High-temperature sewage treatment reverse demulsifier of ultra-heavy oil

A reverse phase demulsifier and high-temperature sewage technology, applied in the direction of grease/oily substance/suspton removal device, separation method, immiscible liquid separation, etc., can solve problems such as unsatisfactory results, and achieve excellent production and practical effects. The effect of reducing production cost and fast dehydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

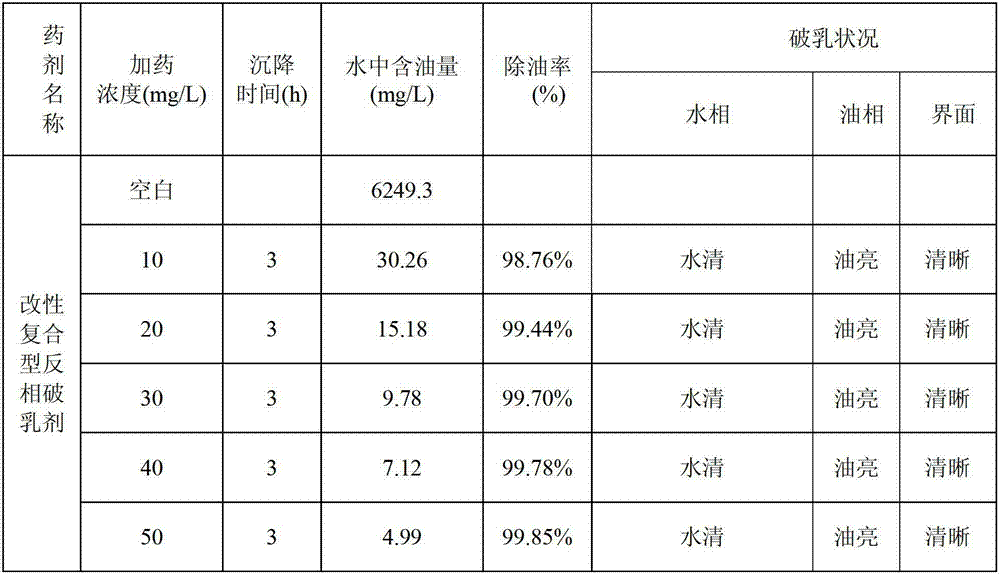

Examples

Embodiment

[0022] 1) Synthesis of cationic polyether:

[0023] Add 0.025mol of glycerol as a starting agent in a four-necked flask equipped with a stirrer, a condenser, and a thermometer, then add 2.13g (about 1%) boron trifluoride ether solution, and control it under stirring conditions. temperature at 50°C, slowly add epichlorohydrin dropwise for 5 minutes, and then raise the temperature to 75°C for 6 hours to obtain a brown viscous hydroxyl-terminated chloropolyether; mix 100g of hydroxyl-terminated chloropolyether with 191.3g Trimethylamine aqueous solution (equivalent of amino group and chlorine atom) is placed in a clean reaction kettle, nitrogen is passed through to remove the air, the temperature is controlled at 75°C, and the reaction is for 5 hours, and the temperature is continued to rise to 125°C, and the reaction is for 7 hours to obtain a brown water-soluble cationic polymer. Ether; Wherein the mass fraction ratio of epichlorohydrin, glycerol, trimethylamine is 40:1:40 or 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com