Manganese salt sludge conditioner and sludge dewatering method

A technology for sludge conditioning and conditioning agent, which is applied in sludge treatment, electrochemical sludge treatment, water/sludge/sewage treatment, etc. It can solve the operation requirements and high energy consumption, the influence of climate factors, and the damage of filter media. and other problems, to achieve the effect of speeding up the dehydration rate, low price, and accelerated removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

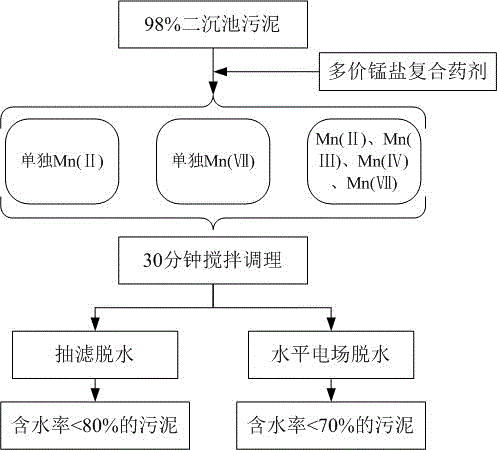

Method used

Image

Examples

Embodiment 1

[0031] After the activated sludge was retrieved, it was concentrated by gravity for 2 hours and passed through 10-mesh and 50-mesh screens. The sludge concentration (MLSS) reached 16.2g / L, the moisture content was 98.35%, and the pH value was 7.34.

[0032] 1) Put the activated sludge in the container.

[0033] 2) Accurately weigh 0.03mol / L of MnCl in wet sludge 2 , at 300rpm / min stirring intensity MnCl 2 Put it into the sludge quickly and stir for 30 minutes.

[0034] 3) Transfer the conditioned sludge to a vacuum filtration device, and perform suction filtration at a pressure of 0.6 MPa for 15 minutes. Collect all the filtrate after the reaction and weigh its mass, collect the dehydrated sludge in the sludge chamber after the reaction, and measure its water content by gravimetric method.

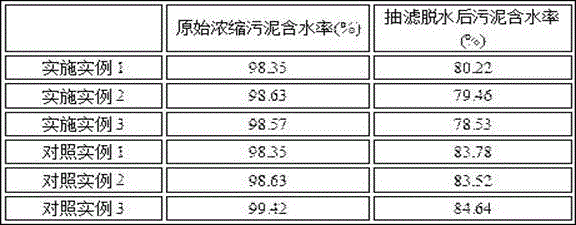

[0035] The measurement results are shown in Table 1.

Embodiment 2

[0037] After the activated sludge was retrieved, it was concentrated by gravity for 2 hours and passed through 10-mesh and 50-mesh screens. The sludge concentration (MLSS) reached 16.2g / L, the moisture content was 98.35%, and the pH value was 7.34.

[0038] 1) Put the activated sludge in the container.

[0039] 2) Accurately weigh 0.05mol / L KMnO in wet sludge 4 , KMnO 4 Put it into the sludge quickly and stir for 30 minutes.

[0040] 3) Transfer the conditioned sludge to a vacuum filtration device, and perform suction filtration at a pressure of 0.6 MPa for 15 minutes. Collect all the filtrate after the reaction and weigh its mass, collect the dehydrated sludge in the sludge chamber after the reaction, and measure its water content by gravimetric method.

[0041] The measurement results are shown in Table 1.

Embodiment 3

[0043] After the activated sludge was retrieved, it was concentrated by gravity for 2 hours and passed through 10-mesh and 50-mesh screens. The sludge concentration (MLSS) reached 16.2g / L, the moisture content was 98.35%, and the pH value was 7.34.

[0044] 1) Put the activated sludge in the container.

[0045] 2) Accurately weigh 0.04mol / L KMnO in wet sludge 4 and NaHSO of 0.2mol / L wet sludge 3 , KMnO 4 Put it into the sludge quickly and stir for 30 minutes.

[0046] 3) Transfer the conditioned sludge to a vacuum filtration device, and perform suction filtration at a pressure of 0.6 MPa for 15 minutes. Collect all the filtrate after the reaction and weigh its mass, collect the dehydrated sludge in the sludge chamber after the reaction, and measure its water content by gravimetric method.

[0047] The measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com