Electromagnetic forming device and method for providing continuous electromagnetic force

A technology of electromagnetic forming and electromagnetic force, which is applied in the field of material processing, can solve the problems of slow increase of electromagnetic force, low forming efficiency, and influence on forming accuracy, and achieve the effect of increasing pulse current time, realizing flexible manufacturing, and improving forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

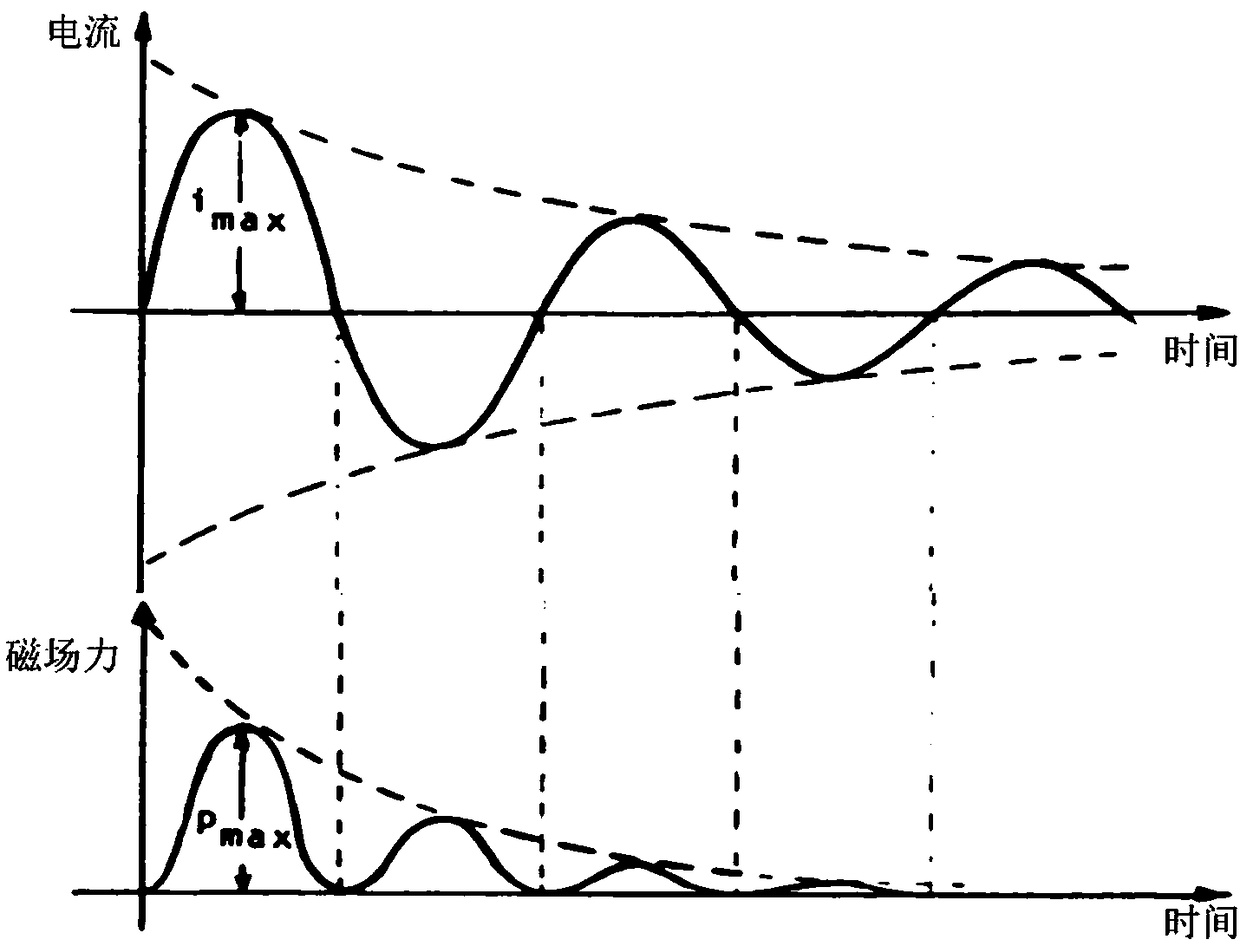

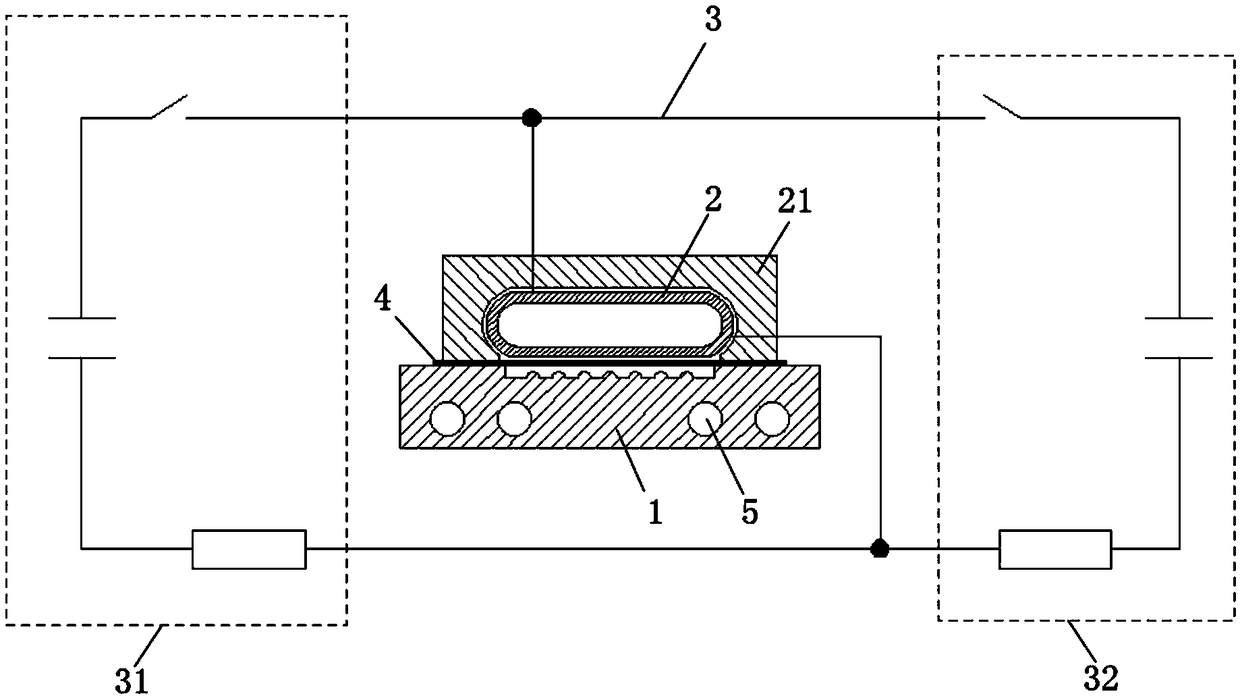

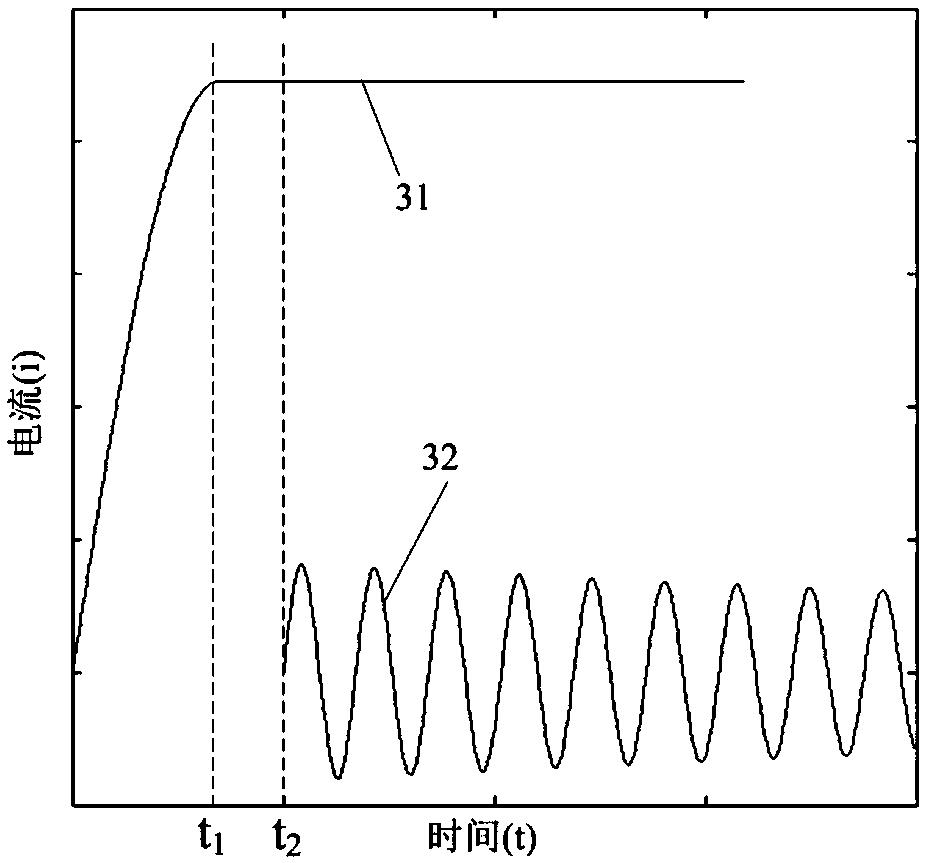

[0039] Such as Figure 1 to Figure 5 As shown, the electromagnetic forming device providing continuous electromagnetic force in this embodiment includes a die 1, a coil 2 and a discharge circuit 3, the coil 2 is arranged on the die 1, and the sheet material 4 to be formed is arranged on the die 1 and the coil 2, the coil 2 is electrically connected to the discharge circuit 3, and the discharge circuit 3 includes a steady-state magnetic field discharge circuit 31 capable of generating a steady-state magnetic field and an alternating magnetic field discharge circuit 32 capable of generating an alternating magnetic field, the steady-state magnetic field discharge circuit 31 and The alternating magnetic field discharge circuits 32 are electrically connected to the coils 2 respectively. The steady-state magnetic field discharge circuit 31 can generate a large value of steady-state current to determine the size of the magnetic field, and the alternating magnetic field discharge circ...

Embodiment 2

[0047] The electromagnetic forming device providing continuous electromagnetic force of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 6 and Figure 7 As shown, the bottom surface of the cavity 11 in this embodiment is a concave fine structure. The sheet material 4 is deformed under the action of the magnetic field force, and is attached to the bottom surface of the cavity 11 of the die 1 to obtain the sheet material 4 with a concave fine structure.

Embodiment 3

[0049] The electromagnetic forming device providing continuous electromagnetic force of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 8 and Figure 9 As shown, the bottom surface of the cavity 11 in this embodiment is a planar structure without protrusions and indentations. The sheet material 4 is deformed under the action of the magnetic field force, and is attached to the bottom surface of the cavity 11 of the die 1 to obtain the sheet material 4 with a planar structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com