materials doped with different contents of silicon are matched, so as to prepare a laminated active layer structure to control a carrier in a channel of a device, so that the device has good performance.

Owner:SOUTH CHINA UNIV OF TECH

Lithium battery cell

InactiveCN110212250AIncreased binding areaPrevent folding phenomenonFinal product manufactureElectrolyte accumulators manufactureEngineeringGlue line

The invention provides a lithium battery cell, and belongs to the technical field of lithium batteries. The lithium battery cell comprises pole plate combination bodies which are arranged in a lamination way, wherein each pole plate combination body comprises a positive pole plate, a negative pole plate and a diaphragm, wherein the diaphragm is arranged between the positive pole plate and the negative pole plate, and at least one glue line or at least one glue surface is pasted onto a front end surface and / or a rear end surface of the pole plate combination bodies arranged in the lamination way. The diaphragm at an end part of the pole plate combination body is comprehensively constrained by the network-shaped glue line, the constraint area of the diaphragm is expanded, a phenomenon that the diaphragm is turned over when the pole plate combination body is assembled into a membrane shell is prevented, turnover caused by electrolyte back flush and the end part collided with the diaphragmduring falling is prevented, the risk that a positive pole plate and a negative pole plate of the battery cell are contacted or pole powder of the negative pole plate and the positive pole plate is contacted can be effectively prevented, the glue pasting has relatively high applicability, different types of battery cells can be compatible, and flexible manufacturing is achieved.

Owner:ZHUHAI COSMX BATTERY CO LTD

An electromagnetic forming device and method for providing continuous electromagnetic force

ActiveCN108856443BPrecise control of magnetic field forceRealize flexible manufacturingShaping toolsElectricityEddy current

The invention discloses an electromagnetic forming device for providing continuous electromagnetic force. The electromagnetic forming device for providing the continuous electromagnetic force comprises a concave die, a coil and a discharging loop. The coil is arranged on the concave die, a sheet to be formed is arranged between the concave die and the coil, the coil is electrically connected withthe discharging loop, the discharging loop comprises a steady-state magnetic field discharging loop capable of generating a steady-state magnetic field and an alternating magnetic field discharging loop capable of generating an alternating magnetic field, and the steady-state magnetic field discharging loop and the alternating magnetic field discharging loop are electrically connected with the coil separately. The invention further discloses an electromagnetic forming method. The electromagnetic forming method comprises the steps of discharging of the steady-state magnetic field discharging loop, discharging of the alternating magnetic field discharging loop, superimposing of the current generated by the steady-state magnetic field discharging loop and the current generated by the alternating magnetic field discharging loop, obtaining induced eddy current by induction of alternating pulse current, forming completing of the sheet under the action of magnetic field force and the like. The electromagnetic forming device for providing the continuous electromagnetic force has the advantages of being high in forming efficiency and good in forming precision, effectively avoiding sheet rebound, being capable of providing the continuous electromagnetic force, accurately regulating and controlling the electromagnetic force to realize flexible manufacturing and the like.

Owner:CENT SOUTH UNIV

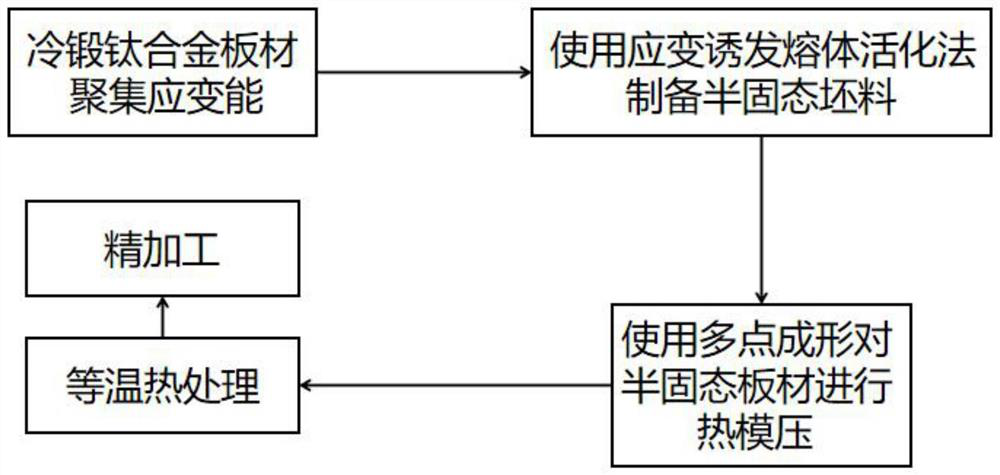

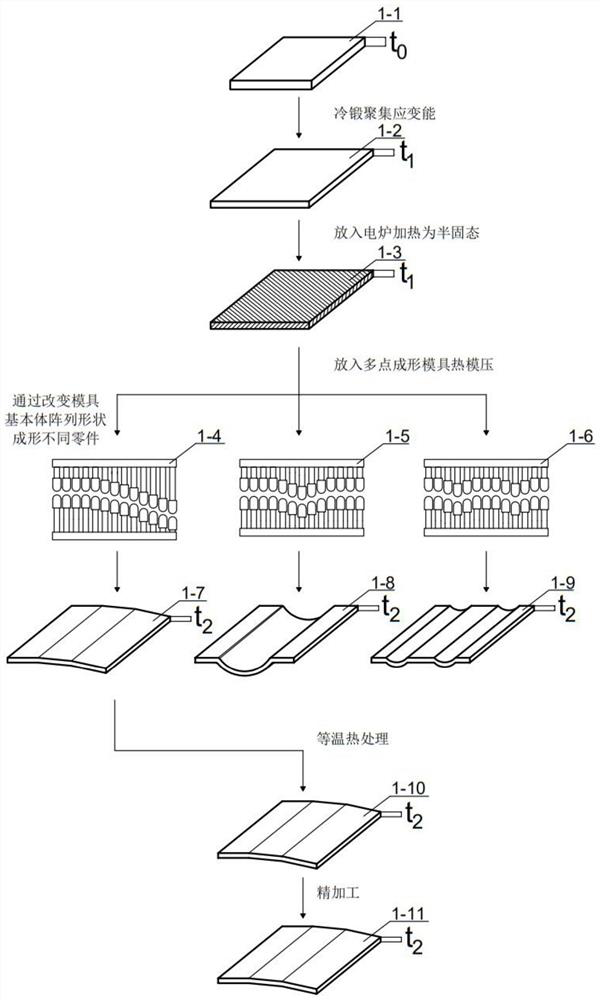

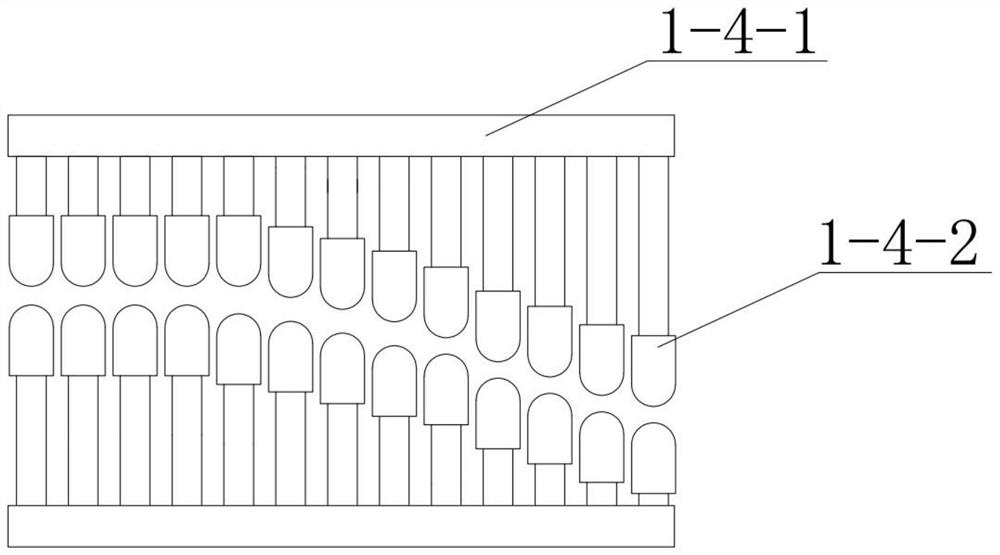

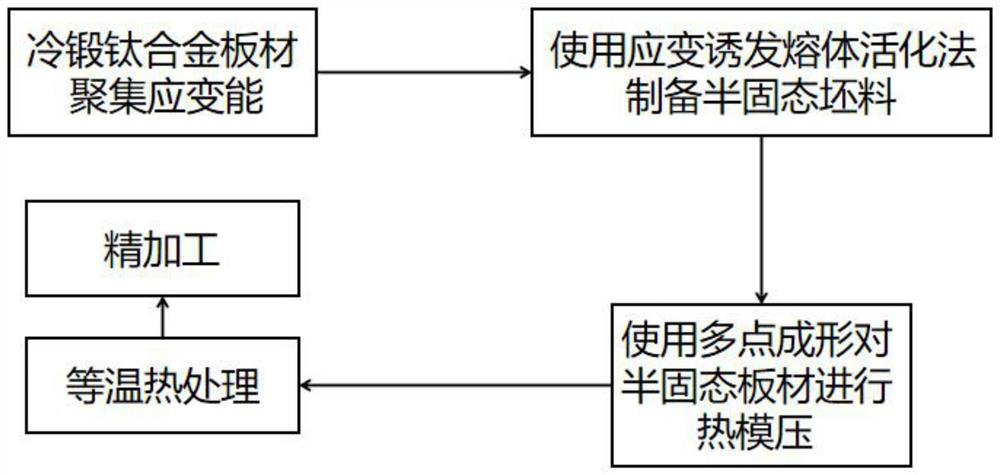

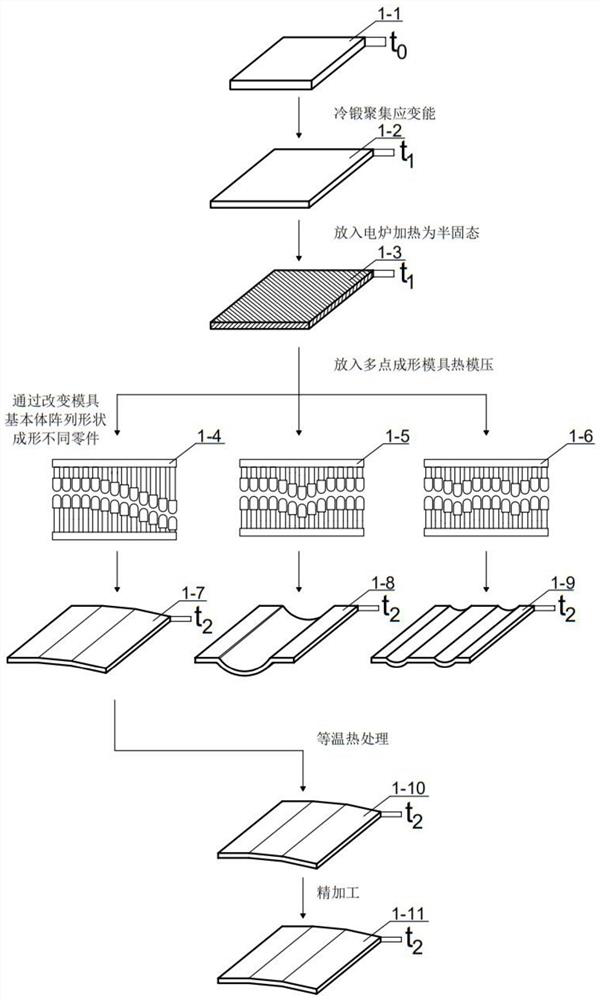

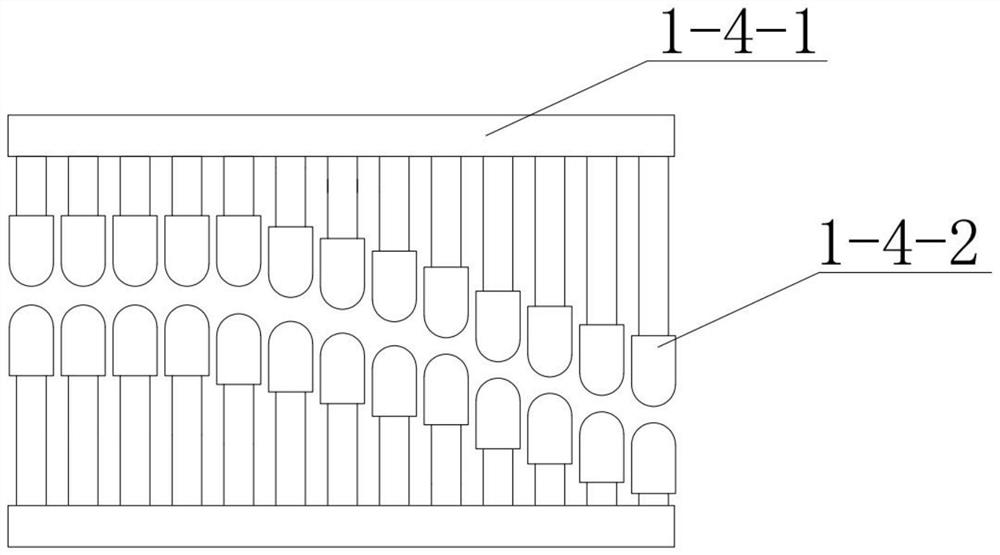

Strain-induced semi-solid multi-point compression molding process for aerospace titanium alloy sheet

ActiveCN112453299BAvoid changeSimple methodMetal-working apparatusFurnace typesSemi solidHeating furnace

The strain-induced semi-solid multi-point compression molding process for aerospace titanium alloy sheets first cold-forges the original titanium alloy sheets to obtain the aggregated strain energy titanium alloy sheets; then puts the aggregated strain energy titanium alloy sheets into induction heating furnaces Heating and heat preservation treatment, and then use the strain-induced melt activation method to prepare semi-solid titanium alloy sheets; then place the semi-solid titanium alloy sheets in a multi-point mold, adjust the shape of the forming surface of the basic body array of the multi-point mold, and use a press Push the upper mold body of the multi-point mold, and perform semi-solid multi-point press thermoforming on the semi-solid titanium alloy sheet to obtain a semi-solid formed titanium alloy sheet; finally, perform isothermal heat treatment on the semi-solid formed titanium alloy sheet, and then perform finishing The final titanium alloy part is obtained; the invention improves the processing efficiency and forming quality, shortens the working hours; the forming range is relatively wide, and flexible manufacturing can be realized.

Owner:XI AN JIAOTONG UNIV

Flexible online method for preparing micro-group wire electrodes

ActiveCN105108250BAvoid the problem of poor positioning accuracyRealize flexible manufacturingElectrochemical machining apparatusBiochemical engineeringReciprocating motion

The invention discloses a method for flexible on-line preparation of micro-group wire electrodes, which belongs to the field of electrochemical micro-manufacturing. It is characterized in that it includes the following process: 1. Fix a metal sheet and the group wire electrode in the workpiece fixture and the group wire electrode fixture respectively, and respectively connect with the positive pole and the negative pole of the ultrashort pulse power supply, so as to realize the flexible preparation of the cathode tool ; The cathode tool is composed of micro-slits and cathode holes corresponding to each electrode wire in the group wire electrode; after processing, the electrode wire is located at the center of the cathode hole; 2, the cathode tool and the group wire electrode are respectively connected to an ultrashort pulse power supply Using the axial reciprocating movement of the wire electrode, the online preparation of the submicron group wire electrode is realized; 3. The electrode wire "exits" the cathode tool along the micro-slit, and then replaces the cathode tool with the workpiece to be processed; The wire electrode and the workpiece are respectively connected to the negative pole and the positive pole of the ultrashort pulse power supply, and the multi-wire electrode micro-electrolytic wire cutting process is performed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

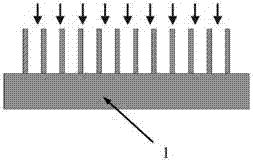

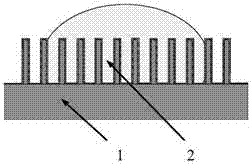

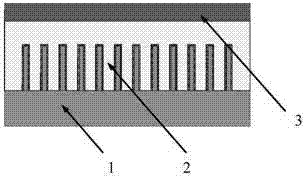

A method for fabricating flexible nanocolumn arrays with high aspect ratio

ActiveCN105047525BRealize flexible manufacturingSemiconductor/solid-state device manufacturingNanotechnologyMicro nanoNanostructure

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A three-dimensional embossed graphene PU tire manufacturing method and equipment

ActiveCN106378945BRealize flexible manufacturingImprove heat resistanceTyresAdhesion processNitrogen

Owner:BEIJING UNIV OF CHEM TECH

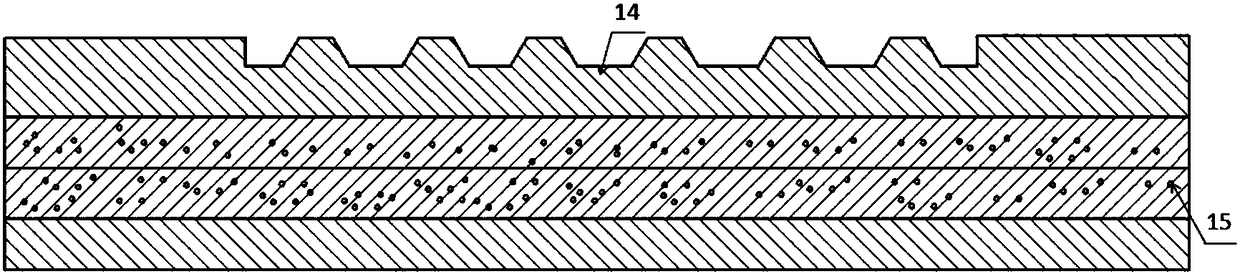

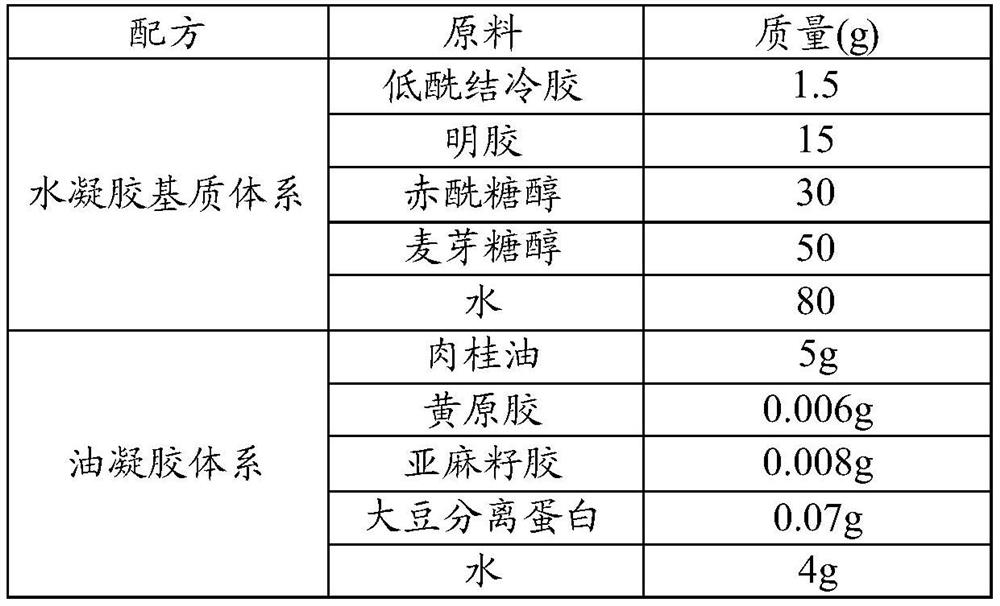

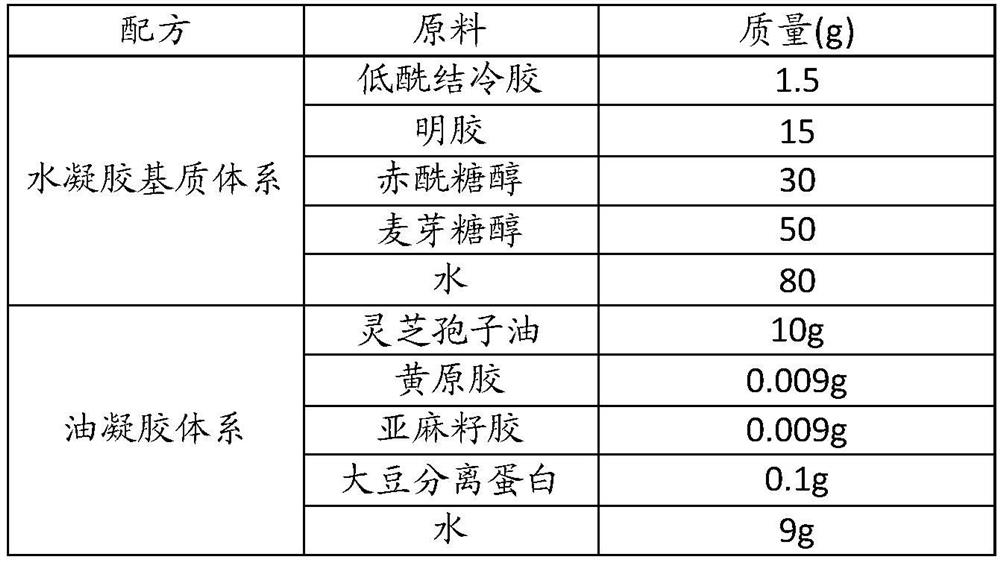

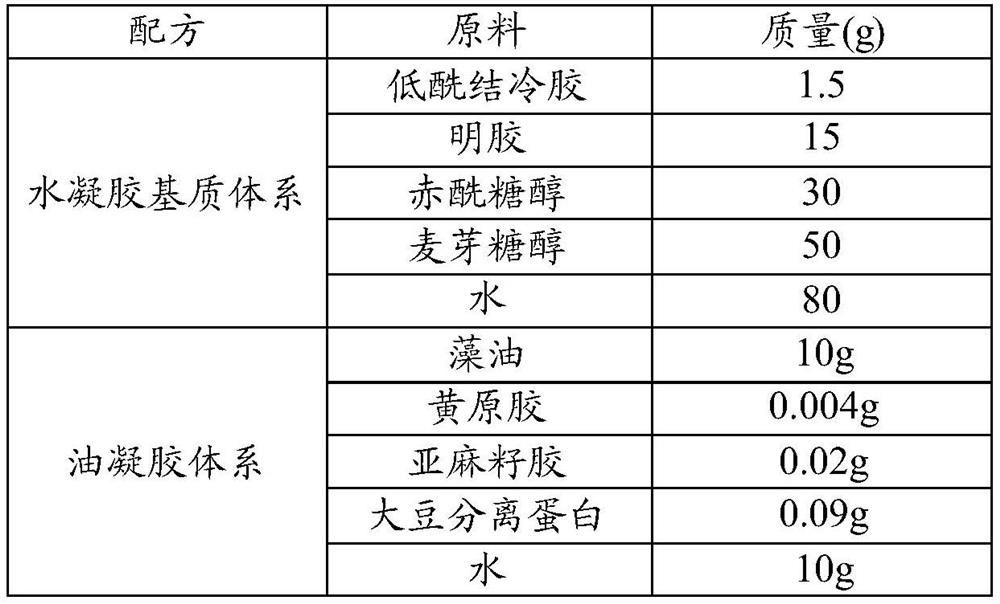

A kind of grease jelly jelly and preparation method thereof

ActiveCN109123033BGreat tasteRealize flexible manufacturingConfectionerySweetmeatsComputer printingAlcohol sugars

Owner:INFINITUS (CHINA) CO LTD

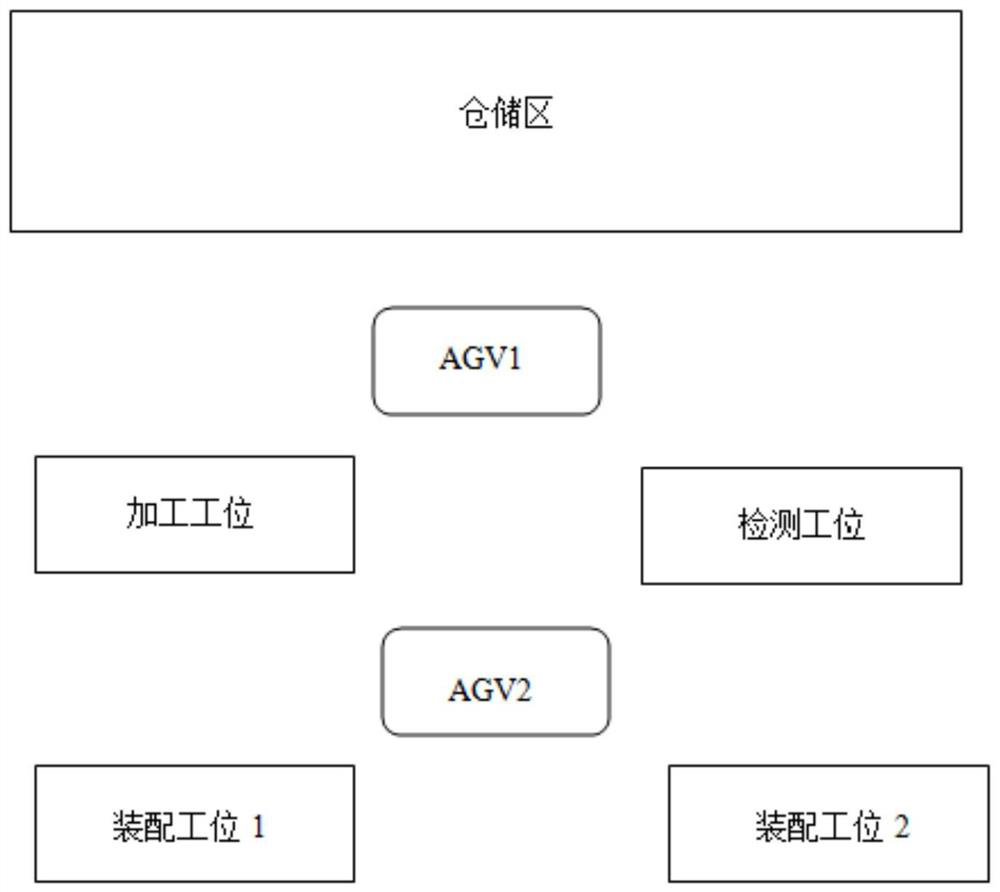

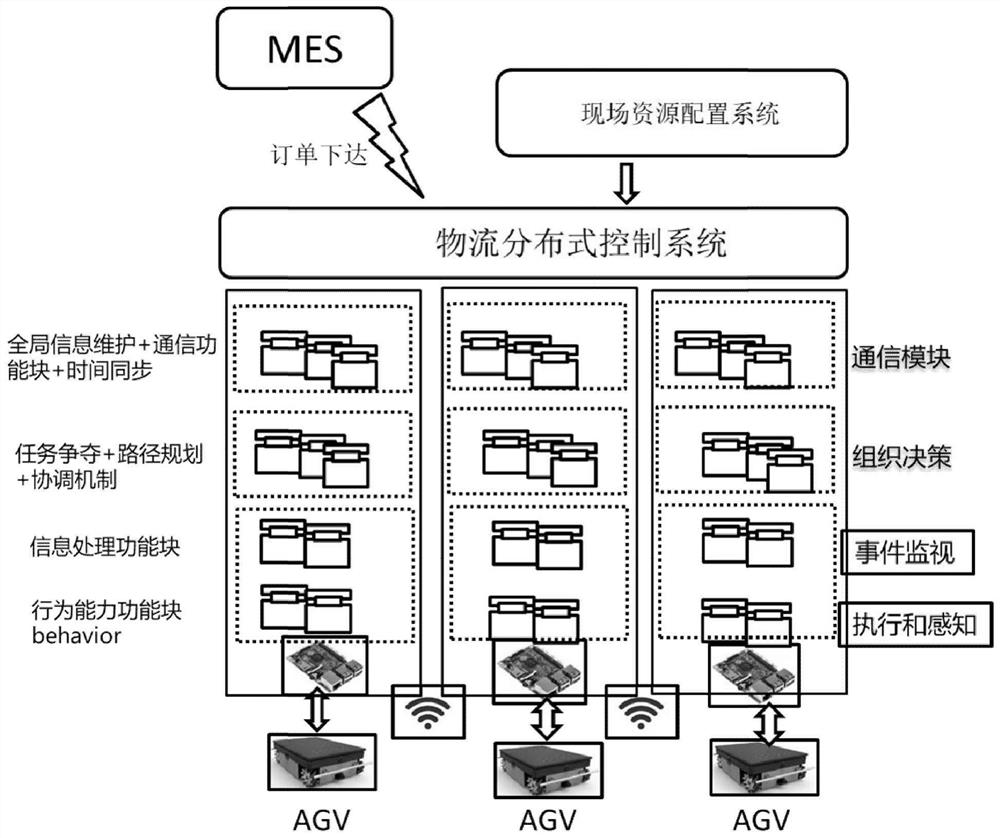

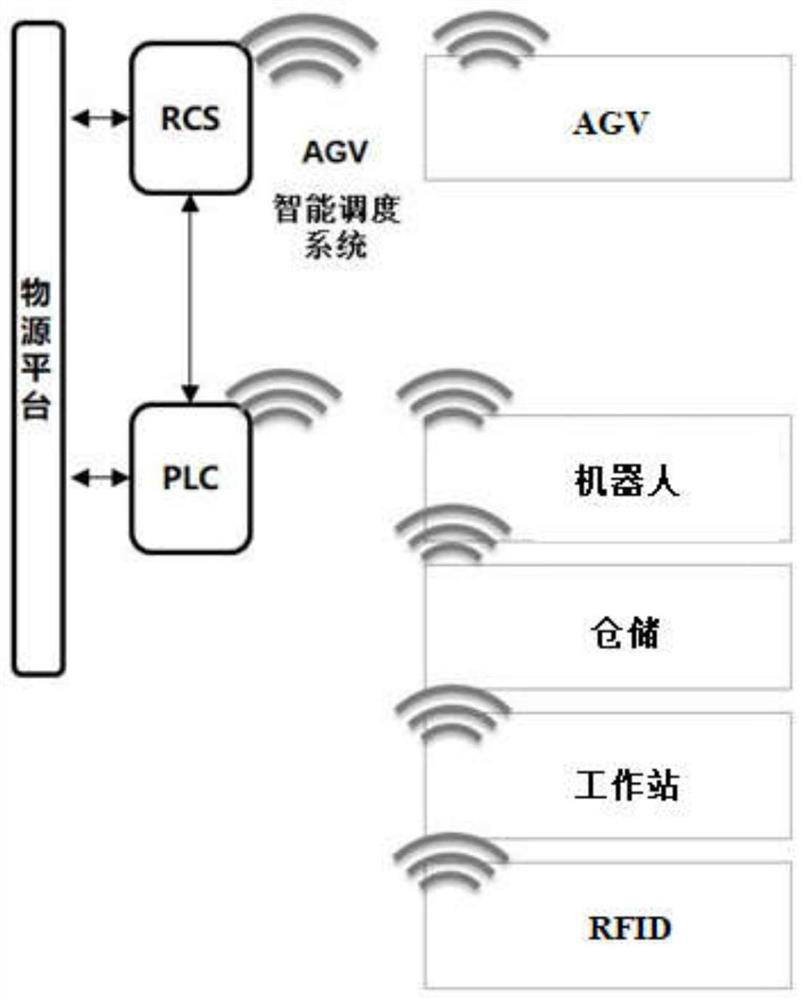

Flexible production control system based on multiple agents

PendingCN113009887AGuaranteed stabilityRealize automatic generationElectric/hybrid propulsionTotal factory controlAutomatic controlMachine

The invention belongs to the technical field of automatic control, and particularly relates to a flexible production control system based on multiple agents. The system includes an intelligent warehousing system, an intelligent manufacturing system, a communication system and a material source platform. The intelligent warehousing system comprises but is not limited to a warehousing shelf, a warehousing tray and an RFID information reader-writer; the intelligent manufacturing system comprises but is not limited to an intelligent assembly station, an intelligent processing station and an intelligent detection station; the communication system comprises but is not limited to a WIA-based wireless networking module; the material source platform comprises but is not limited to management and control integrated flexible control software and an edge controller; the edge controller highly integrates functional modules of robot control, AGV control, machine vision, artificial intelligence and the like. According to the invention, a single intelligent agent is regarded as a unit, and each intelligent agent makes different work decisions according to own environment and information feedback of other units. According to the invention, flexible production can be realized, and mixed-line production of different products is realized.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +2

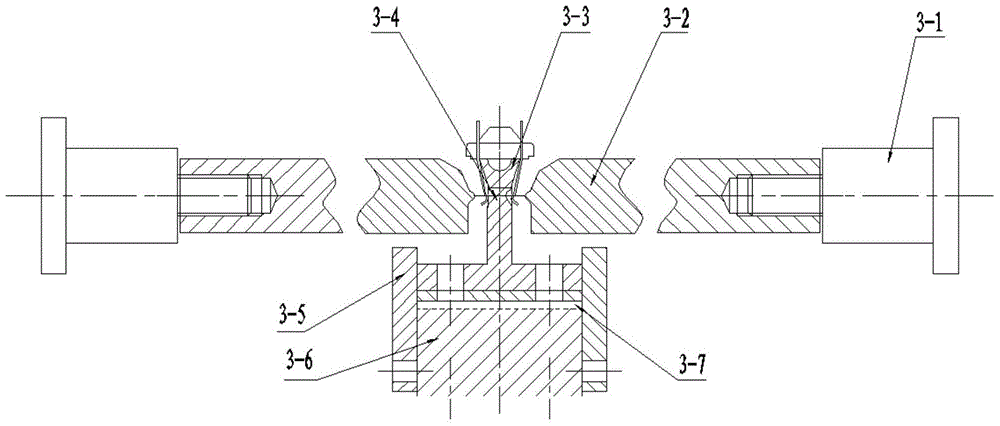

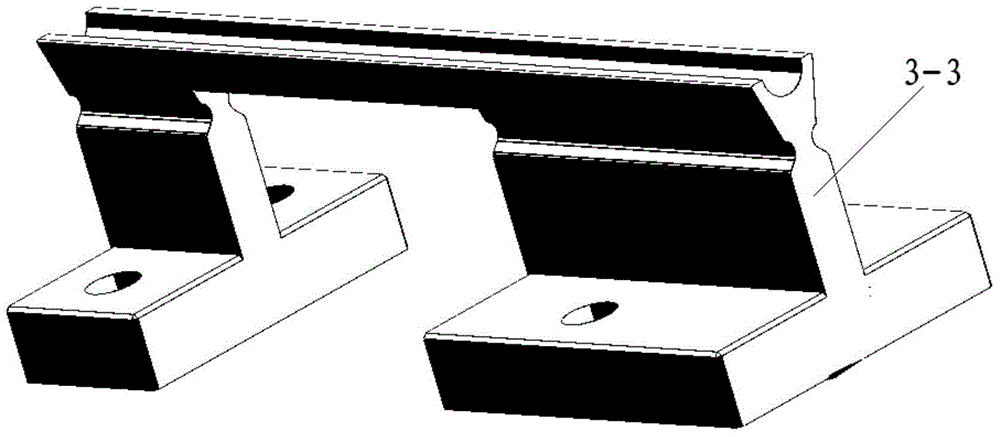

Switch plug profiling equipment

InactiveCN106513528AIncrease productivityImprove consistencyShaping toolsMetal-working feeding devicesMachine partsFully automatic

The invention discloses switch plug profiling equipment which comprises a vibration disk, a linear vibrator which is connected with an outlet of the vibration disk and is used for conveying plugs to a machining part one by one, a sensor for detecting the positions of the plugs and a profiling fixture for profiling the plugs, wherein the sensor is arranged between the linear vibrator and the plug profiling fixture; the plug profiling fixture comprises a profiling female die and profiling male dies symmetrically arranged on two sides of the profiling female die; grooves matched with the male dies are symmetrically formed in two sides of the profiling female die; the profiling female die comprises a movable female die for determining the profiling size and a fastening female die which is used for guaranteeing guiding for the plugs obtained before and after profiling and is arranged in an inner cavity of the movable female die in a sleeving manner; and the profiling fixture adjusts the working state according to a signal of the sensor. Reversing light switch plug automatic profiling equipment disclosed by the invention is fully automatic in the whole process, and the production efficiency and the product quality are both obviously improved.

Owner:CHONGQING SHANQING MACHINERY MFG

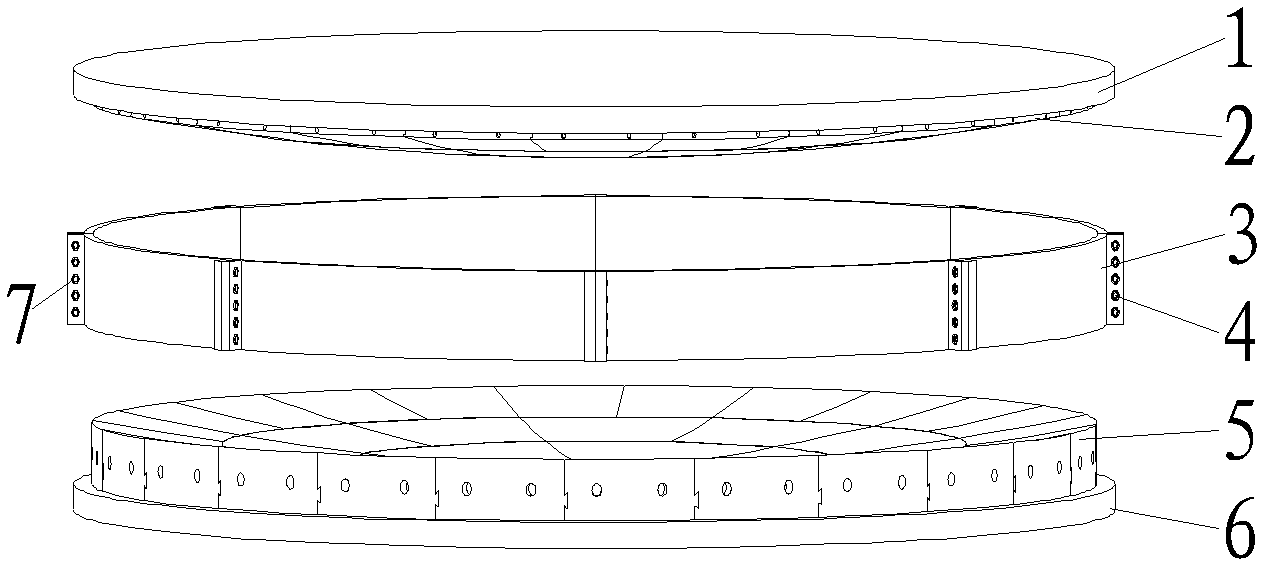

Large-caliber solar plastic lens splicing die

InactiveCN102529035AReduce processing difficultyRealize flexible manufacturingOptical articlesEngineeringLens plate

The invention discloses a large-caliber solar plastic lens splicing die, and relates to a lens splicing die. The solar plastic lens splicing die is provided with a male die pedestal, a male die, a lateral die, a female die, a female die pedestal, inside hexagonal bolts and nuts; the male die consists of a primary male sub-die block, a secondary male sub-die block, a tertiary male sub-die block and a quaternary male sub-die block; the female die is formed by splicing a primary female sub-die block, a secondary female sub-die block, a tertiary female sub-die block and a part or all of a quaternary female sub-die block; the lateral die is formed by splicing small-caliber lateral sub die blocks; the male die pedestal and the female die pedestal are fixed on an injection molding platform; the primary female sub-die block, the secondary female sub-die block, the tertiary female sub-die block, the quaternary female sub-die block and a dovetail groove structure are spliced and fixed on the female die pedestal; and the lateral sub die blocks are connected into the lateral die by the inside hexagonal bolts and the nuts and encircle the lateral surfaces of the male die and the female die.

Owner:XIAMEN UNIV

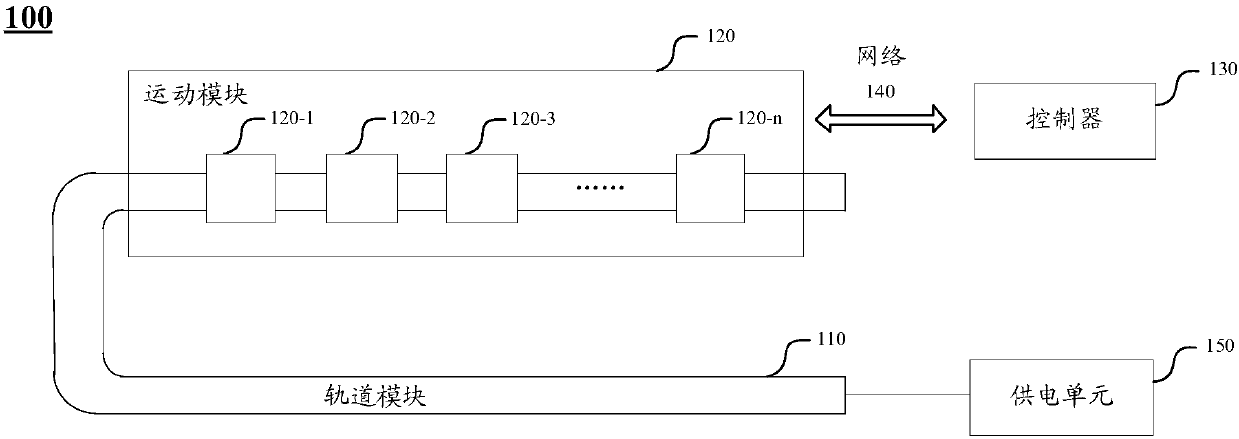

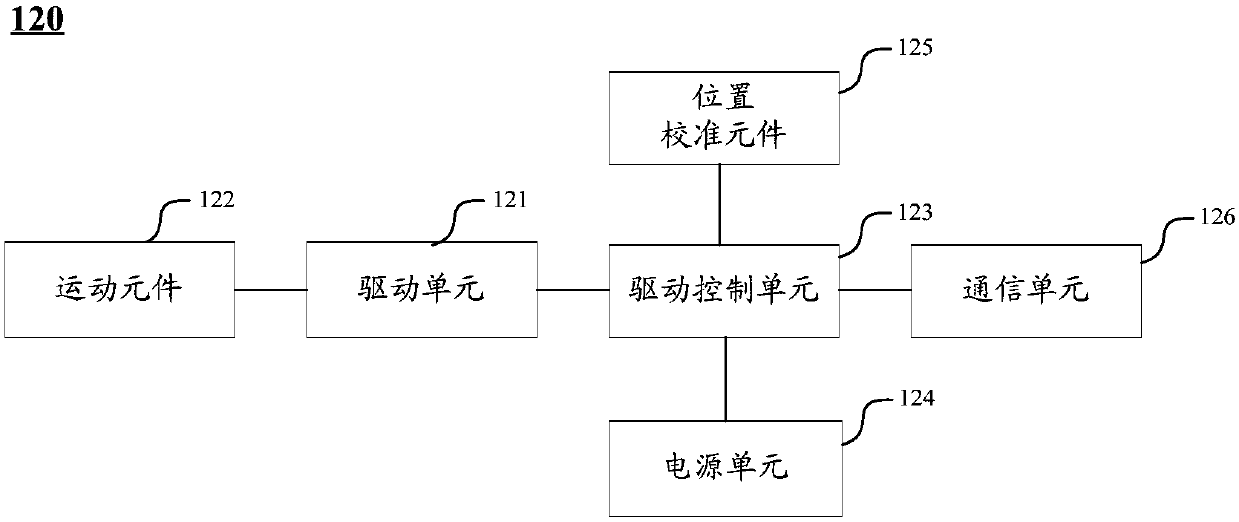

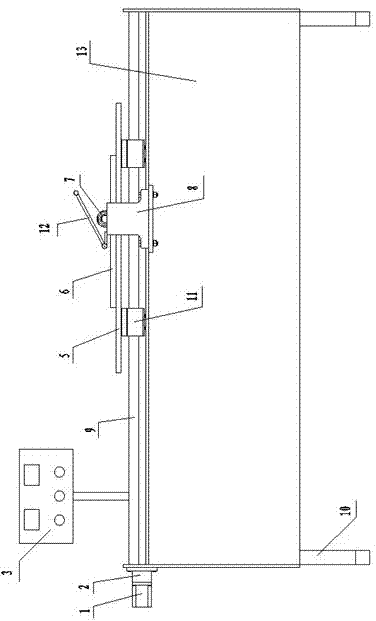

System and method for conveying objects

InactiveCN110316525AAchieve independence movementLow costMechanical conveyorsComputer moduleSimulation

The invention discloses a system and method for conveying objects. The system comprises a track module, one or more movement modules and a controller, wherein the one or more movement modules are arranged on the track module, and each of the one or more movement modules can independently move relative to the track module; the controller is configured to generate movement control information used for each of the one or more movement modules correspondingly; and each of one or more movement modules comprises driving units, and the driving units are configured to drive the movement modules to move independently relative to the track module according to the movement control information used for the movement modules.

Owner:杨新 +1

Strain-induced semi-solid multi-point die pressing forming process for aerospace titanium alloy plate

ActiveCN112453299ASolve the problem of inability to form spheroidized tissueSolving Elasticity ProblemsMetal-working apparatusFurnace typesSemi solidHeat conservation

A strain-induced semi-solid multi-point die pressing forming process for an aerospace titanium alloy plate comprises the steps that firstly, an original titanium alloy plate material is subjected to cold forging machining, and a strain energy gathered titanium alloy plate is obtained; then the strain energy gathered titanium alloy plate is put into an induction heating furnace to be heated and subjected to heat preservation treatment, and then a semi-solid titanium alloy plate is prepared through a strain-induced melt activation method; then the semi-solid titanium alloy plate is placed in a multi-point die, the shape of the forming face of a basic body array of the multi-point die is adjusted, an upper die body of the multi-point die is pushed through a pressure machine, and semi-solid multi-point die pressing hot forming is conducted on the semi-solid titanium alloy plate to obtain a semi-solid formed titanium alloy plate; and finally, the semi-solid formed titanium alloy plate is subjected to plate isothermal heat treatment, then finish machining is conducted, and a final titanium alloy part is obtained. According to the strain-induced semi-solid multi-point die pressing formingprocess for the aerospace titanium alloy plate, the machining efficiency and the forming quality are improved, and the work hours are shortened; and the forming range is wide, and flexible manufacturing can be achieved.

Owner:XI AN JIAOTONG UNIV

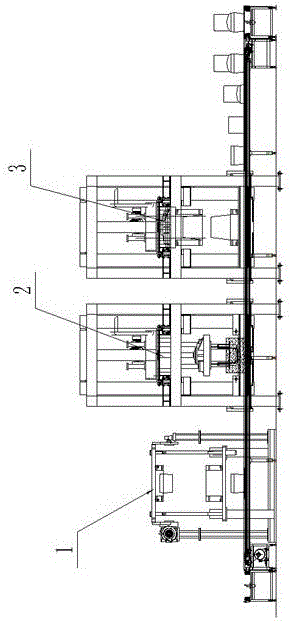

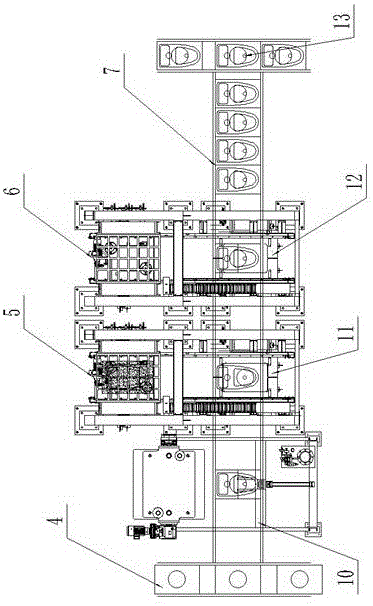

Intelligent pedestal pan high-pressure forming system

PendingCN107520951AReduce wasteMeet mixed productionCeramic shaping plantsProcess engineeringMaterial resources

The invention discloses an intelligent pedestal pan high-pressure forming system. The system is applicable to production of products with complex structures such as intelligent pedestal pans, all-in-one split pedestal pans and all-in-one integrated pedestal pans; an original production mode is changed, the mixed production of the various products can be realized, and flexible manufacturing can be realized; and an original model parting technology is completely changed so that the equipment development difficulty can be reduced, automatic high-pressure forming production of the complex products can be completed by combining existing high-pressure equipment, and therefore the problem that the existing equipment cannot meet the production of the products with complex structures can be solved, the operation efficiency of the equipment can be improved, and the waste of material resources and financial resources can be reduced.

Owner:TANGSHAN HEXIANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com