Demulsification method for aqueous enzymatic extraction of soybean oil and fat

A technology of soybean oil and water enzymatic method, which is applied in the direction of fat oil/fat production and fat production, and can solve the problems of long time for demulsification, low demulsification rate, poor demulsification safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

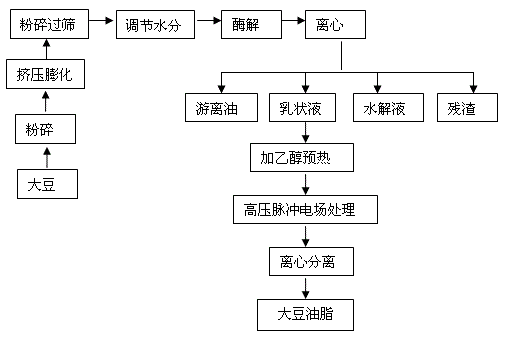

Image

Examples

Embodiment 1

[0013] Grind the soybeans and adjust the water content to 14%, then perform extrusion pretreatment to obtain puffed materials, crush the puffed materials and pass through a 60-mesh sieve, weigh 100g of the puffed materials after crushing and sieving, add 600ml of water and stir evenly to obtain a mixed solution , adjust the pH of the mixture to 9.5, heat up to 60°C, add alkaline protease for enzymolysis, enzymolysis for 2.5 hours, and centrifuge at a speed of 5000r / min for 30 minutes to obtain free oil, emulsion, hydrolyzate and residue; Add ethanol with a volume fraction of 85% to the emulsion and stir for 10 minutes. After the emulsion is heated to 60°C, keep it for 30 minutes. Perform high-voltage pulses at a pulse intensity of 28 kV / cm, a pulse flow rate of 60 mL / min, and a pulse frequency of 450 Hz. After electric field treatment for 200s, soybean oil was obtained by centrifugation at 8000r / min for 15min, and the demulsification rate at this time was 92%.

Embodiment 2

[0015] Grind the soybeans and adjust the water content to 14%, then perform extrusion pretreatment to obtain puffed materials, crush the puffed materials and pass through a 60-mesh sieve, weigh 100g of the puffed materials after crushing and sieving, add 600ml of water and stir evenly to obtain a mixed solution , adjust the pH of the mixture to 9.5, heat up to 60°C, add alkaline protease for enzymolysis, enzymolysis for 2.5 hours, and centrifuge at a speed of 5000r / min for 30 minutes to obtain free oil, emulsion, hydrolyzate and residue; Add ethanol with a volume fraction of 85% to the emulsion and stir for 10 minutes. After the emulsion is heated to 60°C, keep it for 30 minutes. Perform high-voltage pulses at a pulse intensity of 28 kV / cm, a pulse flow rate of 80 mL / min, and a pulse frequency of 500 Hz. After electric field treatment for 200s, soybean oil was obtained by centrifugation at 8000r / min for 15min, and the demulsification rate was 88%.

Embodiment 3

[0017] Grind the soybeans and adjust the water content to 14%, then perform extrusion pretreatment to obtain puffed materials, crush the puffed materials and pass through a 60-mesh sieve, weigh 100g of the puffed materials after crushing and sieving, add 600ml of water, and stir evenly to obtain a mixed solution , adjust the pH of the mixture to 9.5, heat up to 60°C, add alkaline protease for enzymolysis, enzymolysis for 2.5 hours, and centrifuge at a speed of 5000r / min for 30 minutes to obtain free oil, emulsion, hydrolyzate and residue; Add ethanol with a volume fraction of 85% to the emulsion and stir for 10 minutes. After the emulsion is heated to 60°C, keep it for 30 minutes. Perform high-voltage pulses at a pulse intensity of 28 kV / cm, a pulse flow rate of 60 mL / min, and a pulse frequency of 400 Hz. After electric field treatment for 200s, soybean oil was obtained by centrifugation at 8000r / min for 15min, and the demulsification rate at this time was 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com