Lithium battery cell

A technology of lithium batteries and batteries, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, and can solve problems such as battery drop failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

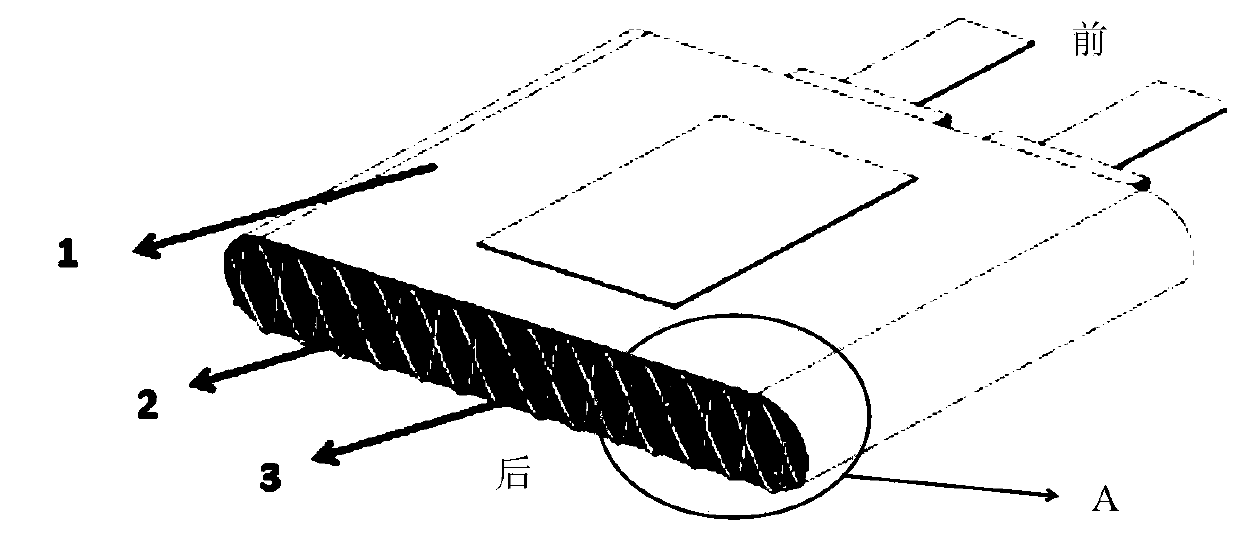

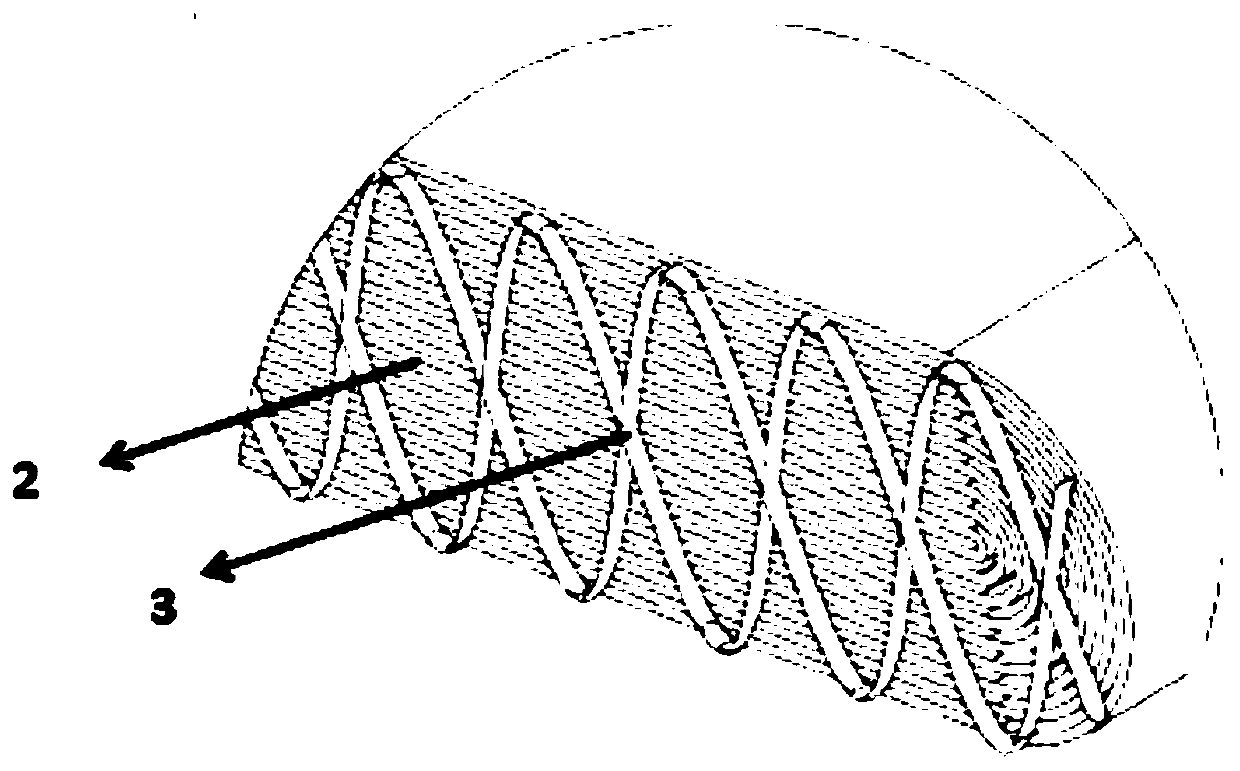

[0032] A lithium battery cell includes a stack of pole piece composites 2 that include a positive electrode sheet, a negative electrode sheet, and a separator. The separator is located between the positive electrode sheet and the negative electrode sheet. Two glue lines 3 are glued on the rear end surface of the pole piece composite body 2 provided, and the two glue lines 3 are in the shape of a'wave line', and the two glue lines 3 are staggered and arranged symmetrically. A mesh glue line 3 is formed, and the height of at least one of the crests and troughs of the glue line 3 is equal to the thickness of the lithium battery cell 1, and the diaphragms of each layer of the pole piece composite 2 are bonded together to achieve the purpose of fixing.

[0033] Further, the way of stacking arrangement is a'Z'-shaped stacking arrangement.

[0034] Further, the lithium battery cell further includes a cell membrane shell, a positive electrode ear, and a negative electrode ear. The positive...

specific Embodiment approach 2

[0036] A lithium battery cell includes a stack of pole piece composites 2 that include a positive electrode sheet, a negative electrode sheet, and a separator. The separator is located between the positive electrode sheet and the negative electrode sheet. A glue line 3 is glued on the rear end surface of the pole piece composite body 2. The glue line 3 is in the shape of a'wave line', and the height of the wave peaks and troughs of the glue line 3 is equal to that of the lithium battery cell 1. Thickness, the glue line 3 connects all the laminated pole piece composites 2 to bond the diaphragms of each pole piece composite 2 together to achieve the purpose of fixation.

[0037] Further, the way of stacking arrangement is a'Z'-shaped stacking arrangement.

[0038] Further, the lithium battery cell further includes a cell membrane shell, a positive electrode ear, and a negative electrode ear. The positive electrode ear is fixedly connected to the positive electrode sheet, the negative...

specific Embodiment approach 3

[0040] A lithium battery cell includes a stack of pole piece composites 2 that include a positive electrode sheet, a negative electrode sheet, and a separator. The separator is located between the positive electrode sheet and the negative electrode sheet. A plurality of glue lines 3 are glued on the rear end surface of the pole piece composite body 2 provided, and the plurality of glue lines 3 are all vertically distributed straight lines, and each glue line 3 is partially bonded to the pole piece composite body On the rear end surface of 2, all the glue lines 3 are combined and pasted to connect all the laminated pole piece composites 2. The diaphragms of each pole piece composite body 2 are bonded together to achieve the purpose of fixing.

[0041] Further, the way of stacking arrangement is winding stacking arrangement.

[0042] Further, the lithium battery cell further includes a cell membrane shell, a positive electrode ear, and a negative electrode ear. The positive electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com