Equipment and method for orderly arranging beaded grinding material of super-hard brass solder grinding material

A super-hard abrasive and equipment technology, applied in the field of abrasives manufacturing, can solve problems in the initial stage, achieve uniform distribution, high-efficiency and flexible manufacturing, and realize automation and semi-automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in detail:

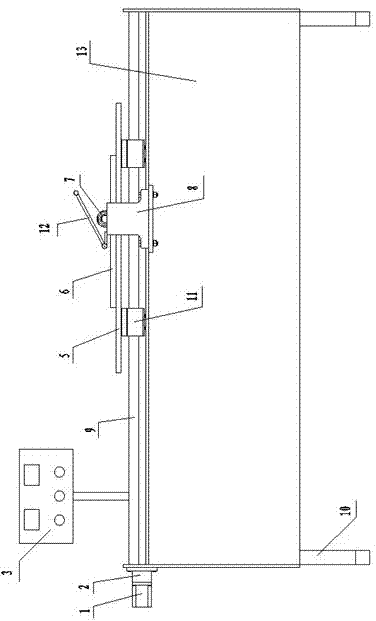

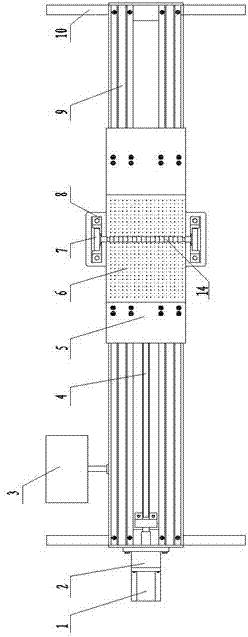

[0030] Such as figure 1 , figure 2 As shown, a superabrasive beaded orderly distributing equipment includes a motor 1, a speed reducer 2, a controller 3, a screw 4, a workbench 5, a distributing mold 6, a beading adjustment driving device, a guide rail 9, a bracket 10, Slider 11, box body 13 and wire saw beading 14. Among them, the fabric mold is an elastic template structure, and its surface is covered with regular and evenly distributed grooves or hole arrays. Its length and width range from 10mm to 1000mm, and its thickness ranges from 1mm to 30mm.

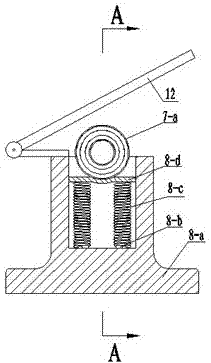

[0031] The bead mounting mechanism is composed of a bearing, a mandrel and a bearing holder. The bearing is installed on the bearing holder. The bearing holder fixes the mandrel through threads or slots. The diameter of the mandrel ranges from 1mm to 20mm, and the length ranges from 10mm to 500mm.

[0032] Such as image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com