Switch plug profiling equipment

A technology of molding equipment and plugs, which is applied in the field of fully automatic molding equipment for reversing light switch plugs, can solve problems such as poor quality stability, large bending resilience, and large human factors, so as to achieve good product consistency, The effect of low manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

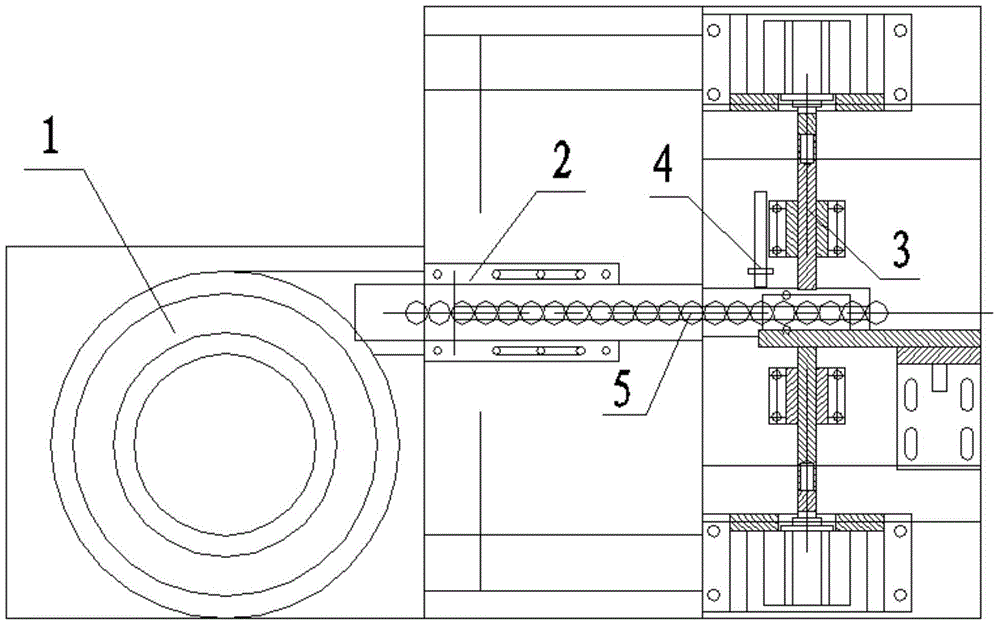

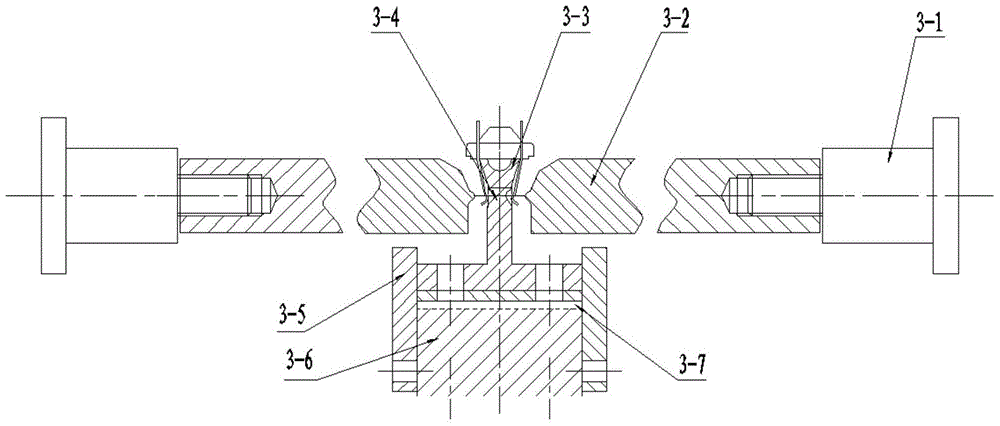

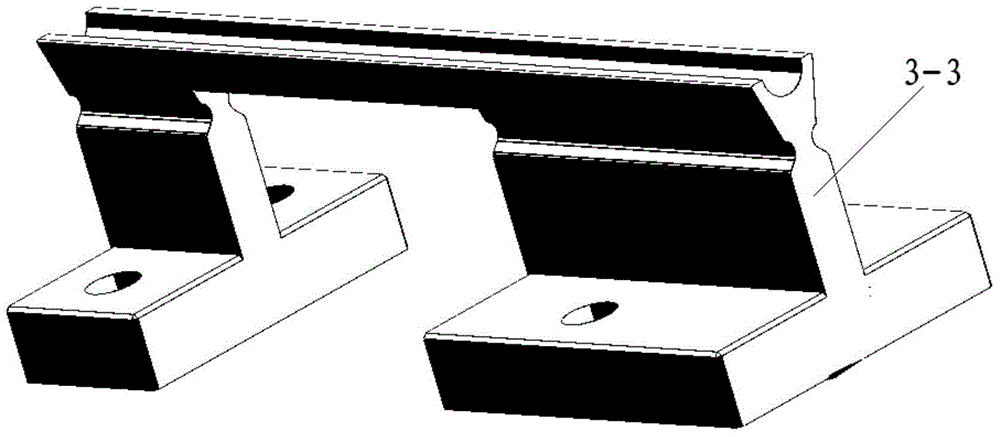

[0017] Such as Figure 1-4 As shown, the reversing light switch plug automatic profiling equipment of this embodiment includes a vibrating plate 1, a linear vibrator 2 connected to the outlet of the vibrating plate 1 and used to transport the plugs to the processing part one by one, and a linear vibrator for detecting A sensor 4 for the plug position and a profiling tool 3 for profiling the plug, the sensor 4 is arranged between the linear vibrator 2 and the plug profiling tool 3; the plug profiling tool 3 includes a Forming die and the pressing die that are symmetrically arranged on both sides thereof, the two sides of the pressing die are symmetrically provided with grooves matched with the punch; the pressing die includes activities for determining the size of the pressing die The die 3-3 and the fastening die 3-4 used to ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com