Main valve of four-way reversing valve and four-way reversing valve provided with main valve

A four-way reversing valve and valve body technology, applied in the field of valve components, can solve the problems of large friction between the piston and the valve body, inability to apply to the air conditioning system, poor actuation performance, etc., so as to improve the actuation performance and improve the adaptability properties, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the invention is to optimize the design of the main valve component and pilot valve component of the four-way reversing valve so as to improve its working performance and adaptability. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

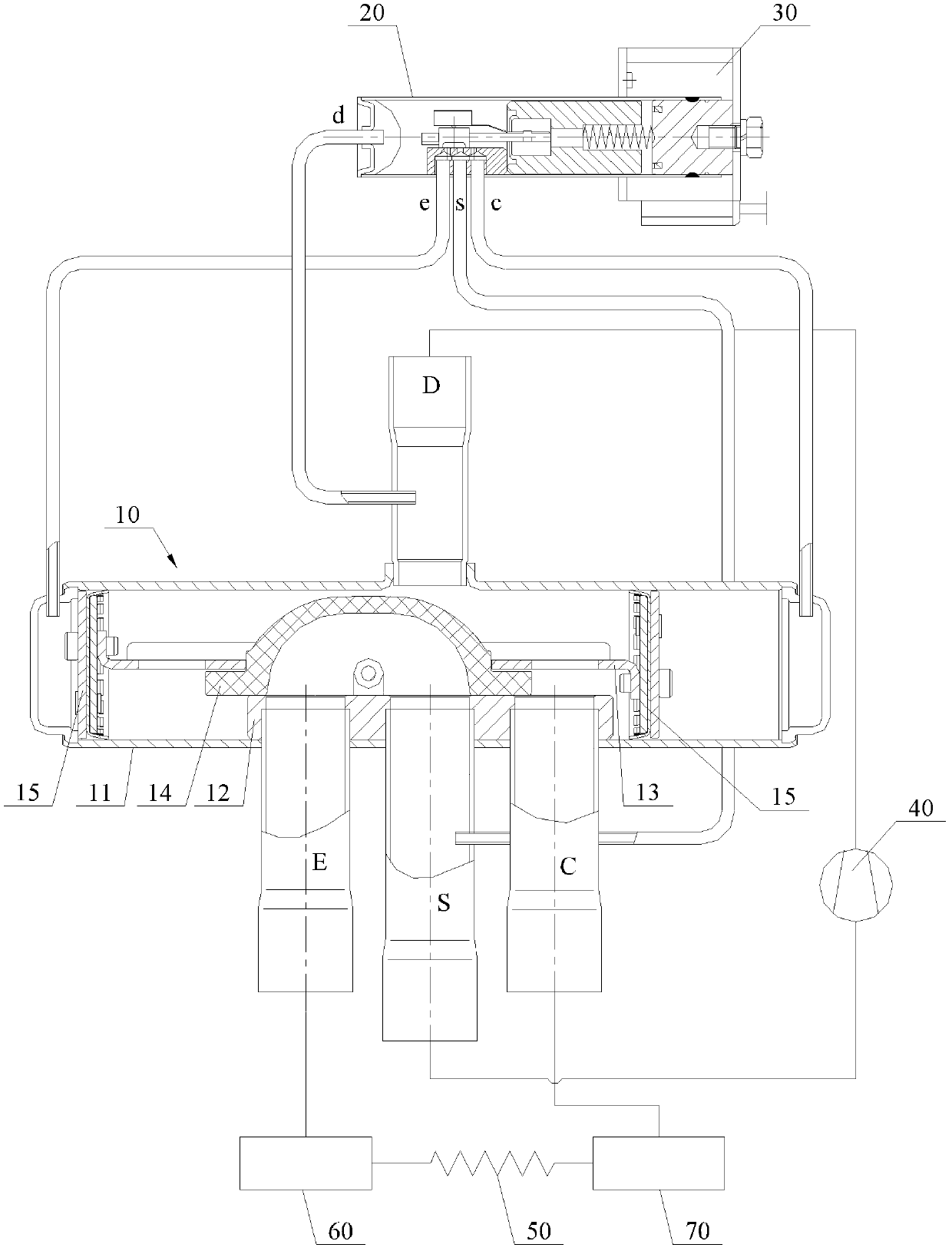

[0031] See figure 1 , which shows a schematic diagram of the application principle of the four-way reversing valve described in this embodiment.

[0032] Same as the prior art, the four-way reversing valve has a main valve 10, a pilot valve 20 and an electromagnetic coil 30 sleeved outside the pilot valve. The four-way reversing valve is interposed in the refrigerant circuit composed of the compressor 40, the condenser 50, the indoor heat exchanger 60 and the outdoor heat exchanger 70, and the direction of the refrigerant circuit is switched through the main valve 10, thereby switching between cooling and heating .

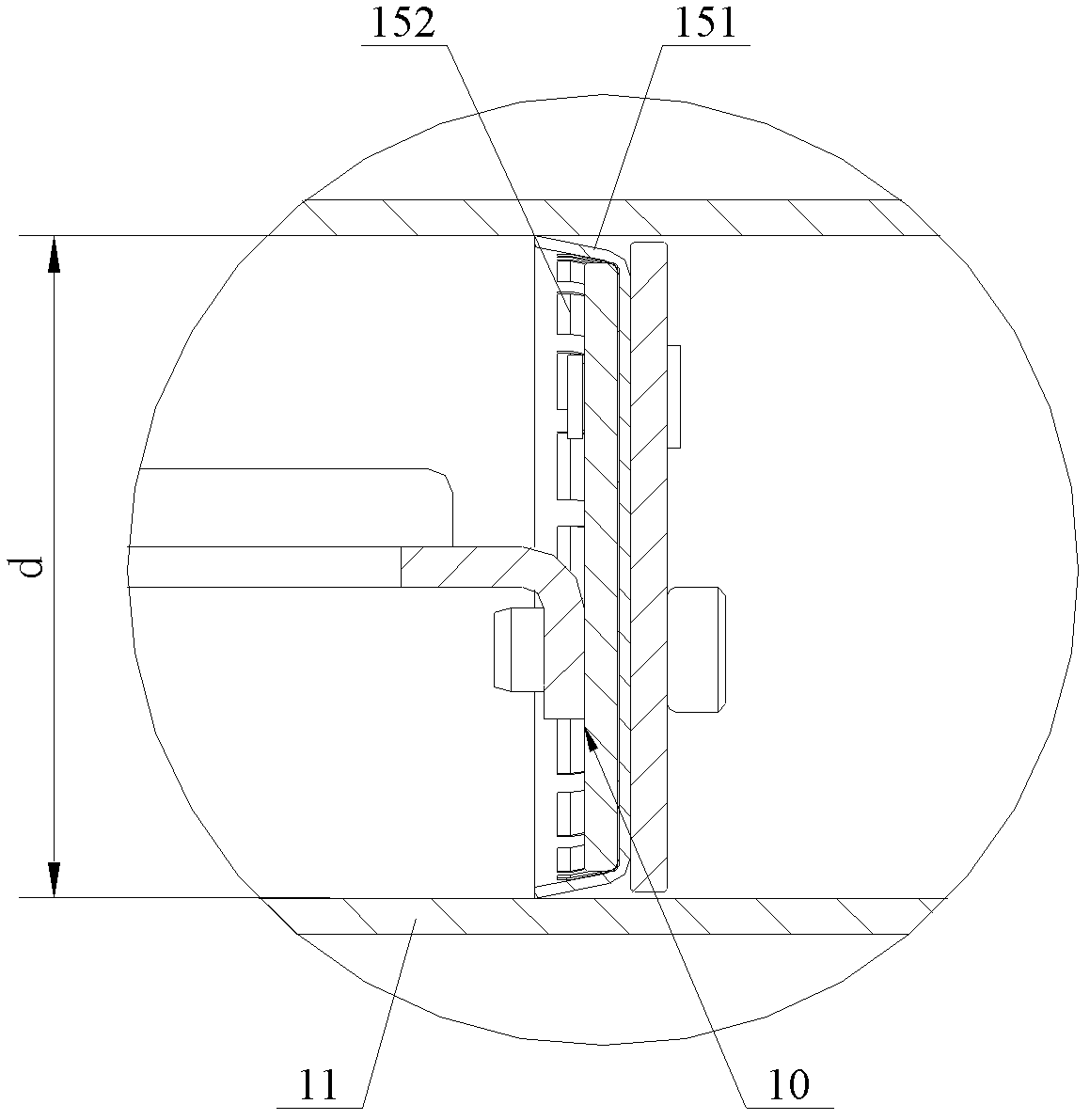

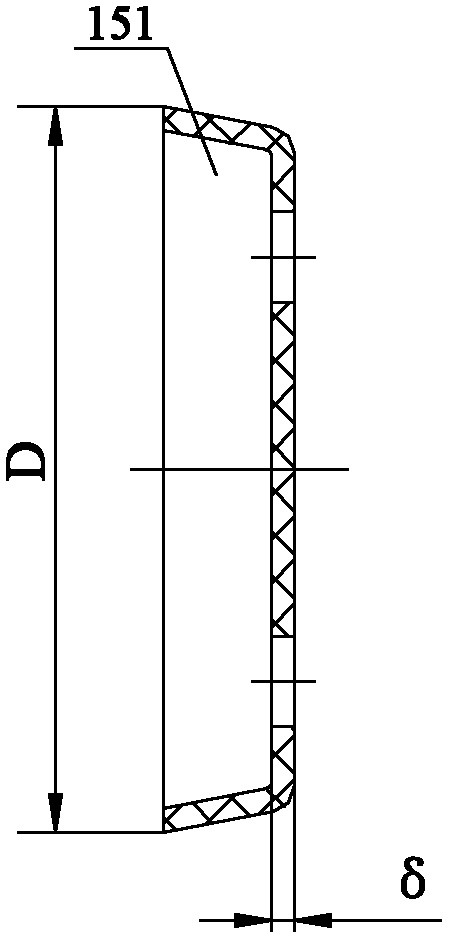

[0033] Wherein, the cylindrical valve body 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com