A three-dimensional embossed graphene PU tire manufacturing method and equipment

A manufacturing method and graphene technology, applied to tires, household appliances, and other household appliances, can solve the problems of limiting tire driving speed, high tire heat generation, and easy damage, so as to improve the puncture resistance and reduce the wear and tear of tires. Increased weight and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

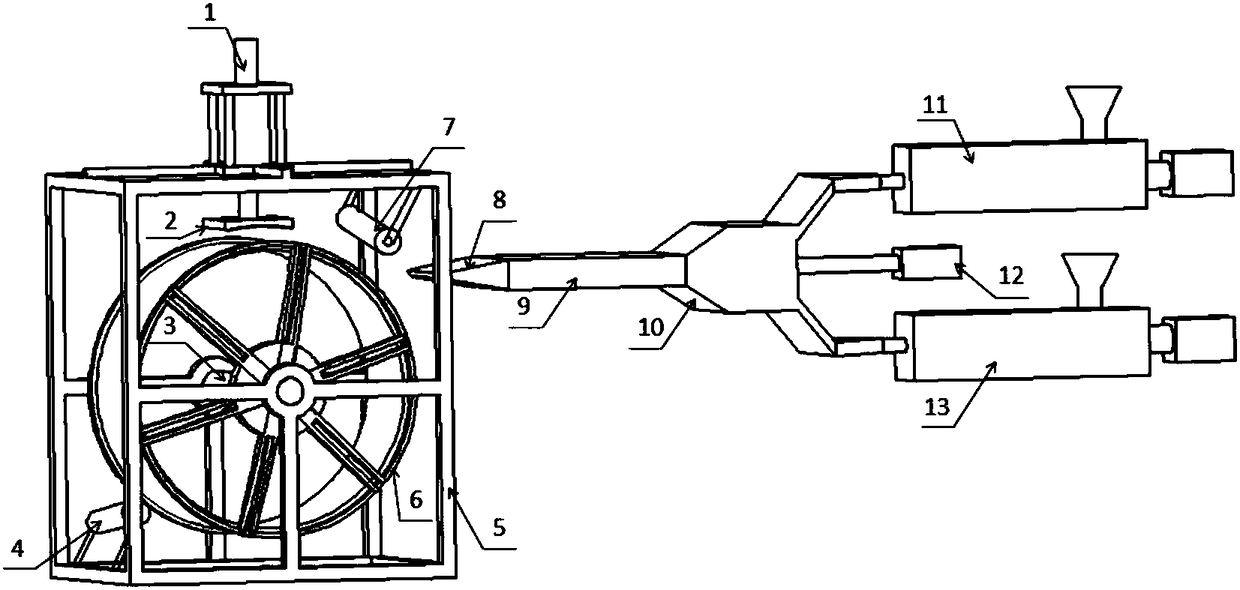

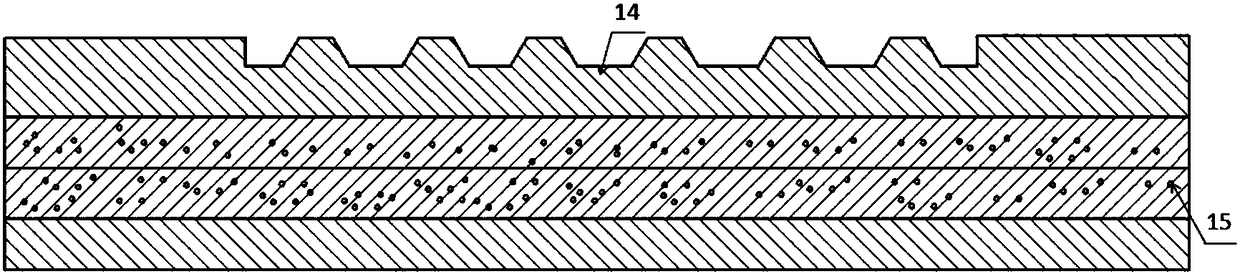

[0022] The present invention aims to provide a method and equipment for manufacturing a three-dimensional embossed graphene PU tire. The specific implementation method is as follows: firstly, the material formulation is carried out firstly, graphene is added into the traditional polyurethane tire material for blending according to a certain amount, and the tire carcass material is obtained. In the second step, the entire extruding section advances so that the machine head 8 is close to the rim; the graphene PU blended material is added to extruder one 11 and extruder two 13 for plasticization, and passes through confluence 10, stacker 9 and The head 8 extrudes the graphene PU14 material sheet; the rim 6 rotates counterclockwise under the drive of the rotating shaft 3, and the upper pressure roller 7 presses the sheet onto the rim, and the sheet is bonded to the rim and rotates with the rim. When the front part of the sheet turns to the lower pressure roller 4, the lower pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com