Composite cationic starch and preparation method thereof, and method for making paper by using starch

A technology of cationic starch and its manufacturing method, which is applied in the field of papermaking, can solve the problems of increasing the cost of retaining additives, affecting the speed of the paper machine, and insufficient dehydration capacity of the pulp, so as to improve the dehydration capacity of the pulp, the retention of the system and the retention of ash , is conducive to the effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

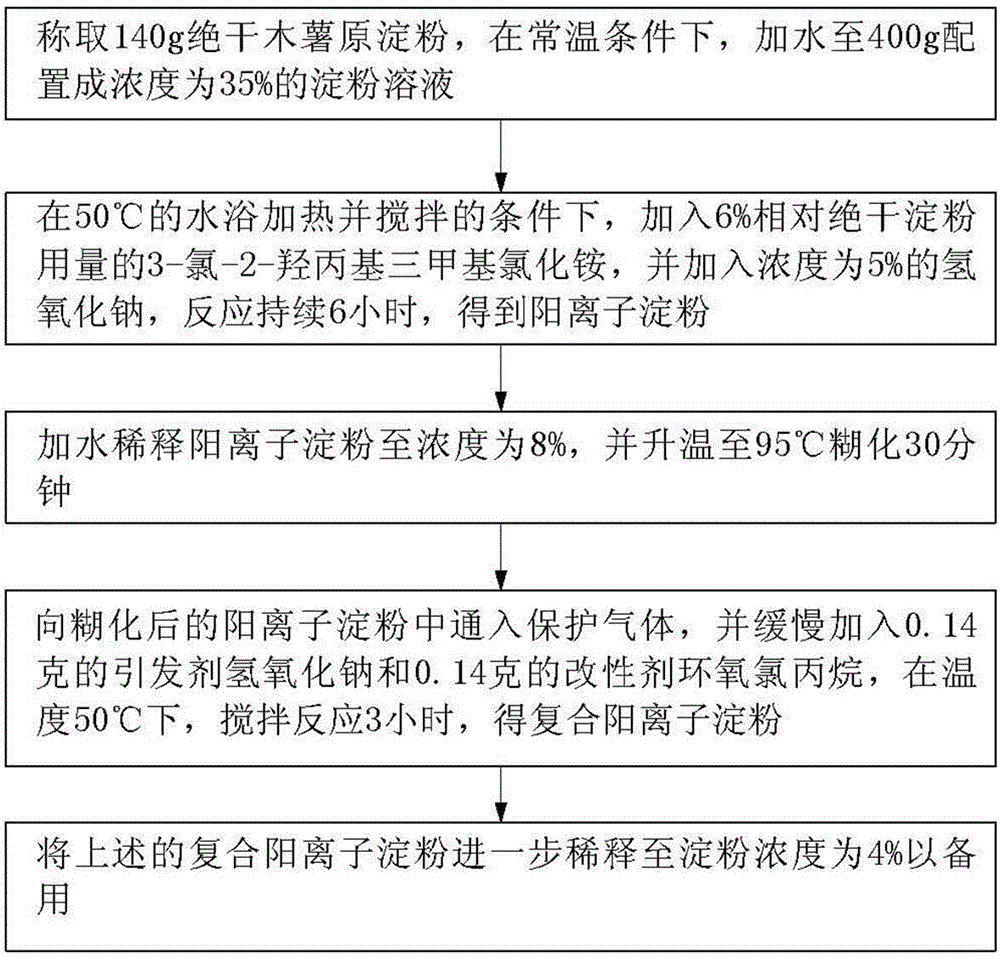

Examples

Embodiment Construction

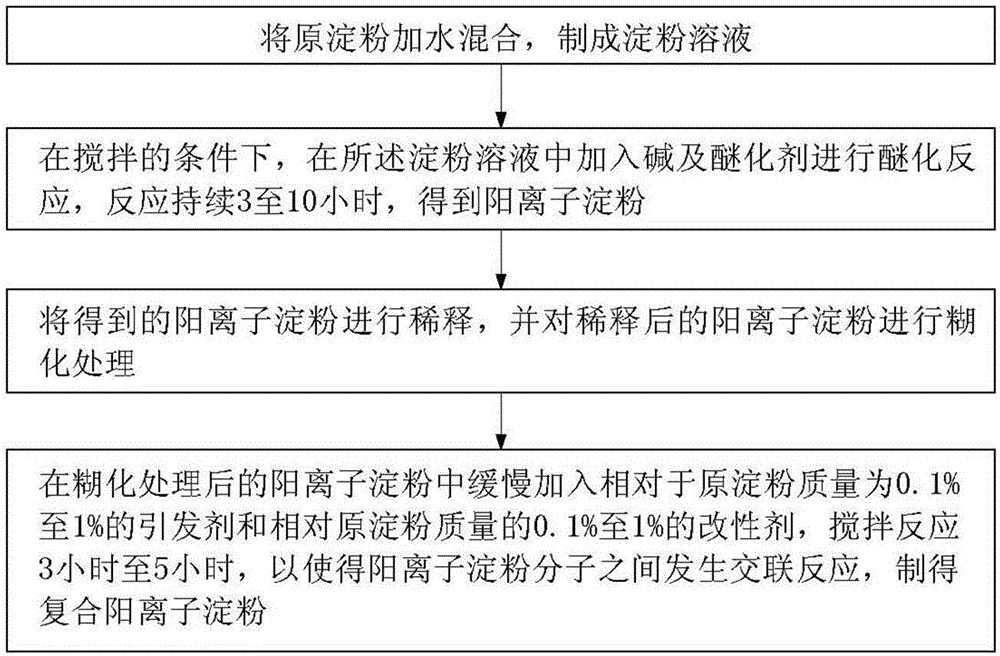

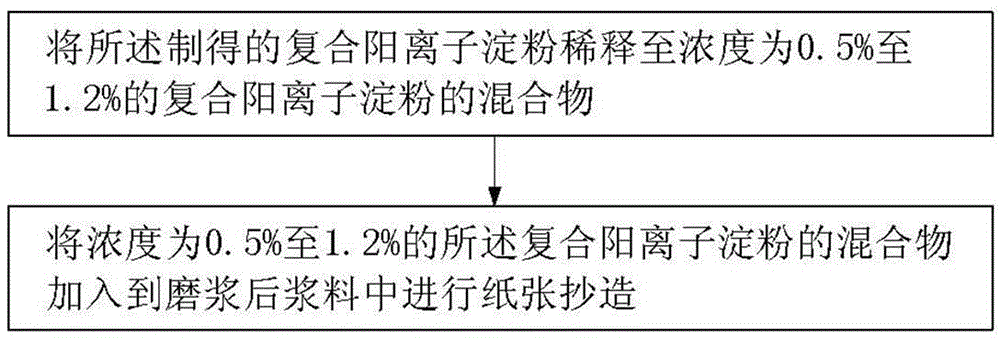

[0016] Below in conjunction with a plurality of drawings, the compound cationic starch manufacturing method provided by the present invention, the compound cationic starch and the method for making paper with the compound cationic starch prepared by the method will be further described in detail.

[0017] see figure 1 , the invention provides a kind of manufacture method of composite cationic starch, described composite cationic starch manufacture method comprises the following steps:

[0018] In the first step, the raw starch is mixed with water to make a starch solution.

[0019] In this step, the raw starch can be mixed with water at normal temperature. The raw starch used can be any one or a mixture of tapioca raw starch, corn raw starch, potato raw starch and wheat raw starch. Potato starch and tapioca starch are preferred. The concentration of the prepared starch solution is 35% to 40%, preferably the concentration of the starch solution is 35%.

[0020] In the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com