A method capable of improving the magnetic saturation of cemented carbide calcined billets

A cemented carbide pre-burning technology, which is applied in the field of cemented carbide processing, can solve problems such as uneven magnetic saturation, different carbon content, and carburization of cemented carbide pre-sintered billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A kind of method of the present invention can promote the magnetic saturation of cemented carbide calcined billet, it comprises the steps:

[0021] Take an appropriate amount of solid paraffin and put it into the preset container;

[0022] Place the vessel that has been filled with solid paraffin on a heating device for heating, and heat until the solid paraffin melts into a liquid state;

[0023] Putting cemented carbide calcined billets into the vessel in batches, and completely soaking them in liquid paraffin;

[0024] Control the temperature during the soaking process, and soak for a certain period of time according to the carbon content of the calcined billet;

[0025] When the immersion time is up, take out the pre-sintered cemented carbide billet, and sinter it according to the conventional sintering method in the prior art; thus obtain a cemented carbide product with enhanced magnetic saturation and uniform magnetic saturation.

[0026] Wherein, said controlli...

no. 1 example

[0031] Take a cemented carbide product with a component of 12wt.% Co and a WC particle size of 0.4 μm, and immerse it in liquid paraffin with a melting point of 58°C; before implementation, the magnetic saturation of the cemented carbide calcined billet is 72%;

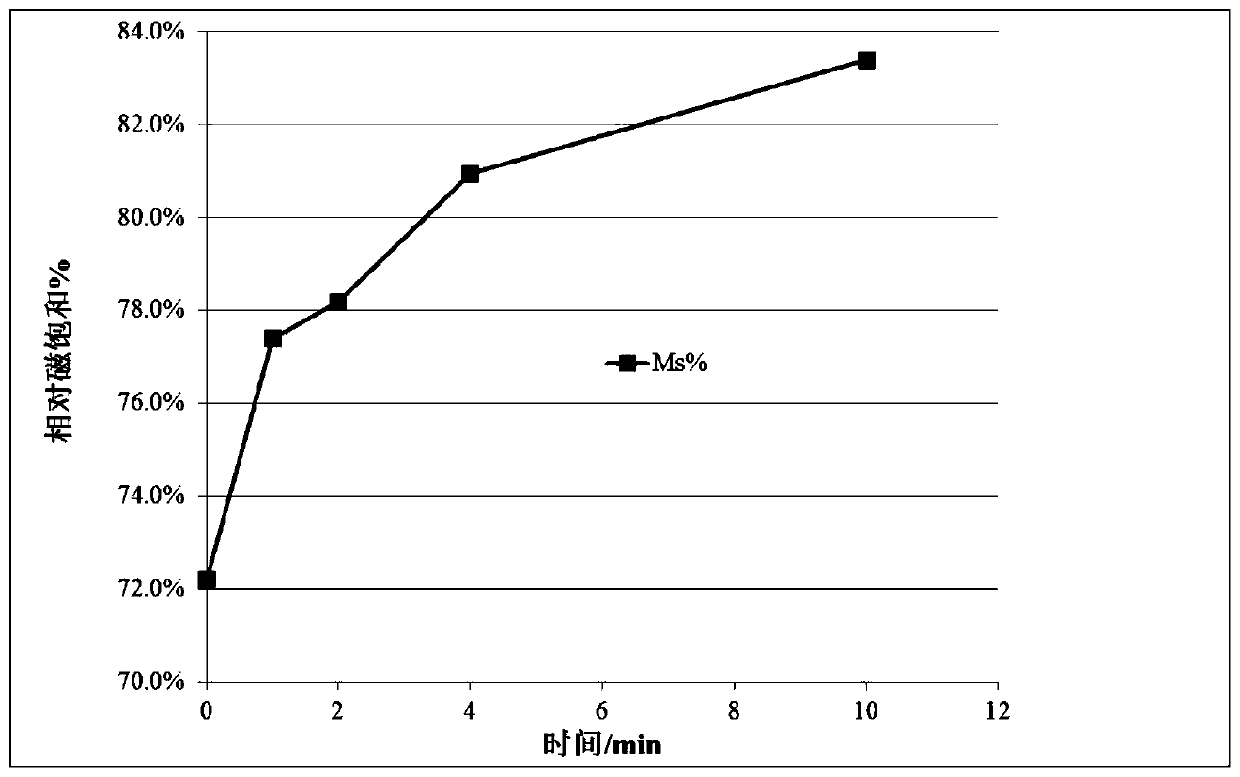

[0032] figure 1 is the corresponding relationship between the increase in magnetic saturation and the soaking time of the product, given by figure 1 It can be seen that the magnetic saturation increases significantly with the increase of soaking time;

[0033] When the product is soaked for 2 minutes, the magnetic saturation increases to 78.1%, when the product is soaked for 4 minutes, the magnetic saturation increases to 81%, when the product is soaked for 10 minutes, the magnetic saturation increases to 83%;

[0034] For this reason, the soaking time of the cemented carbide calcined compact can be determined according to the carbon content requirement (i.e. the degree of magnetic saturation) of the calcined compact...

no. 2 example

[0036] Take a cemented carbide product with a component of 3wt.% Co and a WC particle size of 1.0 μm, and immerse it in liquid paraffin with a melting point of 64°C; before implementation, the magnetic saturation of the cemented carbide calcined billet is 74%;

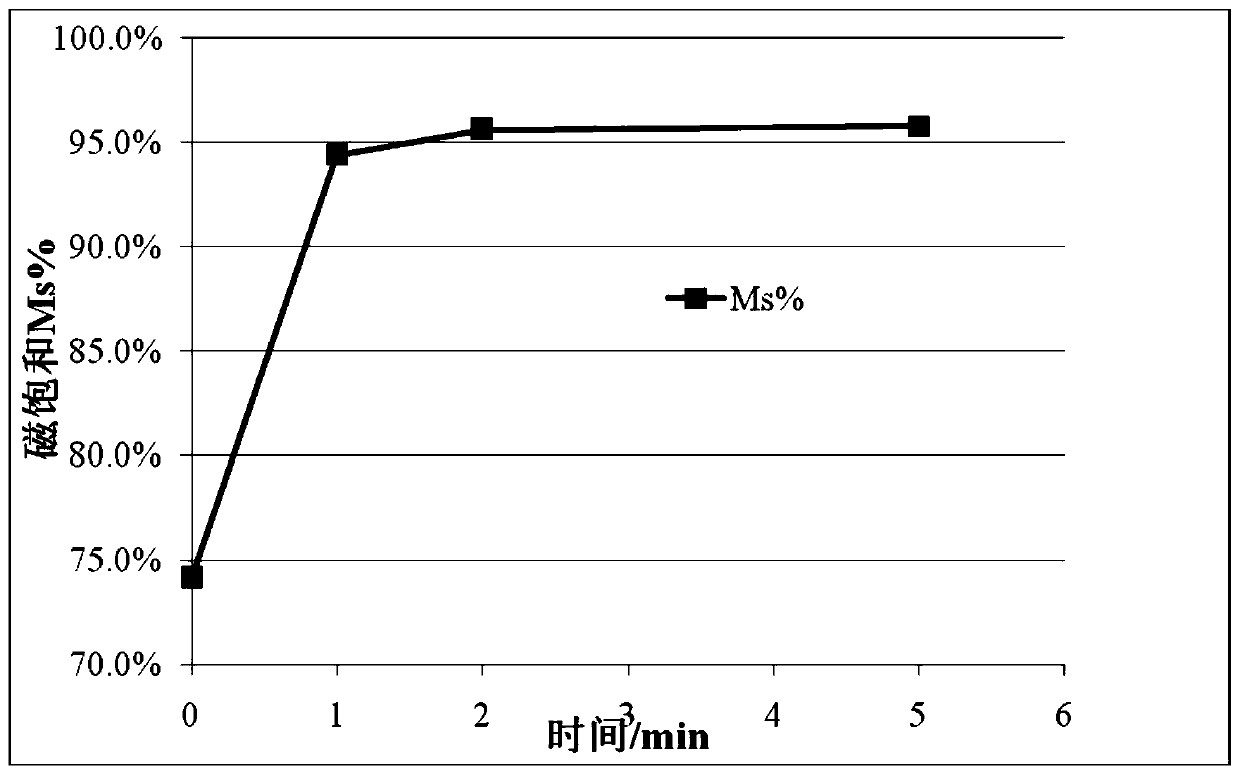

[0037] figure 2 is the corresponding relationship between the increase in magnetic saturation and the soaking time of the product, given by figure 2 It can be seen from the figure that as the soaking time increases, the magnetic saturation increases significantly; when it increases to a certain extent, as the soaking time continues to increase, the magnetic saturation increases slowly;

[0038] When the product is soaked for 1 minute, the magnetic saturation increases to 94%, when the product is soaked for 2 minutes, the magnetic saturation increases to 96%, when the product is soaked for 5 minutes, the magnetic saturation increases to 96.5%;

[0039] For this reason, the soaking time of the cemented carbide calcine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com