Novel gradient asymmetric air gap electrical excitation motor

An electrical excitation, asymmetric technology, used in motors, synchronous motors for single-phase current, electric vehicles, etc., can solve the problem of low output torque and output power, little difference in motor drive performance, and reduced torque output capability. and other problems, to achieve the effect of high magnetic permeability, high hardness, and improved forward drive torque and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

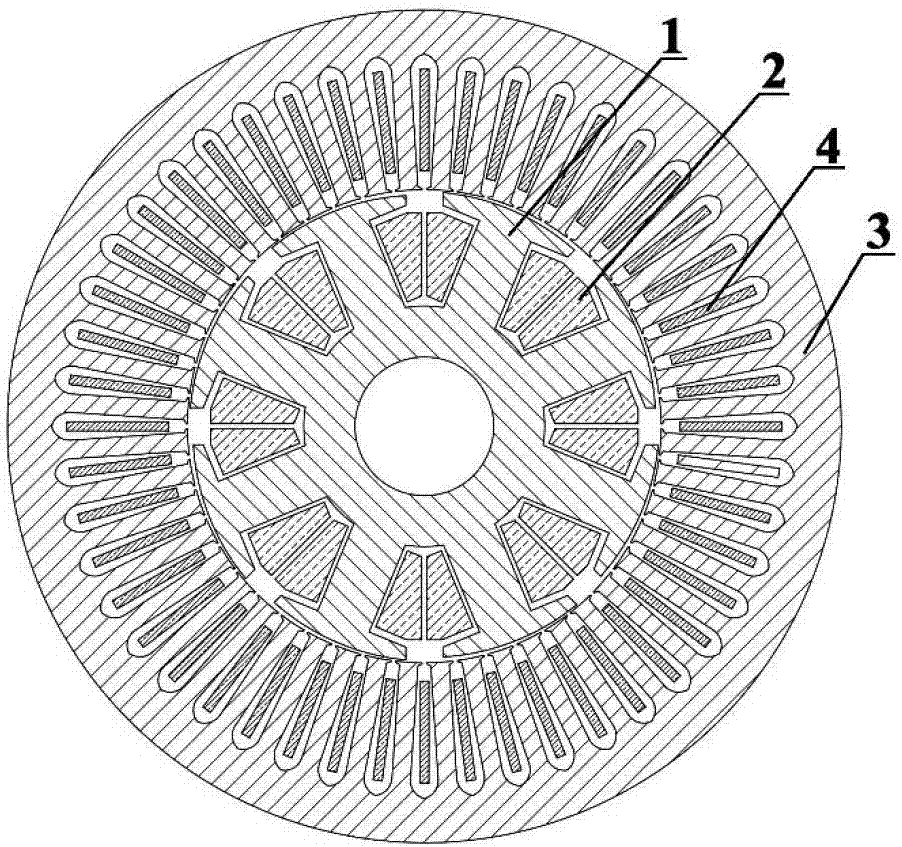

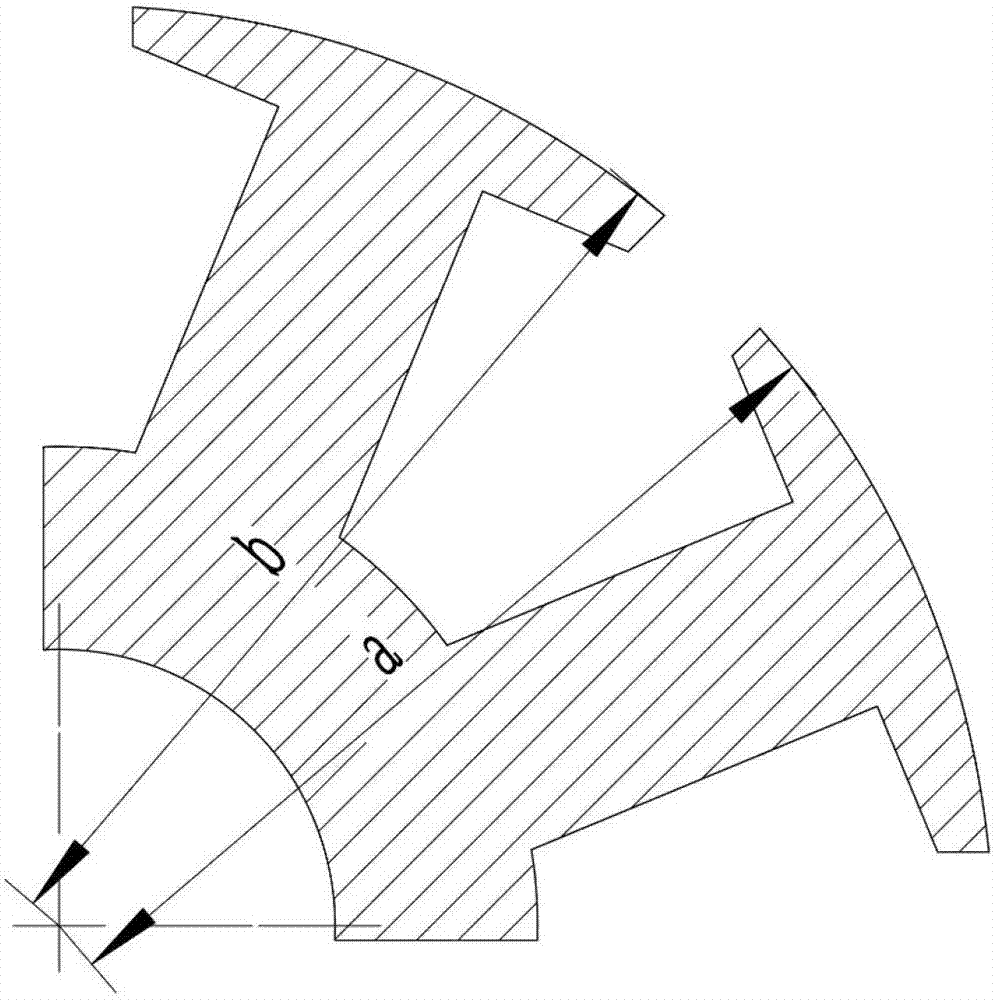

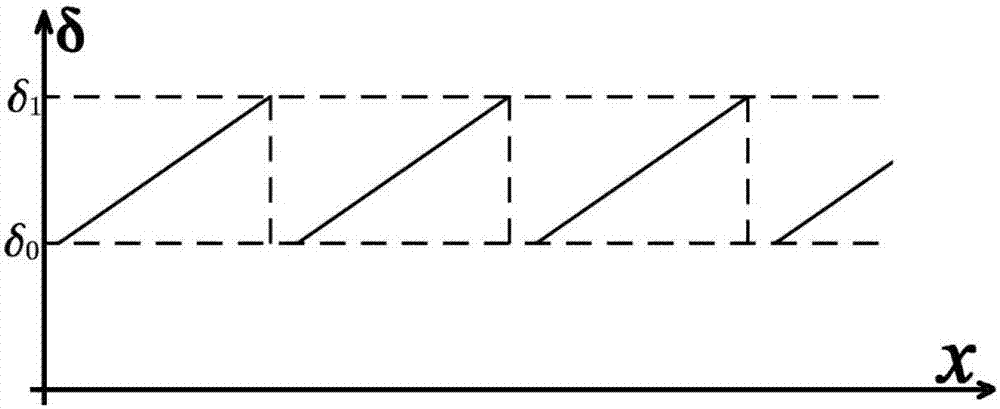

[0030] Such as figure 1 As shown in the figure, the new electric excitation motor with gradually changing asymmetric air gap adopts the electric excitation structure with gradually changing asymmetric air gap. The winding 2 is wound on the pole shoe of the electric excitation core 1, and a stable electric excitation magnetic field with alternating magnetic poles is generated after power-on. The stator winding 4 is wound in the slot of the stator iron core 3, and the inner surface of the stator iron core 3 is in contact with the electric excitation magnet. The width δ of the air gap between the outer surfaces of the core 1 is gradual and asymmetric, so as to provide an asymmetric periodic excitation magnetic field along the outer surface of the electrically excited core 1 for the driving motor of the electric vehicle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com