Preparation method of nickel hydroxide nanosheet array material growing on surface of foamed nickel

A nanosheet array, nickel hydroxide technology, applied in the field of new material technology and chemical synthesis, can solve the problems of many types and yields of polluting wastes, deviation from the concept of green chemical synthesis, cumbersome preparation process, etc. The effect of low equipment and energy requirements and high atomic economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take a piece of commercial nickel foam (0.15cm thick) and cut it into a 2x 2cm square of nickel foam. Take the cut foam nickel, place it in 50ml alcohol, ultrasonically clean it for 5 minutes, then take out the foam nickel and rinse the foam nickel with deionized water for 20 seconds.

[0037] Then place the rinsed nickel foam in 0.1M hydrofluoric acid solution and soak for 1 hour, take it out and place it in deionized water for ultrasonic cleaning for 5 minutes; after cleaning, immerse the foam nickel in 30ml of deionized water for natural oxidation for 2 days, and Under room temperature conditions, nickel hydroxide nanosheet array electrode materials grown vertically on the surface of nickel foam are obtained.

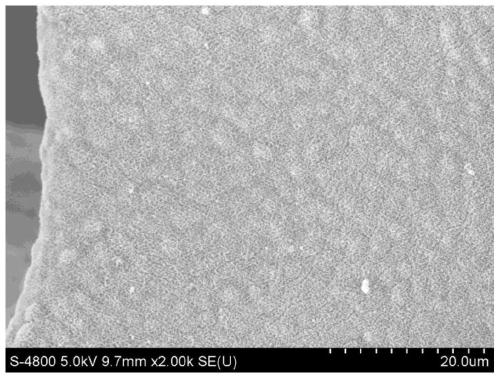

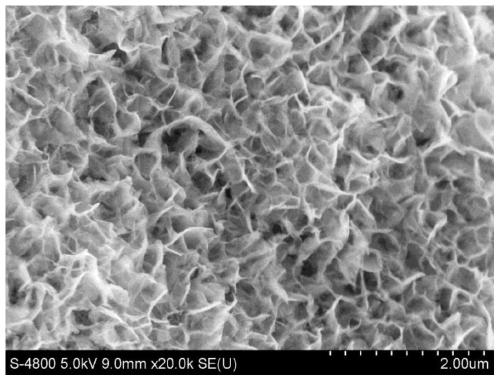

[0038] figure 1 It is a scanning electron microscope photo of the nickel hydroxide nanosheet array material grown on the surface of nickel foam obtained in this example. The photo shows the surface area of the nickel foam skeleton with a magnification of 2...

Embodiment 2

[0044]Take a piece of commercial nickel foam (0.15cm thick) and cut it into a 2x 2cm square of nickel foam. Take the cut foam nickel, place it in 50ml alcohol, ultrasonically clean it for 5 minutes, then take out the foam nickel and rinse the foam nickel with deionized water for 20 seconds.

[0045] Then place the rinsed nickel foam in 1M hydrofluoric acid solution to soak for 1 hour, take it out and place it in deionized water for ultrasonic cleaning for 5 minutes; Under room temperature conditions, nickel hydroxide nanosheet array electrode materials grown vertically on the surface of nickel foam are obtained.

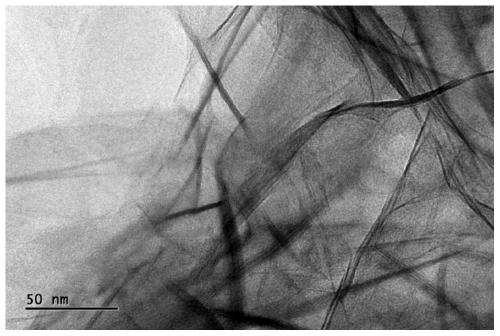

[0046] Figure 6 It is a transmission electron micrograph of the nickel hydroxide nanosheets prepared in the present embodiment, and the photo shows a single film-like nickel hydroxide nanosheet.

[0047] Figure 7 It is a scanning electron micrograph of the nickel hydroxide nanosheet array material grown on the surface of nickel foam prepared in this example. The...

Embodiment 3

[0049] Take a piece of commercial nickel foam (0.15cm thick) and cut it into a 2x 2cm square of nickel foam. Take the cut foam nickel, place it in 50ml alcohol, ultrasonically clean it for 5 minutes, then take out the foam nickel and rinse the foam nickel with deionized water for 20 seconds.

[0050] Then place the rinsed nickel foam in 0.5M hydrofluoric acid solution and soak for 2 hours, take it out and place it in deionized water for ultrasonic cleaning for 5 minutes; after cleaning, immerse the foam nickel in 42ml deionized water for natural oxidation for 5 days, react The temperature is room temperature, and the nickel hydroxide nanosheet array electrode material vertically grown on the surface of the nickel foam can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com