Hole-bottom tubular linear motor electric impactor

A technology of linear motors and impactors, applied in the direction of electromechanical devices, electric components, percussion drilling, etc., can solve the problems of hydraulic impactors affecting the working performance, unsatisfactory, and affecting drilling efficiency, etc., to achieve flexible structural size design, The effect of low maintenance cost and simple and strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

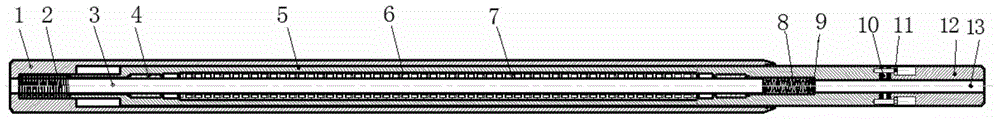

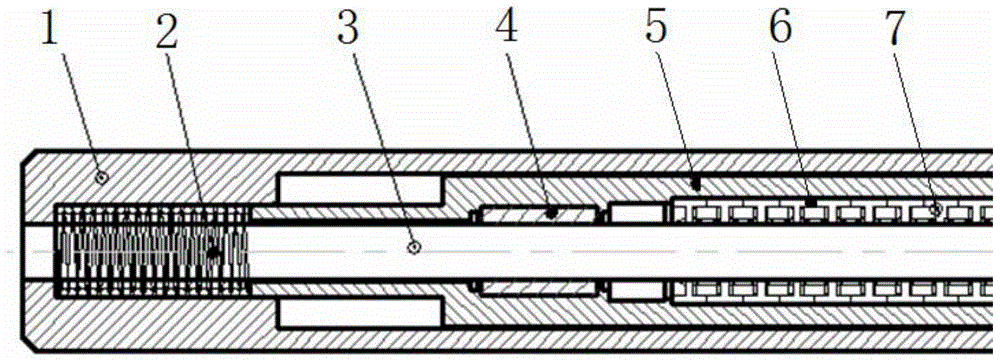

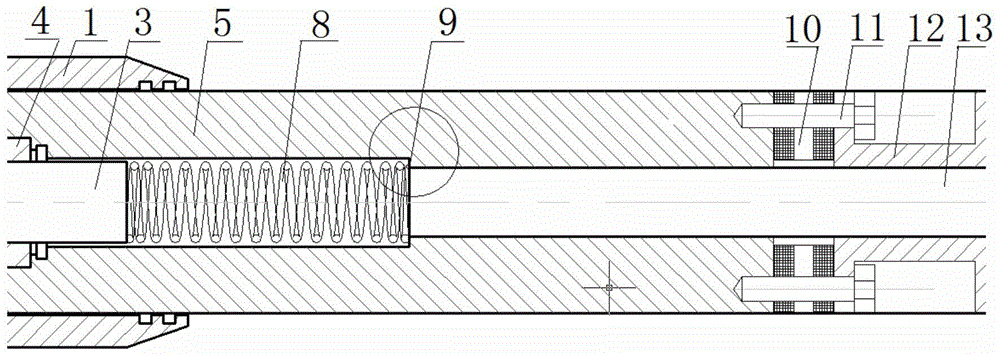

[0027] Embodiment 1: A kind of hole bottom tubular linear motor electric impactor provided by the present invention, its structure is as follows figure 1 , 2 , 3, including motor outer cylinder 1, permanent magnet rod 3, linear ball bearing 4, mover outer ring 5, mover silicon steel sheet 6, mover coil 7, damping spring, buffer gasket 11 and base 12, The motor outer cylinder 1 is the shell of the entire electric impactor, the motor outer cylinder 1 is used to connect with the drilling tool, the permanent magnet rod 3 of the linear motor is fixed on the motor outer cylinder 1, and the permanent magnet rod 3 is used as a straight line The stator of the motor, the permanent magnet rod 3 is a permanent magnet, and the outer ring of the permanent magnet is wrapped with a stainless steel layer. The center of the permanent magnet rod 3 has a chip removal channel 13 for chip removal, and the chip removal channel 13 runs through the entire motor. impactor; the mover outer ring 5 is th...

Embodiment 2

[0030] Embodiment 2: A hole-bottom tube-type linear motor electric impactor provided by the present invention, its structure is basically the same as that of Embodiment 1. The cylindrical linear motor adopted by the invention is suitable for the inner hole space of the drill pipe, the length of the mover and the stator is not limited by the space, and the power of the impactor can be flexibly designed, so that it has the characteristics of large electromagnetic force.

[0031] The main dimensions and electromagnetic parameters of the tubular linear motor electric impactor of the present invention are shown in the following table: some symbols in the table refer to Figure 5 .

[0032]

[0033] It can be seen from the above table: the impactor is calculated according to the impact stroke of 30mm and the mass of the mover of 10kg, and the cylindrical permanent magnet motor with an outer diameter of 62mm is the impactor. The single stroke time is t≈0.1s, α≈3~9g, v≈3~9m / s, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com