Soft magnetic high-entropy alloy material of island magnetic crystal structure and preparation method thereof

A technology of high-entropy alloys and magnetocrystals, applied in magnetic materials, metal processing equipment, inductors/transformers/magnets, etc., can solve problems such as low resistivity, low toughness, and high brittleness of FeNi alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

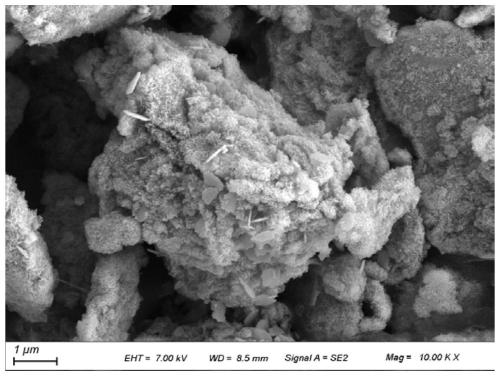

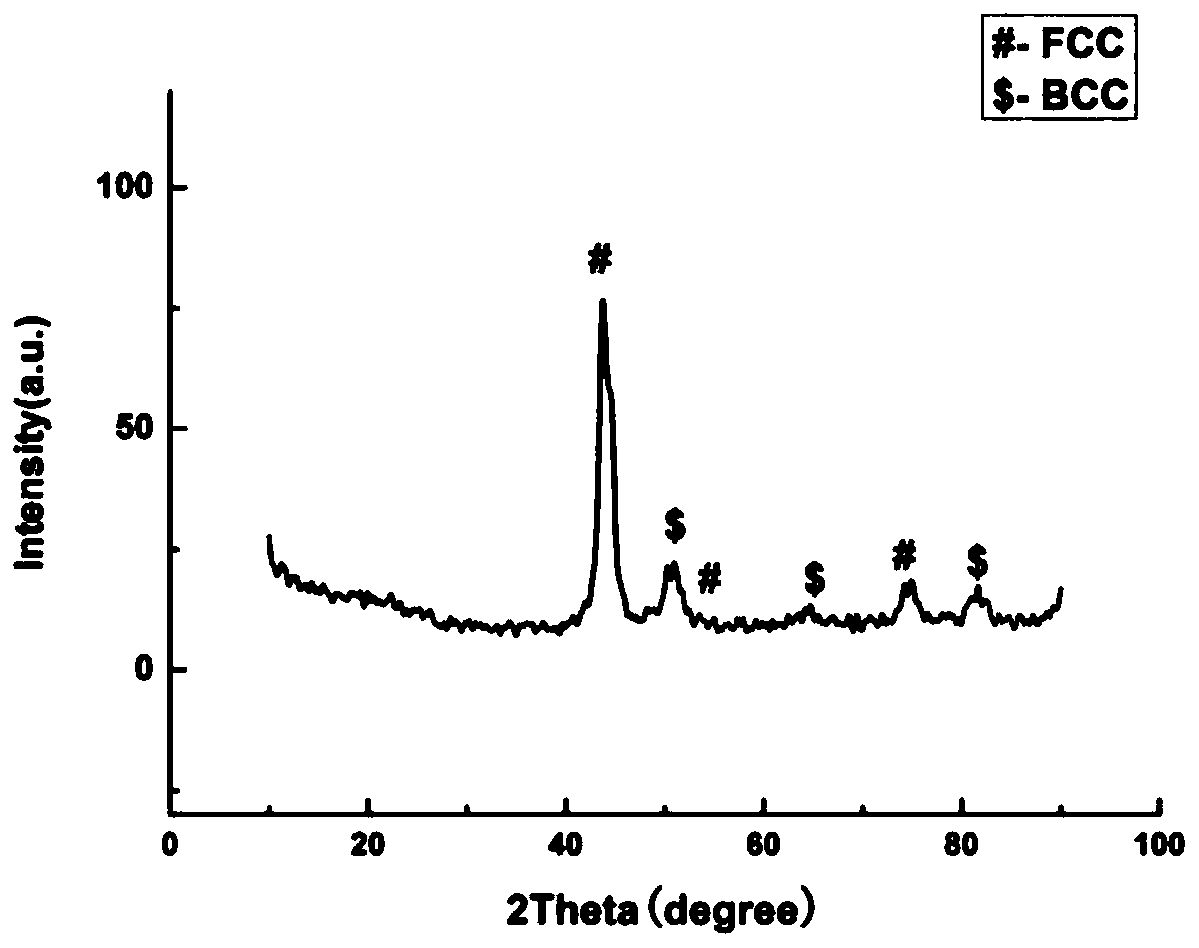

[0025] A method for preparing a soft magnetic high-entropy alloy material with an island magnetic crystal structure, comprising the steps of:

[0026] 1) Weigh Fe, Ni, Co, Cr, Cu metal powders with a purity of 99.99% in a molar ratio of 1:1:2:1:1, and the particle size of the powder is ≤45 μm;

[0027] 2) Put the powder weighed in step 1) into a stainless steel ball mill tank, use stainless steel balls as the grinding body, and perform ball milling at a ball-to-powder mass ratio of not less than 10:1. Before ball milling, use a vacuum machine to evacuate for 3 minutes, and then rush into 0.5MPa argon as a protective gas; first perform dry milling, the speed of the ball mill is 400r / min, and the rotation direction is adjusted every 60 minutes.

[0028] Add absolute ethanol to the powder after dry milling for 45 hours, and carry out wet milling for 5 hours at a wet milling speed of 200 r / min. After the ball milling, take out the ball mill jar, open the lid of the ball mill jar ...

Embodiment 2

[0034] A method for preparing a soft magnetic high-entropy alloy material with an island magnetic crystal structure, comprising the steps of:

[0035]1) Weigh Fe, Ni, Co, Mn, Al metal powders with a purity of 99.99% in a molar ratio of 1:1:1:1:1, and the particle size of the powder is ≤45 μm;

[0036] 2) Put the powder weighed in step 1) into a stainless steel ball mill tank, use stainless steel balls as the grinding body, and perform ball milling at a ball-to-powder mass ratio of not less than 10:1. Before ball milling, use a vacuum machine to evacuate for 3 minutes, and then rush into 0.5MPa argon as a protective gas; first perform dry milling, the speed of the ball mill is 400r / min, and the rotation direction is adjusted every 60 minutes.

[0037] Add absolute ethanol to the powder after dry milling for 40 hours, carry out wet milling for 5 hours, and the wet milling speed is 300r / min. After the ball milling, take out the ball mill jar, open the lid of the ball mill jar to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic saturation | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com