High-pressure steam emulsion breaking method for aqueous enzymatic extraction of soybean oil

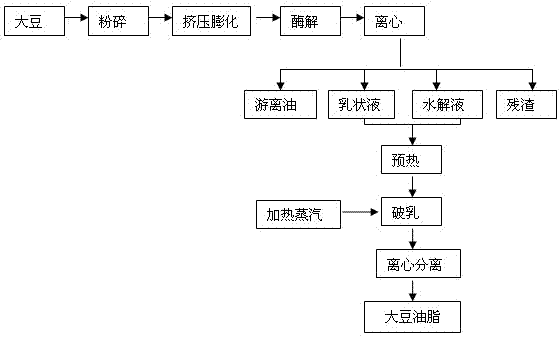

A soybean oil and high-pressure steam technology is applied in the production of fat oil/fat, refining of fat oil/fat, and fat generation, which can solve the problems of long demulsification time and low demulsification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

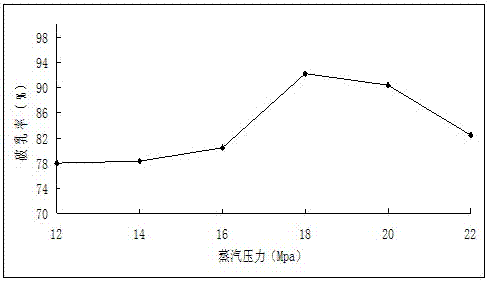

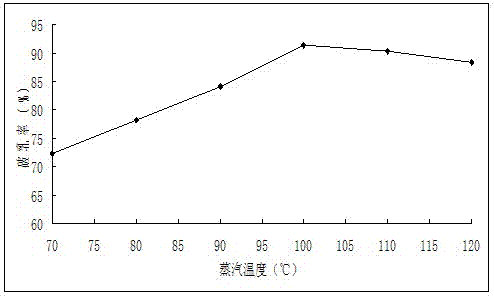

[0021] Example Screening Test of Optimal Parameters of High Pressure Steam Demulsification Process

[0022] 1 Materials and methods

[0023] 1.1 Test raw materials

[0024] soybeans Kennong 42 cultivated by Heilongjiang Academy of Agricultural Sciences has a protein content of 41.6%, an oil content of 21.3%, a moisture content of 10.6%, and an ash content of 4.3%. Alcalase alkaline endoprotease novo (1.2 x 10 5 U / mL)

[0025] 2.1.2 Test instruments and equipment

[0026] instrument Manufacturer CX-500 Ultrasonic Cleaning Machine Beijing Second Medical Equipment Factory electronic analytical balance Mettler-Toledo Instruments (Shanghai) Co., Ltd. hammer mill China Tianjin Test Instrument Co., Ltd. LDZ5-2 Desktop Low Speed Centrifuge Shanghai Anting Scientific Instrument Factory Electric constant temperature water bath Yuyao Dongfang Electrical Instrument Factory TGL-16G High Speed Desktop Centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com