Tin oxide-based thin film transistor based on plasma enhanced atomic layer deposition gate insulating layer and preparation method

A gate insulating layer, atomic layer deposition technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of low "on-state" current, low device mobility, low dielectric constant, etc. The effect of reducing the turn-on voltage, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

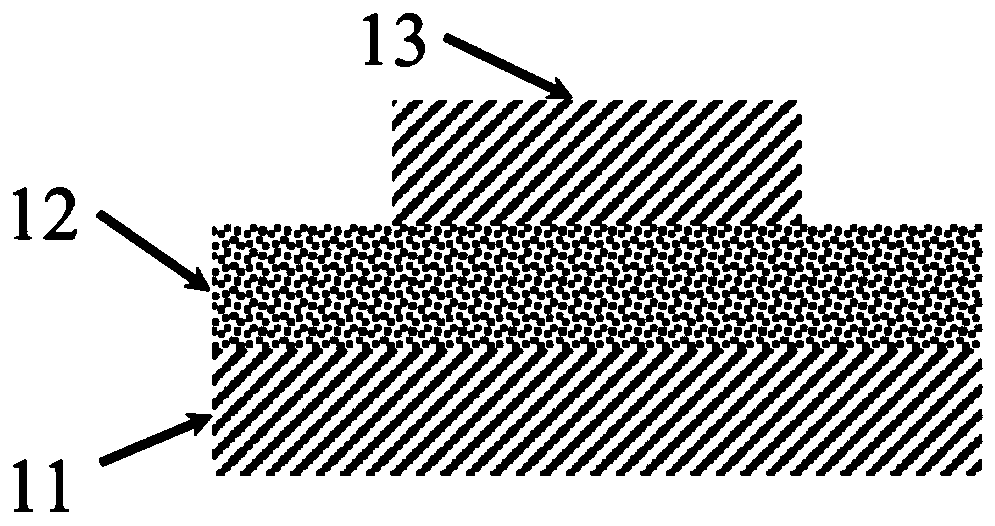

[0030] A tin oxide-based thin film transistor based on plasma-enhanced atomic layer deposition gate insulating layer, comprising: a substrate, a gate, a gate insulating layer, an active layer and a source-drain electrode arranged in sequence, wherein: the gate insulating layer The aluminum oxide film is prepared by plasma-enhanced atomic layer deposition, and the active layer is a silicon-doped tin oxide film prepared by magnetron sputtering deposition.

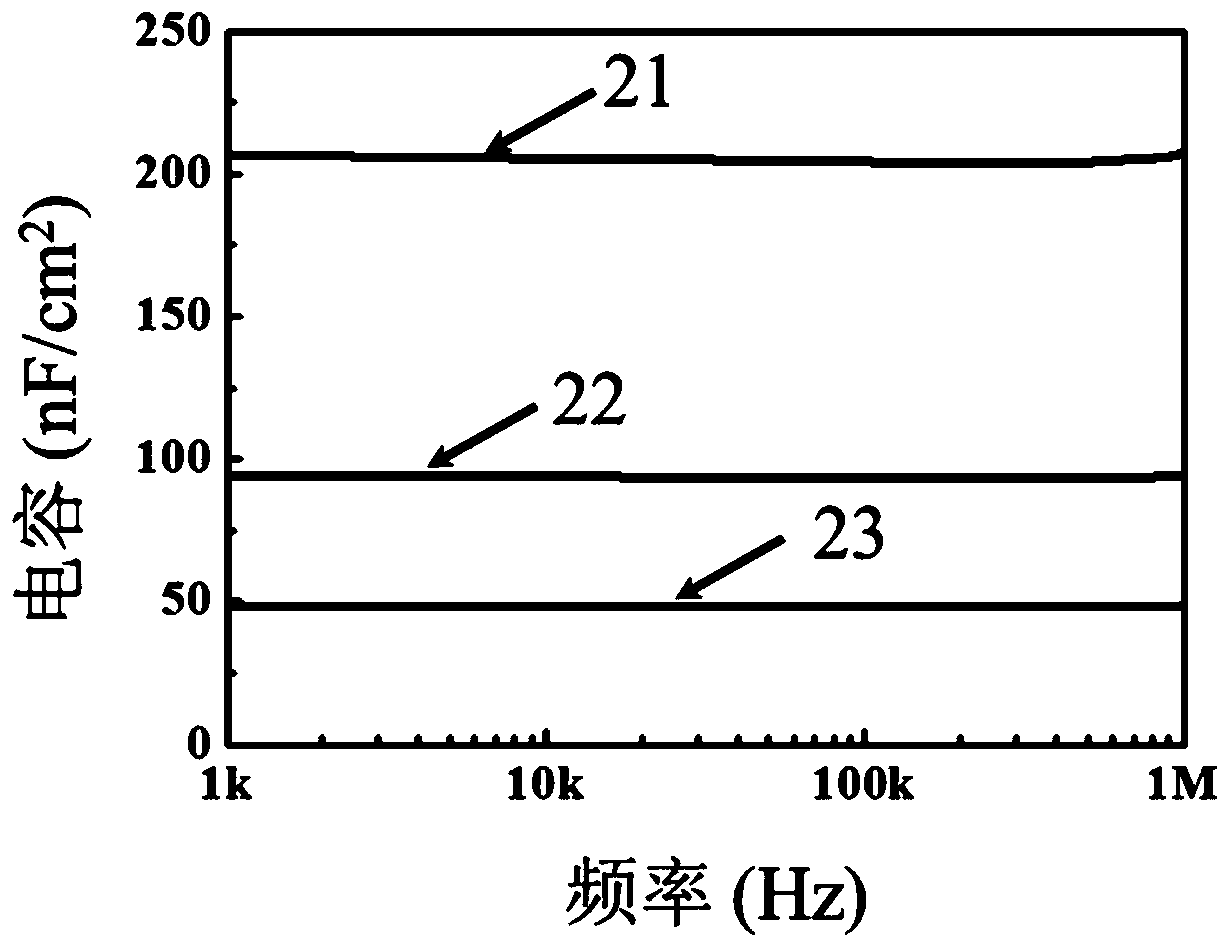

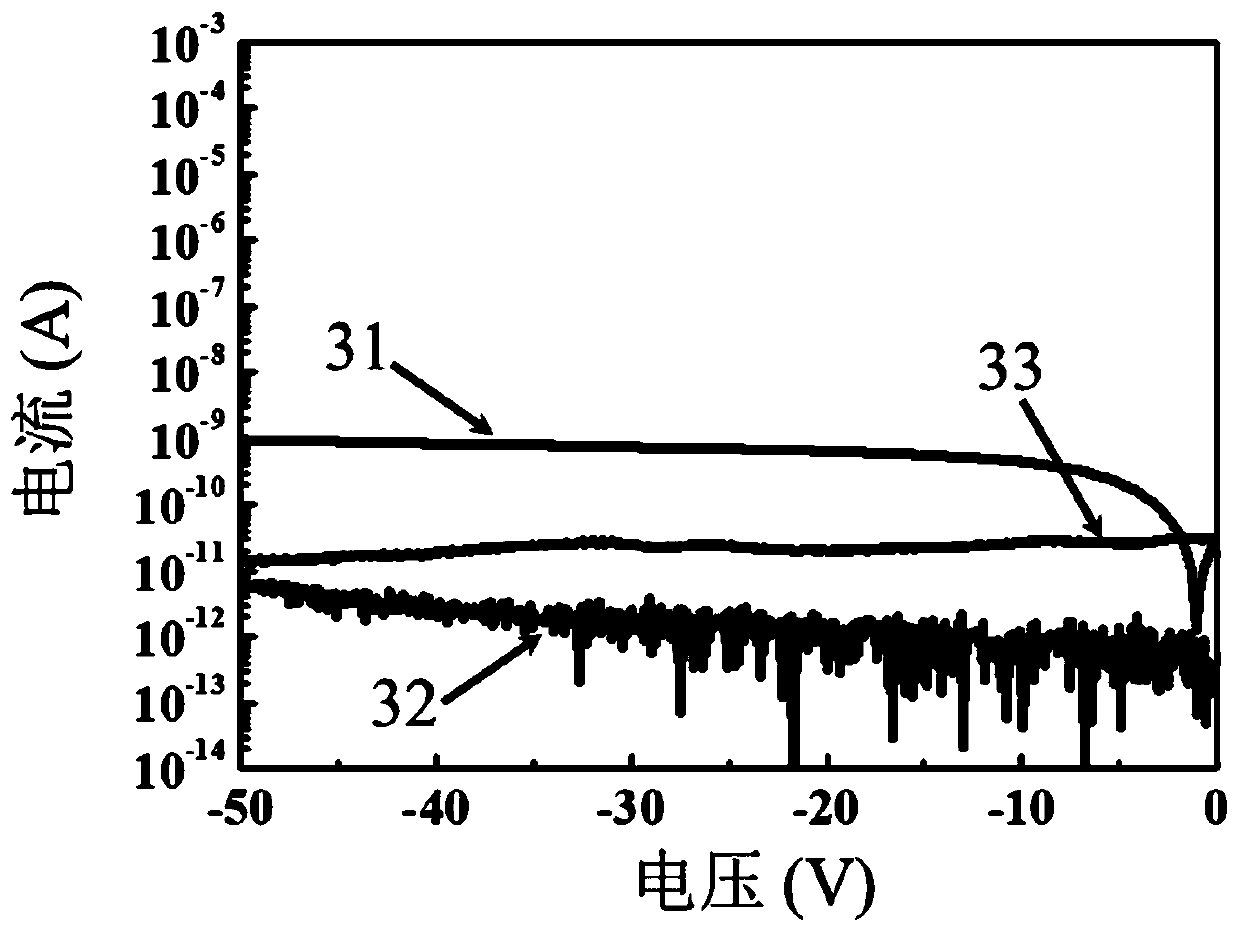

[0031] The invention introduces high-quality aluminum oxide as the grid insulating layer, improves the interface quality of the grid insulating layer / active layer, and effectively improves device mobility and stability. Alumina film is prepared by atomic layer deposition, the material of the gate insulating layer is alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com