A method for fabricating flexible nanocolumn arrays with high aspect ratio

A technology with high aspect ratio and manufacturing method, which is applied in the fields of nanotechnology, semiconductor/solid-state device manufacturing, photolithographic exposure device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

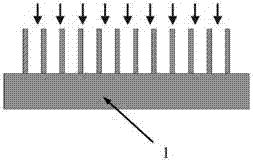

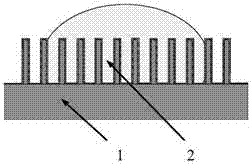

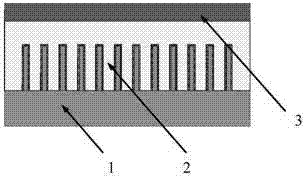

[0027] In this embodiment, a method for fabricating a high aspect ratio flexible nanoarray based on the above-mentioned secondary nanoimprinting is given, which specifically includes the following steps:

[0028] Step 1: The soft film plate with high aspect ratio flexible nano-cilia structure uses PDMS as the casting material, and performs the first film molding on the template of silicon-based nano-cilia structure. The specific process is as follows:

[0029] (a) adopt the passivation process in the high-density plasma etching to process the silicon-based nano-cilia array to carry out surface hydrophobicity treatment, and its specific process is as follows: C 4 f 8 The gas flow rate is 85sccm, the power of the lower plate is 600W, and the APC valve is 82%. After a 1-minute passivation process, the thickness of the fluorinated carbon deposited on the surface of the silicon-based nano-cilia array is about 150nm.

[0030] (b) Mix the PDMS solvent and curing agent (RTV615, GE Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com