Cadmium sulfide-sulfur indium zinc heterojunction nanorod array composite material and preparation method thereof

A technology of cadmium sulfide nanorods and nanorod arrays, which is applied in electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of low utilization rate of photogenerated holes, high preparation cost of noble metals, unfavorable industrial production, etc., and improve the utilization of atoms High efficiency, strong photoelectric conversion performance, and enhanced electron directional migration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Pretreatment of FTO: FTO was ultrasonically cleaned with acetone, isopropanol and water mixed solution (volume ratio 1:1:1), and deionized water for 60 min and 15 min, respectively, and dried at 60 °C for later use.

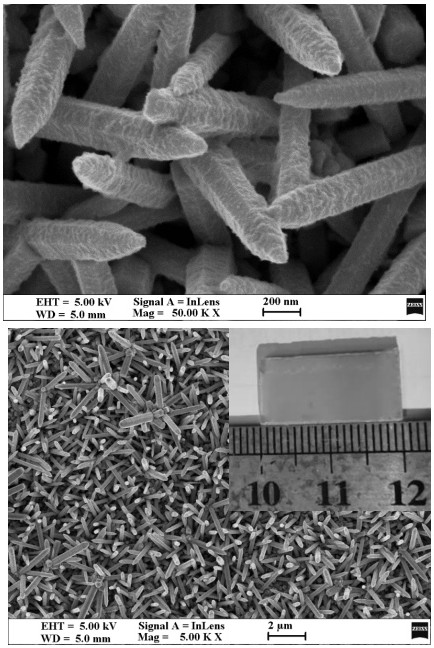

[0042] (2) Weigh 148.0mg of cadmium nitrate, 36.5mg of thiourea and 34.9mg of reduced cysteine (molar ratio is 1:1:0.6) and dissolve them in 20mL of deionized water, then transfer to a polytetrafluoroethylene reactor , lean the FTO against the polytetrafluoroethylene liner wall of the reactor at a certain angle, and keep the conductive side facing down. React at 160°C for 1 h, then raise the temperature to 180°C for 2.5 h, after the reaction, cool to room temperature, take out the sample, rinse twice with deionized water and ethanol, and dry in vacuum at 60°C to obtain cadmium sulfide nano rod array.

[0043] (3) Dissolve 152.8mg indium nitrate, 60.0mg zinc nitrate and 60.0mg thioacetamide (molar ratio 1:2:4) in 5mL glycerin and 15mL N,N-dimethylfor...

Embodiment 2

[0047] (1) Pretreatment of FTO: FTO was ultrasonically cleaned with acetone, isopropanol and water mixed solution (volume ratio 1:1:1), and deionized water for 60 min and 15 min, respectively, and dried at 60 °C for later use.

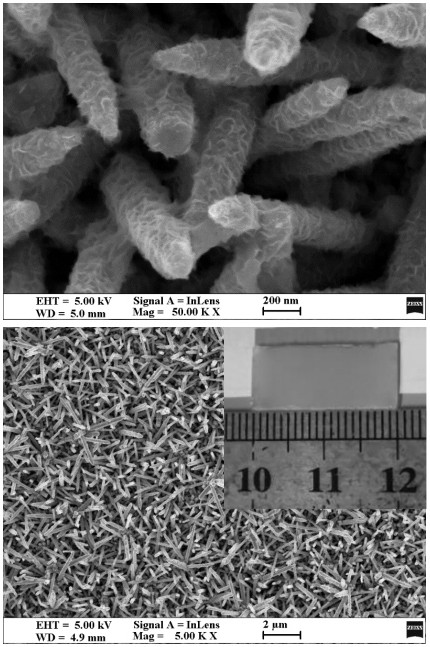

[0048] (2) Weigh 148.0mg of cadmium nitrate, 36.5mg of thiourea and 34.9mg of reduced cysteine (molar ratio is 1:1:0.6) and dissolve them in 20mL of deionized water, then transfer to a polytetrafluoroethylene reactor , lean the FTO against the polytetrafluoroethylene liner wall of the reactor at a certain angle, and keep the conductive side facing down. React at 160°C for 1 h, then raise the temperature to 180°C for 2.5 h, after the reaction, cool to room temperature, take out the sample, rinse twice with deionized water and ethanol, and dry in vacuum at 60°C to obtain cadmium sulfide nano rod array.

[0049] (3) Dissolve 152.8 mg indium nitrate, 27.3 mg zinc chloride and 60.0 mg thioacetamide (molar ratio 1:2:4) in 5 mL glycerol and 15 mL N,N-dimet...

Embodiment 3

[0053] (1) Pretreatment of FTO: FTO was ultrasonically cleaned with acetone, isopropanol and water mixed solution (volume ratio 1:1:1), and deionized water for 60 min and 15 min, respectively, and dried at 60 °C for later use.

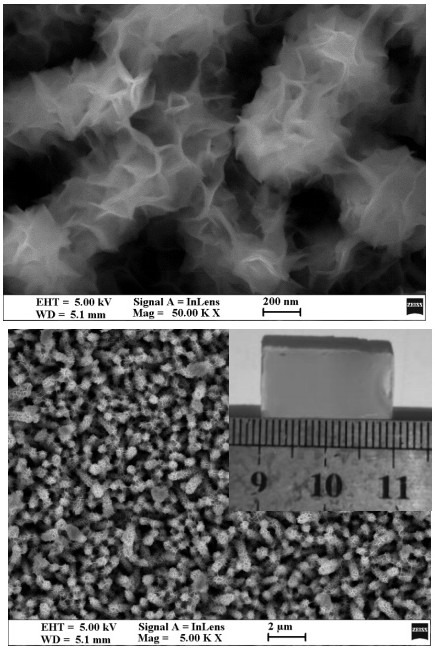

[0054] (2) Weigh 148.0mg of cadmium nitrate, 36.5mg of thiourea and 34.9mg of reduced cysteine (molar ratio is 1:1:0.6) and dissolve them in 20mL of deionized water, then transfer to a polytetrafluoroethylene reactor , lean the FTO against the polytetrafluoroethylene liner wall of the reactor at a certain angle, and keep the conductive side facing down. React at 160°C for 1 h, then raise the temperature to 180°C for 2.5 h, after the reaction, cool to room temperature, take out the sample, rinse twice with deionized water and ethanol, and dry in vacuum at 60°C to obtain cadmium sulfide nano rod array.

[0055] (3) Dissolve 117.3mg of indium chloride, 27.3mg of zinc chloride and 60.0mg of thioacetamide (molar ratio 1:2:4) in 5mL of glycerol and 15mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com