Ferrite material, small high-current laminated chip broadband magnetic bead and its preparation method

A ferrite material and ferrite technology, applied in the field of inductance, can solve the problems of small frequency range, long production cycle, and low current resistance of magnetic beads, and achieve the ability to suppress electromagnetic interference, improve production efficiency, and reduce parasitic capacitance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

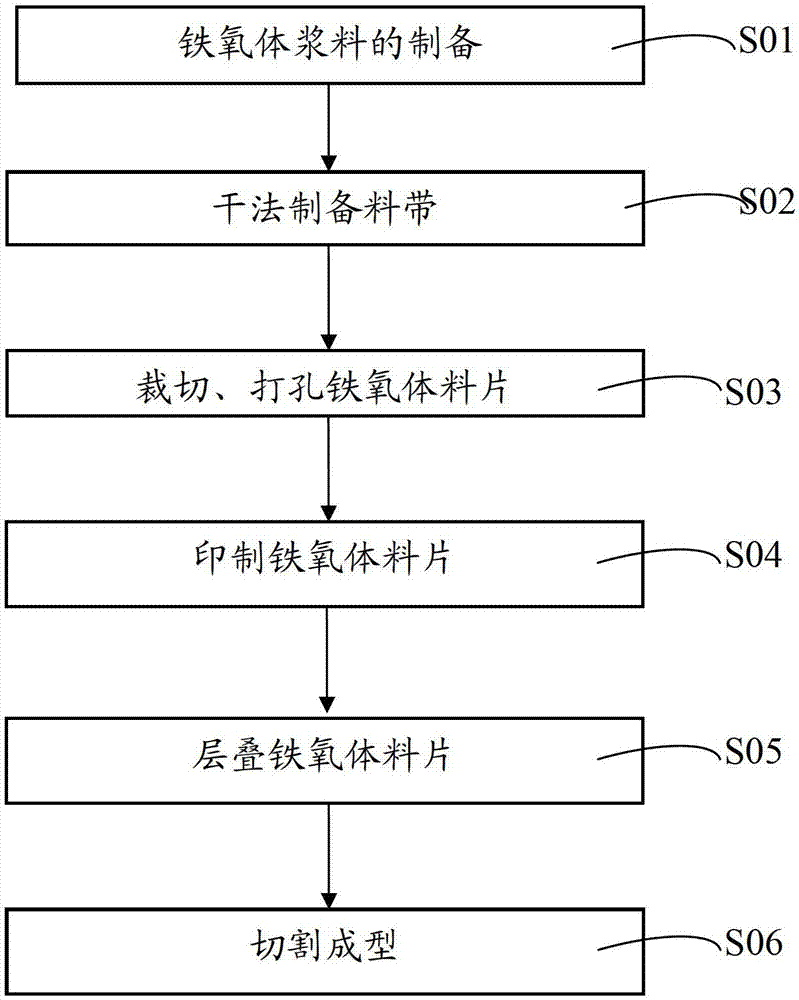

[0034] S01. Preparation of ferrite slurry: mix the ferrite material of the above formula with solvent, binder and plasticizer by ball milling to prepare ferrite slurry; wherein, the ferrite material, solvent, binder The weight ratio of agent and plasticizer is (55~59): (34~38): (4~6): (1~3);

[0035] S02. Preparation of material tape by dry method: apply the ferrite slurry prepared in step S01 on the surface of PET release film by scraper molding method, and dry to obtain a ferrite film material tape;

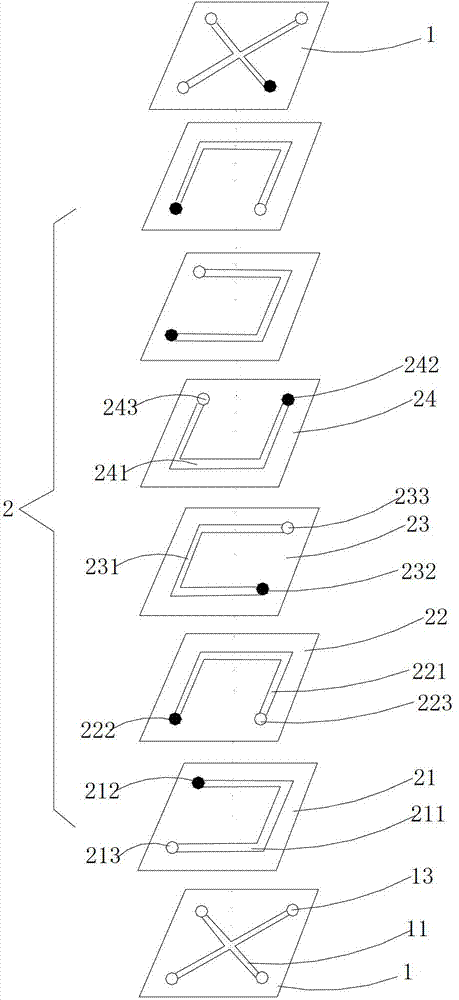

[0036] S03. Cutting and perforating the ferrite material sheet: cutting the ferrite film material strip prepared in step S02 into multiple ferrite material sheets, and opening a lead-out hole and connection on each piece of the ferrite material sheet Holes, and in two adjacent ferrite sheets, according to the lamination design structure sequence of the ferrite diaphragm of the magnetic bead, the lead-out hole on one ferrite sheet corresponds to the connection hole position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com