A kind of amphiphilic hyperbranched polymer and its preparation and application

A hyperbranched polymer, amphiphilic technology, used in fuel additives, liquid carbon-containing fuels, petroleum industry, etc., to achieve the effects of accelerated collision, strong adsorption capacity, and reduced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: NH 2 (CH 2 ) 5 CONH(CH 2 ) 5 COOH preparation

[0038] (1) Dissolve 3g of the compound of formula (a) in DMF, add 4.9g of potassium carbonate, and drop 2g of methanol to react overnight to obtain the compound of formula (b);

[0039]

[0040] (2) Spin-dry the product in step (1) and dissolve it in methanol again, add a certain amount of Pd / C, overnight under the protection of hydrogen, and obtain the compound of formula (c) after suction filtration;

[0041]

[0042] (3) Then take 3g of compound of formula (a) dissolved in chloroform, add 1.5g of compound of formula (c) and react at 70°C for 3h, evaporate the solution to dryness, dissolve it in a mixed solution of water and tetrahydrofuran and add a small amount of LiOH, After reacting for 6 hours, dilute HCl was added dropwise to adjust the pH to acidic, and then hydrogenated and reduced with Pd / C to obtain the product NH 2 (CH 2 ) 5 CONH(CH 2 ) 5 COOH.

[0043] Its structural formula is as ...

Embodiment 2

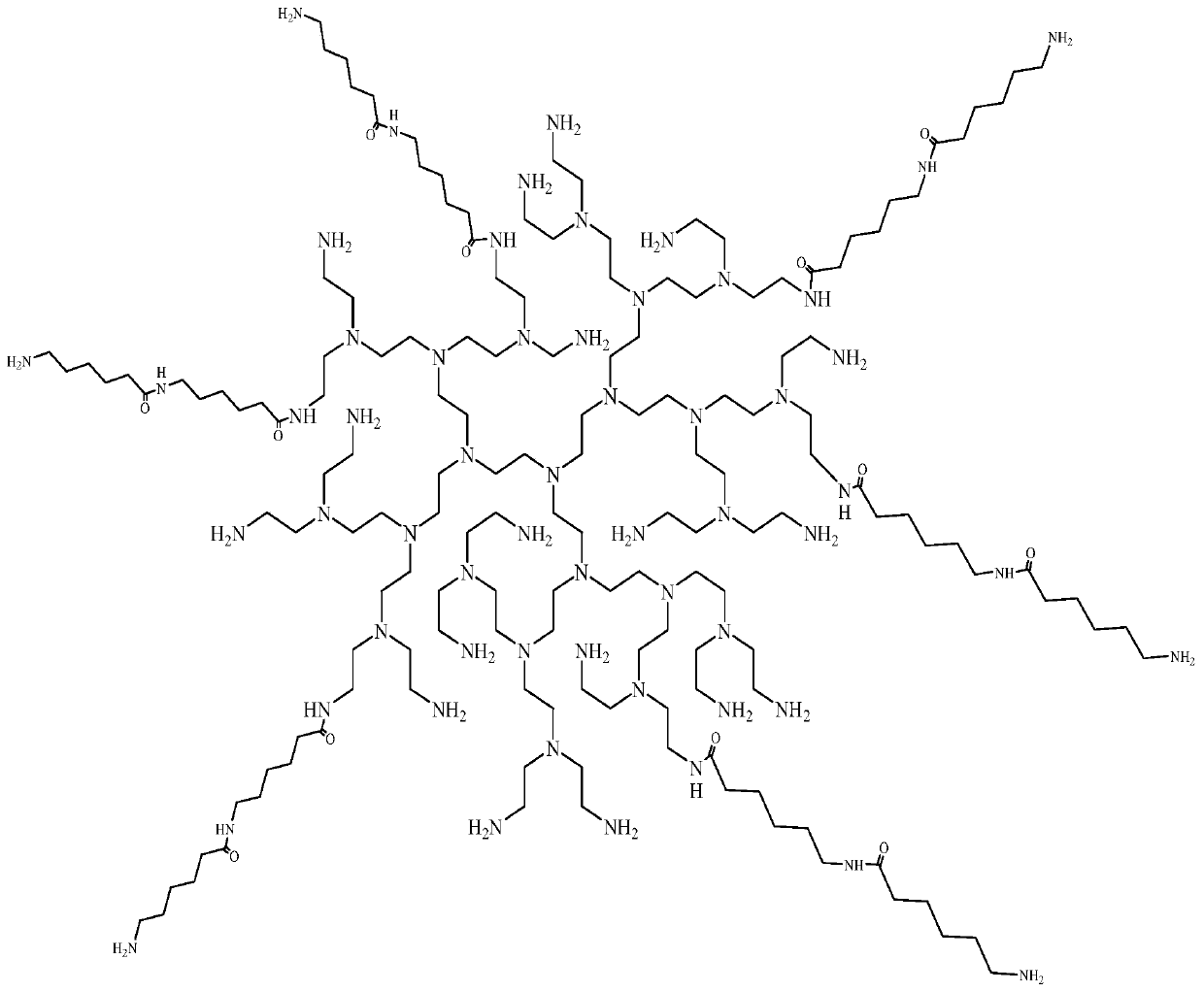

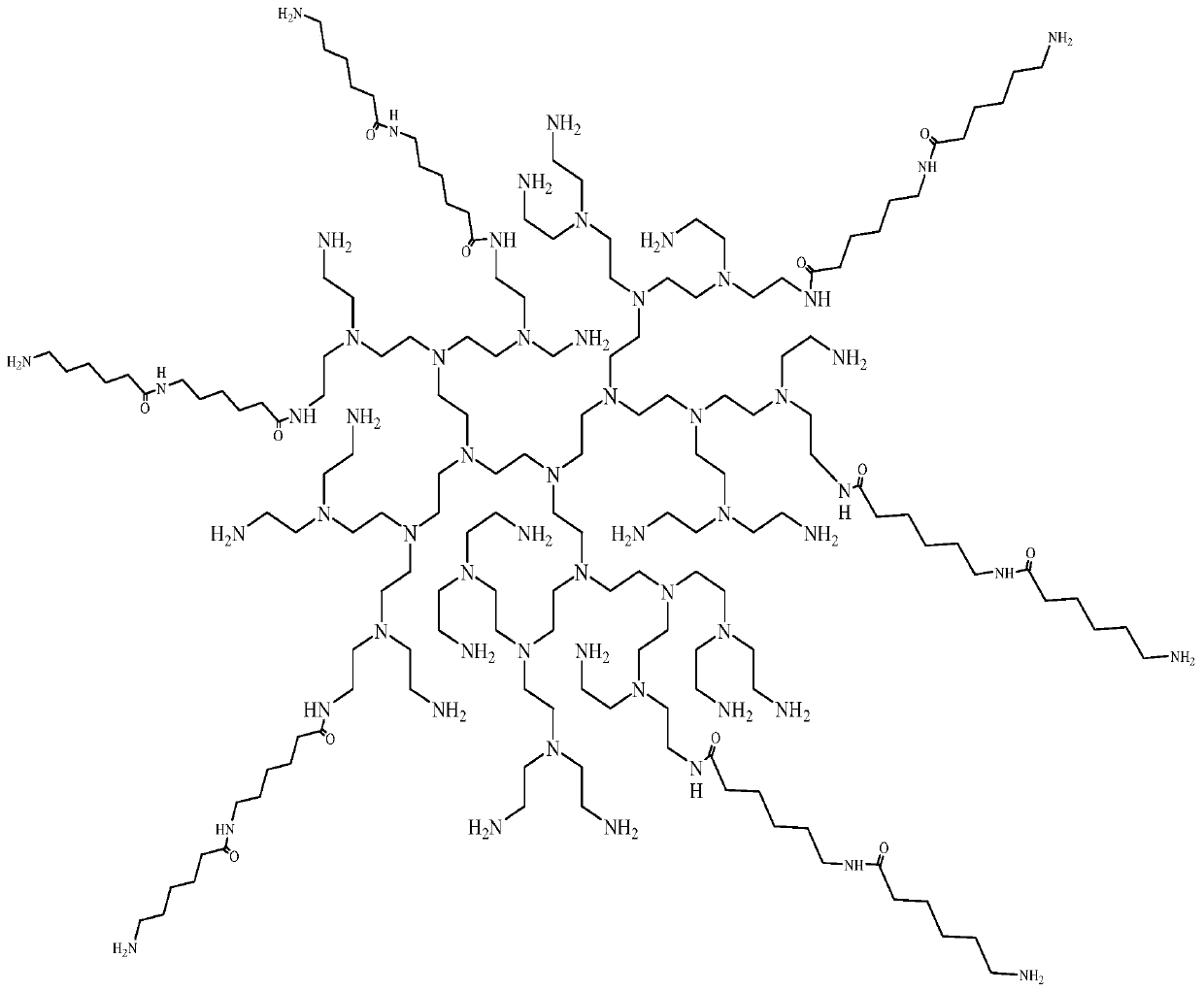

[0045] Embodiment 2: amphiphilic hyperbranched polymer (HPEI-am-C 12 )preparation

[0046] Take 4g NH 2 (CH 2 ) 5 CONH(CH 2 ) 5 COOH was dissolved in 30mL of methanol, 2.83g of CDI was weighed and added to the reaction system, stirred until it was dissolved, and a mixed solution was obtained. Dissolve 2.5g of HPEI in 10mL of methanol, then add it dropwise to the mixture, and carry out amidation reaction at 55°C for 9h to obtain a crude product with a high degree of polymerization; subsequently, the crude product is cooled to room temperature Then pour it into 250mL acetone and stir for 60min. It can be observed that the yellow transparent viscous liquid sinks to the lower layer. The upper layer of acetone is discarded, and the precipitation is repeated twice. The HPEI-am-C can be obtained by rotary evaporation at 50°C under vacuum. 12 .

[0047] Amphiphilic hyperbranched polymer (HPEI-am-C 12 ) structure diagram, such as figure 1 As shown, it should be noted that sinc...

Embodiment 3~8

[0049] Refer to Example 2 to prepare the amphiphilic hyperbranched polymer. The specific process parameters are shown in Table 1, and the amphiphilic hyperbranched polymer can be obtained. NH 2 (CH 2 ) 5 CONH(CH 2 ) 5 COOH is denoted as a in the table below.

[0050] Table 1: Comparison of preparation process parameters of Examples 2-8

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com