Permanent-magnet DC brushless motor of refrigerator compressor

A refrigerator compressor, permanent magnet DC technology, applied in electromechanical devices, electrical components, magnetic circuit static parts and other directions, can solve the problems of single model, waste of energy, complex process, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

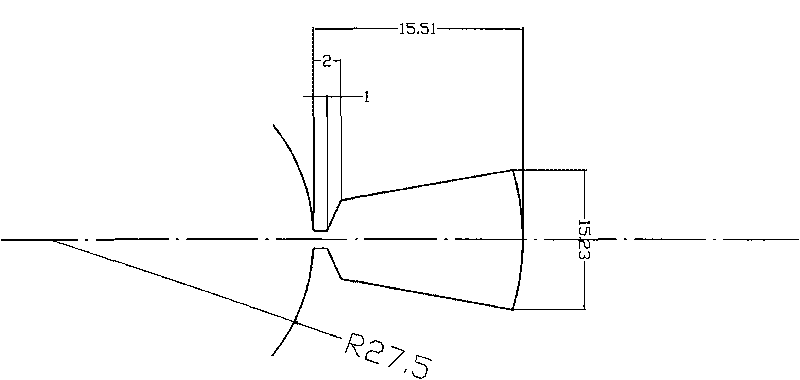

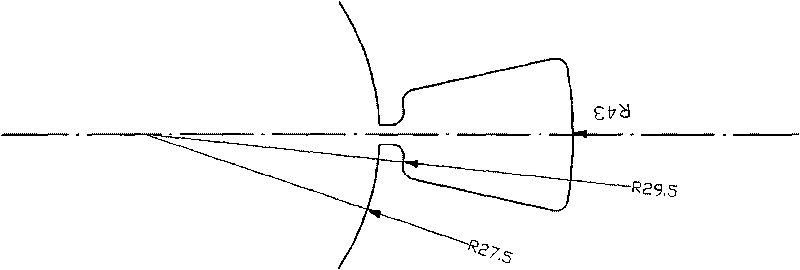

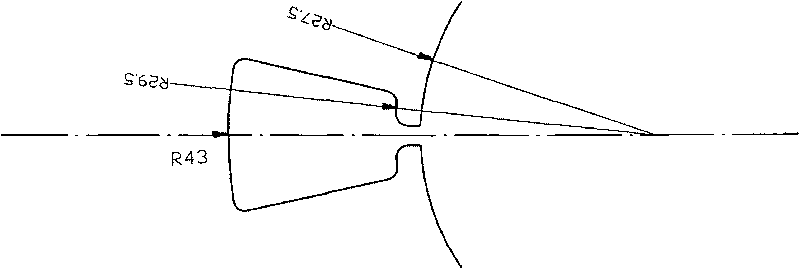

[0022] A permanent magnet DC brushless refrigerator compressor motor, which includes a rotor, a stator, and a circuit control system. The outer edge of the concentric groove shape has a radius of curvature of 43mm, the outer radius of the choke at the bottom of the concentric groove is 29.5mm, and the inner base circle radius of the choke is 27.5mm. As an improvement, the winding distribution on the stator adopts fractional concentrated winding, and the pole pitch of each pole of each phase is 1 / 2. The rotor adopts a built-in magnetic structure.

[0023] Other structural principles are similar to the traditional rotor, stator, and circuit control system, and will not be described in depth in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com