Method for treating thickened oil oil-in-water type emulsion by magnetic nanoparticles and microwave

A magnetic nanoparticle and microwave treatment technology, which is applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problems of limiting the application of magnetic nanoparticles, not exerting the coupling effect of magnetic nanoparticles and external electromagnetic fields, and low water separation rate. To achieve the effect of improving demulsification efficiency, improving demulsification rate and enhancing effect

Active Publication Date: 2020-06-09

XI'AN PETROLEUM UNIVERSITY

View PDF11 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

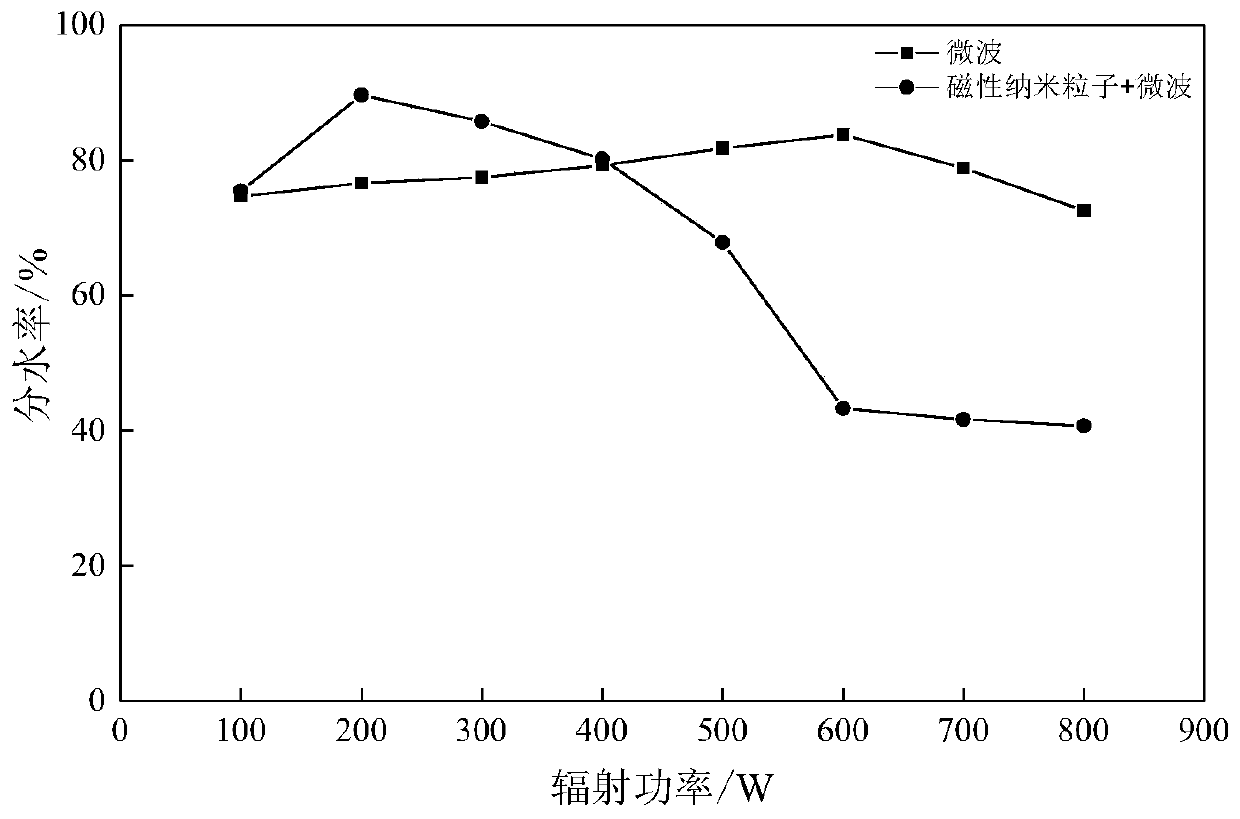

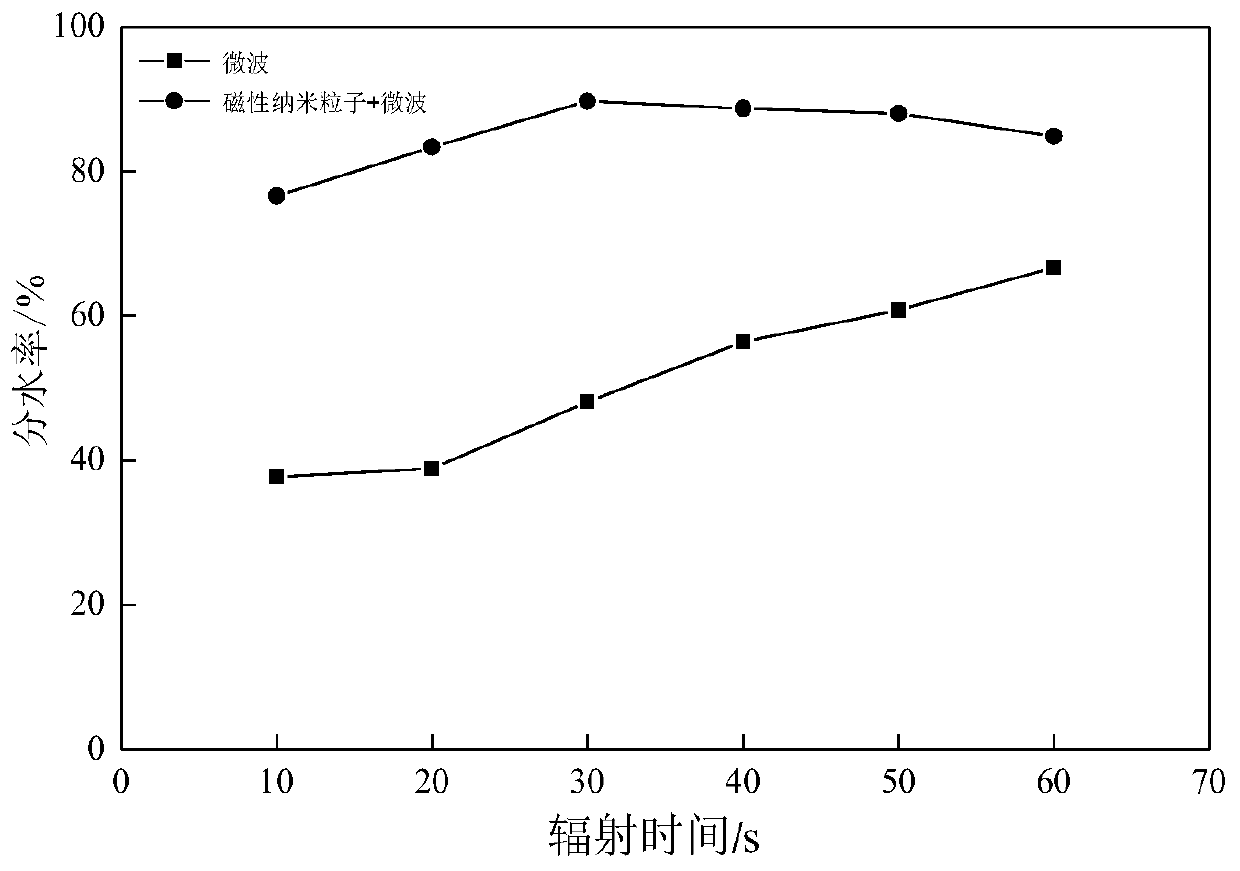

However, the pure application of magnetic nanoparticles for demulsification has a low water separation rate, and the coupling effect between magnetic nanoparticles and an external electromagnetic field has not been exerted, which limits the application of magnetic nanoparticles.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific tests, which are explanations of the present invention rather than limitations.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

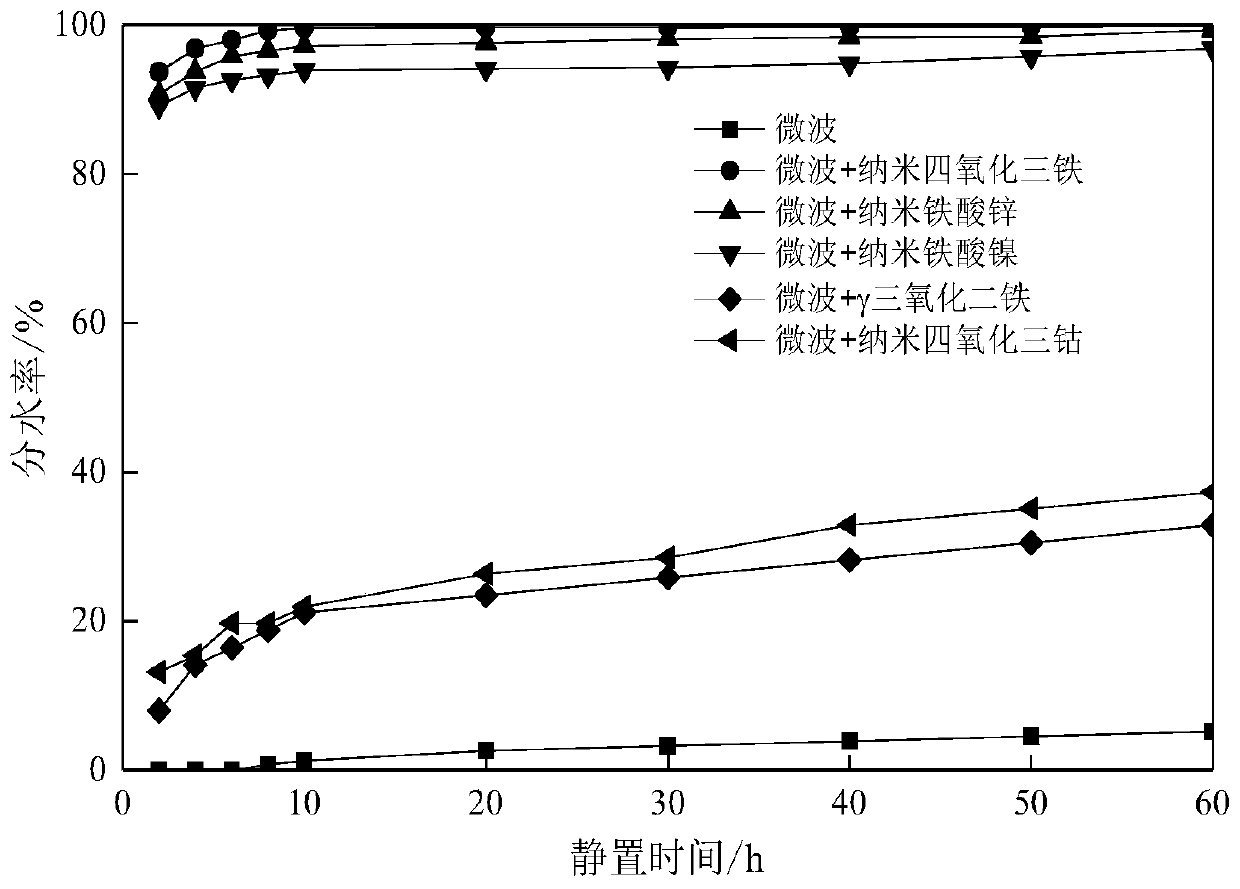

The invention discloses a method for treating thickened oil oil-in-water type emulsion through magnetic nano particles and microwaves, which belongs to the technical field of oil-water separation engineering. By means of the coupling synergistic effect of the magnetic nanoparticles and the microwave high-frequency electromagnetic field, the demulsification rate and demulsification efficiency are greatly improved, and the water diversion rate of a high-stability thick oil O / W type emulsion can exceed 99% in a short time. The problems that a traditional chemical demulsifier is large in dosage and limited in application range, so that a catalyst is poisoned, flocculate generated after demulsification stays in a water phase or an oil phase all the time, and secondary pollution is caused to theenvironment are solved. Besides, the magnetic nanoparticles can be repeatedly recycled for multiple times, the demulsification cost is reduced to a great extent, the demulsified magnetic nanoparticles can be adsorbed and recycled again under the action of an external magnetic field, environmental pollution is avoided, and the magnetic nanoparticles have good application prospects.

Description

technical field [0001] The invention belongs to the technical field of oil-water separation engineering, and in particular relates to a magnetic nanoparticle-microwave treatment method for oil-in-water emulsion of heavy oil. Background technique [0002] In order to improve the recovery rate of heavy oil, major oilfields have successively adopted chemical flooding recovery technology. However, with the increase of the production period of chemical flooding, the composition of the produced fluid becomes more complex, making oil-water separation more difficult. Milk technology will bring a series of problems to the gathering and transportation process, such as: increasing the burden of storage and transportation, reducing the service life of pipelines, and causing serious corrosion of high-temperature distillation equipment. In addition, the water phase of the produced fluid after oil-water separation is mainly refilled underground or discharged. If it is not handled properly,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G33/02

CPCC10G33/02

Inventor 孙娜娜蒋华义张兰新靳凯斌

Owner XI'AN PETROLEUM UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com