Method for flexibly online preparing micro line group electrode

A group wire electrode and flexible technology, applied in the field of electrochemical micro-manufacturing, can solve the problems of cathode tool installation and positioning error, difficulty in making cathode tools with small spacing size, difficulty in guaranteeing, etc., and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

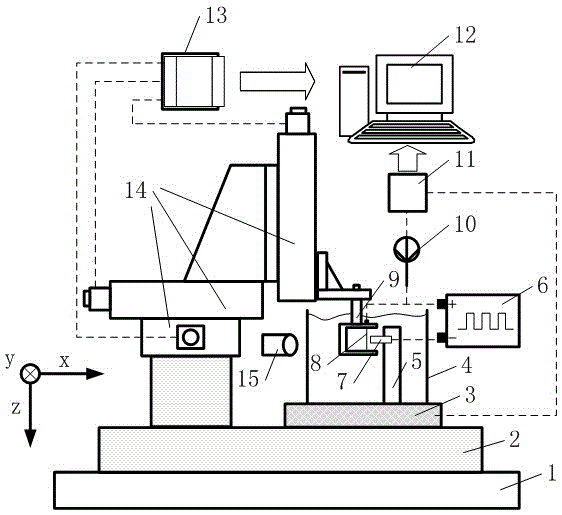

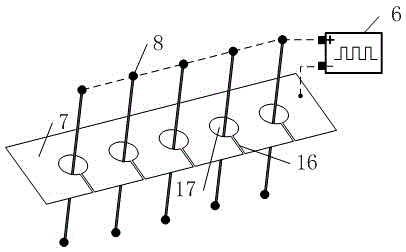

[0025] According to attached figure 1 As shown, the overall schematic diagram of the flexible on-line preparation of micro-group wire electrode device is composed of the following parts: an air flotation platform 1, a machine tool body 2, and a piezoelectric ceramic 3 located on the machine tool body 2; it also includes a group wire electrode fixture 9 , group line electrode 8; sheet metal clamp 5 links to each other with sheet metal 7 and is fixed in the electrolyte tank 4; ultrashort pulse power supply 6; current sensor 9; CCD camera 15; Current waveform; the industrial computer 12 realizes the control of the X-Y-Z three-axis precision mobile platform 14 through the motion control card 13 .

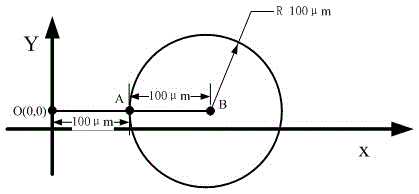

[0026] Attached below figure 1 , figure 2 with image 3 Illustrate the method of the present invention, be specifically divided into the following several steps:

[0027] (1) Tungsten wires with a diameter of 10 μm are used as the group wire electrodes 8 , and fixed in the group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com